6 Mistakes to Avoid Making During Supplier Evaluation

Key Takeaways:

Believe it or not, even a single mistake during supplier evaluation can lead to serious consequences, ranging from legal risks to significant hits to profitability.

The good news?

We’re here to help you dodge these pitfalls.

In this article, we’ll uncover the six most common (and damaging) supplier evaluation errors, complete with research-backed facts and real-life examples.

By learning what not to do during this process, you’ll ultimately be able to keep your operations running smoothly, reliably, and free of unnecessary disruptions.

Let’s jump right in.

Rushing through the evaluation process can prevent you from making a clear and accurate assessment of a vendor’s performance.

And wrong assessments directly translate to wrong decisions.

If you rush, you can easily end up selecting suppliers that fail to meet your quality, reliability, or long-term requirements—a move that can cost you greatly.

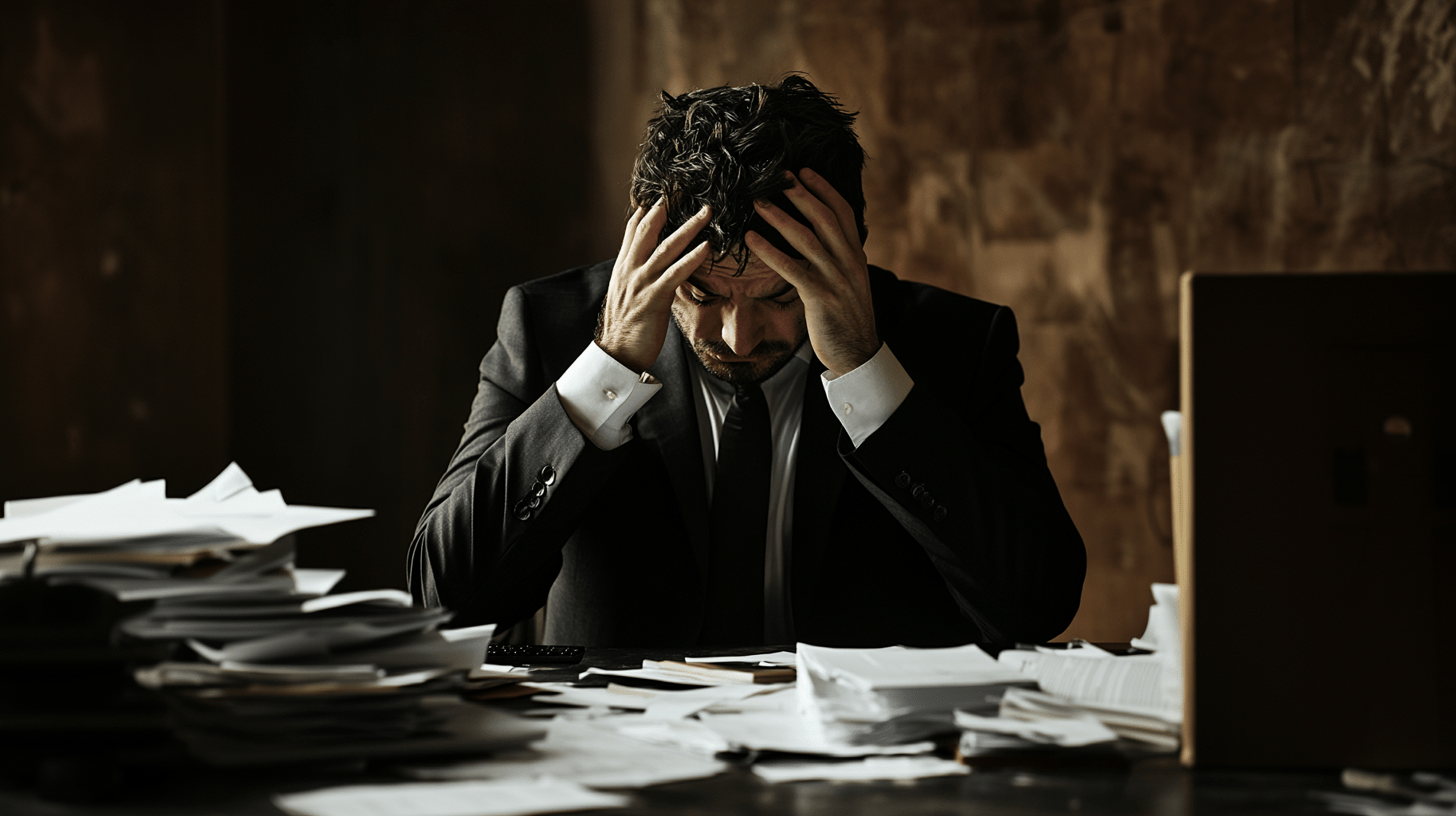

Canadian federal government learned this lesson the hard way during the COVID-19 pandemic.

In 2021 and 2022, they awarded $2 billion in contracts to a rapid COVID-19 test supplier that was later exposed for manipulating data to make their products seem more sensitive than they were.

Source: Global News

Why did this happen?

Because the government was rushing through the procurement process amidst a global scramble for resources during the pandemic.

Prime Minister Justin Trudeau confirmed this in a statement:

“During the pandemic, we were doing everything we could in unprecedented ways to get as many different ways of keeping Canadians safe as we possibly could […] every step of the way through the pandemic, it was all hands-on deck with every different way we could do to try and make sure we were saving as many lives as possible, and getting our economy back on its feet as quickly as possible.”

However, poor vendor performance doesn’t just affect public procurement: it harms all industries equally.

For instance, a 2024 Hexagon and ETQ survey found that 61% of manufacturers attribute up to half of their product recalls to supplier issues.

The cost of these recalls?

Between $8 million and $50 million.

Illustration: Veridion / Data: ETQ

Unfortunately, this is something that can happen to you as well when you cut corners in supplier evaluations.

