Supplier Development: Everything You Need to Know

Key Takeaways:

Have you ever wondered how some companies turn average suppliers into strategic partners who consistently deliver value?

Beyond focusing on fixing issues in supplier performance, these companies invest time and resources into building stronger, more collaborative relationships that benefit both sides.

This approach is what we refer to as supplier development.

But what does it really take to implement an effective supplier development program?

In this guide, we’ll break it all down, sharing proven strategies and practical examples to help you develop suppliers that bring a long-term competitive advantage.

Before we dive into supplier development, let’s clarify what it is not.

Supplier development is NOT supplier management—it’s a strategic subset of it.

Supplier management is a broad process aimed at ensuring supply chain efficiency and strong relationships with all suppliers.

In contrast, supplier development takes a more focused approach, targeting the improvement of specific suppliers’ capabilities.

Supplier development usually focuses on existing suppliers. It begins after you’ve worked with them long enough to evaluate their performance and identify areas for improvement.

However, it can also apply to new suppliers, especially when you’re looking to expand into new regions or add specific capabilities to your supply base.

The Chartered Institute of Procurement and Supply (CIPS) definition highlights another key point:

Illustration: Veridion / Quote: CIPS

This concept of shared benefits is crucial if you want your development efforts to deliver meaningful results.

So, keep in mind that the purpose of supplier development is two-fold:

Now, let’s see what the goals of supplier development can be.

As you might expect, they can include supplier improvements in one or more of the following areas:

With the definition and goals out of the way, let’s shift our focus to why supplier development is important.

In short, supplier development pays off in more ways than one.

Some companies may believe it’s easier to replace underperforming suppliers rather than invest in developing them.

While that might be feasible in certain situations, there are many cases where switching suppliers is either impractical or highly risky.

Moreover, replacing a supplier is costly, requiring time and resources for sourcing, vetting, and onboarding.

On the other hand, supplier development focuses on building long-term value, which can translate into a host of benefits.

Here are just the top ones:

Source: Veridion

For starters, improved supplier performance comes from identifying gaps in their capabilities and offering support, resulting in higher quality, shorter lead times, and enhanced reliability.

For example, training programs, process optimizations, or joint development agreements can help suppliers consistently meet or exceed your expectations.

Second, stronger partnerships are a natural outcome of supplier development.

Suppliers who feel valued are more likely to prioritize your business, offer better terms, and assist you during emergencies.

Competitive advantage follows as supplier relationships strengthen.

Investing in developing your suppliers enhances supply chain agility and fosters innovation, enabling you to stay ahead of market shifts.

Rahul Sahai, CEO of Kirloskar Oil Engines Limited, agrees with this approach:

Illustration: Veridion / Quote: LinkedIn

All the above leads to the more tactical benefits of cost savings and risk mitigation.

When suppliers are developed, they become more efficient, with fewer defects and disruptions, ultimately lowering operational costs.

Their streamlined processes and improved quality also reduce the need for costly supplier changes.

Additionally, stronger relationships and enhanced reliability help mitigate supplier risks, extending to sustainability and fair labor practices.

This minimizes the likelihood of regulatory violations, supply chain disruptions, or reputational damage related to these areas.

All these benefits highlight why supplier development should be a key part of your procurement strategy.

A supplier development program (SDP) is a strategic initiative focused on enhancing the capabilities and performance of your suppliers.

The first step in implementing such a program is identifying which suppliers will benefit most from development.

We’ll explore the criteria for making these selections in the next section.

Once you’ve identified your candidates for development, the next step is to assess their current capabilities and performance to pinpoint areas for improvement.

This is typically done through supplier audits and scorecards, which help highlight areas that need attention.

As Kristiina Tiilikainen, Director for Sustainable Procurement at Lindström Group, explains:

Illustration: Veridion / Quote: Lindstrom Group

This quote succinctly covers the next step in implementing an SDP—developing a strategic plan for improvement in collaboration with your supplier.

The plan should be clear and actionable, with specific goals, timelines, and the necessary resources outlined.

It must focus on realistic, measurable improvements that both you and your supplier can track over time.

Of course, development doesn’t end here.

Continuous monitoring is crucial to ensure the supplier is making progress.

Actions like transparent communication, follow-up audits, and post-development performance reviews will help maintain momentum and keep your SDP on course.

