Increase Procurement Efficiency With These 5 Tips

As you are well aware, procurement teams constantly strive to do more with less, making efficiency a non-negotiable priority.

However, achieving significant improvements in your procurement process can feel daunting, especially with limited resources and today’s dynamic state of the industry.

This article can give you something to get you started, by giving you five tips to boost procurement efficiency and streamline day-to-day operations.

We’ll share actionable ideas focusing on adjustments in your methodology, tips regarding supplier selection and management, and why leveraging data can improve your workflows.

Read on, as implementing these tips can unlock some tangible efficiency gains.

Let’s begin by exploring why you should streamline the supplier selection process.

Comparing and evaluating potential suppliers is a significant part of procurement, so it really makes sense that optimizing this area can lead to substantial efficiency gains across your operations.

Your first step is to carefully examine your current selection process as inefficiencies and opportunities exist at each of the stages outlined below.

Source: Veridion

For example, consider the phase of identifying supplier criteria and assigning weights to those criteria.

If procurement doesn’t fully understand the specific needs of other departments, bottlenecks can easily arise in deciding what to prioritize—whether it’s cost savings, delivery speed, product quality, or a combination of factors.

Or, maybe the evaluation step can hinder progress.

Teams might find themselves stuck in analysis paralysis, unable to make a timely decision due to conflicting information or too many subjective opinions.

These issues often stem from an inefficient supplier evaluation method.

Source: Veridion

Maybe the procurement team relies primarily on desk appraisals, collecting information from supplier websites, data sheets, and articles.

But, if this data is outdated or incomplete, it can lead to poor supplier choices.

Or, another issue might be that the sheer time it takes to conduct these evaluations manually might lead to considering third-party appraisals.

However, these can be costly and may not always align perfectly with your organization’s specific needs.

To gain the most accurate and up-to-date information about potential suppliers without excessive manual work or relying on third parties, you can consider using a supplier sourcing enabler like Veridion.

We take a structured approach to gathering data for our system, and we have created a global database containing over 80 million companies.

Source: Veridion

This massive dataset is constantly filtered, structured, and updated using machine-learning-powered comprehension, refreshed weekly to ensure you have the freshest insights.

Searching for suppliers is straightforward with advanced search APIs, allowing you to easily assess suppliers for factors such as financial stability, quality standards, and compliance, and mitigate the risk of engaging with unreliable or non-compliant vendors.

Overall, by streamlining your supplier selection process with the right protocols and supported by tools like Veridion, you’ll make faster, data-driven decisions.

Let’s continue with supplier management tips and explore why consolidating your supplier list can significantly boost procurement efficiency.

In a large organization, it’s natural to accumulate a vast number of suppliers over time.

While having a diverse pool of options might seem essential, an overly extensive supplier list can actually become a significant hindrance.

At the moment you might believe that you need all those suppliers to meet your diverse needs.

But, by asking yourself some of the key questions illustrated below, you might start to uncover opportunities for consolidation.

Source: Veridion

Maybe you’ll discover that some suppliers are redundant, offering similar products or services.

Or, you may find that your spend is concentrated on just a small percentage of your suppliers.

