Procurement Lead Time: Things You Need to Know

In the world of procurement, the adage “time is money” really holds true.

Timely acquisition of goods is crucial for ensuring smoother processes within a company, reducing unnecessary costs, enhancing customer experience, and, at times, even bolstering reputation to attract new business.

When it comes to managing procurement lifecycles and timelines, one element emerges as a key factor in navigating this task—procurement lead time.

This is precisely what we’ll be tackling in today’s article.

So, buckle up and read on to discover what procurement lead time entails, the benefits of measuring it, and strategies to shorten it.

Let’s dive in.

Lead time is a crucial Key Performance Indicator (KPI) within many sectors and aspects of business operations, procurement included.

As you can see from Investopedia’s definition below, the concept itself is really quite straightforward.

Illustration: Veridion / Data: Investopedia

Specifically in procurement, it denotes the period between ordering items from a supplier and their delivery to a buyer, including the time needed to research suppliers, negotiate contracts, place an order, and then for the items to be shipped and received.

Being conscious of the procurement timelines is key to unlocking many benefits for businesses, like cost savings, ensuring better product quality, boosting customer satisfaction, and increasing efficiency.

Shamba Sarkar, Head of IFM at Deluxe, India, identifies “the right time” as one of the five Rs of procurement essential for success.

Source: LinkedIn

Measuring lead time is indeed all about identifying that “right time” and mitigating possible risks.

For example, if the lead time exceeds expectations, it can cause stockouts, resulting in missed sales opportunities.

Conversely, a shorter lead time than anticipated may result in overstocking, impacting profitability through higher holding costs and potential inventory obsolescence, particularly for perishable items.

Not to mention, precision in forecasting lead times allows you to provide more accurate delivery dates to clients, improving their overall experience.

So, to recap, procurement lead time involves predicting and making sense of the timelines associated with getting the ordered materials from suppliers to buyers.

This gives you better control over your whole procurement system, enhancing resource allocation, minimizing operational disruptions, and, ultimately, maximizing the financial health of the company.

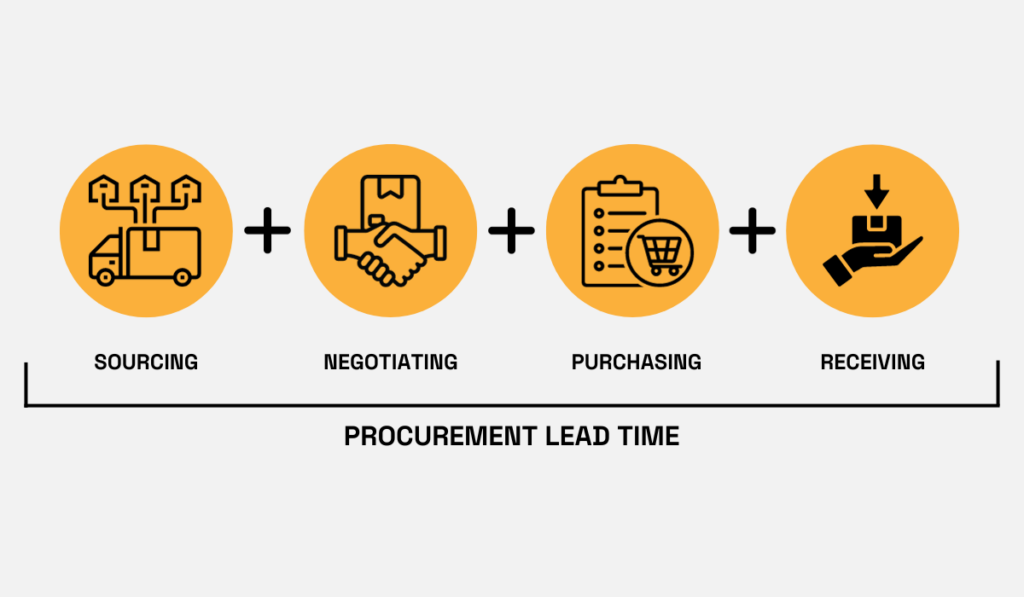

Since lead time encompasses the total time needed to execute all procurement processes, the equation for its calculation must include all these activities as well.

Therefore, the formula for procurement lead time looks like this:

Source: Veridion

To achieve more accurate and precise results, let’s break down each part of the calculation.

Before we do that, make sure to have your list of required materials ready. You first need to determine the items you need to estimate how long it will take to obtain them.

