Supplier Criticality Assessment 101

Key Takeaways:

There are many ways to categorize your suppliers: by spend, by risk, or by innovation capabilities.

However, few segmentation criteria provide a deeper dive into your supplier base as criticality.

That’s why we’ve dedicated this entire article to supplier criticality assessment.

We’ll guide you through why it matters, how to do it right, and the common challenges you might face along the way—plus practical tips for overcoming them.

Ready to unlock new potential in your supply chain?

Let’s get started!

Supplier criticality assessment identifies which vendors are most essential to your business operations, highlighting where issues would have the greatest impact.

Armed with those insights, you can channel your risk and supplier management efforts to your most critical partners, ensuring you’re not wasting precious resources on less impactful ones.

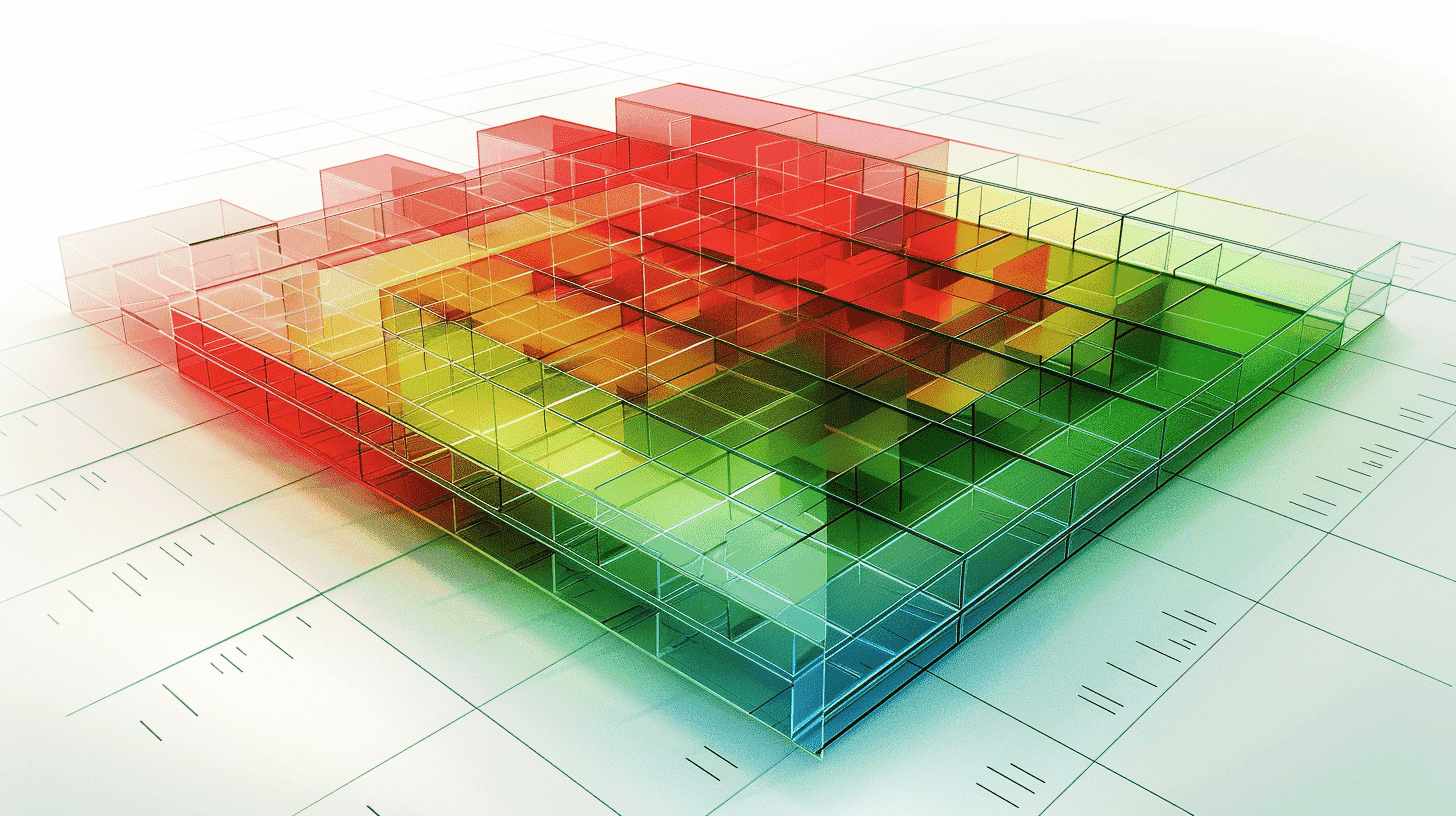

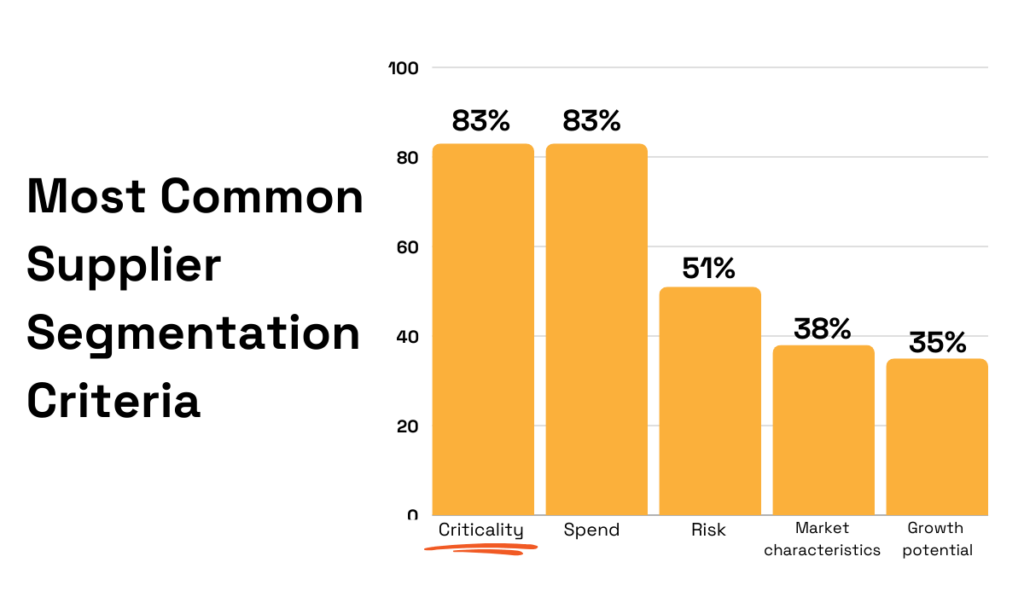

It’s probably no surprise, then, that criticality has become the most commonly used criterion for segmenting suppliers.

In fact, the 2024 State of Flux survey found that 83% of companies rely on it.

Illustration: Veridion / Data: State of Flux

That’s because criticality helps them manage suppliers—and the risks they bring—far more effectively.

For instance, highly critical suppliers might require more proactive risk management measures; like diversification or securing long-term contracts with performance guarantees.

On the other hand, non-critical vendors might only need basic compliance checks.

Thanks to criticality evaluation, you’ll know which are which, allowing you to keep your operations profitable, compliant, and disruption-free.