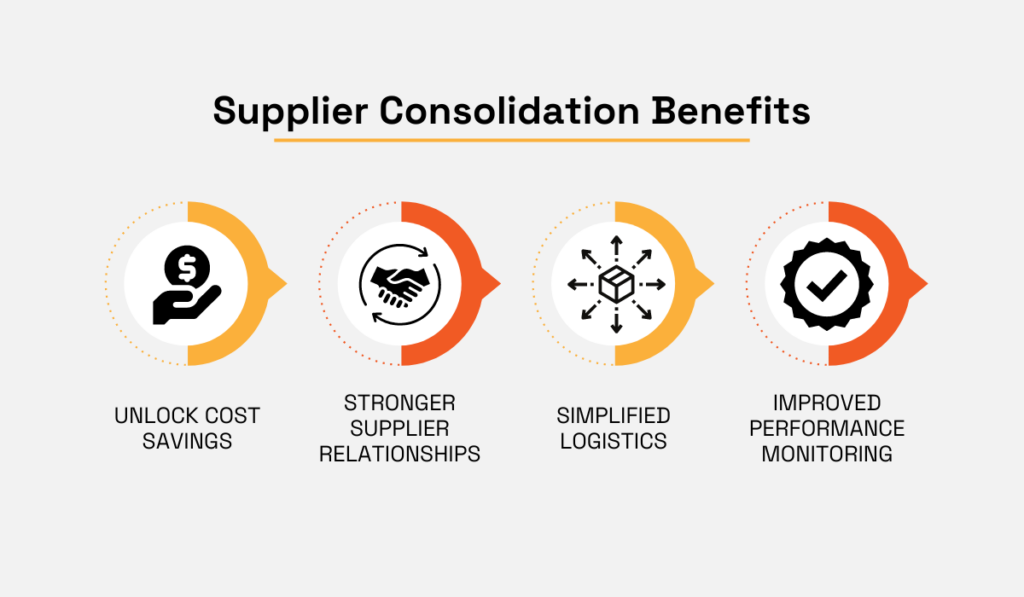

Choosing to capture these opportunities and consolidate suppliers can offer numerous benefits, some of which are shown below.

Source: Veridion

Obviously, reducing the number of suppliers often leads to cost savings as you get greater negotiating power and the potential for volume discounts.

Additionally, managing a shorter list of suppliers greatly simplifies logistics and administrative tasks.

With fewer suppliers, you also have the opportunity to foster stronger, more strategic relationships.

This can lead to improved communication, collaboration on innovation, and priority during times of supply chain disruption.

Finally, having less supplier data to manage allows you to track and measure performance more effectively, leading to better decision-making.

While the benefits are compelling, let’s briefly consider scenarios where extreme consolidation might not be ideal, as shown in the table below.

| Effect | Consolidated Suppliers | Multiple Suppliers |

|---|---|---|

| Ideal Scenario | Common needs, consistent demand, strong existing relationships | Varied needs, unpredictable demand, niche products |

| Cost Savings | Bulk discounts, reduced admin overhead | Potential for competitive bidding |

| Relationships | Deeper partnerships & collaboration | Less leverage with individual suppliers |

| Risk | Higher reliance on fewer suppliers | Spread risk, less vulnerable to disruptions |

| Agility | May be slower to react to market | Quicker to find substitutes if needed |

As you can see, consolidating suppliers works best when you have predictable needs and can focus on reaping the benefits of stronger relationships and less administrative overhead.

On the other hand, relying on a small number of suppliers brings risks.

If you need unique or specialized products, or if you are in an industry with unpredictable demand, maintaining some supplier diversity might be necessary.

Ultimately, your specific needs will dictate the ideal level of consolidation. However, given the significant advantages, we urge you to at least carefully review your current supplier list.

In the end, you may find that you can safely downsize your list without compromising your operational needs, leading to a more streamlined and efficient procurement process.

Our third tip for procurement efficiency also focuses on optimizing your supplier relationships, this time by taking a closer look at sourcing locally.

Naturally, the degree to which you can implement this tip will depend heavily on your specific needs and industry.

However, let’s explore why it might be a worthwhile strategy.

Let’s say you’re currently sourcing components or services from international suppliers when there might be viable local alternatives you haven’t fully explored.

While it’s understandable to want to stick with existing suppliers whom you’ve established relationships with, consider the potential benefits of sourcing locally:

Let’s start with costs.

Shipping and logistics can be a significant pain point when dealing with international suppliers.

