Supplier Evaluation Matrix: Quick Guide

So, you’re looking for new suppliers?

In today’s interconnected world, the sheer number of options and factors—such as cost, quality, delivery, and sustainability—can make supplier selection overwhelming.

This often leads to decisions based on intuition rather than data.

Luckily, that is where a supplier evaluation matrix comes in.

It is a versatile tool designed to simplify this process and make it more structured and data-driven.

In this quick guide, we’ll explore how you can leverage evaluation matrices to choose the best suppliers for your needs.

A supplier evaluation matrix has many other names, such as a supplier selection matrix, vendor evaluation matrix, or simply a supplier or vendor matrix.

Regardless of the name, this matrix is a strategic tool that enables your procurement team to compare potential suppliers side by side using multiple evaluation criteria.

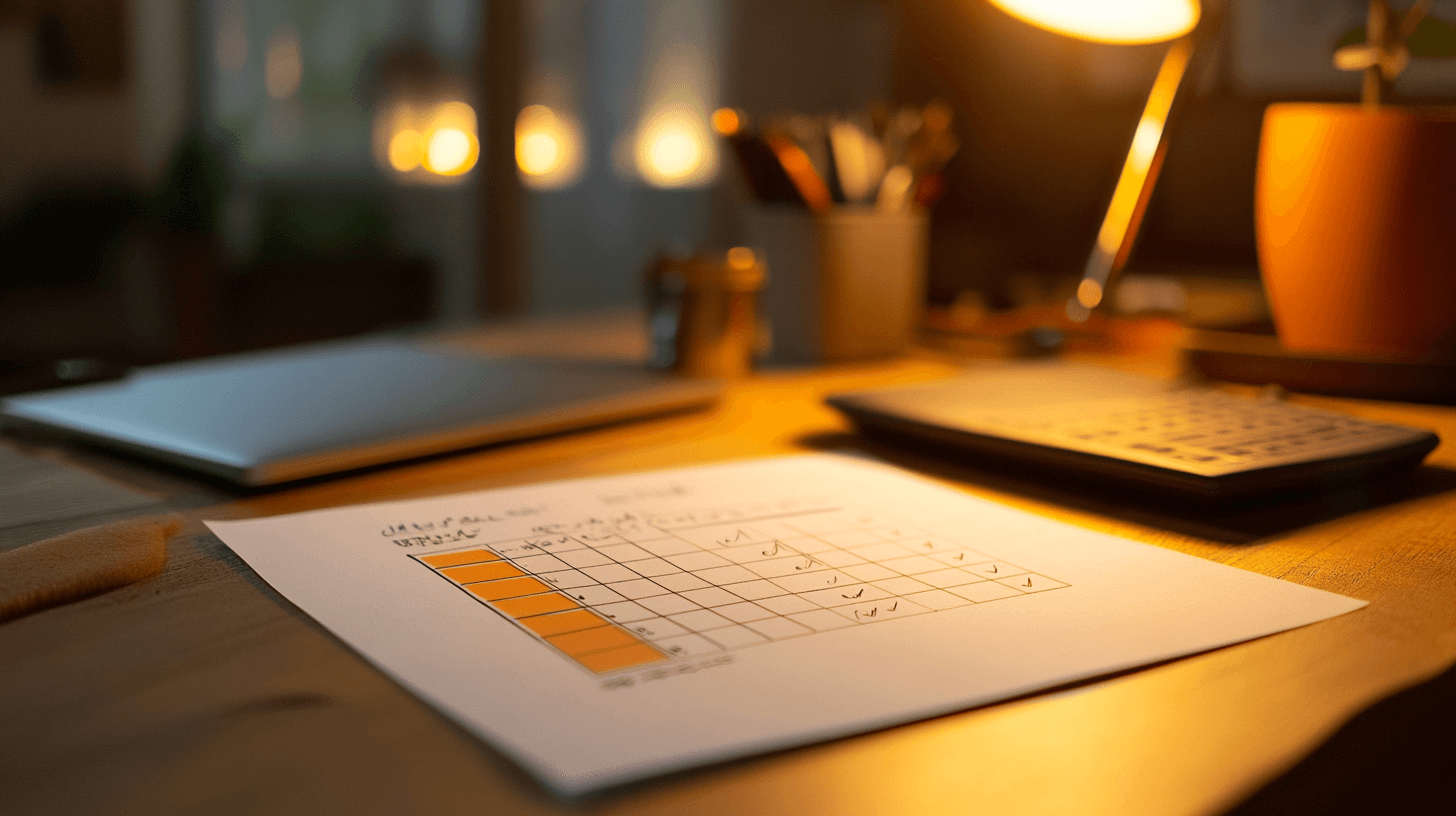

The matrix structure features two axes: one axis lists the criteria, while the other lists evaluated suppliers.

