Top 6 Challenges of Procurement Automation

Digitalizing the procurement world and automating the procurement process offers significant advantages for businesses.

From reducing manual mistakes to enhancing strategic sourcing and cutting costs, procurement automation is indeed the future of procurement practices in companies.

However, despite its benefits, procurement automation also comes with its fair share of challenges. And if not managed properly, these challenges could turn into disadvantages.

In this article, we will address the top six challenges of procurement automation that you should be aware of. We will also do our best to explain how you can effectively manage these challenges in your business.

Without further ado, let’s dive in.

As companies embrace new technologies, they often forget to do one thing—align their existing internal policies with the new systems.

This can create significant setbacks for the company.

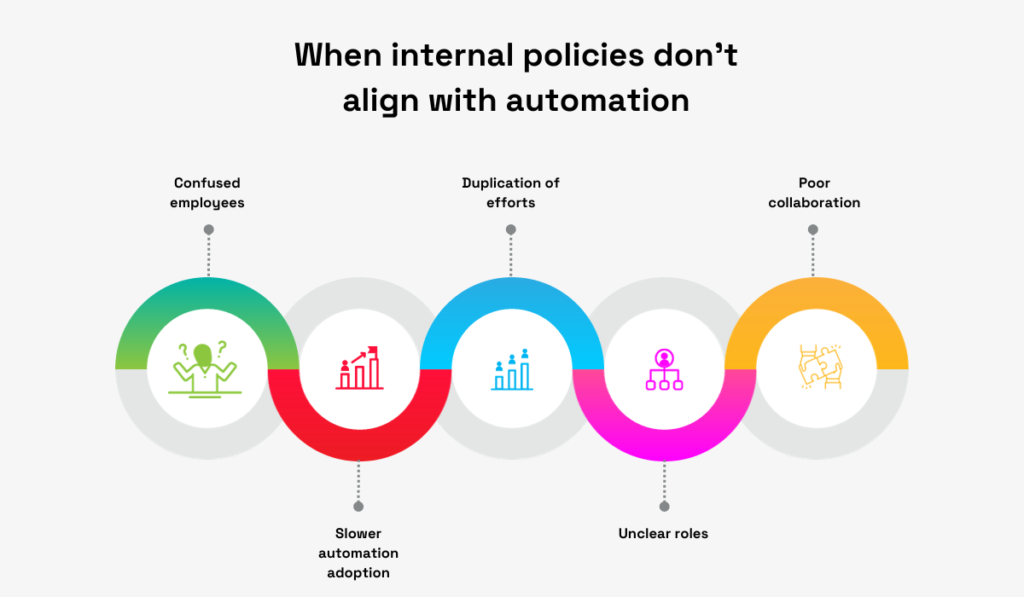

When existing internal policies are not updated to align with the changes introduced by procurement automation, there can be confusion among employees.

They may not fully understand how the new automated processes work or how to navigate the system.

This confusion can slow down the adoption of automation. Employees may hesitate to use the system or make errors due to unclear guidance.

Also, automation can lead to changes in roles and responsibilities within the organization.

Without internal policies that follow the organizational changes brought by new automation, employees may not be aware of their new roles or may continue to perform tasks that are now automated.

Source: Veridion

That means that unclear roles can lead to inefficiencies, duplication of efforts, and a lack of accountability, hindering the overall effectiveness of procurement operations.

Such inefficiencies can counteract the intended benefits of procurement automation, such as faster processing times and cost savings.

So, how can you address this challenge?

To overcome these potential setbacks, align your internal policies and standard operating procedures with the goals and requirements of procurement automation. Make sure every stakeholder involved is up to date with the changes.

On top of that, clearly communicate the resulting roles and responsibilities to your employees and train them to use procurement automation systems properly.

By doing so, you can maximize the advantages of automation while minimizing any confusion or inefficiencies in your processes.

When it comes to procurement automation or automating any other aspect of your company, just adding a new tool is not enough.

What is even more important for the success of your business is that this solution seamlessly integrates with other tools you are using.

If that’s not the case, implementing automation will result in more harm than good.

Think about it. Why do companies choose to automate their procurement processes in the first place?