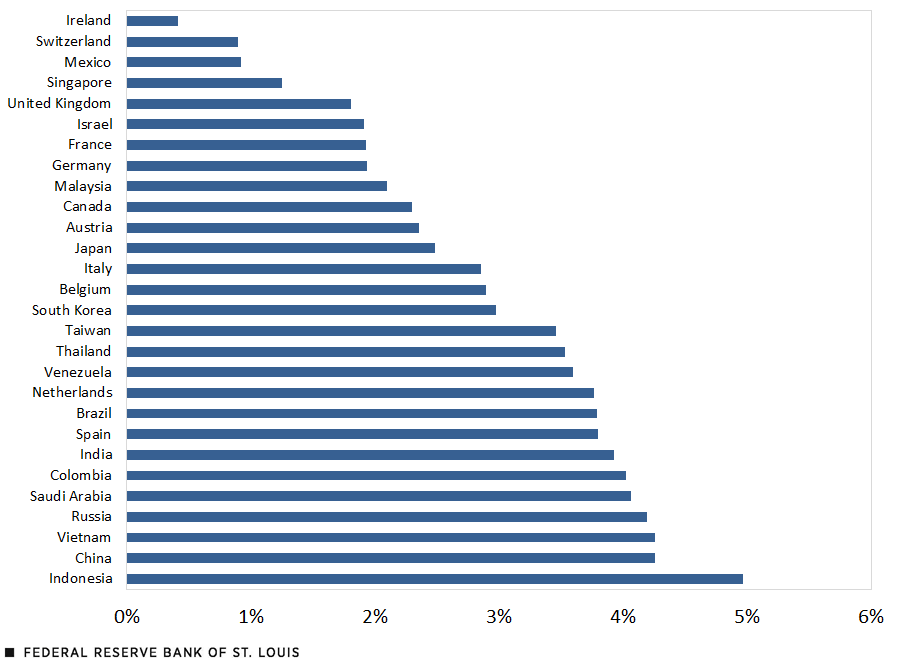

To back up this point, take a look at the data below, which illustrates shipping costs from various countries to the US.

Source: St. Louis Fed

As you can see, shipping costs can account for a considerable percentage of your import expenses depending on the origin, sometimes exceeding 4% of the total import value.

Additionally, shipping costs can vary wildly depending on the type of product.

Large, low-value items like furniture or certain raw materials have shipping costs upwards of 8%, while high-value but compact products like electronics often have lower shipping costs within the 2% range.

If you’re dealing with the former type of items this just adds more costs on top of everything.

Even if your bottom line is not an issue for you, sourcing locally can reduce your environmental impact due to less transportation.

The shorter lead times associated with local suppliers can also improve flexibility, allowing you to react faster to market changes and potentially launch new products quicker.

Considering all of these advantages, it’s no wonder that more organizations are embracing local sourcing.

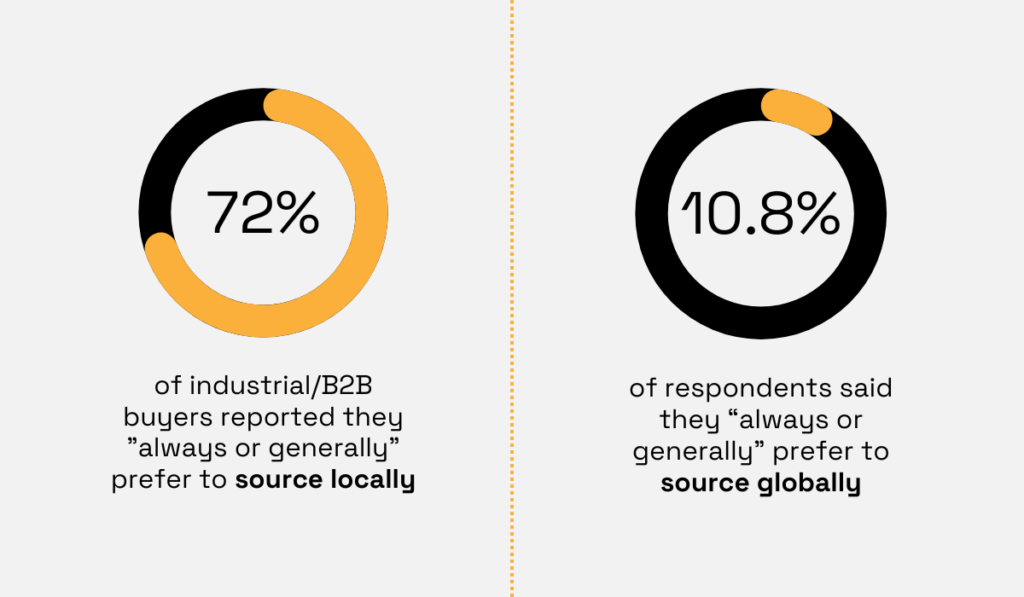

Illustration: Veridion / Data: Thomasnet

As only 10.8% of respondents in a Thomasnet survey indicated they prefer global sourcing compared to the vast majority that source locally, it’s clear that the trend is shifting towards prioritizing suppliers closer to home.

