6 Ways to Generate Procurement Cost Savings

Unlocking cost savings stands as a linchpin for the sustainable financial health of any company.

The procurement department, tasked with sourcing suppliers and securing goods and services of the best quality for the best price, is essential for realizing this goal.

If you want to learn how to generate cost savings in your procurement department, you came to the right place!

Today, we bring you six ways to achieve substantial cost savings, ensuring an improved bottom line for the entire company.

Without further ado, let’s start with the first cornerstone of generating savings: demand forecasting and planning.

We all agree that business is done much easier and more effectively when you are prepared for what’s coming.

This is the beauty of forecasting and planning. And as such, it also helps generate cost savings.

With new technologies and procurement automation , forecasting and planning demand has never been easier for procurement departments.

New technologies, such as predictive analytics and artificial intelligence, combine internal procurement data with external market information and economic indicators, enhancing predictions’ accuracy.

This enables procurement teams to make data-driven decisions that result in significant cost savings.

These decisions manifest in improved risk management and streamlined inventory processes—both integral to achieving savings.

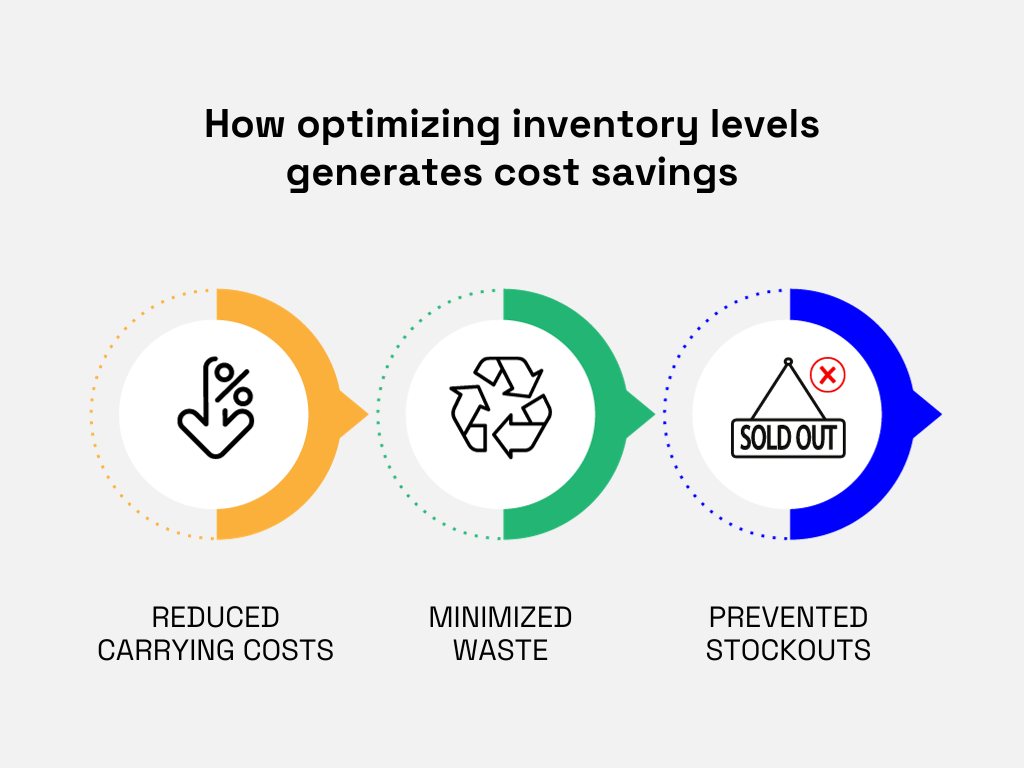

Let’s focus for a moment on how accurate demand forecasting generates cost savings by helping you optimize inventory levels.

To put it briefly, when you have a clear understanding of future demand, you can allocate resources efficiently, prevent unnecessary overstocking and ensure that the right quantities are procured at the right time.

Source: Veridion

This strategic approach results in significant cost savings by minimizing inventory carrying costs and reducing waste. Simultaneously, it mitigates the risk of stockouts, ensuring customer demands are consistently met.

An illustrative example comes from one predictive planning platform that assisted a convenience store chain in reducing inventory costs and preventing millions of dollars in potential losses.