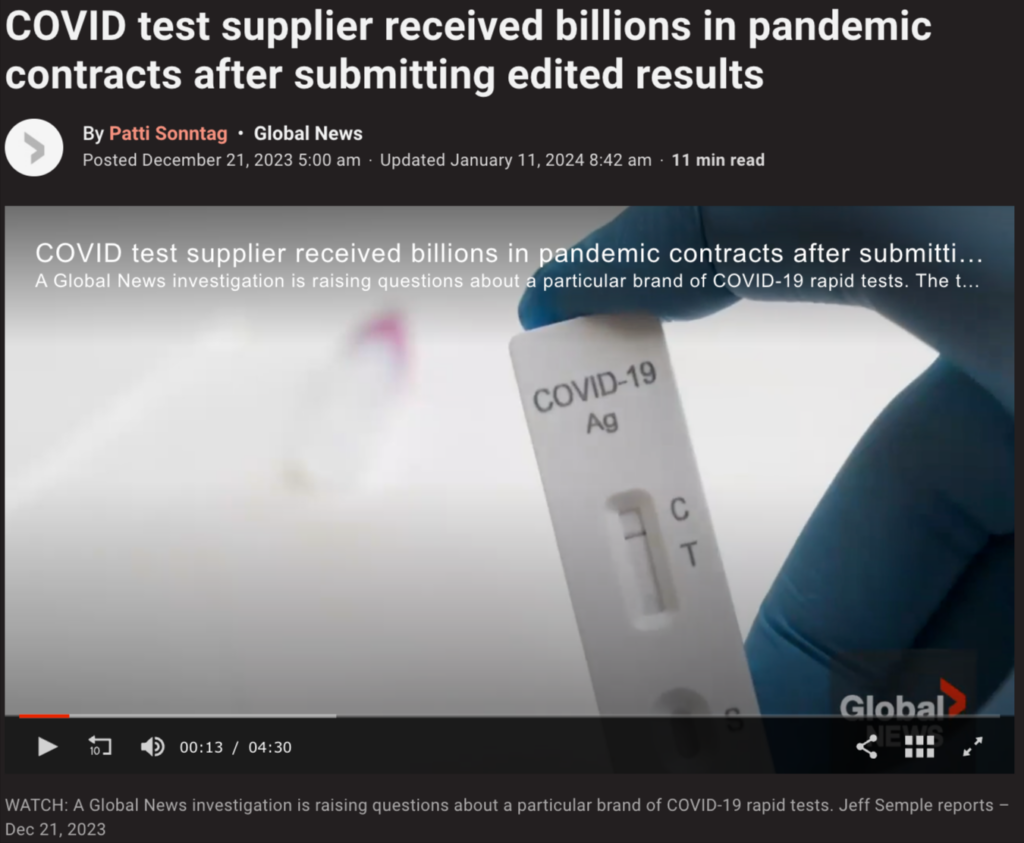

Therefore, to avoid making this mistake, consider establishing a detailed vendor evaluation checklist.

This document will help you ensure no aspect of a vendor’s performance is overlooked and create a consistent assessment process across all suppliers.

Take a page out of Sargent Aerospace & Defense’s book.

This manufacturer of aerospace bearings and hydraulic assemblies developed a supplier evaluation checklist that spans 20 pages.

Source: Sargent Aerospace & Defense

That way, they make sure nothing slips through the cracks and maintain a consistent product quality.

Remember, a rushed evaluation today can lead to costly mistakes tomorrow.

So invest in reliability, consistency, and peace of mind by creating a thorough supplier assessment checklist.

Poor or limited communication before, during, and after supplier evaluation can render the entire process practically futile.

Why?

Because without proper dialogue, suppliers may misunderstand your expectations, assessment criteria, and even feedback.

In turn, this can prevent them from properly demonstrating compliance with your standards or addressing issues identified during the evaluation.

And doesn’t that defeat the whole purpose of this process?

According to the HICX supplier survey, poor communication between buyers and suppliers is a quite common problem.

As it turns out, 98% of suppliers believe communication with buyers needs improvement.

Even more concerning is the fact that 33% struggle to find key information, like compliance requirements and sustainability policies—the very things they’re being evaluated on.

Illustration: Veridion / Data: HICX

If they can’t find this information, how can they be expected to meet your standards?

Fortunately, this mistake is easily avoidable with frequent and open communication.

For example, Candice Bolivar, Category Manager at FleetPride, a distributor of truck and trailer parts, shares that her team holds weekly or biweekly meetings with suppliers.

Illustration: Veridion / Quote: Fleet Equipment