The final step involves adjusting your plan based on progress.

If a supplier isn’t meeting expectations, the plan should remain flexible, allowing for tactical refinements and additional support where needed.

Now, let’s take a step back and look closer at considerations when selecting suppliers for development.

When managing a large supply base, time constraints and resource limitations often make it impossible to work with every supplier on their development.

This raises a critical question: how do you identify suppliers whose development will yield the greatest mutual benefit?

The process starts with prioritization.

Of course, this can quickly become complex, as criteria for selecting suppliers often vary.

In simple terms, your goal is to focus on high-potential suppliers critical to your operations or strategically important to your long-term goals.

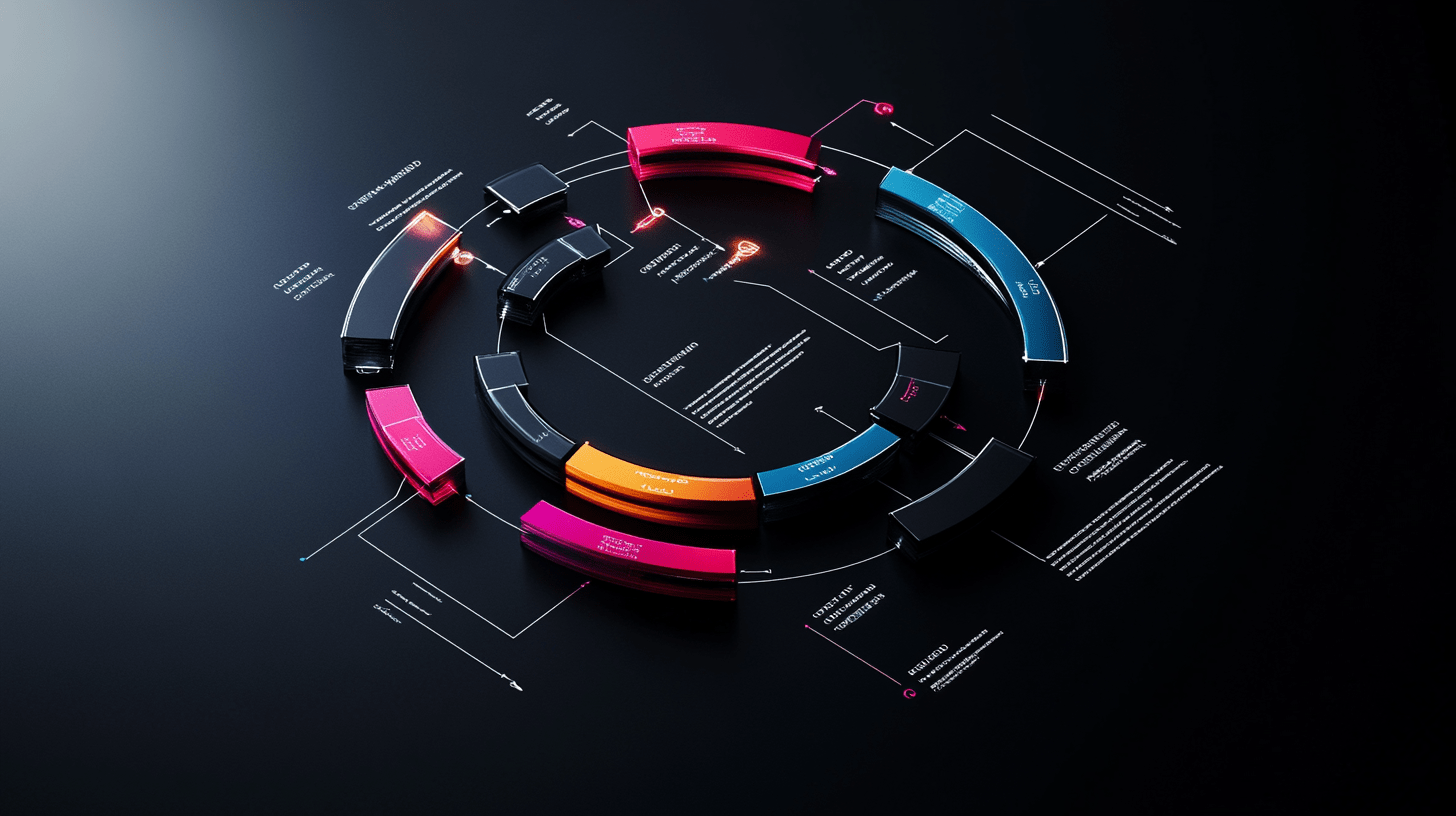

To begin, you can leverage the Kraljic Matrix, a strategic framework for supplier segmentation and management.

