Procurement Master Data Management: What You Need to Know

Key Takeaways:

Procurement runs on data.

Every PO, contract, supplier record, and invoice depends on it.

And when that data’s off, everything starts breaking down.

Duplicates show up, part numbers don’t match, terms go missing, audits drag, reports mislead, and teams waste hours fixing messes.

That’s why more and more companies are turning to Master Data Management.

In this article, we’ll break down MDM essentials: what it is, how it works, the problem it solves, and what you need to get it right.

Let’s start with the definition.

“Master Data Management (MDM) in procurement is the process of creating, organizing, standardizing, controlling, and maintaining core data used across procurement activities in an organization.”

The whole purpose of MDM is to help you create a single, reliable source of truth.

Why is this so important?

Well, in large organizations with multiple departments, it’s common for each team to use their own systems, formats, and tools.

One team might store data in an ERP. Another might keep it in spreadsheets. A third might rely on a separate sourcing platform or procurement software.

And each team uses a different format, structure, and way of handling information.

Over time, this leads to inconsistencies like:

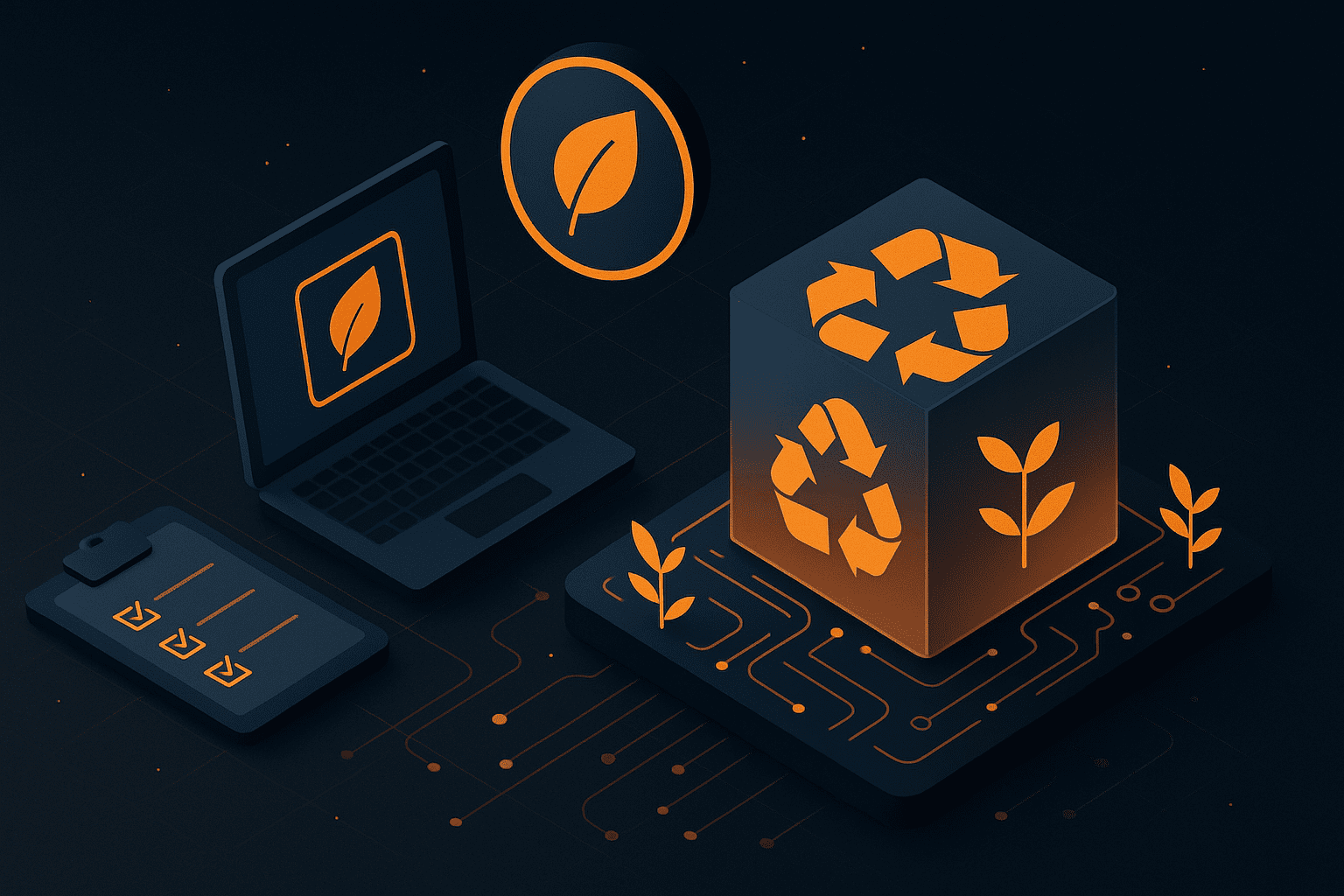

Here’s an example of what that can look like in practice.