After all, they expect a lot from their partners, so regular discussions keep everyone on the same page and performing at their best.

So, if you’re trying to achieve a more transparent and effective evaluation process that drives meaningful progress, talk to your suppliers—regularly and honestly.

It’s that simple.

Focusing on short-term needs and ignoring long-term compatibility, i.e. how a supplier fits into your broader goals can be a recipe for disaster.

At best, a supplier that’s not a long-term match won’t be able to adapt as your business grows, hindering your operations.

At worst, they won’t be able to adhere to your standards at all, potentially leading to legal trouble or reputational damage.

Take, for example, the Samsung Galaxy Note 7 incident.

In 2017, just two months after launching the new mobile phone, the company had to recall over 2 million units.

What caused this?

Well, due to errors in both design and manufacturing, batteries from two different suppliers had critical flaws that caused them to overheat and catch fire.

Source: BBC

Although these defects originated with the suppliers, Samsung accepted full responsibility, admitting they failed to properly assess the suppliers’ design and manufacturing processes.

Ultimately, their narrow focus on achieving the exact product specifications within tight timelines made them completely overlook the supplier’s ability to deliver a reliable product.

This cost them not just in trust and reputation, but financially too: they reportedly lost about $5.3 billion because of this incident.

Then there’s the Rana Plaza collapse in 2013.

In an effort to cut costs, 29 global brands sourced garments from factories housed in the Rana Plaza building in Bangladesh, without evaluating the quality and safety of their operations.

Had they performed their due diligence, they’d have known that the supplier’s business practices were anything but safe.

Structural cracks had been discovered in the building, but factory owners ignored warnings to vacate it, ordering their workers to return to work.

Finally, on April 24, 2013, the building collapsed, killing more than 1,100 people and injuring thousands more.

