6 Tips for Minimizing Supplier Onboarding Risks

Key Takeaways:

Did you know that only 41% of executives feel confident managing external risks?

Since supplier onboarding is one of the earliest, highest-risk processes in procurement, it’s the perfect place to start closing that confidence gap.

This article covers five proven tips to minimize supplier risk from day one and build a stronger, safer, and more resilient supply base.

Taking the time to define requirements ensures a smooth onboarding process and helps prevent misunderstandings and errors down the line.

It’s one of the simplest, yet most effective ways to minimize supplier risk.

Why?

Because the lack of clarity during onboarding often leads to compliance gaps, unmet expectations, and costly rework.

And the larger your supply base, the higher the stakes.

According to The Hackett Group’s research, organizations are estimated to onboard an average of 10% of their supply base annually.

Illustration: Veridion / Data: The Hackett Group

Given the number of supplier onboarding processes in just one year, it’s clear that even small process inefficiencies can quickly add up.

A 2019 Gartner report revealed that 60% of organizations worked with over 1,000 third parties, but this number has likely grown as supply chains continue to globalize and digitize.

With the scale and complexity of supplier ecosystems increasing, there is a greater need for clear, structured onboarding processes and proactive risk management.

Exposure to regulatory and operational vulnerabilities often stems from the lack of alignment between organizations and their suppliers.

As pointed out by Albert Kim, VP of Talent at Checkr, this invites friction and misunderstandings.

Illustration: Veridion / Quote: Softr

So, what’s the solution for proactively preventing confusion, delivery issues, and compliance risks?

A good starting point is developing a unified supplier onboarding framework that clearly outlines the process itself, from documentation and approvals to minimum supplier requirements.

At the least, it needs to cover:

Creating an onboarding checklist, like the one shown below, makes it easier to stay aligned with your organizational framework and ensures none of the key points get overlooked.

Source: Veridion

It should also outline review timelines and designate decision-makers for each step to avoid bottlenecks.

Remember that onboarding isn’t just a procurement issue, which is why we’ll cover how to build that cross-functional alignment in one of the upcoming sections.

To sum up, setting clear, well-documented onboarding requirements lays the foundation for smoother supplier relationships while helping you keep risks at bay.

Due diligence is a critical step in the supplier onboarding process, and for good reason.

It helps organizations uncover red flags early on, such as prior contract breaches, lawsuits, financial instability, or missing certifications, and avoid unreliable partners before any real commitments are made.

Conversely, skipping or rushing this stage leaves businesses vulnerable to financial losses, operational disruption, and reputational damage.

But here’s the challenge: issues often slip through the cracks even when due diligence is performed.

According to Gartner, 83% of legal and compliance leaders identified supplier risks after initial due diligence and before recertification.

Illustration: Veridion / Data: Gartner

In other words, many onboarding processes may be missing critical risk signals or failing to monitor for new ones amid evolving circumstances.

And those oversights are far from harmless.

The same report found that 31% of these risks had a material impact on organizations, affecting their finances, operations, as well as industry and public reputation.

One of the most cited examples is Boohoo’s well-publicized supply chain scandal.

In 2020, poor working conditions at a Leicester supplier’s factory made headlines, causing Boohoo’s share price to drop 18% in a single week.

The fallout continued with major retailers distancing themselves from the company, which even faced the threat of a U.S. import ban.

Source: Sky News

The lesson?

Due diligence is essential, and complying with tightening regulations around ethical labor, environmental practices, and data protection is the only way to avoid bad press.

As Richard Reichman, Partner at BCL Solicitors, points out, organizations must continuously reassess the legal and ethical standards of their supply chains and adapt their due diligence to address evolving risks.