Source: WinPure

Although these inconsistencies may seem small at first, they lead to much bigger, costlier problems:

Master Data Management solves all of this by addressing the root cause: messy, inconsistent, duplicated, scattered, and unreliable data spread across too many systems and teams.

In procurement, MDM typically manages four key types of data:

| Supplier Data | Basic company information, onboarding records, compliance files, financial data, risk assessments, performance metrics |

| Material Data | Item identification, classification, key specifications, catalog assignment, ordering units |

| Service Data | Service descriptions, classification, pricing structures, delivery expectations, vendor assignments |

| Transactional Data | Purchase order details, invoice references, delivery confirmations, payment terms, contract links, approval records |

MDM helps you manage all this data in a consistent and centralized way.

It ensures that everyone works with the same records, formats, and rules.

As a result, all teams, departments, and systems use accurate and up-to-date information.

This reduces duplicates, prevents errors, and supports better decision-making. It also helps with compliance and improves reporting.

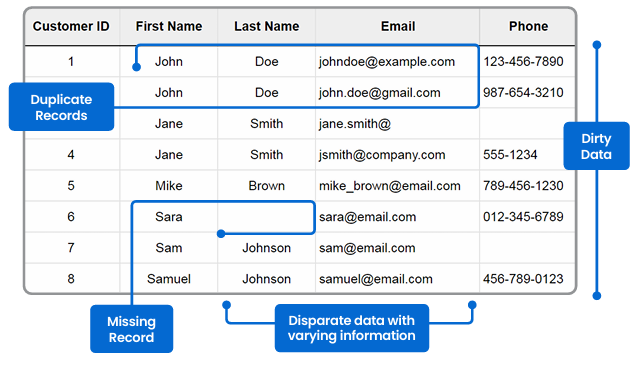

Let’s now take a look at key Master Data Management components.

Master Data Management has five essential components shown below.

Source: Veridion

Together, they transform messy, unreliable procurement data into a structured and trusted foundation your teams can depend on.

Let’s walk through each component.

Data governance is the foundation of Master Data Management.

It defines who owns the data, how it should be managed, and what rules need to be followed.

Put simply, data governance ensures that procurement data is reliable, consistent, and under control.

Or, in more formal terms:

“Data governance is a system of rules, roles, processes, policies, and standards that ensure the effective and efficient management of an organization’s data assets.”

Let’s break that down:

| Rules and standards | Define how procurement data should be named, formatted, categorized, and validated to stay consistent across tools and teams. |

| Policies | Set clear expectations for how data is created, approved, updated, used, maintained, and eventually archived or deleted. |

| Processes | Outline the exact steps and workflows for managing master data through its entire lifecycle. |

| Roles and responsibilities | Assign clear ownership over supplier, material, service, and transactional data, so everyone knows who’s accountable. |

When implemented correctly, data governance prevents future data chaos.

It creates structure and consistency without slowing teams down.

If data governance sets the rules, data quality management ensures those rules are followed by both the data and the people working with it.

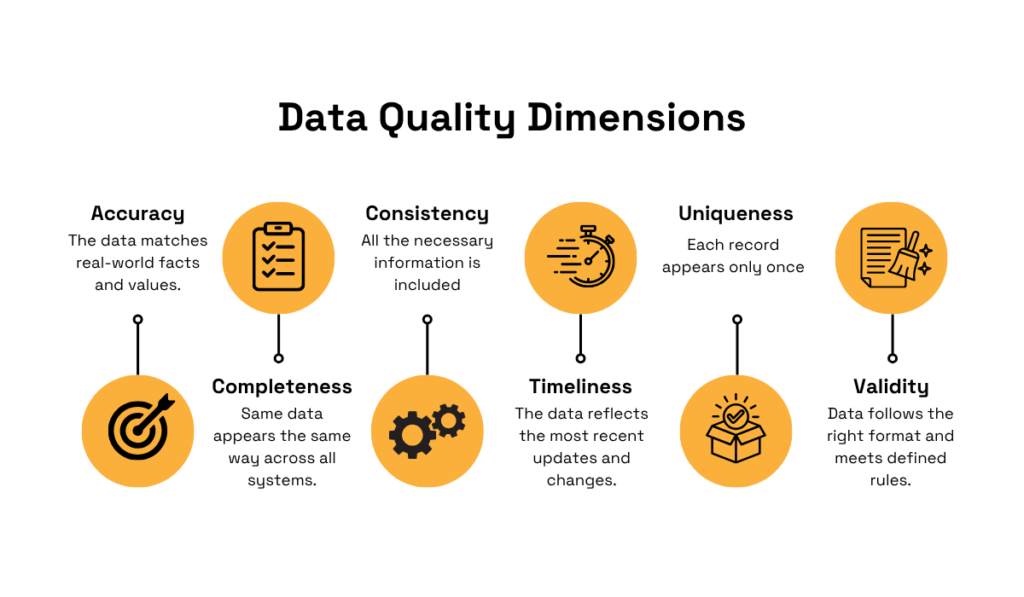

In other words, governance creates the framework and quality management applies it to the real data, checking whether it meets six key criteria:

| Data Quality Dimension | Definition | Procurement Example |

|---|---|---|

| Accuracy | Data reflects real-world values. | Supplier bank details are correct and match the invoice. |

| Completeness | All required fields and records are present. | Each purchase order includes payment terms and contact info. |

| Consistency | Data is uniform across systems, teams, and formats. | Same part number used across ERP, sourcing, and P2P tools. |

| Timeliness | Data is up to date and reflects the latest status. | Supplier risk scores are regularly refreshed and current. |

| Uniqueness | No duplicate records or repeated entries exist. | One record per vendor with no variations or duplicates. |

| Validity | Data follows expected formats and business rules. | Payment terms use only predefined, accepted values. |

These six dimensions help procurement teams keep their data clean, trusted, and ready to use in day-to-day operations.

Before you can bring all your data together, you need to make sure it speaks the same language.

That’s exactly what data standardization does.

It applies consistent standards across all procurement data, such as:

Without these, even accurate data becomes hard to work with.

For example, a supplier might appear in three systems with three slightly different names: “GE Healthcare,” “GE-Health,” and “G.E. Healthcare Inc.”

Each version is correct, but without standardization, they won’t match during reporting or analysis.

With proper data standardization, this confusion disappears. When all records follow the same format, they’re easier to match, merge, and analyze.

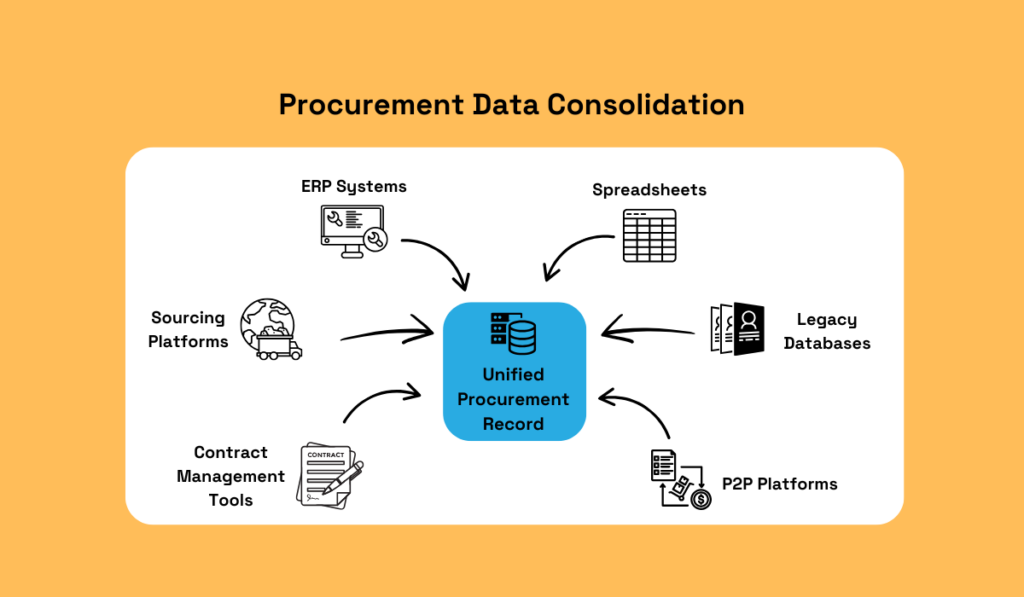

As we mentioned at the start, the purpose of Master Data Management is to create a single, reliable source of truth.

Data consolidation is how you get there.

In most organizations, procurement data lives in different systems (ERPs, spreadsheets, P2P platforms, etc).

And each of them may hold a different version of the truth.

One system has the supplier’s old address, another has a different contact person, a third lists outdated payment terms.

Data consolidation brings all of this together.

It matches, cleans, and merges records from various sources into one unified, structured view.

Source: Veridion

So, instead of five fragmented versions of a supplier, you get one accurate, complete profile that everyone can use and trust.