Source: The Daily Star

According to a report from Clean Clothes Campaign, the garment industry’s largest alliance of labor unions and non-governmental organizations, each buyer was just as responsible as the supplier.

Their focus on cheap, fast production meant they turned a blind eye to long-term safety risks.

And they paid the price in public outrage, operational disruption, and the eventual costs of finding new suppliers.

This disaster remains a painful reminder that chasing short-term benefits without assessing long-term risks and compatibility never pays off and can, in fact, have catastrophic consequences.

So, during supplier evaluation, ask yourself—can they support your business in the long run?

Are there any guarantees they can maintain consistency in terms of safety, quality, and scalability, even if your needs change?

If not, you could end up in Samsung’s shoes—or worse, linked to a tragedy like Rana Plaza.

Not evaluating suppliers’ financial health exposes your company to significant risks.

When you ignore this critical step, you might miss signs of trouble, only to be blindsided later by issues like supplier bankruptcy, failure to meet demand, or a sudden drop in quality.

For instance, Ineos Automotive, a British manufacturer of off-road vehicles, recently had to halt production of its popular Grenadier and Quartermaster models due to the bankruptcy of a supplier.

Source: Acko Drive

This wasn’t just any supplier—it was the provider of a crucial part without which they simply can’t make the cars.

Now, until a new supplier is found, production is on hold.

Had the company been monitoring the supplier’s financial health, they just might have spotted the warning signs early enough to secure alternatives.

But Ineos is not the only one who has to deal with this problem.

According to the 2024 Sphera report, financial risks are on the rise as high inflation rates in the EU and the U.S. have eroded vendors’ purchasing power.

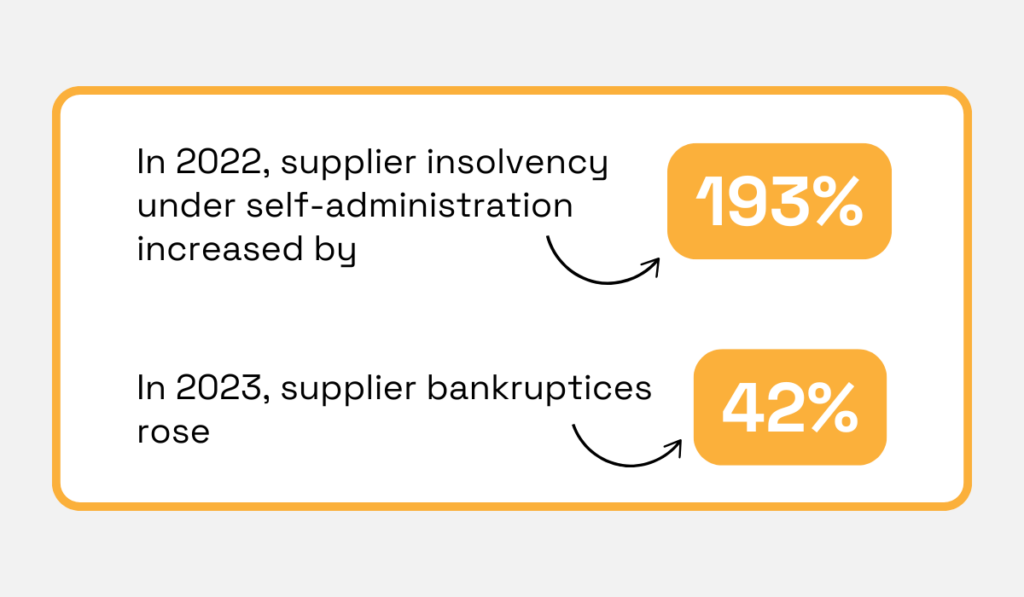

As a result, insolvencies under self-administration soared by 193% in 2022, followed by an additional 23% increase in 2023.

Moreover, bankruptcies, which dipped by 6% in 2022, rose sharply by 42% in 2023.

Illustration: Veridion / Data: Sphera

However, keep in mind that these problems rarely arise overnight.

That’s why evaluating your suppliers’ finances is paramount.