Through a comprehensive analysis of external data and by considering economic factors, they created predictive models for the store chain.

These models, specific to each market area, empowered procurement departments to stock shelves with products aligned with consumer demand and avoid inventory excess, which led to both cost avoidance and cost savings .

Illustration: Veridion / Quote from Prevedere

This example echoes a universal truth—forecasting and demand planning are indispensable for generating savings.

And with the advent of procurement automation and data analytics tools, implementing these practices in your procurement processes has never been more straightforward or effective.

Another smart move to generate procurement cost savings is through reverse auctions.

These auctions are what their name implies—reverse.

Instead of you (the buyer) bidding for the product and having to increase the price, reverse auctions involve suppliers bidding competitively for your business.

This process can drive prices down as suppliers strive to offer the most competitive rates, which makes it an effective way to reduce costs.

Reverse auctions bring several advantages:

| Make procurement more transparent. | The open bidding format fosters clarity and trust between buyers and suppliers, setting the stage for fair and informed transactions. |

| Automate the bidding process. | This not only saves time but also introduces a more streamlined and organized workflow. This efficiency gain is a key benefit, ensuring a more effective procurement cycle. |

| Create a competitive environment among suppliers. | Suppliers are incentivized to offer their most competitive rates as they strive to secure your business, making reverse auctions a powerful tool for cost reduction. |

However, to bring these benefits, reverse auctions must be prepared and executed properly.

As Edward Ainsworth, sales operations account coordinator at NEC Europe, explains , such auctions are only fruitful when there are enough suppliers in the marketplace, so there is genuine competition.

What’s more, he emphasizes that cost savings should never be done at the expense of product quality.

Illustration: Veridion / Quote from LinkedIn

So, how can you start with reverse auctions? Consider the following few steps:

By adhering to these steps, you can harness the potential of reverse auctions as a powerful tool for procurement cost savings while maintaining a focus on quality and competition.

If your company procures parts from different suppliers, standardizing components is another effective way to generate cost savings.

Through parts standardization, a company simplifies its inventory by replacing multiple diverse components with a single, standardized part.

This strategy contributes to operational efficiency, cost reduction, and overall improvement in the procurement and maintenance processes because now you have compatible and interchangeable parts.

Standardizing components comes with several benefits:

Let’s see how these benefits translate into cost savings in a real-world example.

This case study describes how a $700 million global mining machinery manufacturer dealt with challenges arising from disparate operations after recent integrations.

The company has been dealing with numerous designs for crucial components (such as rollers in mining equipment) across its global operations.

This diversity in designs led to several challenges, including increased complexity in managing inventory, sourcing, and production.

However, representatives from diverse regions collaborated to standardize designs, beginning with highly engineered roller parts.

The goal was to identify commonalities, eliminate unnecessary variations, and create a unified set of specifications or standards for these roller components for more efficient production, procurement, and maintenance procedures.

Ultimately, the team proposed a “Global Roller Design Matrix,” documented global standards, and consolidated sourcing practices.

Swift approvals from senior executives led to $500,000 in immediate cost savings, rationalization of roller designs, and the development of a competitive hybrid product.

And that’s not all—the project achieved recurring year-to-year cost savings of $2,000,000.

Illustration: Veridion / Data: Gagnon Associates

As evident, by fostering collaboration across global regions and implementing standardization, this company achieved substantial cost savings.

Therefore, if your company happens to procure similar parts from different suppliers, now is the time to consider standardizing your components.

As you likely know, spend can be consolidated into fewer supplier agreements by sourcing more products from the same suppliers rather than spreading your procurement across many similar vendors.

And believe us when we say—this is another excellent way to generate cost savings.

Let’s delve into why.

Imagine a manufacturing company where the procurement department handles the purchase of various raw materials and components from different suppliers.

However, due to a lack of order consolidation practices, each production unit within the company independently places orders for the materials they need, often without coordinating with other units.

Unfortunately, because of this, the company misses many cost-saving opportunities.