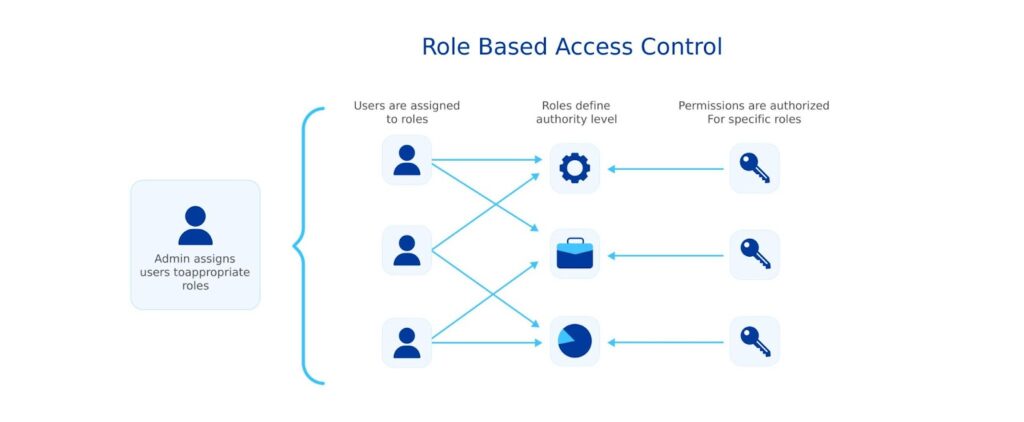

Just like data quality management, this is another layer that enforces governance.

While quality management ensures the data meets defined standards, access management controls who can view, edit, approve, or delete that data, and in which systems.

In practice, this means assigning clear permissions to users and roles.

Source: Astera

For example, a supplier record might be viewable by everyone, editable only by procurement, and deletable only by data stewards.

This keeps master data protected, ensures accountability, and reduces the risk of accidental or unauthorized changes, all of which contribute to better data quality.

When your master data is accurate, complete, current, and centralized, it’s only natural that good things follow.

Fewer errors. Faster decisions. Smarter sourcing. Better compliance.

We’ll explore the three biggest benefit buckets of master data management through real examples, data, and context so you can see the real-world impact it can have.

Why “buckets”?

Because nearly every benefit of strong MDM fits into one (or more) of these three.

Alright, time to spill them.

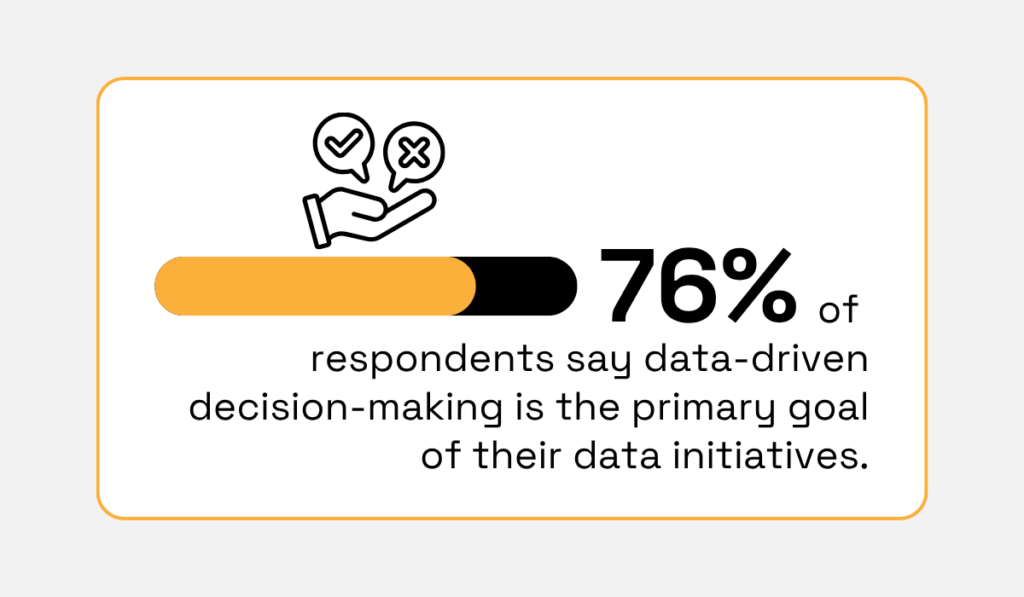

Every good decision starts with good data.

That’s why, according to a joint report by Drexel LeBow University and Precisely, data-driven decision-making is the top goal behind most data initiatives.

Illustration: Veridion / Data: Precisely

But there’s a big gap between goal and reality.