Now, onto the formula.

The first component is supplier sourcing, which means you’ll have to factor in the time required to evaluate and select suppliers for the listed goods.

If your company already maintains a roster of reliable suppliers, the lead time can be considerably reduced.

However, if there’s no such list, anticipate spending a considerable amount of time researching and selecting adequate suppliers.

Research from McKinsey tells us that it takes an average of about three months to complete a single supplier search.

Illustration: Veridion / Data: McKinsey & Company

Hence, this is a pivotal element of the lead time estimation.

The next step involves negotiating the contract terms, which can be quite a lengthy process in itself, especially when dealing with larger suppliers.

As Mohsin Ali, a procurement specialist with over 14 years of experience, aptly stated:

“Negotiation is a process and should be treated as such, as it could take weeks or months to achieve the desired results.”

So, be sure to include this negotiation time in your formula, too.

When it comes to the purchasing phase, consider the time necessary to prepare the purchase order as well as the supplier’s processing time, including the steps such as preparing, packing, and dispatching the goods after receiving the order.

In the final stage, keep in mind the time needed for the goods to be:

As you can see, while the concept of procurement lead time itself may be simple, calculating it can be very complex, with a multitude of elements to take into account.

Nevertheless, arriving at a precise estimation is well worth the thoroughness, as it can significantly enhance your processes.

Before delving into tips on shortening procurement lead time, it’s crucial to understand why this is something to work towards in the first place.

Short lead time holds substantial advantages for both procurement departments and overall business operations, especially in three key areas:

When a company sells products but doesn’t have inventory ready to be shipped, procurement plays a pivotal role.

Short procurement lead time contributes to the delivery times of the final product to end customers.

It’s a straightforward situation: reduced lead time means clients wait less for their orders, resulting in heightened satisfaction.

Finally, a shortened lead time results in cost savings and thus increased profitability.

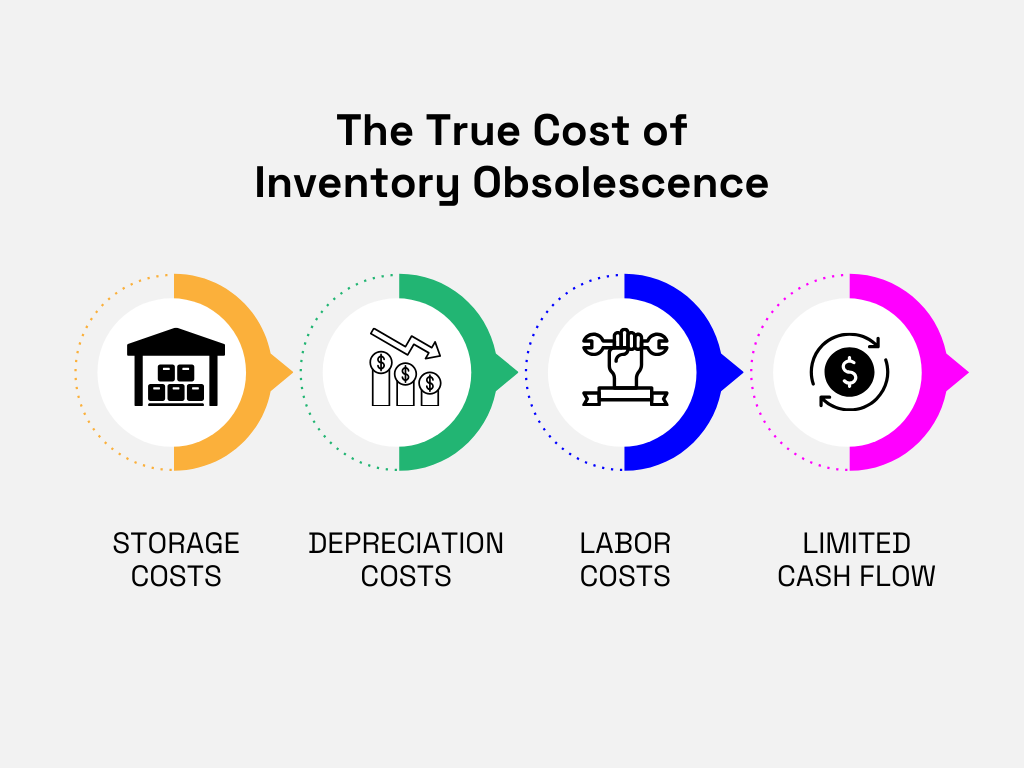

When the ordered goods take too long to reach you, they could face the risk of obsolescence, whether due to insufficient demand or technological advancements.