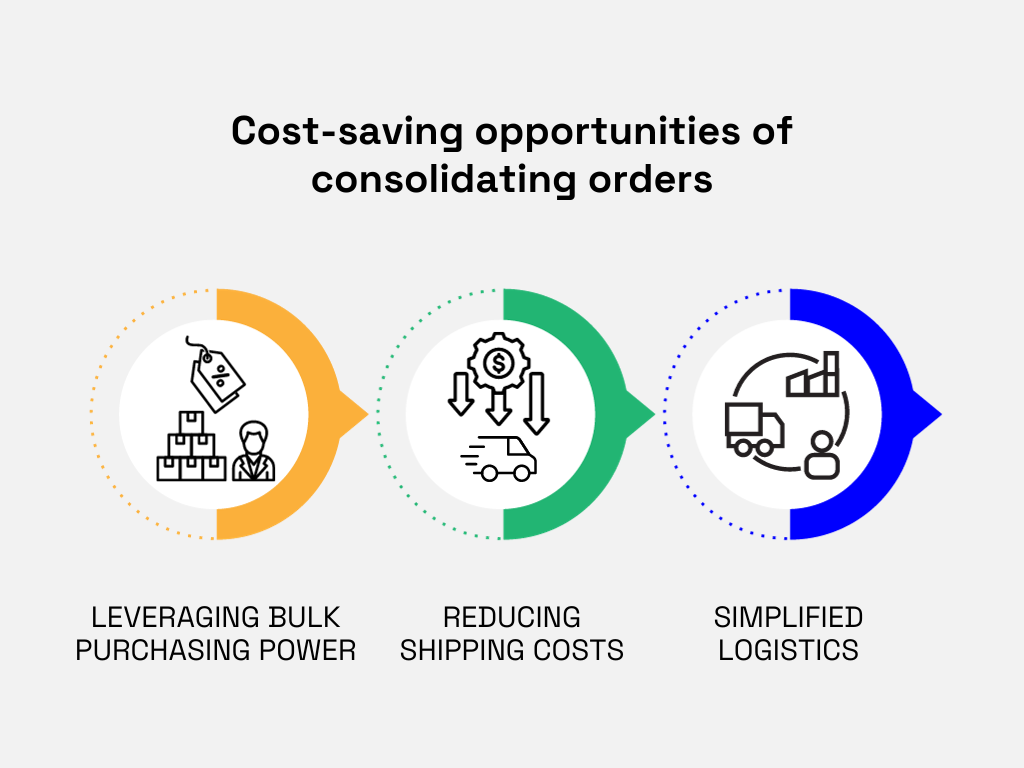

Source: Veridion

First and foremost, without consolidating orders, the procurement department misses out on the opportunity to leverage bulk purchasing power.

Suppliers often offer discounts for larger order quantities, but by placing individual orders for each production unit, the company fails to secure these cost-saving benefits.

And if each production unit independently arranges shipments for their orders, the company incurs higher shipping costs since smaller, frequent shipments are generally more expensive than consolidated shipments.

This lack of consolidation can also lead to inefficiencies in logistics and increased transportation expenses.

However, consolidating your orders leads to economies of scale, where you can both reduce shipping costs and ensure better bulk purchase discounts.

A lot of businesses, both big and small, have to work closely with suppliers and negotiate discounts.

Balancing cost with quality is a challenge. We pride ourselves on offering top-notch vehicles, which sometimes comes at a premium. I’ve had to work closely with suppliers to negotiate bulk discounts without compromising on the quality or safety standards required by our clients. For example, securing affordable financing options has been crucial, allowing us to offer competitive pricing while maintaining our high standards.

—Michael Sensano, Sales Manager, Apple Truck and Trailer

What’s more, you can negotiate simultaneous arrival dates for your shipments, which will simplify logistics and have a positive impact on your company’s sustainability goals, too!

Finally, consolidating orders simplifies the overall procurement process.

Your team will spend less time processing paperwork, managing invoices, and coordinating with multiple suppliers, which will, in turn, lead to reduced labor hours or simply allow them to focus on more strategic tasks.

However, consolidating orders could potentially bring some disadvantages.