Illustration: Veridion / Quote: Raconteur

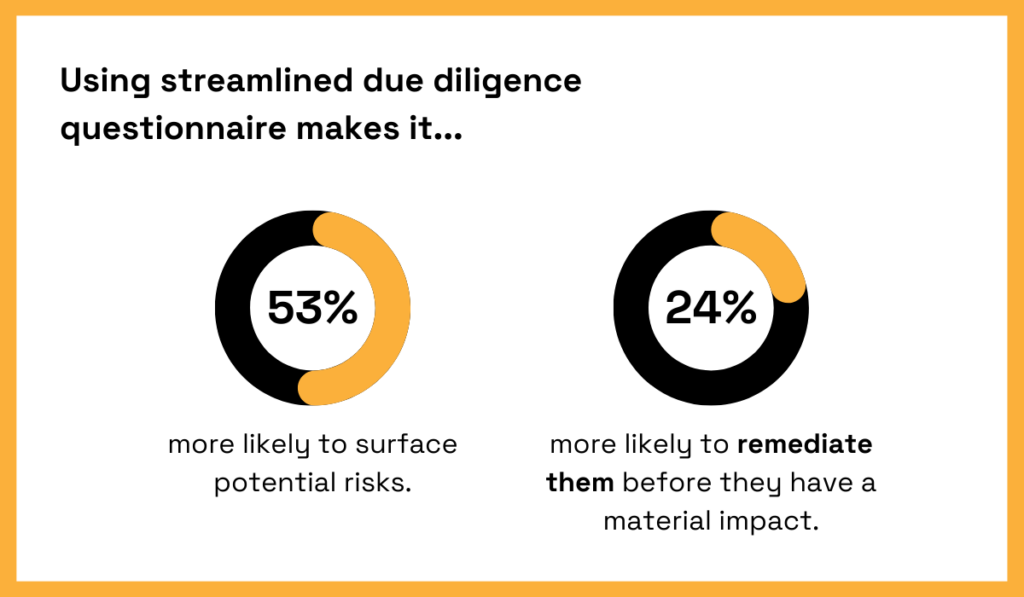

These risk management efforts start with onboarding, which is why many organizations make it a point to introduce exhaustive questionnaires right off the bat.

But adding more checks isn’t always the answer.

Overly complex questionnaires often fail to improve outcomes and can slow down onboarding.

In fact, a Gartner study found that organizations using lean, well-targeted due diligence processes were significantly more effective at identifying third-party risks before those risks caused material harm.

Illustration: Veridion / Data: Gartner

In the end, it all comes down to striking the right balance between being thorough and staying focused.

Do that, and you’ll be able to pinpoint the most critical risk areas early, addressing them before they escalate.

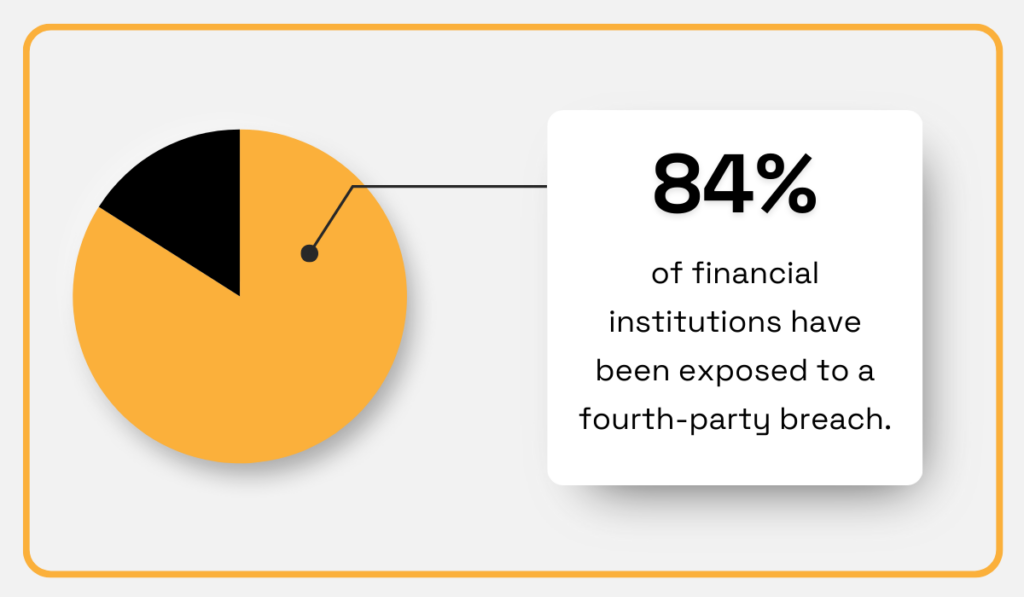

By evaluating fourth-party relationships, you uncover and mitigate risks hidden deeper in your supply chain, originating from your suppliers’ own vendors.

What happens when your procurement team requires suppliers to disclose and document these critical relationships?