This clear, visual layout helps you objectively assess suppliers and identify the one that best aligns with your organization’s needs.

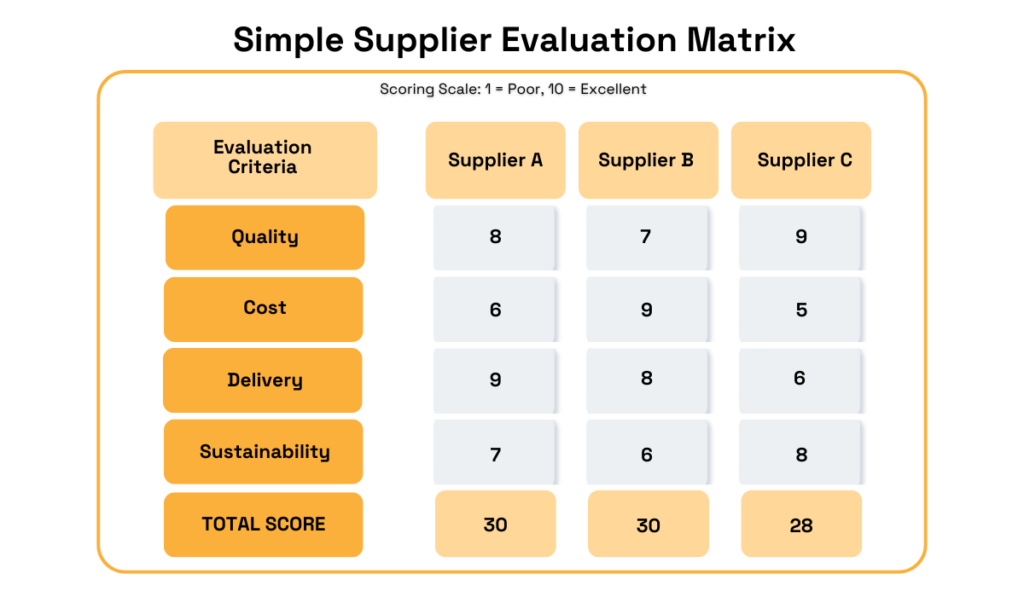

Here’s a simple template:

Source: Veridion

Of course, this simplest example of an evaluation matrix is highly flexible and can be tailored to meet your specific procurement needs.

Both axes—the criteria and the assessed suppliers—can be expanded as needed.

For example, the list of evaluation criteria can be adjusted to include factors like innovation capabilities, compliance history, and more.

As we’ll see, you can also assign weights to each criterion to reflect its importance in the decision-making process.

Similarly, the supplier axis can be expanded to include more suppliers or additional rounds of assessment for further refinement.

So, what does the matrix provide?

Essentially, it’s a summarization tool that allows you to consolidate, score, and compare all relevant supplier info in one place.

The matrix comes into play once the evaluation criteria have been established and after the initial supplier discovery and data collection have been completed.