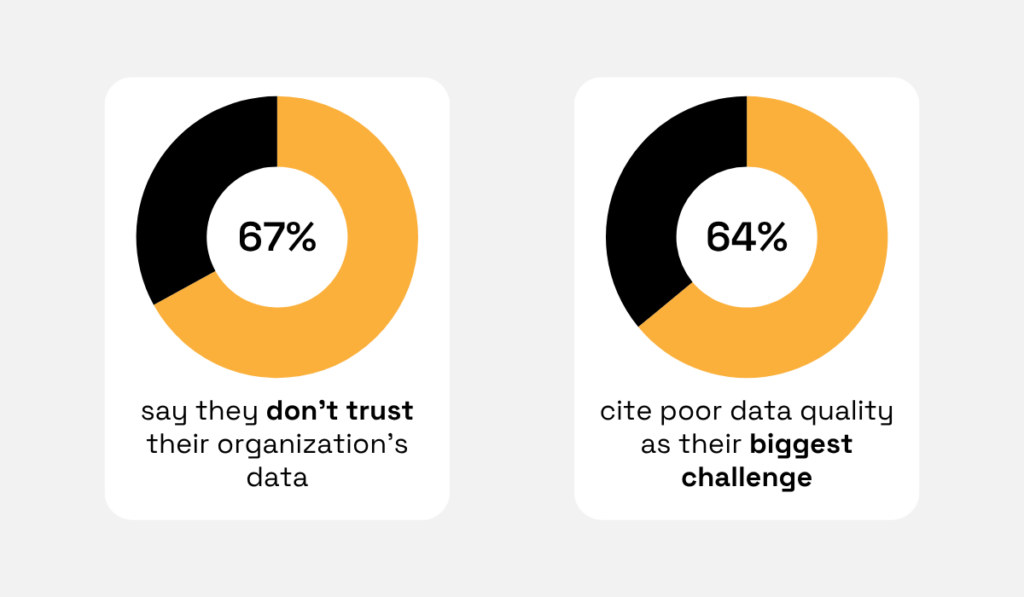

The same report found that 67% of respondents don’t trust their organization’s data, and 64% pointed to poor data quality as their biggest challenge.

Illustration: Veridion / Data: Precisely

In other words, they want to make data-driven decisions—but don’t trust the driver.

It’s hard not to see the irony.

Still, behind the irony is a big, serious problem.

This means that in most organizations, decisions are still being made based on gut feel, guesswork, or outdated and incomplete data.

And when decisions are made like this, they are bad decisions—with costly consequences.

For example:

And the list goes on…

So, what’s the solution?

Master data management.

MDM solves the root problem—bad data—by enforcing all six data quality dimensions and bringing everything into one centralized system.

Source: Veridion

So, not only does MDM solve the biggest problem organizations face (bad data), but it also helps them achieve their biggest goal (data-driven decision-making).

And with that kind of foundation, you can:

And that’s just the start.

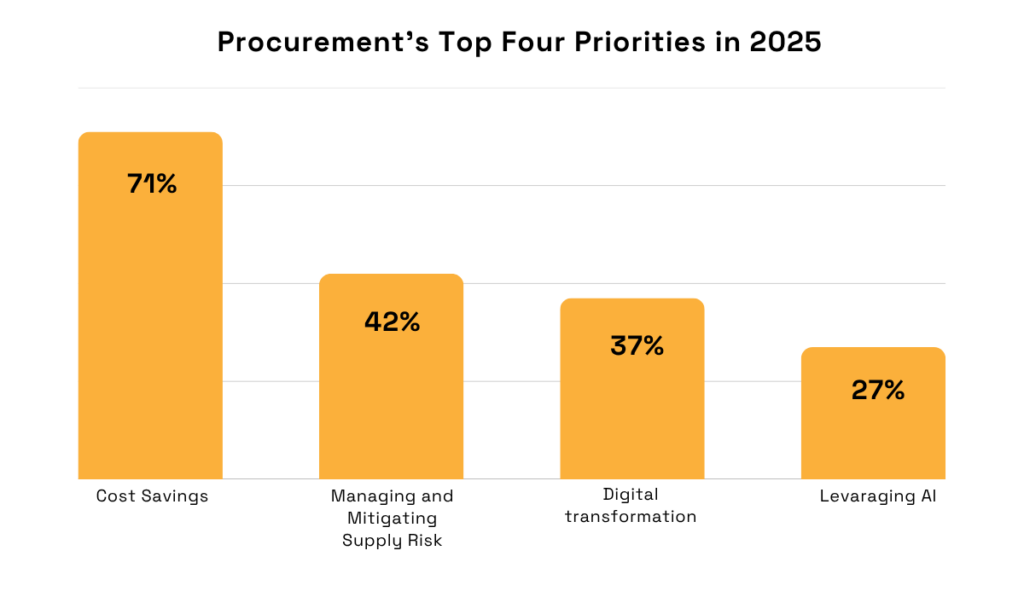

According to The State of Source‑to‑Pay Digitization report by Ardent Partners and Ivalua, cost savings are again the top priority for procurement leaders.

Illustration: Veridion / Data: Ivalua

But priorities don’t mean much without visibility.

When supplier, product, and spend data is scattered, incomplete, or inconsistent, saving opportunities stay hidden.

You can’t spot duplicate suppliers, track contract leakage, see who’s buying off-contract, or understand how much spend is going to which vendor.