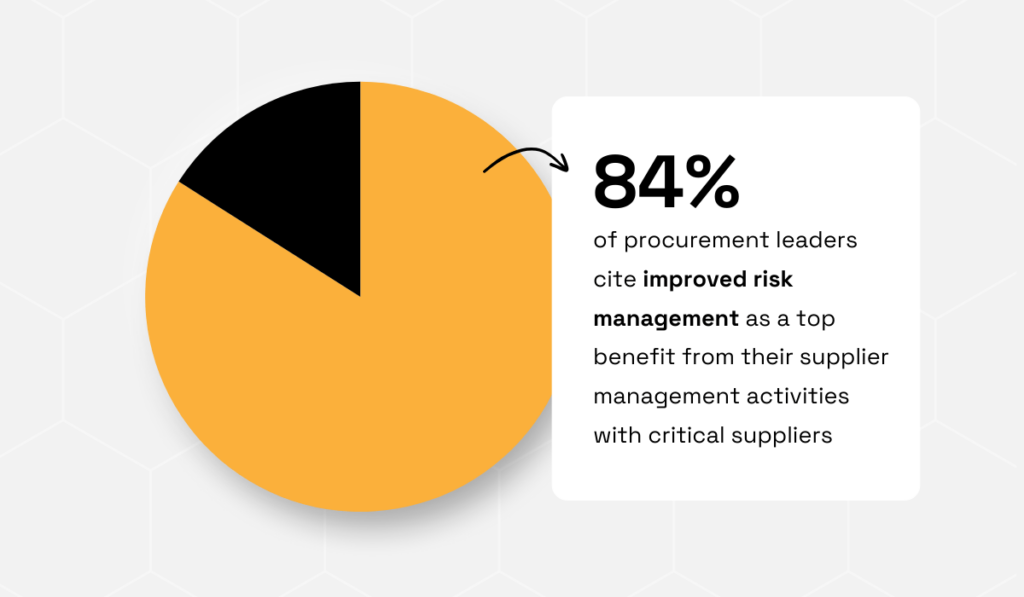

The same survey further supports this point, revealing that 84% of businesses cite improved risk management and risk reduction as the top benefits of managing critical suppliers effectively.

Illustration: Veridion / Data: State of Flux

After all, disruptions in your critical suppliers’ operations or supply chains can significantly harm your own if you’re not careful enough.

Just ask Ineos Automotive Ltd, a British manufacturer of off-road vehicles.

Recently, production of its popular Grenadier and Quartermaster models at the Hambach facility in France was halted due to financial difficulties faced by a key supplier responsible for a crucial “trim part.”

Source: Automotive News Europe

This disruption has not only impacted Ineos’ profitability but also made them scramble for an alternative supplier—which is no easy feat.

Understanding criticality means being able to prevent such incidents.

By identifying your most critical suppliers, you can proactively monitor their operations and prepare for potential risks, keeping your business resilient and uninterrupted.

But for that, you need to know to determine which of your suppliers is critical.

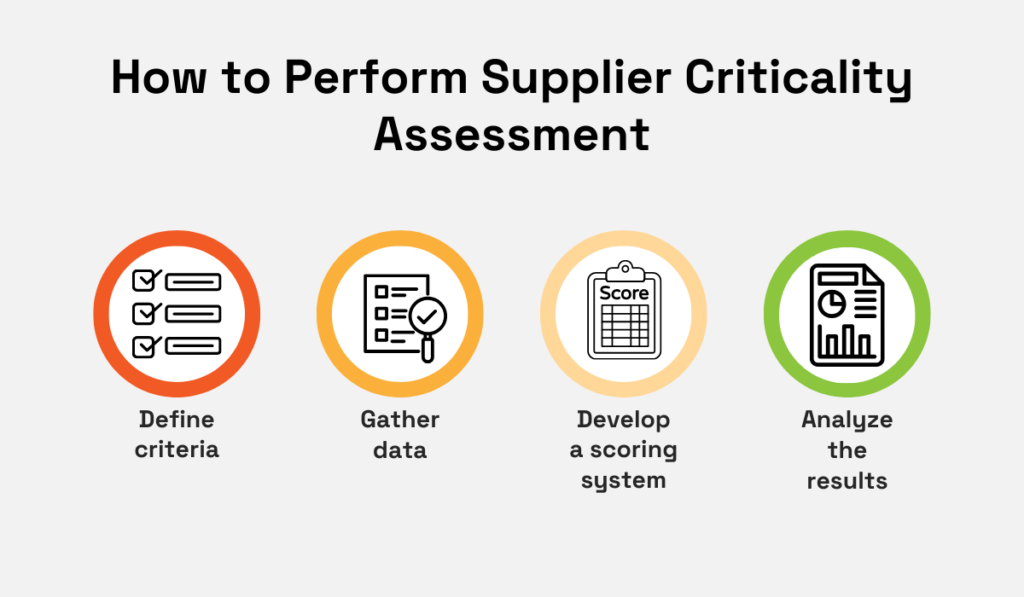

To determine which of your suppliers are critical, follow these steps:

Source: Veridion

The very first step involves identifying the factors that make a supplier critical to your organization.

This will be the foundation of your assessment.

Here, many businesses focus mostly on dependency—i.e., how much your operations rely on a vendor—but you can explore additional criteria for a more holistic view.