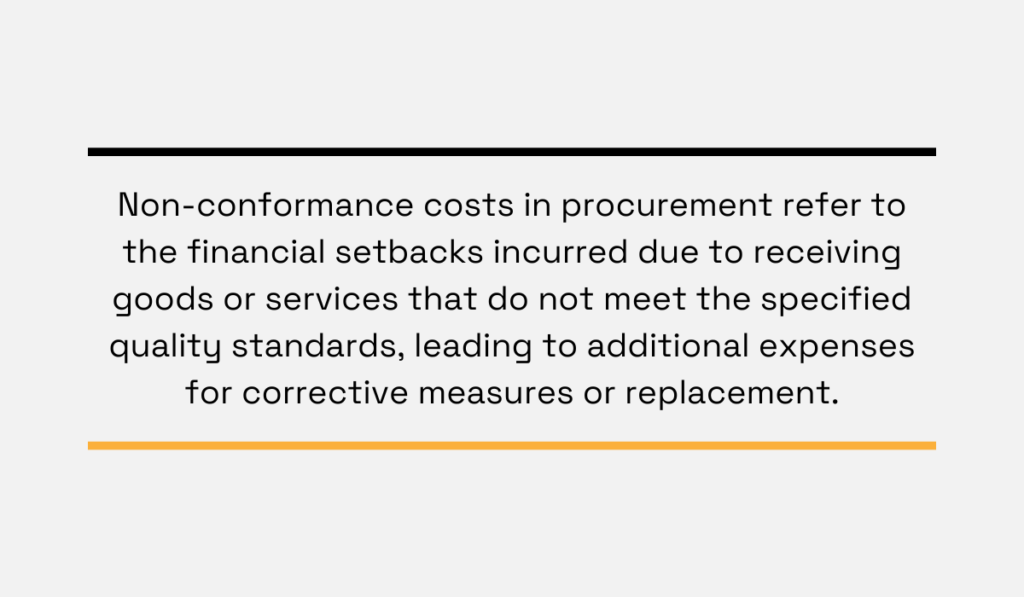

That is—if you lock yourself into a contract with suppliers delivering subpar quality. In that case, you are likely experiencing non-conformance costs.

We explain how to reduce those next.

Tracking suppliers who fall short of meeting expected quality, quantity, or timely delivery standards is a straightforward yet impactful approach to generating cost savings.

When products fail to align with customer requirements, market demand, or quality standards, it triggers an array of costly consequences such as rework costs, scrap costs (involving leftover materials rendered unusable), downtime costs, and potential lost sales.

All these costs fall under the term “non-conformance costs.”

Source: Veridion

However, the consequences of non-conformance can be even more severe.

Take, for instance, the case of Takata —a Japanese airbag manufacturer that had to recall millions of airbags and pay $1 billion in penalties due to its defective airbags being the cause of several deaths and injuries.

The impact, of course, extended beyond Takata. Car manufacturers relying on Takata’s airbags also faced substantial costs and reputational damage.

The safety of their vehicles was compromised due to the supplier’s inability to adhere to quality compliance standards.

This case is a stark reminder that neglecting compliance can lead to disastrous financial penalties and reputation damage, affecting not just the immediate supplier but the entire supply chain and end-users.

So, how can you mitigate non-conformance costs in procurement?

One proactive strategy involves regular supplier performance assessments.

In other words, you should regularly scrutinize the performance of each supplier to pinpoint those who are underperforming and not meeting the established criteria.

You can do that through the following key performance metrics:

| Quality compliance | Evaluate the quality of products or services supplied by each vendor. Identify any deviations from agreed-upon quality standards and specifications. |

| Timeliness and reliability | Examine the punctuality and reliability of deliveries. Late deliveries can disrupt production schedules, leading to downtime costs and potentially affecting customer satisfaction. |

| Quantity accuracy | Verify that the quantities supplied align with the agreed-upon terms. Discrepancies can result in inventory management challenges and potential additional costs. |

| Communication and responsiveness | Assess the level of communication and responsiveness from suppliers. Effective communication is vital for addressing issues promptly and maintaining a collaborative supplier relationship. |

Once you identify the underperforming suppliers through these key metrics, it’s time to make decisions.

Engaging in open discussions with suppliers to address concerns, providing feedback, and seeking improvements can be a constructive approach.

However, in cases where persistent underperformance hampers cost-effectiveness and quality standards, it’s necessary to source new suppliers.