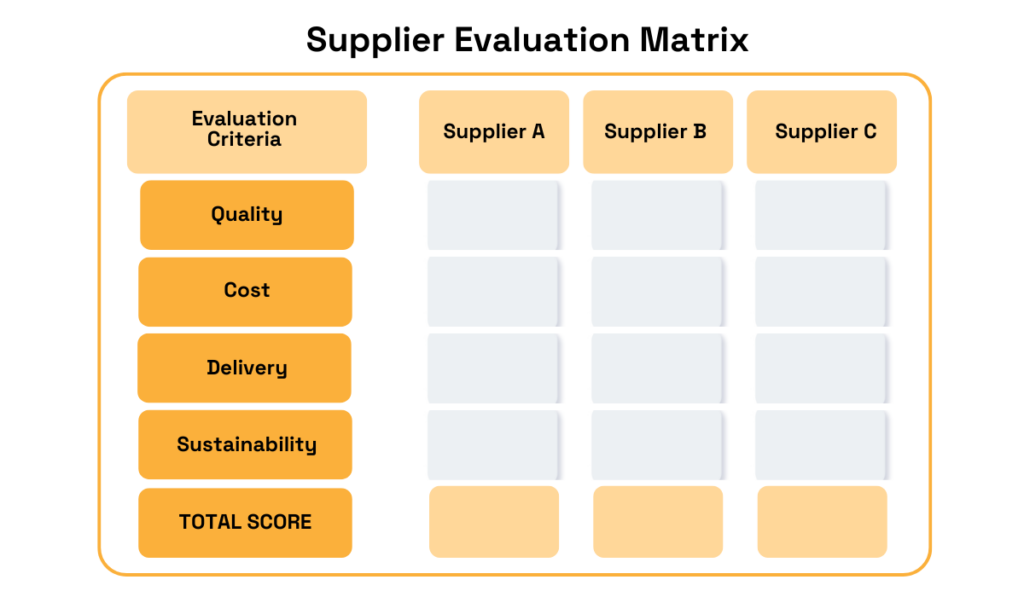

Here’s how and where the matrix fits into the overall supplier evaluation process:

Source: Veridion

As you can see, the supplier evaluation matrix is a dynamic tool used at several stages of the process to refine and finalize supplier selection.

When the groundwork—supplier data collection, vetting, and scoring—is properly done, the matrix helps ensure a structured and objective comparison.

The goal is to make supplier sourcing decisions less intuition-based and more data-driven.

Another important factor is transparency.

As Oliver Machingauta, a procurement specialist, explains:

“This ensures that the best vendors are selected based on their abilities, rather than personal connections or biases.”

With that in mind, let’s explore the different types of supplier evaluation matrices.

As we mentioned earlier, the supplier evaluation matrix is a highly flexible tool.

This flexibility is essential because supplier evaluation varies depending on the complexity and priorities of the procurement process.

In the following sections, we’ll explore three common types of supplier matrices, beginning with the simplest format.

The simplest type of supplier evaluation matrix is designed for quick and straightforward comparisons.

It typically focuses on a few standard criteria, such as cost, quality, and delivery time, with factors added as needed.

Easy to implement, this format is ideal for:

In the previous section, we introduced a simple matrix but didn’t account for scoring.

Scores are typically assigned on a scale (e.g., 1–5, 1–10) and then totaled, providing a clear snapshot of the highest-ranking supplier.

Below is an example with a scoring legend and mock scores:

Source: Veridion

As illustrated, Suppliers A and B are tied, indicating a need to either apply weights to criteria or introduce additional evaluation factors to distinguish them.

Although slightly behind, Supplier C shouldn’t be disregarded.

Despite having the highest cost and slower delivery, they excel in quality and sustainability—factors that may carry more significance depending on a company’s goals.

This example highlights the limitations of the simple matrix:

It treats all criteria as equally important and relies on a limited number of factors.

And while this makes it less effective for complex supplier evaluations, its simplicity has advantages, too.

For smaller projects with limited budgets, fewer vendors, or tight deadlines, it provides a quick and straightforward way to make informed decisions.

Additionally, it serves as an excellent tool for initial screening and shortlisting, helping to eliminate suppliers who fail to meet basic requirements.

Understanding its strengths and weaknesses helps your procurement team decide when to use the simple matrix.

For more complex needs, more sophisticated tools like the weighted matrix are often better.