These criteria include:

| Substitutability | The ease of finding alternative suppliers. |

| Impact on Operations | The consequences of a supply disruption, such as operational downtime or customer dissatisfaction. |

| Strategic Importance | The supplier’s role in enabling long-term goals or providing competitive differentiation. |

| Regulatory and Compliance Requirements | Obligations tied to specific suppliers or products that might not be met due to supplier issues. |

| Data Sensitivity | The classification of data vendors can access (e.g., public, internal, confidential, or restricted). Sensitive data increases risk exposure. |

Once you have your criteria clearly defined, collect relevant information for each vendor such as contract details, historical performance data, and financial health information.

Having this data at hand will make your evaluation more reliable.

From there, you can choose a method to evaluate suppliers against the criteria you outlined.

Here’s how you can approach this:

For example, if uninterrupted operations are a must for you, give “Impact on Operations” a higher weight.

This creates a customized, data-driven system to rank your suppliers.

Finally, it’s time to analyze the results.

This is where you score each supplier against each criterion, multiply scores by weights to calculate the total for each, and classify them into tiers (e.g., high, medium, and low criticality).

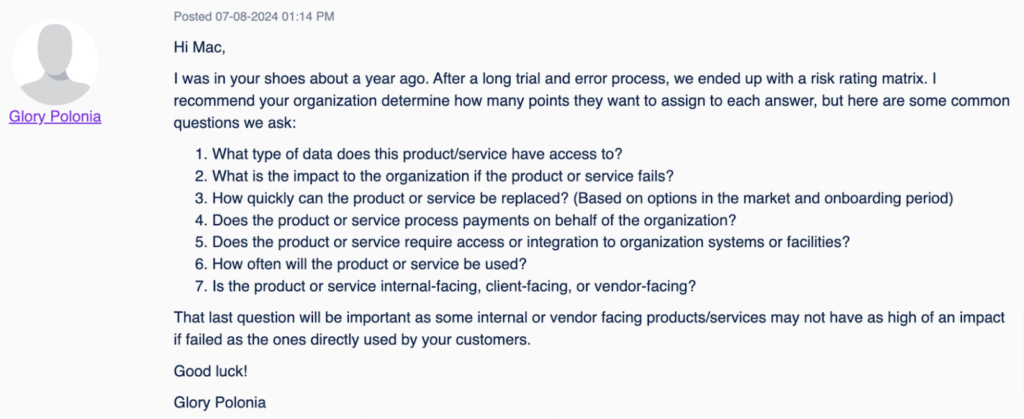

For some extra guidance or inspiration, check out this discussion on Third Party ThinkTank, an online community for third-party risk experts.

Source: Third Party ThinkTank

As you can see from the image above, it’s quite common for businesses to develop a set of tailored questions to determine the supplier’s criticality.

You can borrow this approach, too, and create a system that suits your needs perfectly.

Despite its many benefits, criticality assessment does come with some challenges.

Let’s see what they are and how you can tackle them.

Accessing reliable data on suppliers can be challenging, especially because many of them hesitate to share sensitive information about their operations, financials, or compliance.

Ultimately, this inaccurate or incomplete data doesn’t just slow you down, but can also lead to overlooking critical suppliers entirely.

When that happens, your assessments lose their value—basically making the whole process a waste of time.

As Matt Palackdharry, Founder of Kinetic Talents, a SaaS startup consultancy, says, supplier data is at the center of the effective procurement process.

Illustration: Veridion / Quote: TealBook

Reliable data drives billions of dollars in business decisions and is pivotal to every activity, including criticality evaluation.

Yet obtaining it is no small feat.