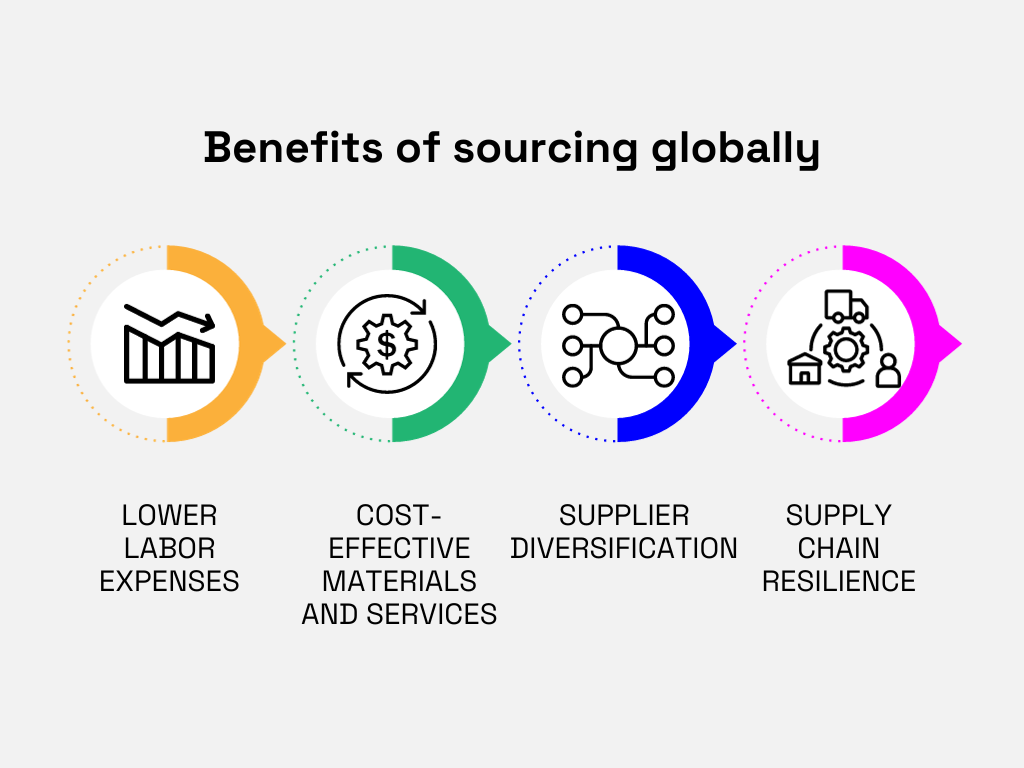

Exploring global sourcing options can open up opportunities for accessing cost-effective materials and services.

Why, you wonder?

Well, for starters, different regions often have varying production costs and labor expenses.

Therefore, when you explore global options, you can identify areas where these costs are lower, resulting in overall cost savings.

Moreover, global markets provide access to a larger pool of suppliers and manufacturers.

This increased scale can lead to economies of scale, reducing production costs and, consequently, the overall cost of materials and services.

Last but not least, relying on a single source for materials or services can pose risks, such as supply chain disruptions, which can be very costly.

On the other hand, global sourcing allows for the diversification of suppliers, spreading risk and enhancing resilience in the face of unexpected challenges.

Source: Veridion

As you can see, sourcing globally offers immense benefits.

However, before you decide to source suppliers this way, you must consider factors such as shipping costs, lead times, and geopolitical risks.

And, of course, you need fresh, accurate, and updated information on suppliers for this approach to work. You can get this data through supplier sourcing enablers.