For starters, you gain much-needed visibility and can better assess whether those extended networks meet operational, ethical, and security standards.

After all, fourth parties introduce another layer of potential risk, from poor-quality materials and non-compliance issues to cybersecurity vulnerabilities.

Recent research by SecurityScorecard found that 84% of financial institutions in the EU had been exposed to a fourth-party breach.

Illustration: Veridion / Data: Security Scorecard

This figure highlights that even well-managed supply chains have unseen gaps that can create problems when you least expect them.

However, this isn’t just about cybersecurity.

Compliance issues, regulatory risks, and performance failures can travel up your chain just as easily, and the bigger your supplier base, the more difficult it is to manage them.

As Saket Modi, CEO of Safe Security, points out, vendor ecosystems often involve 5,800 third-party suppliers or more, magnifying the challenge of managing these risks effectively.

Illustration: Veridion / Quote: CIO Insight

In other words, you’re dealing with an extended supply chain.

As illustrated below, this chain spans a complex web of fourth and nth parties that often operate beyond your immediate oversight.

Source: Veridion

Since you don’t directly interact with fourth parties, it’s vital to uncover them early in your procurement and due diligence process.

For example, if you’re running a competitive bidding procedure, make sure to include questions about fourth-party relationships in your RFPs.

Once you’ve shortlisted a vendor, deepen the inquiry during onboarding by asking the following:

Remember, controlling the entry point of supplier data is crucial, as advised by HICX’s co-founder and CEO, Costas Xyloyiannis:

Illustration: Veridion / Quote: HICX

Ultimately, ensuring accurate, complete information from the outset makes it far easier to uphold standards, manage risks, and avoid downstream surprises later on.

Supplier onboarding requires cross-functional ownership to ensure that no risk factors are overlooked.

Think about it: If procurement leads the onboarding process without input from the other departments, your organization is more likely to remain unaware of specific risks, whether it’s financial exposure or cybersecurity vulnerabilities.

As noted by the Institute for Supply Management expert Jim Fleming, the level of complexity and thoroughness involved in supplier onboarding requires ongoing engagement and alignment across functions.

Illustration: Veridion / Quote: ISM

By involving multiple departments, you ensure a holistic assessment of each supplier’s fit and get to detect risks that a single team might overlook.

At the same time, it’s important to keep the process lean by involving only those teams that closely intersect with procurement, such as finance, legal, operations, and IT.

Source: Veridion

Cross-functional teams should be integrated only where necessary, with clear responsibilities and aligned expectations to avoid delays and miscommunication.

| Function | Key Responsibilities | Risk of Data Silos |

|---|---|---|

| Procurement | Select suppliers, lead onboarding, and conduct due diligence | Medium |

| Finance | Handle financial risk checks, set up payment terms, and process invoices | High |

| Legal | Conduct contract reviews, regulatory, and risk assessments | Low |

| Operations | Assess supplier capability, flag performance or delivery issues | Medium |

| IT | Maintain supplier records, data integrity, and access controls | Medium-High |

But even with key responsibilities known, it’s still possible for vital information to become siloed in one department.

Forbes Solicitors’ Daniel Milnes, specializing in governance, procurement, and information, highlighted the following scenario:

“The buyer might have a valid contractual basis for withholding payment or seeking recourse, based on facts known within the operational function but not recognised elsewhere, leading the finance function to process payments as a matter of routine.”

Other than procurement, finance tends to be the most siloed department, typically operating within secure financial systems with limited visibility into operational issues.

So, how should you handle this?