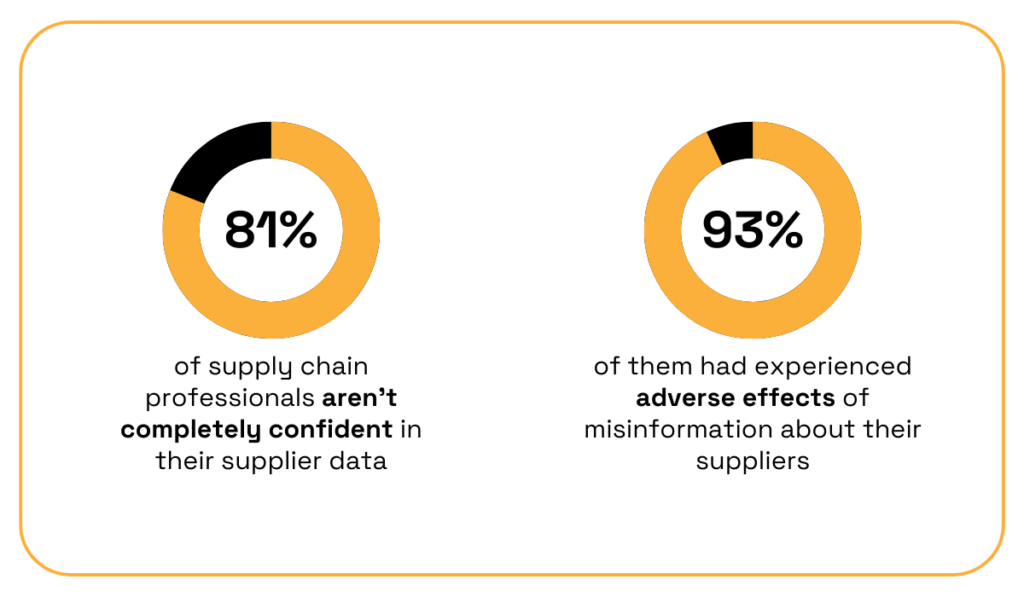

A TealBook survey highlights just how widespread this issue is, revealing that 81% of procurement and supply chain leaders admit they are not completely confident in their supplier data.

And the consequences are significant, with 93% reporting having experienced adverse effects from misinformation about suppliers.

Illustration: Veridion / Data: TealBook

So, to address this challenge and ensure accurate criticality analysis, it’s best to use reliable, AI-powered supplier data platforms like Veridion.

Veridion offers access to a global database of over 100 million suppliers, providing detailed insights into their businesses—from product details to certifications.

Source: Veridion

And guess what?

Our data undergoes a rigorous verification process, ensuring you work with the most dependable information available.

You can use it to ensure fresh information on your current suppliers or even find new ones to replace the risky ones.

Another major challenge with criticality assessments is the high volatility of supply chains and the associated risks.

External factors like geopolitical tensions, pandemics, or natural disasters can abruptly change a supplier’s criticality.

Therefore, your evaluations must also factor in the likelihood of disruptions along with the operational importance.

This adds another layer of complexity to the process, but without it, assessments become irrelevant the moment something changes.

Think back to the pandemic.

Suppliers of personal protective equipment (PPE) and cleaning materials went from marginal to critical practically overnight.

Soon, it got to the point where buyers struggled to secure items like hand sanitizer amid skyrocketing demand, leaving the market in chaos.

Source: Business Insider

While the pandemic may be over, other disruptions remain inevitable.

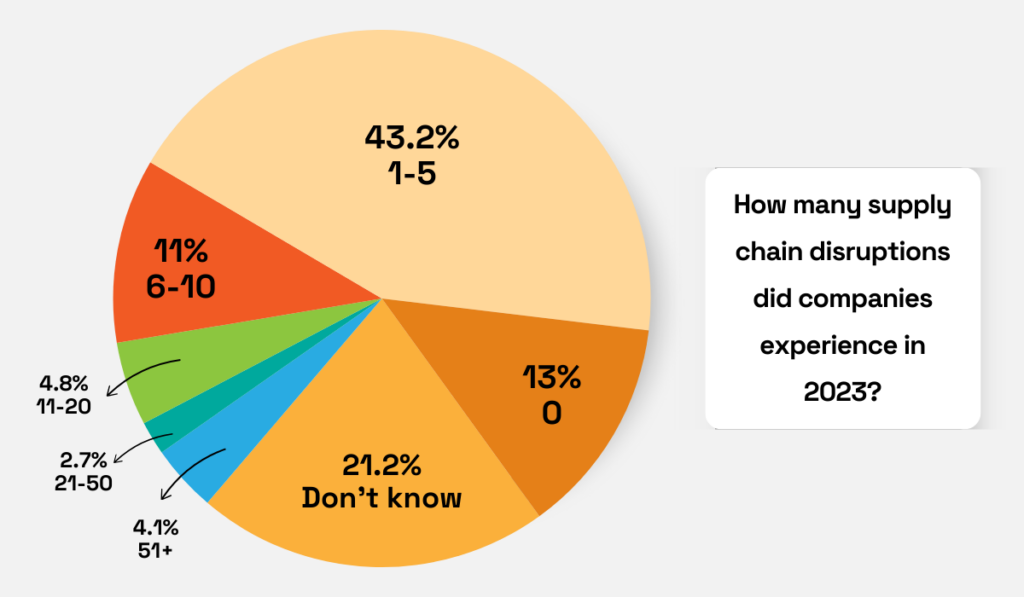

In fact, the BCI Supply Chain Resilience Report shows just how widespread they’ve become: in 2023, 43.2% of companies faced between one and five supply chain disruptions.

