Strategic Sourcing: 7 Examples of Companies That Nailed It

Key Takeaways:

What sets industry leaders apart from the competition?

There’s no single answer to this question, but one thing is certain—strategic sourcing is a part of the winning formula.

By optimizing supplier sourcing and forging strong partnerships, companies cut costs while building resilient supply chains.

The seven companies we’ll be focusing on offer a blueprint for strategic sourcing that you can adapt to your advantage.

Let’s dive right in.

Dell Technologies pioneered direct sourcing, which led to innovations in supply chain and manufacturing that contributed to the company’s rapid growth.

By eliminating third-party distributors, Dell realized substantial cost-savings and refined its processes, ultimately offering customers more choice at an affordable price.

Moreover, direct access to valuable customer data allowed Dell to adapt to changing preferences and introduce new products and services.

But Dell Technologies didn’t stop there.

In 2010, the company switched from a one-size-fits-all to a segmented supply chain model.

Source: Industry Week

Since the direct sales model is very reliant on a robust network of reliable suppliers, this more tailored approach proved to be another game changer for the company.

Having better insight into which vendor relationships should be prioritized helped Dell secure favorable pricing and priority access to components, as well as faster product delivery.

Stronger supplier relationships and increased data flow also fueled further process improvements.

Kevin Brown, Dell’s Head of Supply Chain, highlights the growing role of data in procurement and its critical impact on operations.

Illustration: Veridion / Quote: Supply Chain Digital

One area where data plays a critical role is inventory management.

Strategies like just-in-time (JIT) are essential for minimizing inventory and optimizing production speed.

However, without reliable data to manage supply levels and lead times, implementing JIT effectively can be a challenge.

Data also helps maintain supply chain security and reduces vendor-related risks.

The bottom line is this: any company that values cost savings and better supply chain control can adapt Dell’s direct sourcing model to its operations.

However, success requires a focus on refining supplier segmentation and improving data collection practices.

PepsiCo leverages supplier partnerships to enhance sustainability efforts, and ensure compliance with Scope 3 emissions reductions.

By promoting sustainable sourcing and setting strict ESG standards for suppliers, PepsiCo reaps several benefits, from risk mitigation to future business stability.

Source: Veridion

PepsiCo’s Global Procurement Senior Director, Patsy Duncan, underlines the importance of forward-thinking strategies, particularly those that integrate ESG principles into supplier relationship management:

“The ESG environment gives us another perspective on how to pursue supplier relationship management. It’s not just about business continuity as it is, it’s also about constructing the future of business continuity.”

Falling behind on ESG goals has far-reaching consequences that go beyond financial woes, which is why companies like PepsiCo implement strict supplier codes of conduct and dedicated programs.

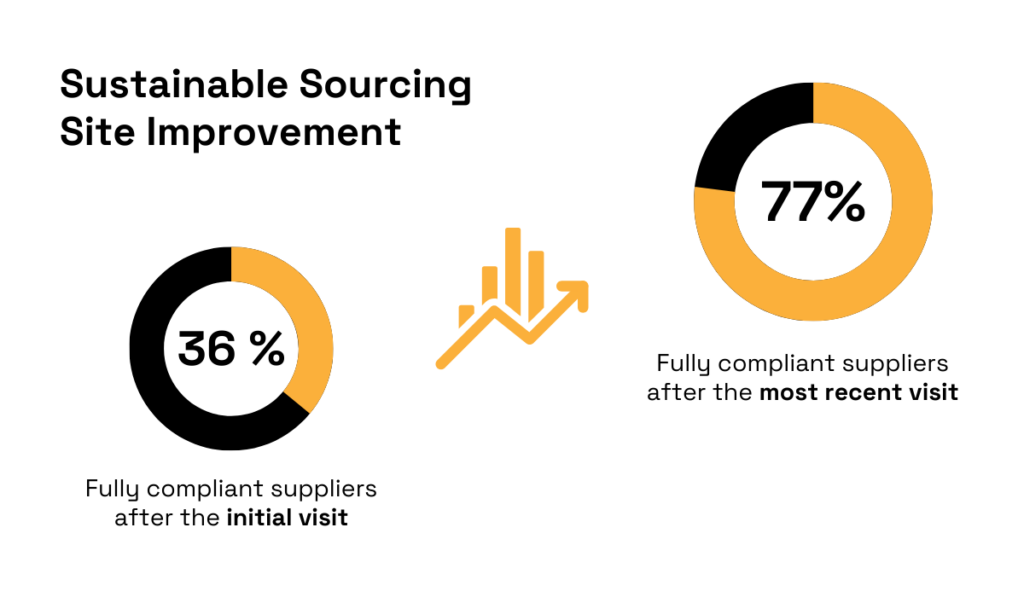

Pepsico launched its sustainable sourcing program back in 2015, and its strict control mechanisms yielded remarkable results.