Well, to have more efficient operations and cut unnecessary costs.

Source: Veridion

One procurement task that can be automated is data gathering—searching and analyzing data to find suppliers that best meet your needs.

When this is done manually, your employees can spend endless hours searching through Excel sheets, old invoices, and papers. And all this data they have to look through is rarely up-to-date.

On the other hand, automation procurement tools can gather and analyze data in a matter of seconds.

Still, what is the purpose of this time-saving approach in data gathering if the tool doesn’t integrate with other systems you use and, thereby, cannot “notify” other departments about important information it gathered?

To prevent this from happening, before adopting a new automation solution, check it for compatibility with other systems.

This includes evaluating compatibility with your existing systems, such as your enterprise resource planning (ERP) systems and other tools used for smooth functioning of supply chain.

And why does integrating your procurement system with these two systems matter?

First and foremost, it brings increased visibility. And visibility across all these systems ensures you can make informed decisions in real time.

Second, when all your employees in different departments share insights on the same subject matter, they can communicate more effectively and avoid miscommunication, delays, and extra costs that come with them.

In a nutshell, your procurement automation system will only benefit your business if you integrate it with other tools you use.

Today, companies source products and services globally, driven by environmental, social, and governance (ESG) regulations that guide investment choices.

In procurement, that boils down to getting the right pricing for ethically sourced products in the world delivered on time and in full.

To make this happen, companies need to rely on up-to-date data.

As businesses evolve continually, the data once used to identify suppliers may no longer be accurate. A supplier you’ve relied on for years may have discontinued certain products or may no longer meet ESG criteria.

Therefore, having fresh, accurate data about suppliers is critical.

But having these up-to-date insights doesn’t only help you find the suppliers that meet your needs. They also help you with assessing the risks associated with certain suppliers and avoiding potential issues.

However, procurement automation can only unlock its full potential when it effectively addresses the challenge of keeping data up-to-date.

This leads to a fundamental question.

How can businesses ensure their procurement automation systems have the most up-to-date data?

The answer lies in selecting procurement automation solutions that regularly update their data.

For example, more advanced procurement automation tools blend artificial intelligence with machine learning models. This enables them to collect data from all over the internet.

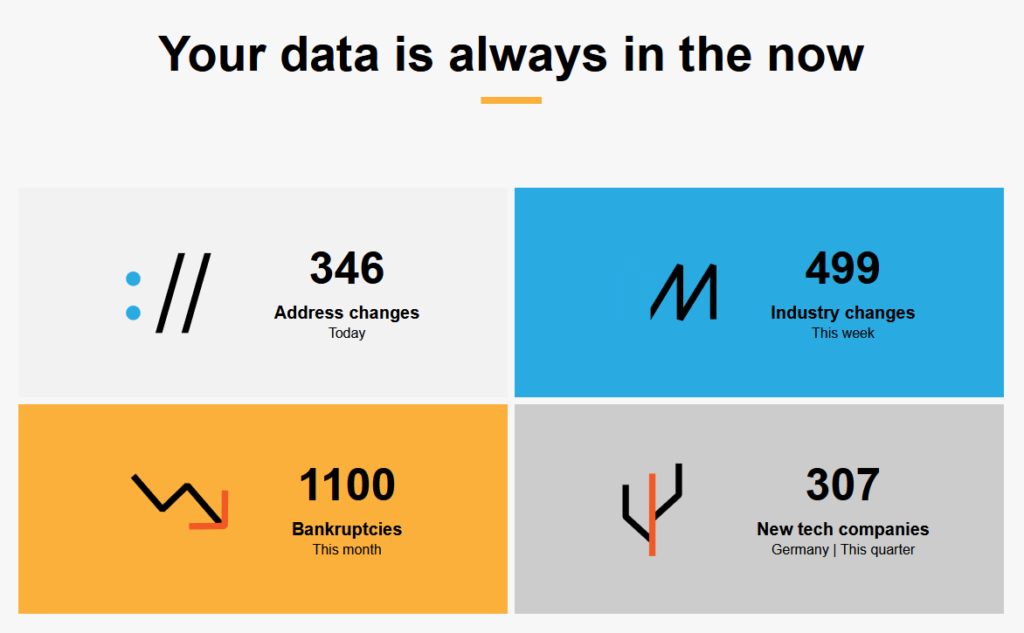

That’s how we at Veridion ensure our users always have the freshest supplier data.