And for some, it was far worse—up to 50 incidents in a single year.

Illustration: Veridion / Data: The Business Continuity Institute

So how do you keep your criticality analyses up-to-date and relevant?

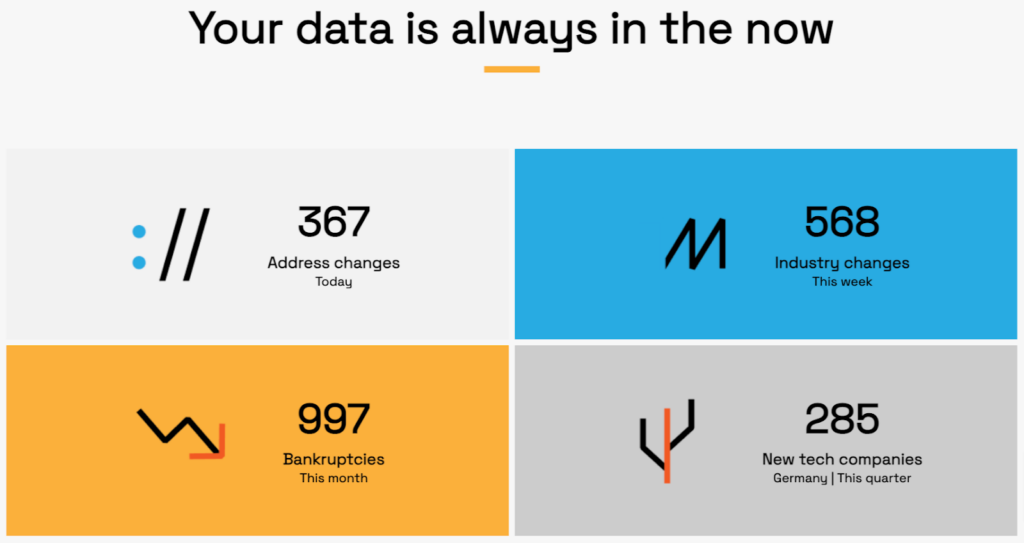

Supplier data platforms emerge as an effective solution yet again.

These platforms frequently update their databases to reflect what’s happening within your supplier landscape in near real time.

Veridion’s data, for example, is never older than two weeks.

Source: Veridion

That kind of agility can be a lifesaver, enabling you to perform accurate, up-to-date criticality assessments and prioritize suppliers effectively.

Conducting supplier criticality assessments is undeniably important, but what if you simply can’t do them?

The reality is that thorough criticality assessments require time, expertise, and budget—resources that are not always readily available.

This often discourages organizations from undertaking them altogether.