By carefully evaluating your current sourcing practices and exploring potential local suppliers, you might uncover opportunities to improve efficiency, reduce costs, and make a positive impact on both your community and the environment.

Let’s switch gears and focus on a tip that addresses your overall procurement methodology.

We’re talking about embracing the principles of Agile procurement.

Originally developed for software development, the Agile methodology is now used across various businesses and can greatly enhance the procurement process as well.

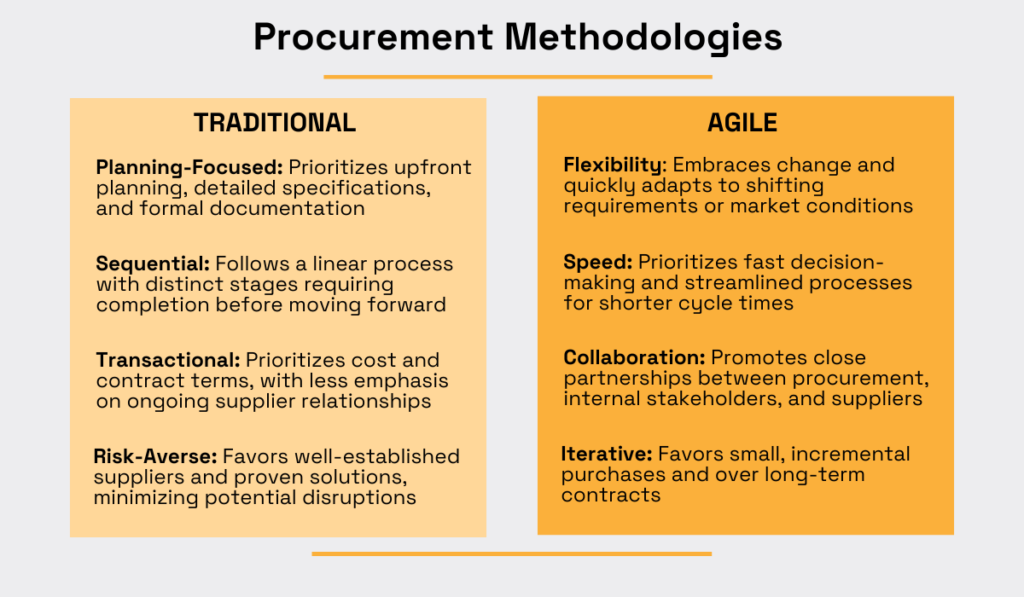

Let’s start by comparing traditional procurement with its Agile counterpart.

Source: Veridion

As you can see, traditional methods rely on a linear process with extensive upfront planning to minimize risk.

While this approach offers a sense of control, it often comes at the expense of flexibility and efficiency—traits that are crucial for success in today’s rapidly changing business landscape.

Agile procurement, on the other hand, prioritizes adaptability, collaboration, and iterative improvements.

The increased collaboration promoted by this approach can have positive benefits that impact all departments within an organization.

For example, take a look at this quote from Kevin Boyle, marketing and demand director at Metro Industries, parts manufacturers, highlighting the benefits of Agile in the supply chain department.

Illustration: Veridion / Quote: SupplyChainDive

With enhanced visibility into orders and incoming supplies, supply chain teams can plan more effectively.

This translates directly into greater efficiency and, ultimately, benefits customers as well.

Even if you’re hesitant to completely overhaul your procurement process, adopting some key principles of Agile procurement can still bring tangible benefits.