As shown below, it segments suppliers based on their supply risk and profit impact:

Source: Veridion

Clearly, suppliers categorized as “Strategic” are the prime candidates for development.

Development activities for these suppliers should focus on initiatives such as:

While “Non-critical” suppliers are typically the lowest priority, “Leverage” and “Bottleneck” suppliers can also benefit from selective development efforts under specific circumstances.

Therefore, such high-potential suppliers—those with significant room for improvement in areas like quality, cost savings, or innovation—should also rank high on your list.

Now, a vital element in this selection process is naturally supplier data.

Of course, the brunt of development-relevant data should come from your internal supplier management systems.

However, internal data alone has its limits.

Supplier questionnaires and audits can help determine development potential, but they also won’t provide a full picture.

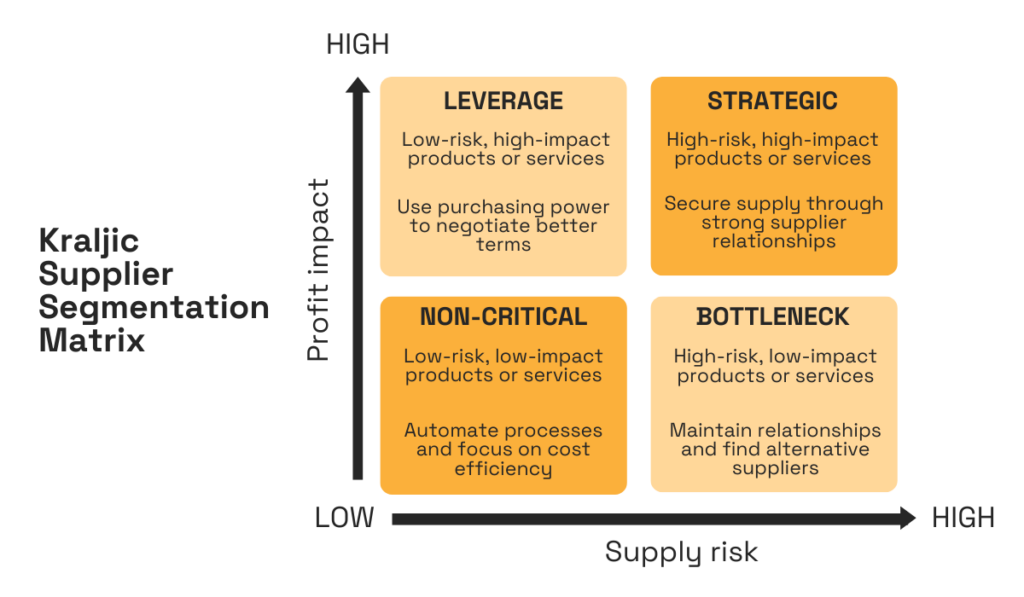

This is where an external, real-time source of supplier data like our Veridion can be invaluable.