For example, regular site visits have helped ensure that 77% of PepsiCo’s suppliers now meet ESG compliance standards, up from just 36% when the program was first implemented.

Illustration: Veridion / Data: PepsiCo

Audit findings led to a better track record among suppliers, but also helped strengthen PepsiCo’s internal management systems and capabilities.

However, making plans and conducting regular site visits can’t help you track risks in real-time.

This is why PepsiCo relies on Veridion’s robust ESG data monitoring.

Veridion provides access to highly accurate supplier data which guides initial supplier discovery but also ongoing risk mitigation efforts.

Below you can see Veridion’s comprehensive ESG taxonomy at a glance.

Source: Veridion

Continuously updated supplier data and real-time alerts prevent ESG-related controversies while enhancing the company’s risk mitigation, reporting, and business visibility.

Sustainable supplier sourcing is a key strategy for businesses today, and PepsiCo’s example shows that ongoing investment in both tools and practices delivers results.

Procter & Gamble (P&G)’s commitment to diverse and ethical sourcing is the secret of their competitive and resilient supply base.

P&G’s global sourcing principles are rooted in fostering relationships with suppliers from various backgrounds, including minority-owned, women-owned, veteran-owned, and LGBTQ+-owned businesses.

This way, the company enhances cost efficiency and mitigates procurement risks while simultaneously building brand reputation.

By enabling these businesses to grow at scale, P&G also opens up space for new perspectives and ideas that are essential for innovation.

Source: Veridion

P&G’s supplier diversity program has been active for more than 40 years, with the company recently putting more focus on specific regions such as Asia Pacific, the Middle East, and Africa.

Notably, the company partnered with WEConnect International and trained more than 1,000 women entrepreneurs across these regions in just five years.

These and similar initiatives have helped P&G maintain consistently high spend with diverse suppliers, as highlighted by Chief Procurement Officer Ana Elena Marziano:

Illustration: Veridion / Quote: Procurement Magazine

Companies looking to replicate this approach should start by establishing clear internal goals and reviewing their existing supplier network.

Keep in mind that experts from The Hackett Group recommend focusing on more than compliance to unlock the full potential of supplier diversity efforts.

For example, P&G works with several supplier diversity organizations that host networking events and offer matchmaking programs to help identify qualified partners.

One such organization is the National Minority Supplier Development Council (NMSDC), whose certified MBEs contributed $400 billion to the U.S. economy in 2015.

The NMSDC continues to drive impact through high-profile events, as highlighted in the video.

Source: NMSDC

P&G’s approach to supplier diversity demonstrates how inclusive procurement practices and strategic partnerships drive economic growth, creating lasting impact across industries.

H&M, a fast-fashion retailer, provides a compelling case study on aligning business growth with sustainability goals.

The company’s commitment to responsible purchasing, ethical sourcing, and environmental sustainability has resulted in several key benefits.

Source: Veridion

Sustainable sourcing helped H&M hit important ESG targets in 2023, but much of these achievements rest on advanced traceability measures.

Namely, H&M had previously expanded its traceability program by partnering with TextileGenesis and leveraging its blockchain technology.

Source: Business of Fashion

The partnership enabled H&M to track and verify the use of sustainable fibres in millions of products across multiple categories, helping to ensure compliance with sustainability standards, and reinforcing its commitment to responsible sourcing.

H&M recognizes that technology, coupled with collaboration, has the potential to drive significant industry-wide change and build consumer trust in ethical fashion.

Former Material Integrity and Traceability Expert at H&M, Merel Krebbers, stressed that industry-wide collaboration is the most effective way to maximize impact:

Illustration: Veridion / Quote: H&M Group

H&M’s dedication to this collaborative approach is demonstrated by its contribution to launching a global traceability solution aimed at improving cotton sustainability within the fashion and textile sectors.

Cotton traceability at scale could transform the industry, but it requires meaningful collaboration across the value chain.