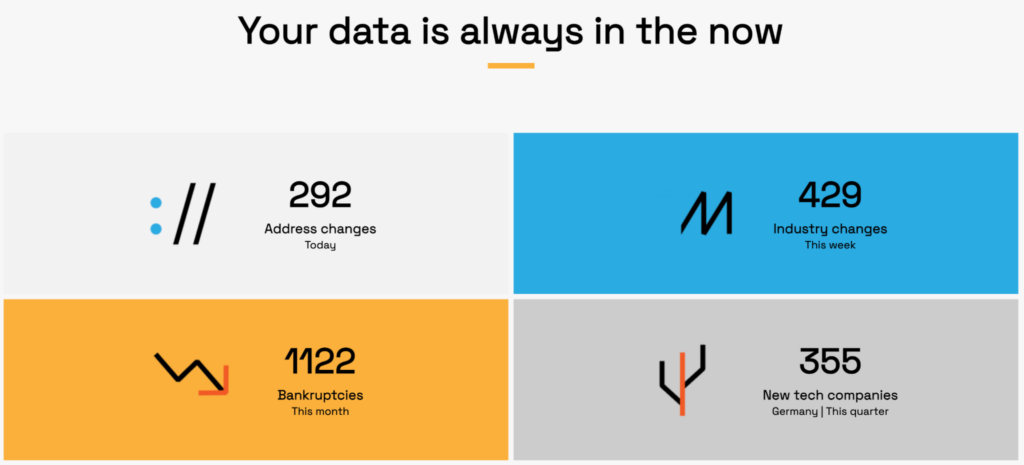

Take, for instance, our Veridion . Veridion provides companies with near real-time data on more than 80 million global suppliers.

Source: Veridion

By leveraging advanced web scraping technology, Veridion aggregates firmographic data, offering insights from general company information and location to specific details on products, specifications, certifications, and sustainability practices.

Basically, Veridion provides insights on everything you need to assess whether the supplier in question is appropriate to work with.

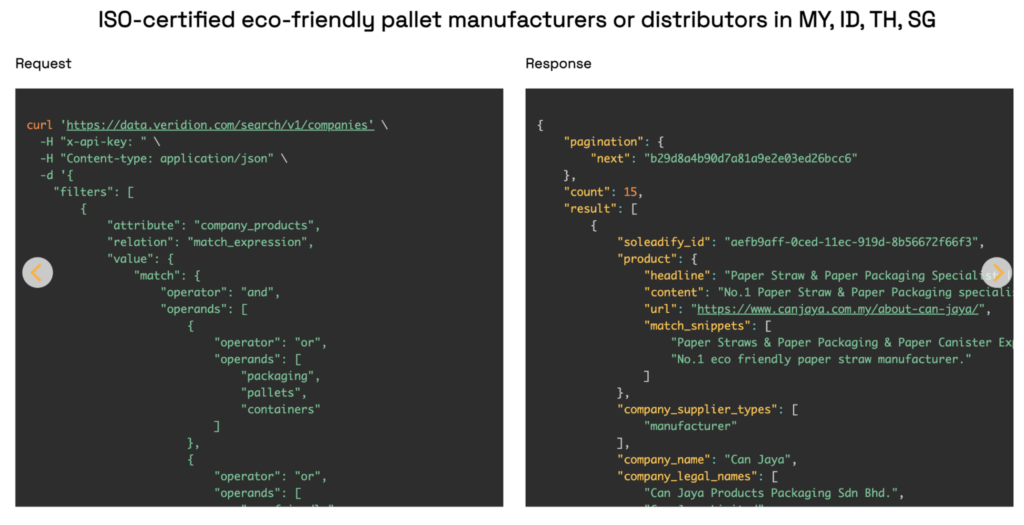

And through its complex search API , you can get a list of potential suppliers in a matter of minutes.

Source: Veridion

Before we conclude, let’s look at some numbers that underscore the cost-effectiveness of global sourcing.

PowerCo , for example, achieved remarkable results by adopting a global sourcing strategy, realizing €31 million in cost savings within the first twelve months and an additional €21 million in the subsequent six months.

This contributed to an 11% reduction in purchasing costs over 18 months.

Without increasing reliance on low-cost global sourcing and standardizing some components (one of the strategies we mentioned earlier), these cost savings wouldn’t have happened.

All in all, global sourcing is the way forward for achieving cost savings through accessing affordable materials and services.

But as we said, carefully considering all factors and having accurate information on suppliers are key elements for this strategy to work.

Wrapping it up, these were the six ways to generate procurement cost savings.

It’s safe to say that each holds merit for your procurement department, not only in terms of savings but also in elevating the overall procurement process.

Whether it’s through demand forecasting, reverse auctions, component standardization, or global sourcing, you are on the right path to improving the financial health of your procurement department and, consequently, the entire company.

By combining these strategies with actions like consolidating purchase orders, regularly reviewing suppliers, and reducing non-conformance costs—or by opting for at least some of these approaches—you are sure to yield tangible procurement cost savings!