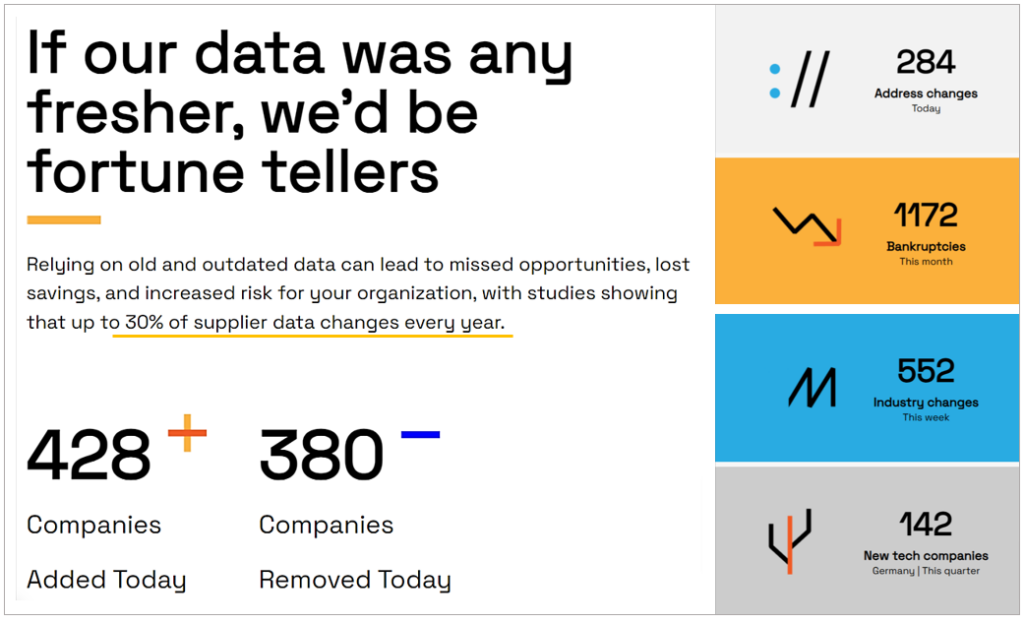

Source: Veridion

How can Veridion help you prioritize suppliers for development?

In short, Veridion’s data allows you to update supplier records with the latest information, ensuring your decisions are not based on outdated or incomplete data.

Source: Veridion

Instead, you’ll be aware of any unreported or emerging issues, such as a supplier’s financial instability, regulatory non-compliance, or poor sustainability practices.

Additionally, you can use Veridion’s market intelligence to benchmark your suppliers against their peers for more in-depth insights into development opportunities.

This empowers you to make informed decisions—whether to target specific areas for development or, if the risks are too significant, deprioritize that supplier altogether.

In the latter case, Veridion provides super-quick supplier discovery.

Ultimately, tools like Veridion give you a more comprehensive view of a supplier’s capabilities, history, and alignment with your goals.

This brings us back to another critical factor in determining which suppliers are best suited for development—alignment with your company’s goals and values.

Simply put, suppliers who share your vision are more likely to integrate seamlessly with your development strategy.

Equally important is the supplier’s willingness to collaborate and invest in development—a topic we’ll cover in the next section.

Although it brings multiple benefits, supplier development also presents some challenges.

As we just mentioned, the first blocker is the supplier’s resistance or unwillingness to be developed.

Development initiatives rely on mutual commitment, and if a supplier isn’t ready to invest their time or effort in growth, your efforts might fall short.

This can happen for various reasons, including the supplier’s unwillingness to share relevant data from the start.

Jonathan Webb, Head of Advisory at Procurement Leaders, a consulting firm, explains the supplier’s reasoning behind it:

Illustration: Veridion / Quote: Forbes

He continues to emphasize that this lack of trust can be fatal to successful supplier development efforts.

To overcome this, effective communication and strong relationships are key, but the level of leverage you hold also plays a role.

Regardless of the circumstances, development proposals should be framed carefully, highlighting the direct benefits for the supplier.

Other best practices for overcoming development blockers include providing targeted training and on-site assistance.

For example, supplier training for adopting new technologies or management practices can be conducted remotely, outsourced to third parties, or delivered directly on-site.

Similarly, on-site support from your staff or external experts can help suppliers implement development activities more effectively.

Before we conclude, we’ll explore some examples of successful supplier development initiatives that illustrate these practices in action.

We’ll describe two examples, one from Volkswagen and the other from Nestlé, showcasing successful supplier development in the automotive and food industries, respectively.