By prioritizing transparency and forming strategic partnerships, H&M has successfully integrated sustainability into its sourcing practices, achieving measurable results.

Their example proves that by aligning sourcing strategies with ethical and environmental goals, businesses can drive sustainable change throughout the supply chain.

Year after year, illycaffè has earned a reputation as one of the world’s most sustainable coffee companies.

This is largely due to its commitment to direct trade partnerships and high-quality raw materials, which not only strengthens supplier reliability but also ensures premium product quality.

Source: Veridion

Unlike traditional procurement models, Illy sources green coffee directly from farmers across South and Central America, India, and other regions.

By bypassing intermediaries, the company gains better control over its supply chain, ensuring that strict quality and sustainability standards are met.

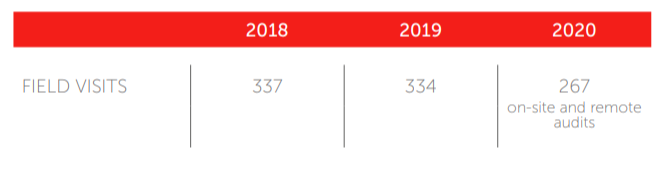

Illy’s direct trade model enhances supply chain stability while incorporating regular audits and performance monitoring.

Even during the pandemic, when global supply chains were under immense strain, Illy maintained rigorous inspection standards.

Source: Illy

Beyond quality control, Illy actively invests in stakeholder engagement and training programs to strengthen sustainability at the farm level.

Knowledge-sharing helps mitigate common agricultural risks, while technology plays a critical role in improving supply chain visibility and supplier collaboration.

To further streamline supplier relationships, Illy partnered with Jaggaer to develop a digital procurement platform.

The company uses the solution in all supplier relationship management phases, from sourcing and contract management to evaluation and risk mitigation.

However, illycaffè’s Procurement Director, Diego Pedroli, explains that this is just the beginning of a larger digital procurement project, which the company sees as essential for its future growth:

Illustration: Veridion / Quote: Jaggaer

Illycaffè’s strategic sourcing model showcases the power of direct trade, supplier engagement, and digital tools in ensuring supply chain stability, premium quality, and sustainable partnerships.

Businesses looking to refine their sourcing strategies can learn from Illy’s commitment to quality, sustainability, and innovation.

Patagonia’s sustainable sourcing practices increase consumer trust and are pivotal for the brand’s long-term profitability.

By working directly with certified suppliers, Patagonia ensures quality control, manages risks, and reduces its ecological footprint—all while reinforcing its commitment to environmental responsibility.

Source: Veridion

Patagonia’s Supply Chain Environmental Impact Program is rooted in transparent and ethical supplier sourcing, which in turn empowers its consumers to make informed purchasing choices.

For instance, the Footprint Chronicles initiative, which started over a decade ago, provides detailed information about the origins of Patagonia’s products, including insights into factory locations, labor conditions, and environmental impact.

Jill Dumain, former Director of Environmental Strategy at Patagonia, explained the idea behind it:

Illustration: Veridion / Quote: Patagonia on Youtube

The company’s dedication to sustainability goes beyond supplier oversight—it is embedded in its culture.

As of early 2025, over 1,000 Patagonia employees have participated in its Environmental Internship Program, which enabled them to gain valuable experience in the field of environmental work.

This model strengthens individual expertise and improves employee retention, but it also brings fresh sustainability insights back into the company, fueling ongoing improvements in procurement and supply chain strategies.

Beyond internal programs, Patagonia channels an estimated $100 million of its annual dividend into sustainable projects.

While this may seem like a substantial investment, it has been key to strengthening the brand’s market position and inspiring deep consumer loyalty.

Want to follow Patagonia’s example and build trust with customers, suppliers, and employees?

Then it’s time to commit to transparent practices and continuous improvement.