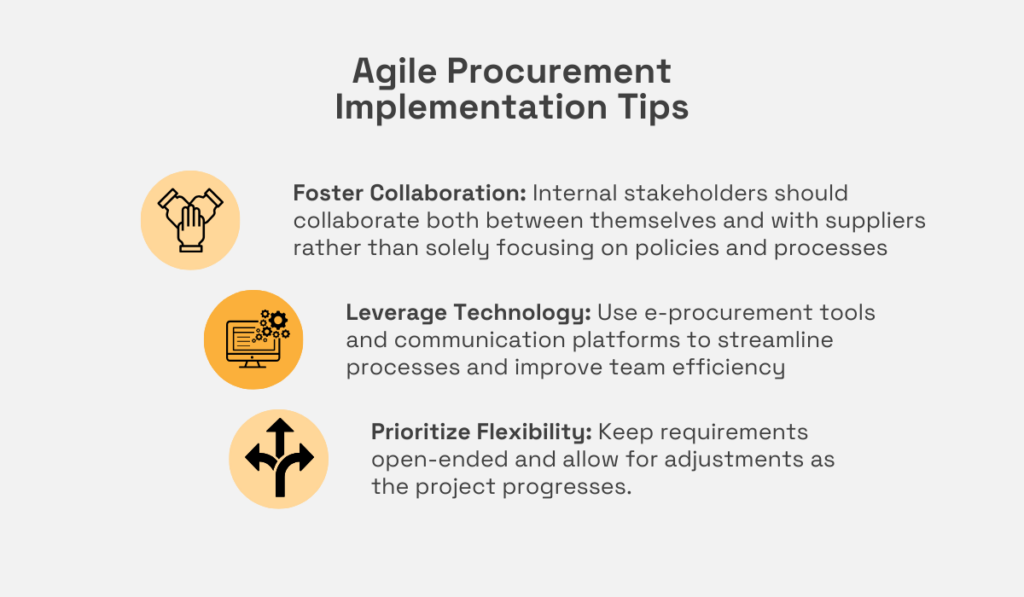

Consider the three implementation tips illustrated below.

Source: Veridion

After all, fostering better collaboration, increasing flexibility, and leveraging powerful technology are always worthwhile goals, regardless of your overarching methodology.

If you’d like to explore Agile procurement in more depth, consider the work of Mirko Kleiner, one of the emerging leaders in this space.

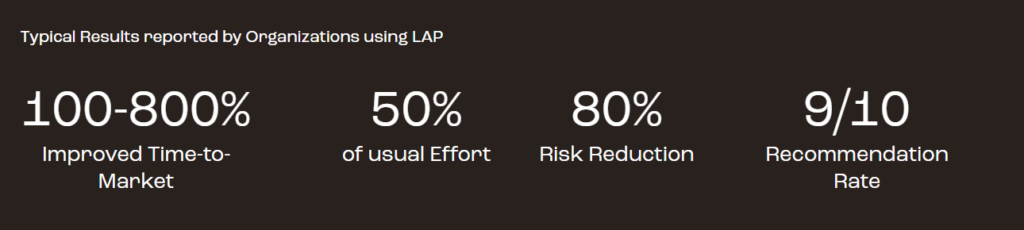

He has developed a Lean-Agile Procurement (LAP) framework that streamlines complex sourcing processes.

Using the LAP approach, teams can distill sourcing documentation down to a single page called the “Lean-Agile Canvas,” which also serves as an “Agile Contract.”

Source: LAP

With organizations reporting numerous benefits like faster time-to-market, more risk reduction, and increased efficiency using the LAP approach, it’s definitely something worth considering.

The bottom line is that embracing even some of the Agile principles can really revolutionize your procurement function, so you might want to give them a try.

Finally, let’s discuss why tracking performance metrics is crucial for maximizing procurement efficiency.