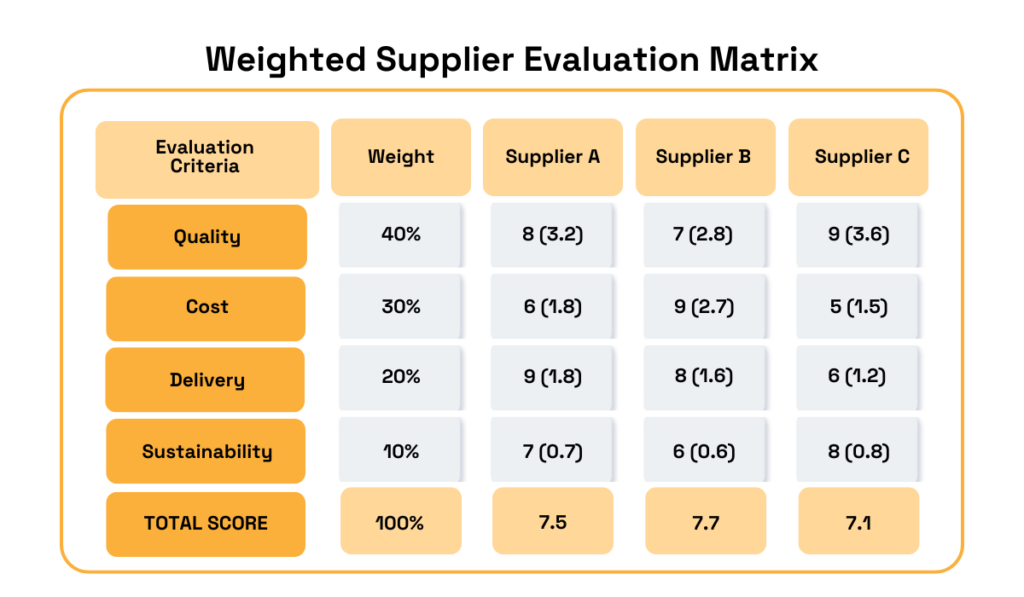

The weighted matrix builds upon the simplicity of the basic matrix by assigning different levels of importance to each criterion.

This, in turn, allows for a more tailored evaluation.

For example, if cost is a primary concern, it can be given a higher weight compared to quality, delivery time, sustainability, etc.

This approach ensures that critical factors reflect your organization’s procurement priorities.

In this method, you score vendors against each criterion, and multiply the scores by their respective weights.

You then total the weighted scores, offering a clear picture of the top-performing supplier.

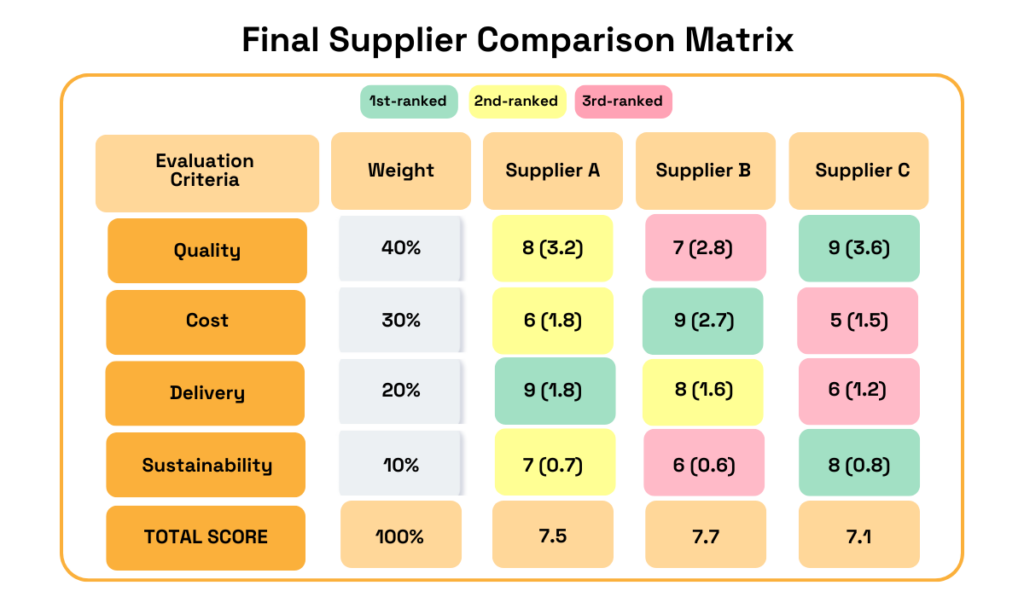

Source: Veridion

Compared to our simple matrix example, Suppliers A and B are no longer tied, with Supplier B slightly surpassing Supplier A.