Without this visibility, you don’t know what’s happening, so you can’t fix it.

But once Master Data Management is in place, that changes.

When your data is clean, structured, and centralized, cost-saving opportunities become visible.

For example, you can:

These are the direct cost savings that you can measure and report.

MDM also drives indirect savings:

So while direct savings are the easiest to spot, it’s the combination of both direct and indirect cost savings that makes Master Data Management such a powerful lever for reducing costs.

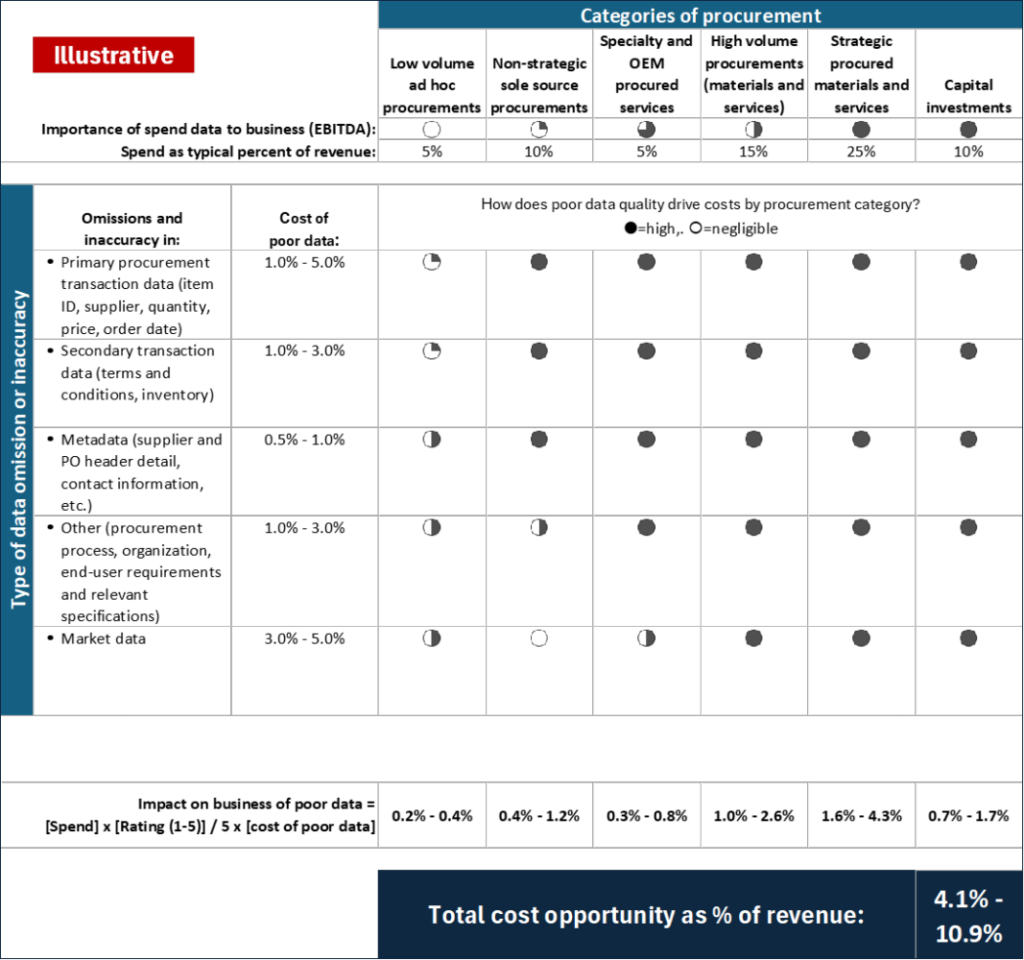

Here’s another way to look at it.

The table below shows common data issues across different spend categories:

Source: LinkedIn Pulse

Sure, it’s not a complete picture.

The table doesn’t separate hard cash losses (like overpaying for materials) from opportunity costs (like not realizing you could get a better deal elsewhere).

It also doesn’t account for the time, money, and effort spent finding and fixing the problems, or the ripple effects that bad procurement data can trigger across warehousing, operations, and beyond.

But even with all that missing, the message is clear:

Data gaps cost real money. A lot of it.

And fixing them? Often pays for itself.

Truth be told, compliance isn’t the most exciting topic in procurement and doesn’t get nearly as much spotlight as cost savings.

But it’s one of the most expensive to get wrong.

Regulatory penalties, contract breaches, disqualified bids, damaged brand reputation, lost business with public sector clients—you name it.

Take GDPR, for example. Penalties come in two tiers:

Source: Usercentrics

And it doesn’t stop with fines.

A single compliance slip can trigger public backlash, negative media coverage, and long-term trust issues.

Look at what happened to Marriott.