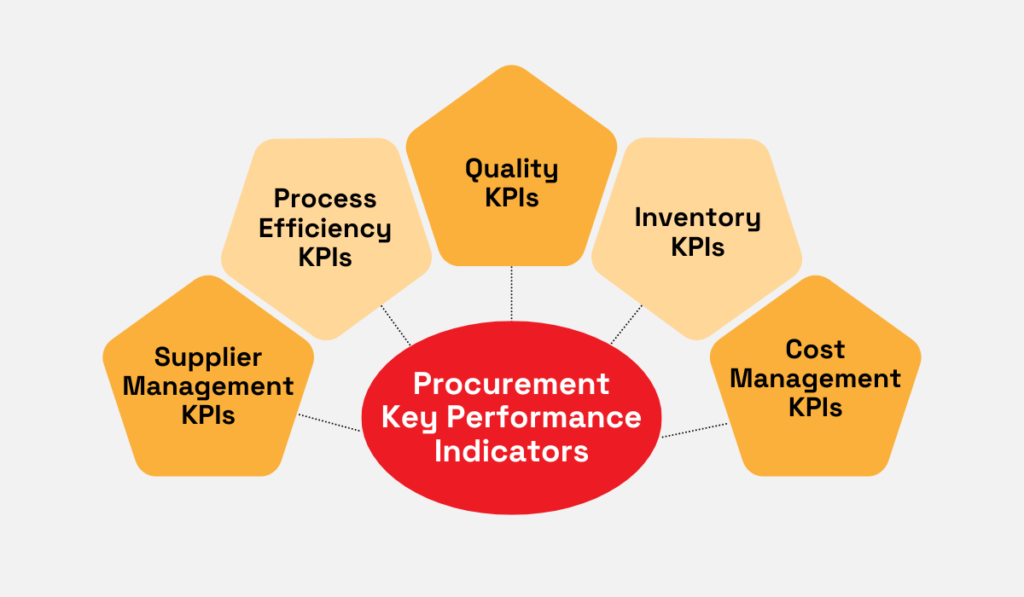

A solid performance monitoring process involves a few key steps, like identifying the most relevant key performance indicators (KPIs), establishing a consistent tracking system, and using the gathered data to inform continuous improvement.

For starters, it’s important to track a variety of metrics to gain a comprehensive view of your procurement process, some of which are illustrated below:

Source: Veridion

Let’s consider supplier management KPIs like availability, compliance rate, and quality.

These metrics directly impact procurement efficiency and by carefully monitoring them you can reveal major issues and bottlenecks.

For example, a drop in supplier quality and an increase in the defect rate of received goods is a red flag. It may indicate a need to re-evaluate suppliers or find ways to improve quality control.

Even seemingly acceptable metrics might hold potential for optimization.

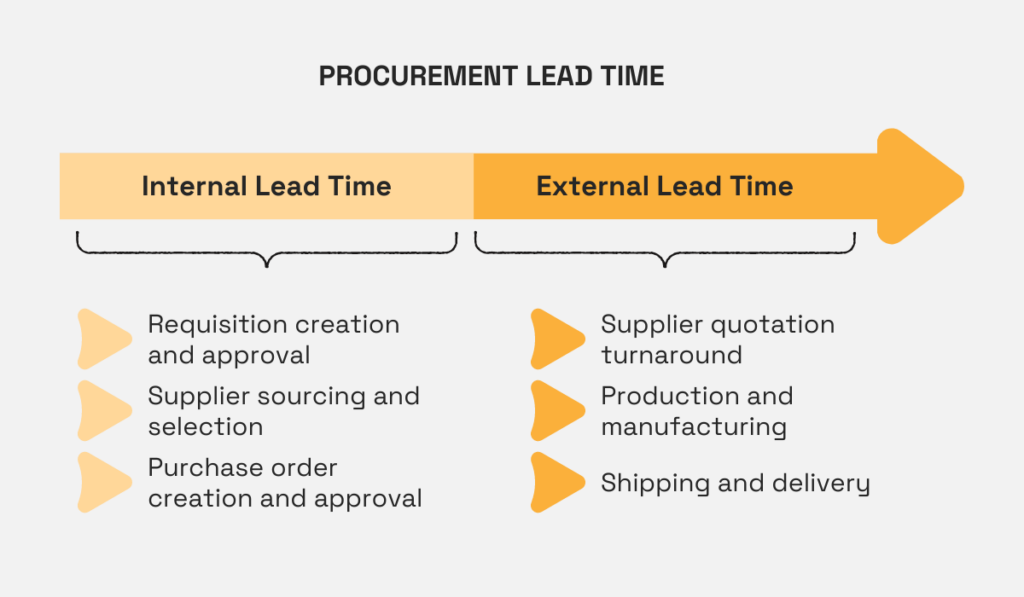

Say your overall procurement lead time isn’t drastically high, but you want to see if there’s room for improvement.

You can break down lead time into its components—internal and external lead times—to identify potential bottlenecks.

Source: Veridion

Perhaps your internal processes involve time-consuming manual documentation that could be streamlined.

Or, you might find that a significant portion of lead time is due to shipping delays, prompting you to consider local suppliers or investigate the root cause of the delays.

As you can see, careful analysis of your performance data leads to actionable insights and optimizations at multiple levels.