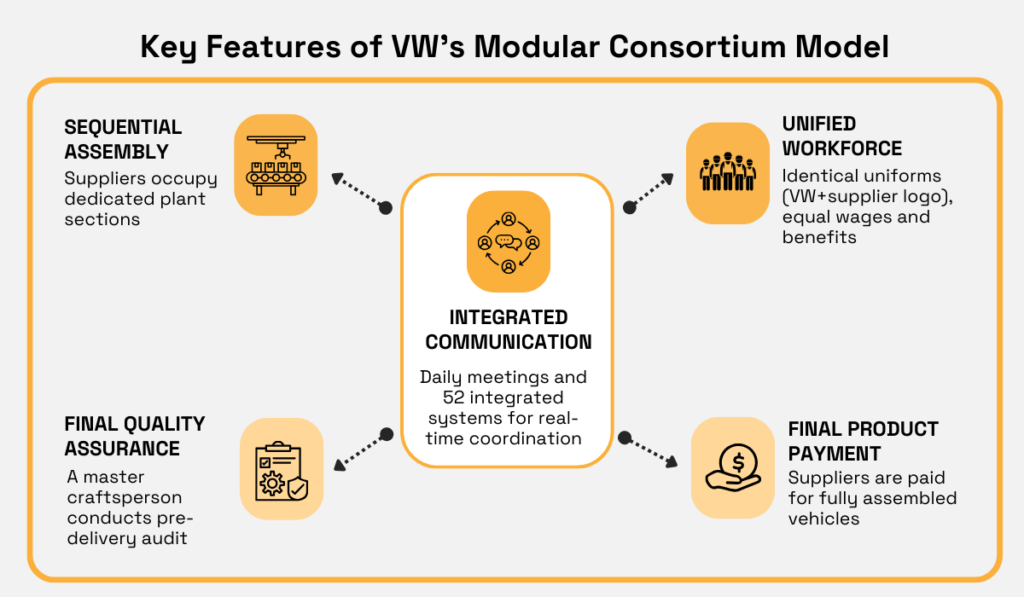

In 1997, Volkswagen (VW) introduced its modular consortium model (MCM) at the Resende truck and bus plant in Brazil.

This approach drastically restructured its supply chain: VW reduced its supply base from 400 to just 7 key suppliers.

Each of these partners would be tasked with managing their own supply chains and assembling major truck modules directly on VW’s assembly line.

However, this development opportunity came with strings attached.

The selected suppliers were required to relocate their operations to the plant, establish on-site facilities, and invest $50 million each into their respective modules.

In exchange, VW offered long-term contracts spanning 5 to 15 years and a unique partnership model.

They agreed, and here’s what the final model looked like:

Illustration: Veridion / Data: NC State University

As shown, close, real-time collaboration was the cornerstone of this innovative model, ensuring supplier accountability and compliance with VW’s quality standards.

The results spoke for themselves.

VW successfully reduced overall costs by 15–25%, increased production flexibility, and accelerated customization processes.

By outsourcing assembly operations to suppliers, VW shifted its focus to logistics, quality control, engineering, and customer service.

On its own, this model of supplier development would be noteworthy.

However, as a research paper examining the modular consortium five years later argues, VW also had strategic motivations beyond cost savings:

“We argue that the choice for the modular consortium was made because of the urgency in building a new truck plant, and because VW did not have the necessary core competencies regarding the production of the truck modules.”

So, it turns out that—by adopting this development model—VW successfully leveraged its suppliers’ specialized expertise.

This enabled the company to fast-track production and address the issue of limited in-house expertise.

While the consortium model evolved over time, it remains a strong example of how supplier development can drive mutual success for all involved.

Now, let’s look at how Nestlé develops its suppliers in regenerative agricultural practices to increase mutual sustainability.

Source: Sustainability Magazine

Through tailored technical, financial, and collaborative assistance, Nestlé equips suppliers to implement diverse cropping systems, enhance soil health, and improve water quality.

By the end of 2023, Nestlé sourced 15.2% of its raw materials from farmers who adopted regenerative practices, achieving a 13.5% reduction in greenhouse gas emissions.

These development efforts help Nestlé meet its sustainability targets and boost supplier efficiency, productivity, and long-term resilience—creating a win-win for all parties.

Additionally, this approach strengthens supplier loyalty and enhances Nestlé’s reputation as a leader in sustainable practices, benefiting both its brand image and bottom line.

The above examples show that supplier development can be a smart, long-term investment that can strengthen your business and supply chain.

However, success requires proper due diligence, clear criteria, and accurate data to identify the right suppliers and design tailored initiatives.

As emphasized in this guide, it also depends on thoughtful planning, open communication, and appropriate tools to measure progress and avoid potential barriers.

At its core, supplier development thrives on collaboration.

When you and your suppliers align on goals, you can create value for your organization and the entire supply chain ecosystem.

So, evaluate your suppliers and start building development programs together.