This scenario poses a significant setback for companies, especially in terms of unnecessary costs.

Take a look at the image below to see in which ways inventory obsolescence costs businesses money.

Source: Veridion

As you can see, it can adversely affect cash flow by forcing companies to pay for extra storage and labor, while simultaneously not contributing to revenue generation.

This diminishes liquidity and restricts companies from investing their resources in other vital areas.

At the end of the day, it’s safe to say that a short lead time contributes to overall business success.

Whether it’s fostering client satisfaction, attracting more clientele, improving profitability, or gaining a competitive edge, the effort invested in reducing lead times is undeniably worthwhile.

To reduce lead time effectively, it’s important to understand the various factors that influence it.

In this article, we’ll examine several key elements, including:

Being aware of these aspects can significantly improve your ability to assess and, of course, shorten procurement lead time.

One of the primary factors influencing lead time is the reliability of your suppliers.

As Chris Waldeck, a buyer and inventory controller at Fairfield Medical Center, says, unforeseen setbacks can impact any supplier, substantially affecting their delivery timelines.

Source: LinkedIn

However, if your supplier consistently makes errors, delivers goods too late, or provides suboptimal quality, working with such a partner will make reducing (or even predicting) lead time impossible.

The next critical factor is the delivery process itself, including the mode of transportation, distance, and even weather.

This one’s pretty straightforward.

Some forms of transportation are simply faster than others and goods from a distant supplier take longer to reach you.

While you have some impact on these elements, there’s one you cannot really control—nature.

Still, severe weather can influence trade routes and slow down deliveries, so it’s no surprise many procurement professionals keep their eye on weather forecasts at all times.

Another thing to pay attention to is the size of your order.

Larger orders take longer for a supplier to process and deliver, as well as for you to inspect and store, thus prolonging the overall lead time.

To mitigate such delays, some procurement teams order smaller quantities of materials more frequently. More on that later.

Finally, customs procedures and various regulations can substantially affect lead time, particularly when ordering goods from a different country.

This adds considerable time to the whole procurement process.

All in all, many factors influence lead time, and it’s up to the procurement departments to decide when to navigate around them, incorporate them into their schedule, and to initiate changes to reduce lead time.

For those interested in the latter, the next section provides insights into strategies for achieving this objective.

Now, let’s see how you can reduce procurement lead time by addressing the factors we mentioned.

The first order of business is selecting reliable suppliers, preferably those that are closer to you.

You need someone who you can count on to deliver the goods on time every single time.

Now, you might be thinking: Doesn’t finding trustworthy suppliers itself take a significant amount of time, potentially adding to the overall lead time?

True, supplier sourcing can be quite a time-consuming task in its own right.

However, it doesn’t have to be.

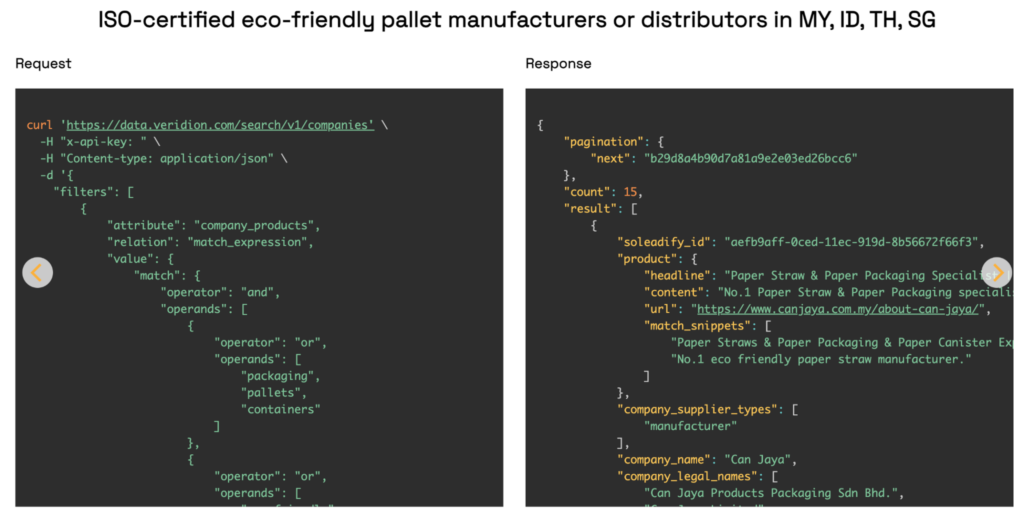

Supplier-sourcing enabler tools like our Veridion can significantly speed up this process for you.