After disclosing a major data breach in 2018, they were hit with a $110 million GDPR fine, later reduced to $23.8 million.

Source: Forbes

But the real damage went beyond the money. The company faced serious partner scrutiny, lost deals, and took a serious hit to its reputation.

And the worst part?

Most compliance failures don’t happen because people are lazy or don’t care.

They happen because the data they rely on is a mess.

You don’t.

That’s what makes bad data the silent killer of compliance.

And it’s also where MDM makes all the difference.

It centralizes all the most important data, so the same clean, validated records show up in every system.

It gives compliance teams the visibility they need to run audits, check contract terms, and track supplier certifications, without chasing ten spreadsheets and three people.

And most importantly, it makes it much harder to go off-script without anyone noticing.

For example:

With MDM, compliance goes from reactive to proactive. You stop hoping you’re covered, and actually know you are.

Most procurement teams rely on a mix of tools for supplier onboarding, contract management, sourcing, and spend analysis.

But without a strong MDM layer in place, those tools end up running on different versions of the truth.

That’s how errors slip in, how compliance breaks happen, and how savings get left on the table.

So, what kind of tools should you actually look for?

You need solutions that can:

Unfortunately, like with almost everything else in business, there’s no one-size-fits-all solution.

But, broadly speaking, most organizations use one (or a mix) of these four types of tools to manage procurement master data:

| Type | Best For | Limitations |

|---|---|---|

| Dedicated MDM Tools | Complex data needs and multiple systems | Expensive, time-intensive, and require heavy IT support to implement and maintain. |

| S2P Platforms | End-to-end procurement | MDM features are often basic or limited to the suite itself. |

| ERP Systems with MDM Modules | Organizations already running large ERPs | Can be rigid, slow to customize, and not focused on procurement-specific workflows. |

| Data Enrichment Tools | Filling gaps and improving data quality | Doesn’t replace core MDM. |

No matter which of the three you go with (MDM platforms, S2P suites, or ERP systems), chances are you’ll end up pairing them with a data enrichment tool.

Because if the data is bad to begin with, nothing else really matters.

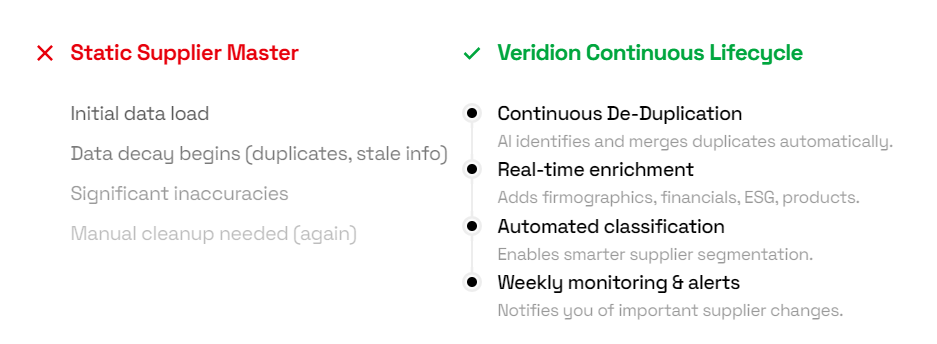

And when it comes to enrichment, few tools come close to what Veridion does.

Veridion is a full supplier data service built to keep your procurement data clean, complete, and accurate at all times.

Not just once. Not just quarterly.

Always.

Source: Veridion

This is very important, as one-time quick fixes that most classic data enrichment tools offer aren’t enough.

Your supplier ecosystem is constantly in motion.

New vendors pop up, others merge, risk profiles shift, certificates expire, prices change, and ESG concerns emerge.

And without a system that keeps up, data quality decays fast.

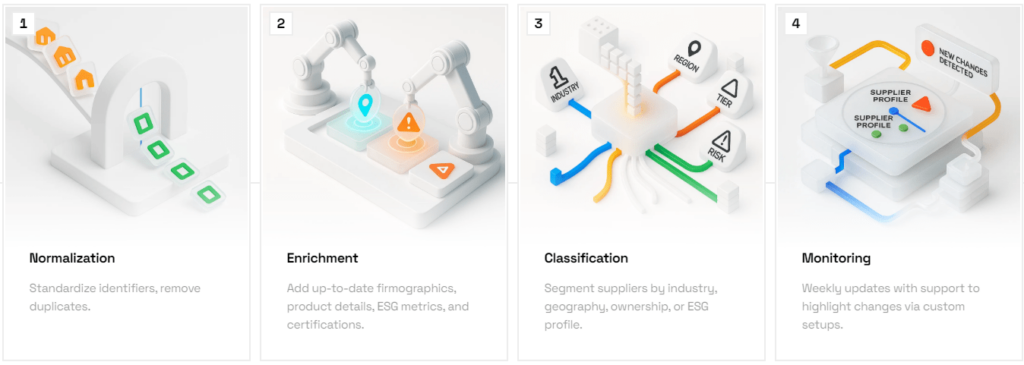

Veridion solves that with a continuous pipeline that handles everything from normalization and enrichment to classification and monitoring.