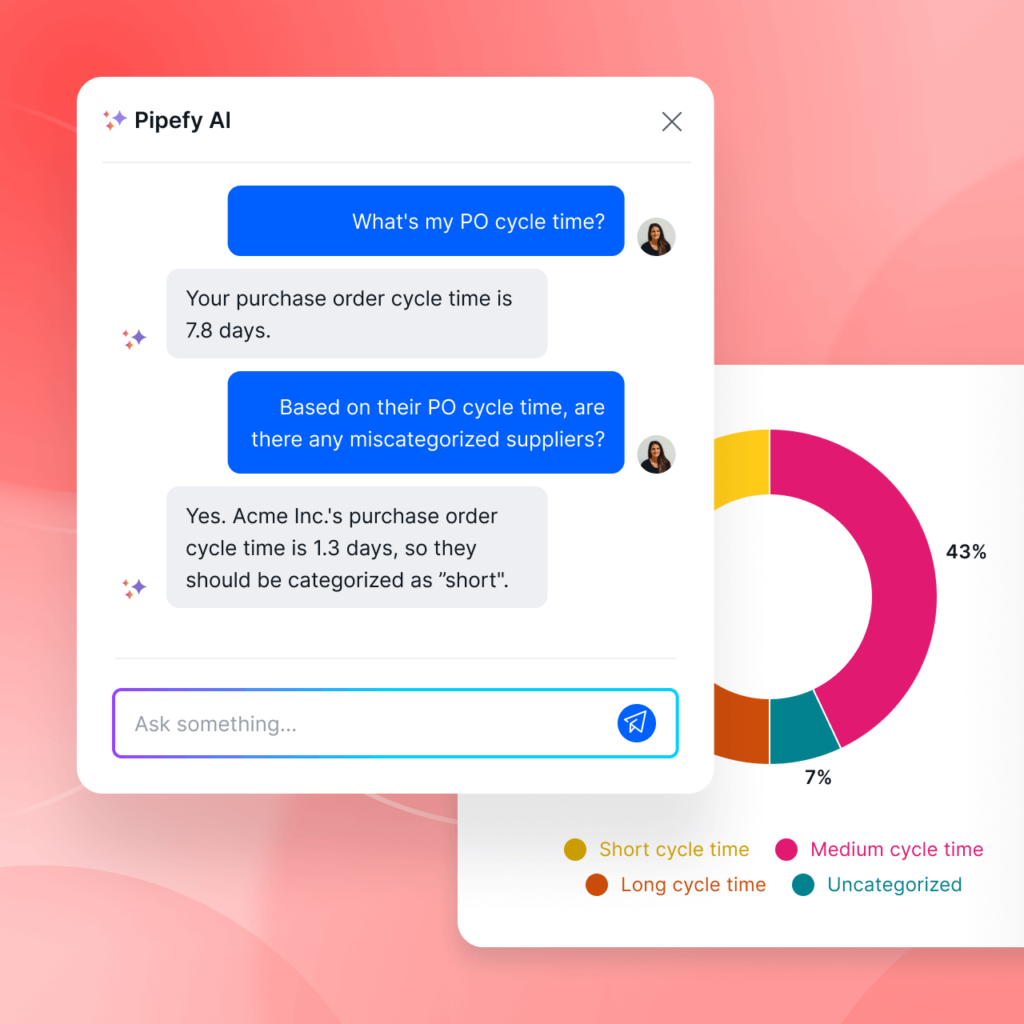

To further streamline your performance monitoring, consider utilizing specialized tools like Pipefy or Kissflow. Let’s take Pipefy as an example.

Source: Pipefy

Using this system’s AI-powered features, you can leverage a conversational chatbot to request key metrics in real time.

This eliminates the need to manually generate reports and frees up your time for strategic analysis while also promoting transparency within your organization.

In summary, by diligently monitoring your key performance indicators, you’ll unlock a wealth of insights that will guide your efforts toward continuous improvement and enhance the overall efficiency of your procurement function.

We’ve covered quite a bit in our exploration of practical tips to enhance procurement efficiency.

From refining your supplier management to embracing Agile and tracking the right metrics, there’s a lot to consider. But remember, you don’t need to transform everything overnight!

Start by focusing on a few key areas.

As you implement these tips, you’ll witness positive changes ripple throughout your procurement process.

This doesn’t just make the procurement team’s life easier—it can translate into faster sourcing, greater cost savings, and stronger supplier partnerships.

Ultimately, these improvements can empower your procurement function to become a true strategic asset for the entire organization.