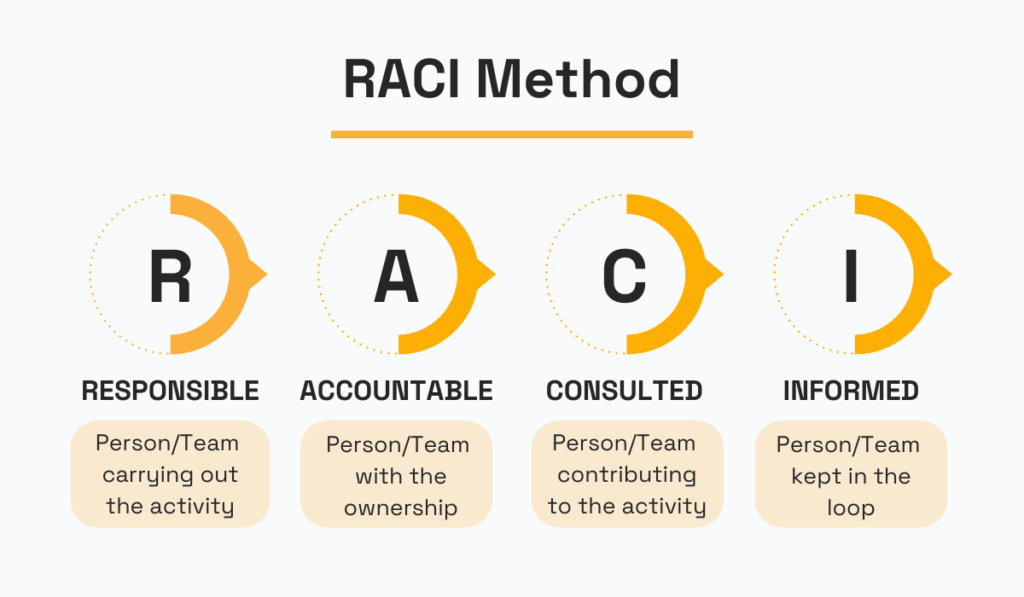

The solution is to establish a clear RACI matrix for supplier onboarding and conduct regular cross-departmental supplier data reviews.

Source: Veridion

This ensures no blind spots, prevents critical information from getting trapped in silos, and keeps risks managed from the outset.

Setting clear responsibilities enables consistent collaboration, which in turn helps you establish and maintain a supplier onboarding process that’s both efficient and resilient against all manner of risk.

As we’ve established by now, supplier onboarding isn’t a one-off task.

Without regular updates, revised checklists and risk criteria, as well as new vetting tools, you will quickly fall out of step with the latest regulations and industry expectations.

What’s more, outdated onboarding procedures expose businesses to risks like non-compliance, supply chain disruptions, or vendor data breaches.

Procurement teams must go beyond risk criteria and periodically review:

But above all, updates need to reflect evolving risks.

A study by Economist Impact surveying 2,000+ executives found that only 41% felt confident in managing external risks.

Illustration: Veridion / Data: Economist Impact

The research revealed a notable gap that highlights the need for sharper, technology-enabled procurement oversight.

Recognizing this, companies are ramping up their investment in process improvement and risk management programs.

The Hackett Group’s latest CPO agenda survey backs this, revealing that 48% of organizations had third-party risk management (TPRM) improvement initiatives planned for 2024.

Illustration: Veridion / Data: The Hackett Group

A key driver behind this transformation is technology, particularly AI-powered tools.

Over the next 12 – 18 months, procurement functions plan to leverage artificial intelligence to strengthen several risk-related areas, including sourcing, onboarding, and supplier management workflows.

One such AI-powered service is our very own Veridion, which provides access to near-real-time data and analytics on over 123 million suppliers globally.

By automating supplier search, Veridion cuts manual search time by over 90% to accelerate the early stages of onboarding.

At the same time, extensive TPRM data enhances monitoring, giving you granular control over risk scores and alerts.

Source: Veridion

This way, you can keep risks to a minimum and focus on building strong supplier relationships.

Beyond data offerings and individual onboarding tools, many companies are focusing their efforts on broader supply chain digitalization projects.

In one such case, Renovit partnered with Ivalua to digitize its supplier management processes, including onboarding, and increase operational efficiency and visibility.

The best part?

Carmen Gioia, Former Head of Supply Chain at Renovit Group, explains that Ivalua’s spend management solution will continue to evolve to match the company’s needs.

Illustration: Veridion / Quote: Ivalua

Staying adaptable and leveraging cutting-edge procurement solutions prevents you from onboarding subpar or non-compliant suppliers, ultimately protecting your business from blind spots and costly missteps.

Minimizing supplier risk starts long before any papers are signed, and onboarding is your first line of defense.

Taking time to map out weaknesses and refine your processes means you won’t have to deal with operational, financial, or other third-party risks creeping up months later.

Whether it’s setting clear requirements, running thorough assessments, or tapping into real-time data tools, the goal is to eliminate onboarding blind spots early.

That way, you’ll build a resilient supplier network and safeguard your business from day one.

So, what’s your first course of action going to be?