Source: Veridion

Updates are done in near real-time, so the information is never over two weeks old. That means you can always have entirely fresh data to help you make informed procurement decisions.

That means the tool (and its functions) is built for change and is flexible enough to support the business long term.

In the article he wrote for Forbes, Peter Bendor-Samuel, founder and CEO of Everest Group, a global research firm, stresses the importance of functions designed for change rather than stability in today’s dynamic business environment.

In summary, accepting change as something normal, relying on fresh data, and choosing automation solutions with robust data updating mechanisms are essential to ensure successful procurement operations in your business.

Negotiation and contracting with suppliers are two vital steps in the procurement process of every company.

To navigate through them successfully, it would be wise to establish and nurture strong relationships with your suppliers.

Let’s see why.

Procurement automation can help you immensely with supplier management—sourcing suppliers, comparing them, and finding the ones that meet your requirements.

On top of that, automation provides transparency for both you and your suppliers, making it easier to collaborate.

This transparency offers immediate insights into essential details like daily production updates, quality reports, and delivery status without constant back-and-forth communication.

However, there’s a misconception that procurement automation can entirely replace negotiating with suppliers. This would be a significant oversight.

You still have to communicate with your suppliers face to face. Through these interactions, you can build and maintain long-term relationships—a key element of successful procurement in your business.

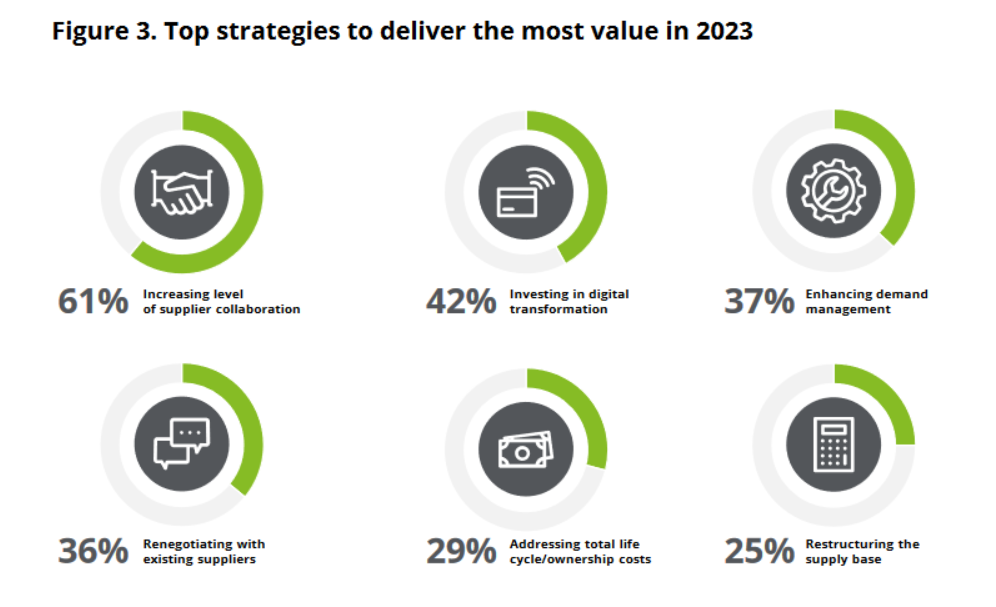

This is also underscored by Deloitte’s recent survey of global chief procurement officers.

The survey showed that collaboration with suppliers and renegotiating with existing ones are two of the top six strategies to bring value to procurement in 2023.

Source: Deloitte

Strong supplier relationships offer opportunities for negotiation not only at the outset but also as your collaboration continues.

So, when starting a partnership with a new supplier, take the time to negotiate terms that ensure a fair price while maintaining quality. Transparent and fair agreements at the beginning will lay the foundation for a successful relationship.

Beyond these initial negotiations, ongoing communication and negotiation are vital for maintaining mutually beneficial supplier relationships.