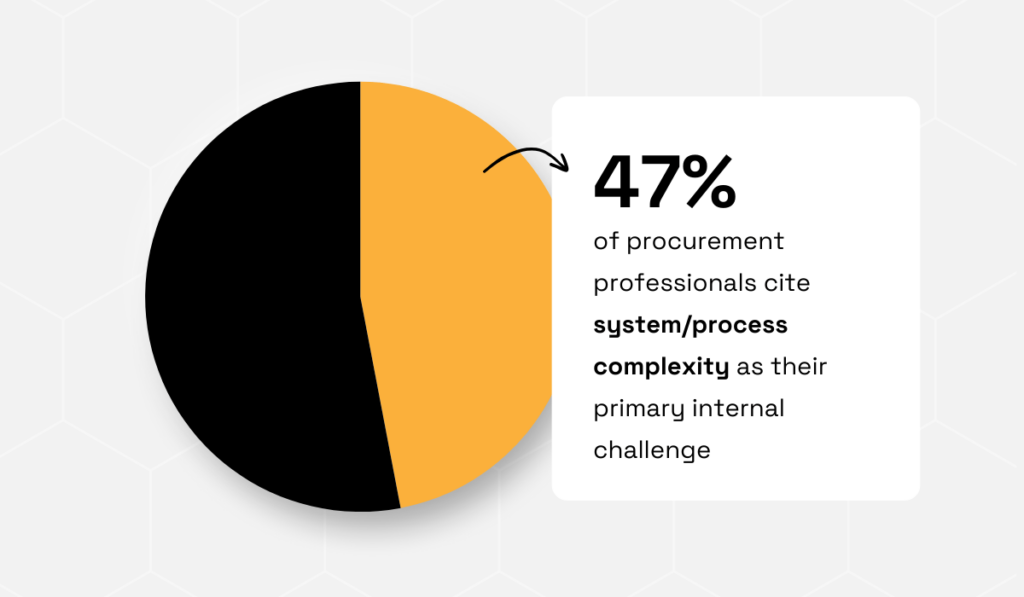

According to the 2024 Amazon Business survey, procurement professionals are already overwhelmed by demanding workloads and complex processes.

Notably, 47% of these professionals cite the complexity of systems and processes as their primary internal challenge.

Illustration: Veridion / Data: Amazon Business

But the challenges don’t stop there.

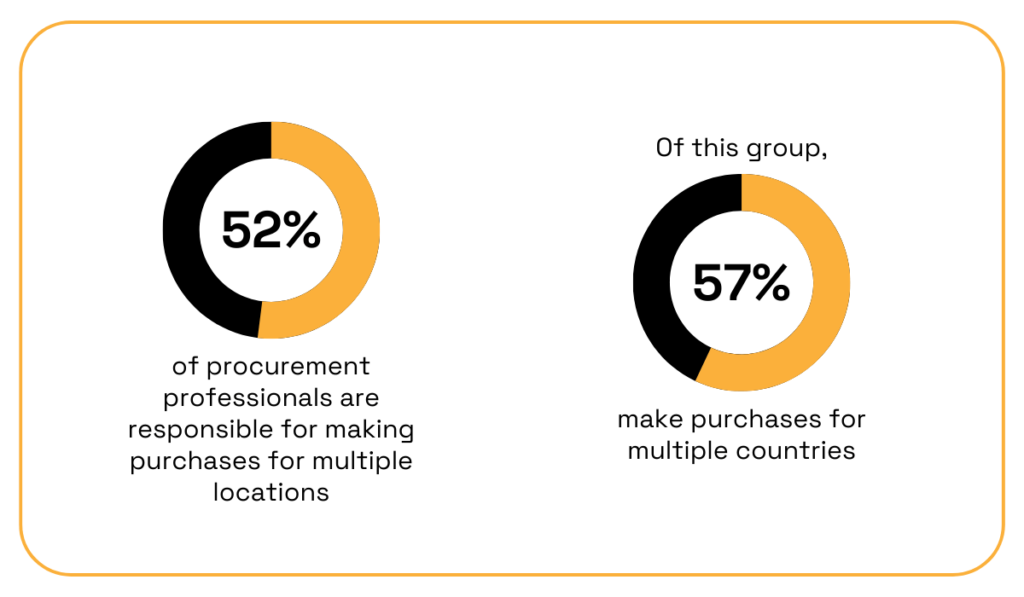

The survey also reveals that 52% of procurement decision-makers manage purchases for multiple locations, and of those, 57% handle procurement across multiple countries.

Illustration: Veridion / Data: Amazon Business

With such immense responsibilities, how can we realistically expect these professionals to take on criticality assessments as well?

The solution lies in automation.

Offloading a portion of this work to automated tools can significantly simplify the process.

One such tool is the supplier data platforms we’ve already mentioned.