Source: Veridion

Our system provides data on more than 80 million global suppliers and refreshes it constantly so you can always be in the (k)now.

Using advanced web scraping technology, Veridion compiles firmographic data about companies, including their location, product details, or even sustainability practices, presenting you with a list of potential suppliers through its complex search API.

Source: Veridion

The best part?

It does so in a matter of minutes.

With dependable suppliers secured, you’re already halfway towards reducing procurement lead time.

Still, there are some other, additional steps you can take.

To optimize the delivery of goods, for example, stay informed about the most efficient modes of transportation.

Remember, the best option for you today may not be the wisest choice in a couple of months.

For instance, those relying on road transportation might experience problems later on due to labor shortages among truck drivers.

In fact, IRU Secretary General Umberto de Pretto says this problem is only going to get worse in the future:

“We are missing over 3 million truck drivers in the countries we’ve examined. Given the demographics of the profession, we forecast that it could double within five years. The consequences of such a shortage are already harming the communities, supply chains, and economies that depend on our industry.”

Therefore, try to stay updated on such industry dynamics, and have backup plans in place to minimize unexpected delays.

Finally, assess whether it’s more cost-effective for you to buy larger quantities less frequently or vice versa.

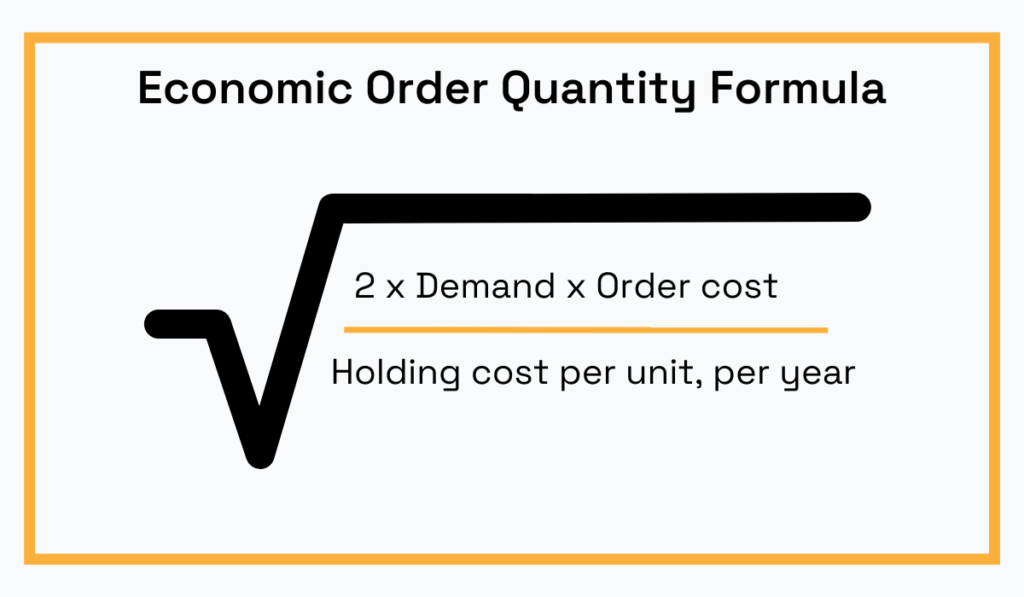

One useful method for determining that is using the Economic Order Quantity (EOQ) calculation.

Source: Investopedia

This equation considers product demand, order costs, and holding costs to give you the optimal amount of units to procure.

This number helps you strike a balance—satisfying demand without unnecessarily extending lead time due to the processing of excessively large orders.

All in all, becoming proficient in procurement lead time management will undoubtedly require some time.

However, don’t be disheartened.

Instead, utilize the insights gained from this article, coupled with your own valuable experience, and, over time, you’ll evolve into an expert capable of assessing and effectively reducing lead times.

As a result, you’ll witness a significant enhancement in your processes, impacting not only the procurement department but also the overall business operations.