Don’t leave this aspect of your procurement process to automation. Instead, consider face-to-face discussions. Negotiations can further optimize your procurement process.

Automated procurement systems have been a game-changer for streamlining operations, reducing labor costs, and enhancing efficiency.

However, surrounded by the convenience of automation, there’s a lurking challenge—the risk of hidden costs slipping through the cracks.

When it comes to monitoring your procurement costs, be observant.

With inflation issues and supplier price increases, it has never been more critical for businesses to keep track of their spending.

In fact, the same Deloitte survey we mentioned above showed that for as much as 54% of CPOs, rising costs and spending pressures due to supplier price increases had a high impact on business in the past 12 months.

For 37% of companies, it had a moderate impact.

Illustration: Veridion / Data: Deloitte

So, to maintain the cost-effectiveness of procurement automation, it’s important that you avoid a “set-it-and-forget-it” attitude and seek areas for further cost reduction wherever you can.

One important strategy that can help you with this challenge is rigorous data analysis.

Automation tools for procurement generate a wealth of data, and it’s crucial for you to scrutinize this data and check your performance metrics regularly.

Why?

By doing so, you can identify anomalies or unexpected cost increases. These data-driven insights will allow you to remain vigilant and responsive to cost fluctuations.

In simpler terms, think of data analysis as your detective work in procurement. It helps you spot any unusual spending patterns or unexpected cost rises and allows you to take action promptly.

Source: Veridion

While automation may manage some parts of the procurement process for you, you still have to do some things regarding cost management.

For example, ensure that suppliers deliver on their promises and offer cost-effective solutions.

Therefore, regular supplier performance evaluations are the second strategy to tackle this challenge.

They can reveal areas where costs can be further reduced. This may involve renegotiating contracts or seeking more competitive suppliers.

To put it plainly, supplier evaluation ensures that you’re getting what you paid for. It’s like checking if a car is running as promised—if it isn’t, you seek adjustments to make it more cost-efficient.

By implementing these two straightforward yet critical strategies, you can proactively address hidden costs that may be overlooked due to automated processes.

Data analysis informs you about cost trends, while supplier evaluations guarantee that you maintain cost-effective partnerships.

These practices contribute to ongoing cost reduction and optimization, even in an automated procurement environment.

While using procurement automation to find suitable suppliers is essential, it’s also crucial to regularly check these suppliers for potential risks that could disrupt your ongoing procurement.

Working with suppliers requires trust, but it also comes with certain risks.

This includes concerns like whether the products you order will arrive on time, if their quality matches the price, and even the possibility of fraudsters pretending to be suppliers to get payments.

Automating your procurement doesn’t eliminate these risks. Instead, it highlights the importance of having a solid risk mitigation strategy.

According to research from Moody’s Analytics, around 70% of companies recognize the need to improve how they manage supplier risks and are investing more in third-party risk management to do this effectively.

But what’s even more concerning is that an even larger percentage of companies (74%) rated their current risk management solutions as poor or mediocre.

Illustration: Veridion / Data: Moody’s Analytics

Luckily, procurement automation solutions can improve supplier risk management—as long as you choose the right tool.

Consider our solution, Veridion. This procurement automation tool stands out because it provides fresh big data on millions of companies that go into great detail.

Source: Veridion

Our advanced machine learning models search vast amounts of data to give you the most current and accurate supplier information.

This helps you quickly spot potential risks and changes in a supplier’s business.

In our database, you’ll find all the details you need to ensure a supplier is trustworthy—from basic company information, location, and size to more specific data like industry specifications, insurance status, UNSPSC codes, and ESG criteria.

Lastly, our custom-made risk factors and real-time alerts can help you stay on top of supplier risks and protect your business from potential disruptions.

In conclusion, investing in effective supplier risk management will make your procurement smoother and more secure.

We hope this article has effectively demonstrated the challenges of implementing procurement automation and solutions for overcoming them.

The challenges we addressed today, including the failure to align internal policies, lack of integration with other essential tools, reliance on outdated data, neglecting negotiations with suppliers, difficulties in cost reduction, and poor supplier risk management, can damage your business.

However, if you acknowledge and manage these challenges, you will position your organization on the path to successful and efficient procurement operations.