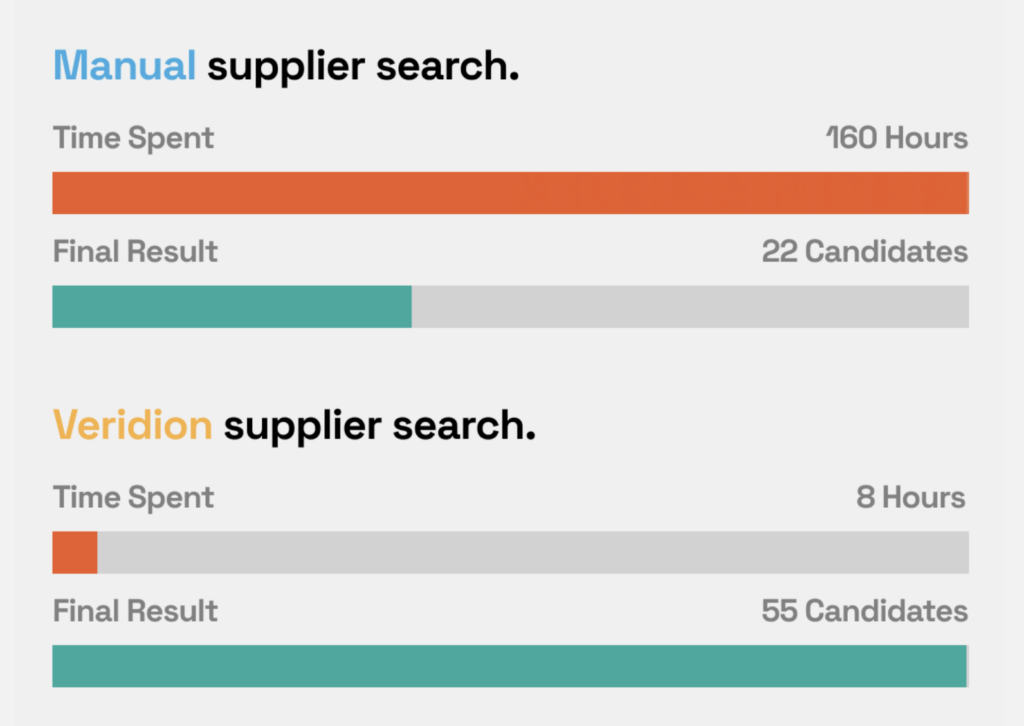

They eliminate the need for manual internet searches, which are highly ineffective and time-consuming.

Source: Veridion

Using such a platform could easily save you a lot of time—and simultaneously deliver better, more reliable results.

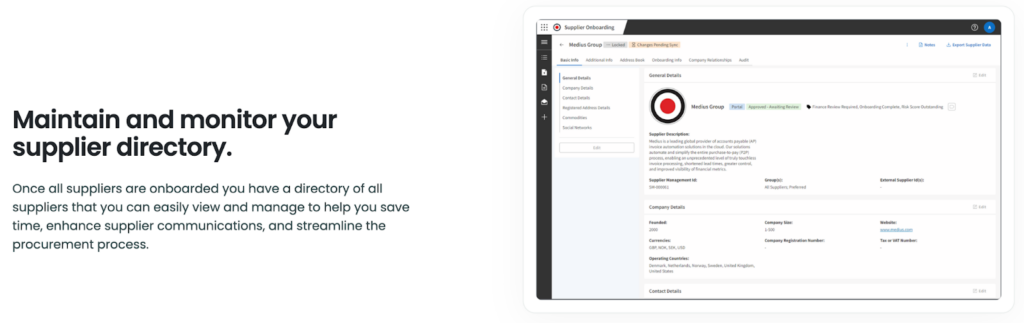

Then there are Supplier Relationship Management (SRM) tools.

These platforms act as centralized hubs for supplier data, offering features such as performance tracking and supplier scorecards.

And since they integrate with systems like ERPs, you don’t have to worry about double-checking or manually updating data.

Everything is automatically updated, synced, and ready for you.

Source: Medius

This reduces silos, minimizes manual input, and simplifies the collection of insights necessary for effective criticality assessments.

Overall, criticality assessments can be a big task—but they don’t have to be overwhelming.

In fact, with the right tools, you can make them simpler, faster, and far less painful.

So why not let automation do the heavy lifting while you focus on what really matters?

In the end, criticality assessment is something you simply can’t afford to ignore.

This kind of analysis offers valuable insights that can transform your risk management strategies, helping you protect your operations from disruptions and challenges.

Just keep in mind that this isn’t a one-time task.

Supplier criticality assessments should be conducted regularly to ensure they stay relevant and up-to-date.

After all, the business landscape is always changing, and your needs, along with your suppliers’ ability to meet them, are constantly evolving, too.

So, make sure your data is accurate, your criteria are crystal clear, and start evaluating—you’ll be amazed at the positive impact this can have.