Although Supplier C excels in quality—weighted at 40%, the highest of all criteria—it scores the lowest overall due to weaker performance in cost and delivery.

The weighted matrix is particularly effective for more complex decisions, where nuanced trade-offs between criteria are necessary.

By focusing on what matters most, you can make more informed decisions that balance cost, quality, and other priorities.

While assigning weights and calculating scores takes additional effort, the insights gained are invaluable for aligning supplier selection with your procurement goals.

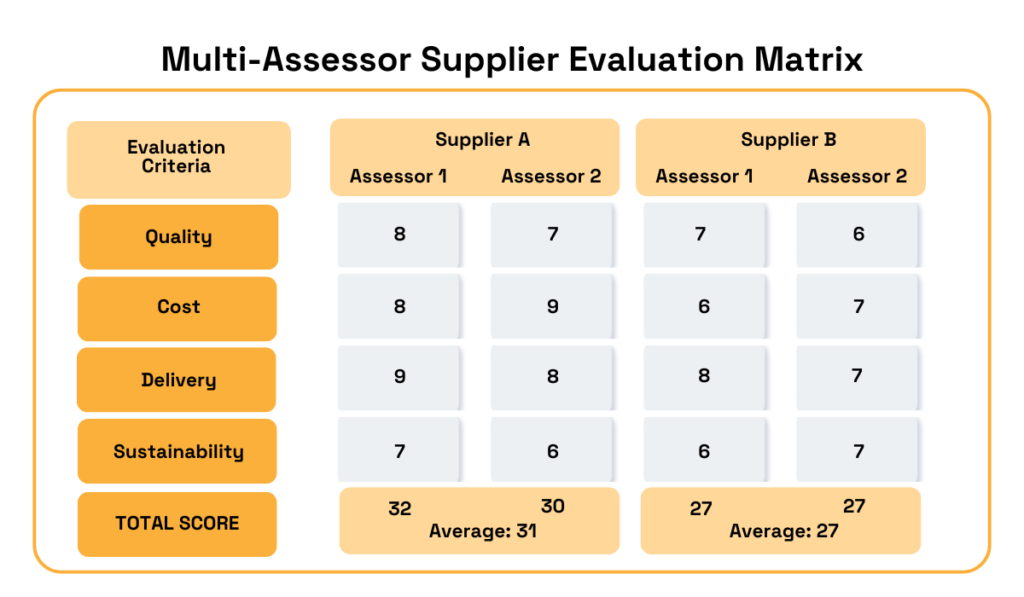

The multi-assessor matrix is a structured tool used to evaluate potential suppliers by incorporating input from multiple evaluators.

These evaluators—often key stakeholders such as procurement, operations, and finance—independently score suppliers based on predefined criteria.

This approach helps mitigate individual biases and provides a more comprehensive assessment of suppliers.

For example, one department may prioritize cost-effectiveness, while another values sustainability.

Each stakeholder independently assigns scores to suppliers, which are then averaged to create a consolidated score.

Source: Veridion

By combining scores from multiple stakeholders, the matrix captures a more balanced view of supplier performance.

This method also helps identify discrepancies among assessors.

If there are significant differences in scoring, it signals areas that may require further discussion or investigation.

The multi-assessor matrix is particularly valuable for high-stakes decisions where multiple departments are impacted.

This collaborative approach fosters transparency in the decision-making process, enabling your team to select suppliers that align more closely with your organizational goals and priorities.