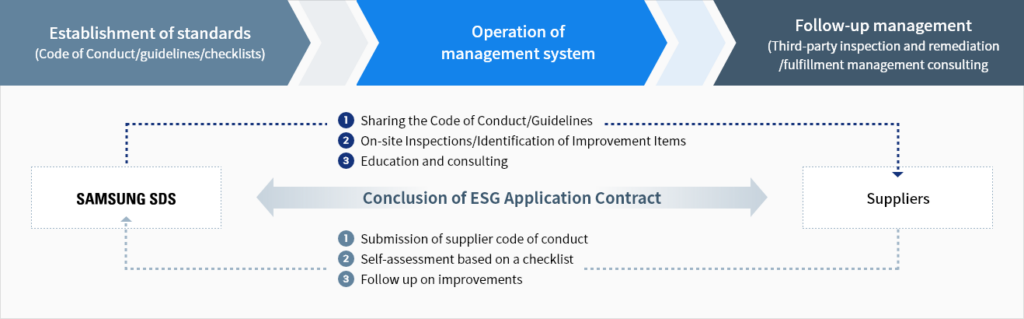

Samsung Electronics also focuses on supply chain transparency and sustainability, but does so by adopting digital procurement solutions.

By introducing AI-driven tools and automating processes, Samsung enhances efficiency, which translates to fewer procurement risks and substantial savings.

Source: Veridion

The company’s strategic sourcing starts with extensive supplier evaluations that ensure all vendors meet sustainability and compliance requirements.

These evaluations involve:

Major suppliers get additional support in establishing and implementing improvement plans, but all vendors are encouraged to enhance their ESG performance.

Source: Samsung SDS

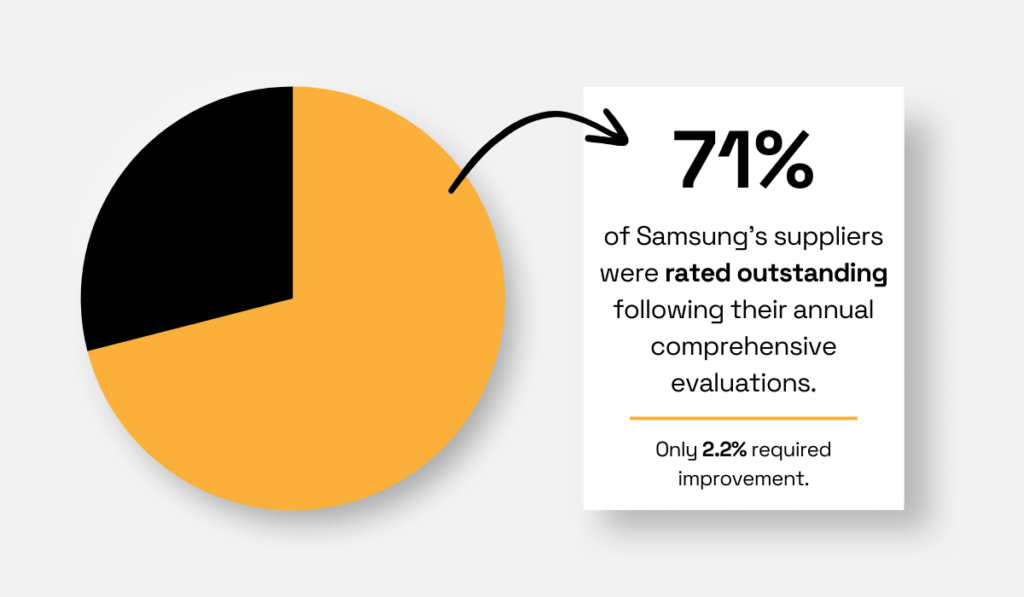

A thorough approach and regular follow-ups ensure that there are fewer cases of non-compliance.

In fact, Samsung’s supplier evaluation data for 2023 shows that the majority of suppliers received outstanding ratings.

Illustration: Veridion / Data: Samsung

To further optimize supplier management, Samsung has deployed an AI-driven SRM solution developed by Samsung SDS.

This system enables:

The combination of rigorous supplier evaluations, hands-on support, and AI-driven monitoring enables the company to proactively address risks and optimize supplier performance.

Companies looking to improve their supplier management can take inspiration from Samsung’s approach, balancing strong foundational practices with cutting-edge digital tools.

Strategic sourcing is never a one-size-fits-all approach—even the best strategies must evolve with changing industry demands.

From direct and sustainable sourcing to diverse supplier networks, industry leaders use various tactics to reduce risk and drive long-term success.

Yet, two common threads remain: strong supplier relationships and data-driven insights.

Access to data enhances sourcing decisions, helping you to surround yourself with the right suppliers while maintaining agility in today’s dynamic procurement landscape.

Now, it’s your turn to refine your sourcing strategy.

The blueprints for resilience, efficiency, and savings are out there—adapt them, innovate, and see how fast you take the lead.