Source: Veridion

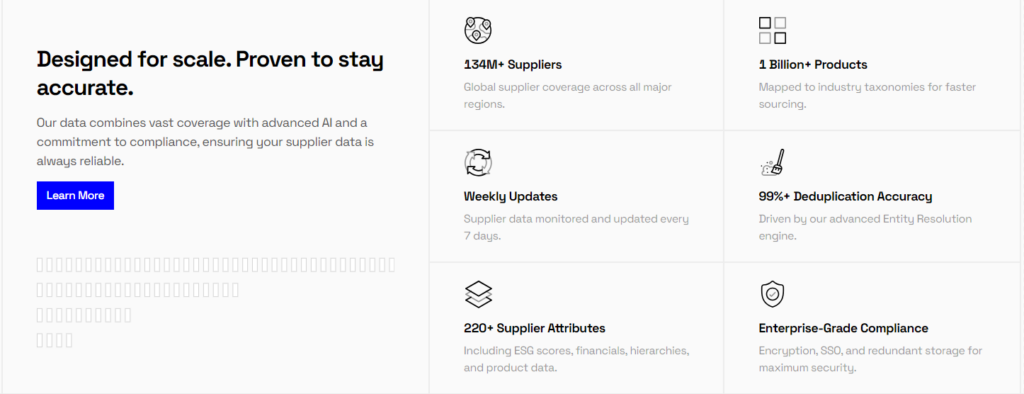

And it’s built to handle scale from day one.

Veridion covers over 134M suppliers and more than a billion products, updated every 7 days with 99%+ deduplication accuracy.

Source: Veridion

That’s enterprise-grade intelligence without the typical manual overhead.

And because we manage our own data pipeline end-to-end, you get full traceability and peace of mind.

Everything is encrypted, monitored 24/7, and compliant with GDPR, CCPA, and other major privacy frameworks.

But the best part?

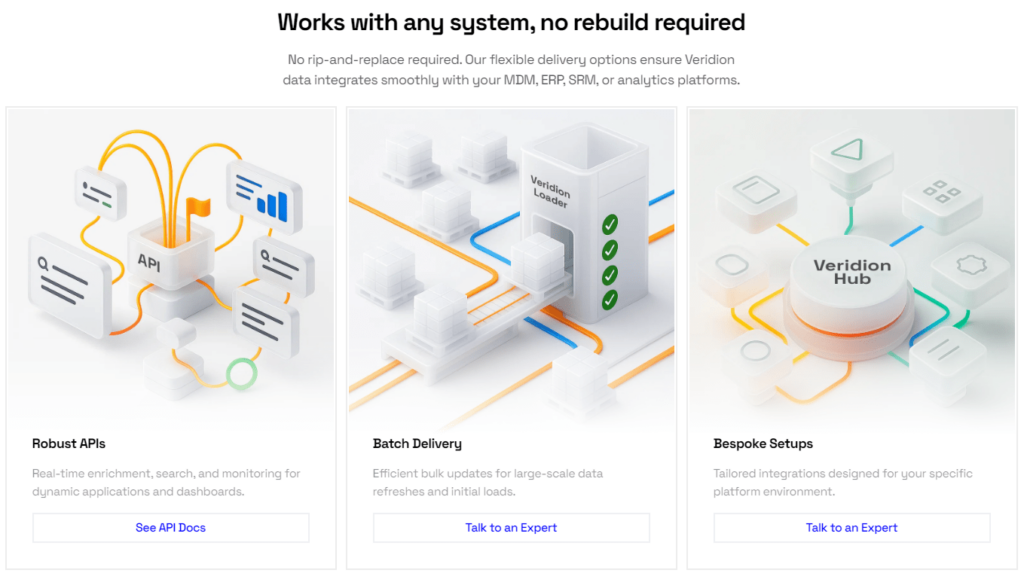

No rip-and-replace.

Whether you’re just getting started with MDM or already running a mature stack, Veridion fits right in.

Source: Veridion

That’s what makes Veridion a strong foundation for any MDM initiative.

It doesn’t try to replace your systems.

It makes them smarter by feeding them accurate, decision-grade data.

Because at the end of the day, MDM only works if your data does.

And Veridion makes sure it does.

Getting your data in order isn’t glamorous nor particularly interesting.

But it’s the foundation everything else depends on.

That’s why Master Data Management is worth the time and effort.

Because at the end of the day, MDM is how you make sure the data everyone relies on is actually reliable.

And although this won’t solve every procurement problem overnight, it’s where real solutions start.

So start.