Now that we’ve covered the basic types of supplier evaluation matrices, let’s see how to use them.

As discussed, any supplier evaluation matrix is primarily a data summarization tool.

This means you can leverage it at various stages of the supplier sourcing process.

Initially, once you’ve established your evaluation criteria and completed the initial search for potential suppliers, the matrix can help you shortlist the most eligible candidates.

These suppliers can then proceed to the next stages of evaluation, such as receiving an RFP or completing a questionnaire.

However, before using the matrix, you need to define your criteria and conduct the initial supplier discovery.

This stage—finding suitable suppliers—can be time-consuming and complex, especially in a globalized market.

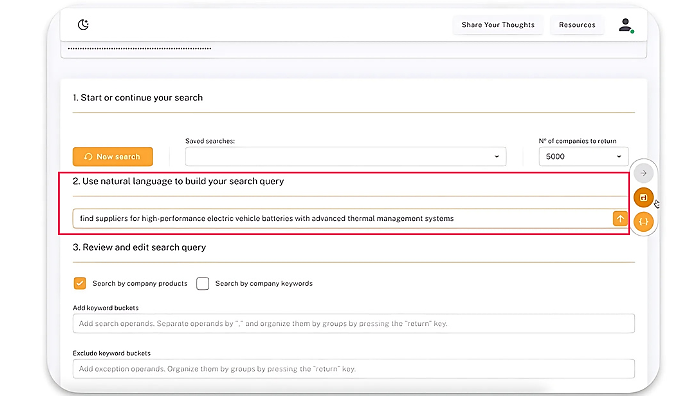

This is where a platform like our Veridion can streamline the process, enabling super-fast supplier discovery and propelling you toward the initial shortlisting matrix.

Source: Veridion

Veridion’s AI-powered algorithms continuously scan the Internet to capture real-time data on all suppliers with an active web presence.

We compile this data into a global, weekly-updated database, which currently covers over 120 million companies across more than 200 million business locations worldwide.

Using Veridion’s natural language search, you can input your specific criteria and generate a list of suppliers that meet them in a matter of seconds.

Source: Veridion

With this curated list, your team can determine which matrix type best suits the goal of shortlisting suppliers for more detailed evaluation.

After selecting the matrix type, the next step is to establish a scoring system.

This involves defining the scale for each criterion, such as a 1-10 range, and deciding whether certain factors should carry more weight than others.

Once the scoring system is set, you can use the matrix to shortlist suppliers in the first round.

Following a more in-depth evaluation of the selected candidates—based on RFP responses, questionnaires, audits, etc.—the same or an expanded matrix can be applied again.

The goal is to refine the list of second-round suppliers who submitted proposals into a final comparison matrix of, ideally, 3-5 top-ranked suppliers.

Source: Veridion

Lastly, it’s time to review the matrix and select the best supplier.

At this stage, it’s crucial to consider additional factors not captured in the matrix, such as recent changes in the supplier’s operations, financial difficulties, or regulatory issues.

This is again where Veridion’s real-time data can help.

Source: Veridion

As shown, Veridion’s features allow you to screen potential suppliers for a range of risks, as well as automate the monitoring of certain risks for your current suppliers.

In addition, you can assess suppliers’ compliance with sustainable and ethical business practices.

Source: Veridion

This capability is increasingly crucial, as companies prioritize strategic sourcing and accountability in their supply chains.

How does all this relate to your use of supplier evaluation matrices?

Simply put, the insights obtained from Veridion’s data inform your supplier matrices, leading to more detailed, accurate, and comprehensive evaluations.

This way, you can make well-informed, data-driven supplier selection decisions that align with both your operational goals and organizational values.

We hope this guide has provided some valuable insights into using supplier evaluation matrices effectively.

By systematically comparing suppliers across key criteria, these tools ensure transparency and minimize biases in the selection process.

Whether for initial shortlisting or final selection, a well-structured matrix supports the development of stronger, more accountable supply chains.

And, when paired with the right tools and strategies for supplier vetting, it enables you to select the most suitable suppliers for your procurement goals.

In the end, that’s how you ensure procurement success.