It enables you to spot red flags early, allowing you to sidestep any surprises, secure alternative suppliers, and keep your operations running smoothly.

According to Venminder, a TPRM platform, reviewing these types of financial information is a good starting point:

| Financial ratios | current ratio, profit margins, total liabilities |

| Financial statements | balance sheet, income statement, cash flow statement |

| Customer and supplier concentration | suppliers with a single customer who makes up more than 25% of their revenue base pose a greater risk |

| Creditors | banks that back the supplier |

| Type of debt/financing | the type of debt or equity the supplier raised or has access to |

With such a proactive approach, you’re more likely to stay ahead of risks, minimize disruptions, and protect your business from costly fallout.

Overlooking a supplier’s environmental and social responsibility practices is a big mistake for several reasons.

For one, it can negatively impact your profitability.

Modern customers increasingly expect sustainably sourced products and if you don’t deliver, they just might look elsewhere.

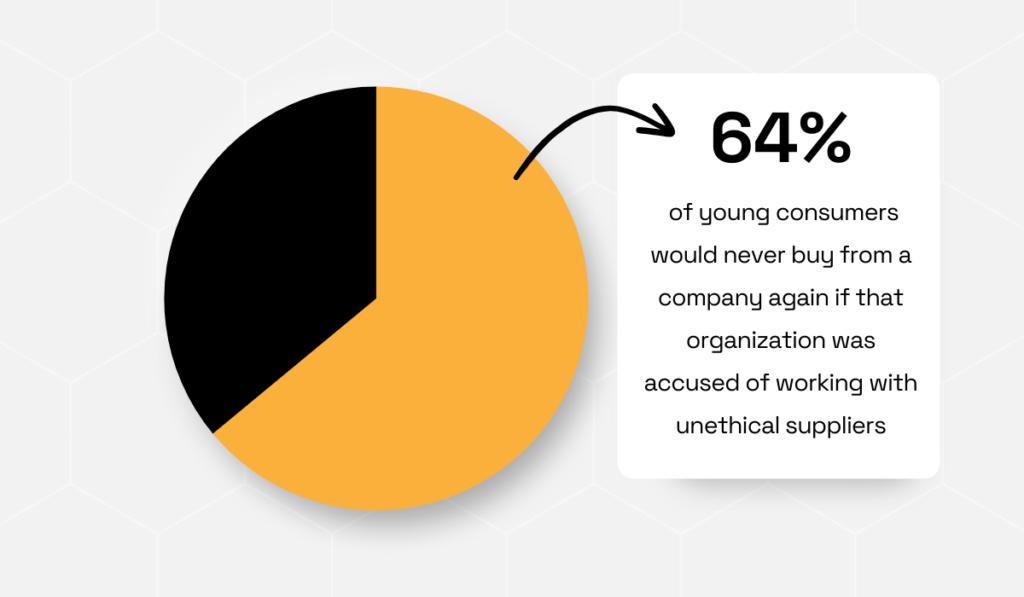

This is in line with findings from an OpenText survey, which shows that 64% of consumers would never buy from a company again if it was accused of working with unethical suppliers.

Illustration: Veridion / Data: OpenText

Secondly, by overlooking this important element of supplier performance, you risk reputational damage.

Take Shein, for instance.

Despite pledging in 2021 to address labor violations, recent reports revealed that workers for some of their suppliers are still putting in 75-hour workweeks.

Source: BBC

The result?

A storm of criticism and growing doubts about Shein’s commitment to improving conditions.

And, as it is evident from this Reddit thread, many feel conflicted about buying from them precisely because of these unethical practices.

Source: Reddit

Thirdly, ignoring your suppliers’ sustainability practices (or lack thereof) could expose you to legal risk.

Starbucks, for example, faced a lawsuit alleging that it sourced coffee from farms engaged in human rights abuses.

The claims include reports of child labor, unsanitary conditions, and wage withholding at farms in Guatemala, Kenya, and Brazil.

Source: NBC News

So, how do you avoid becoming the next cautionary tale?

The answer lies in actionable, trustworthy insights about your suppliers’ ESG practices.

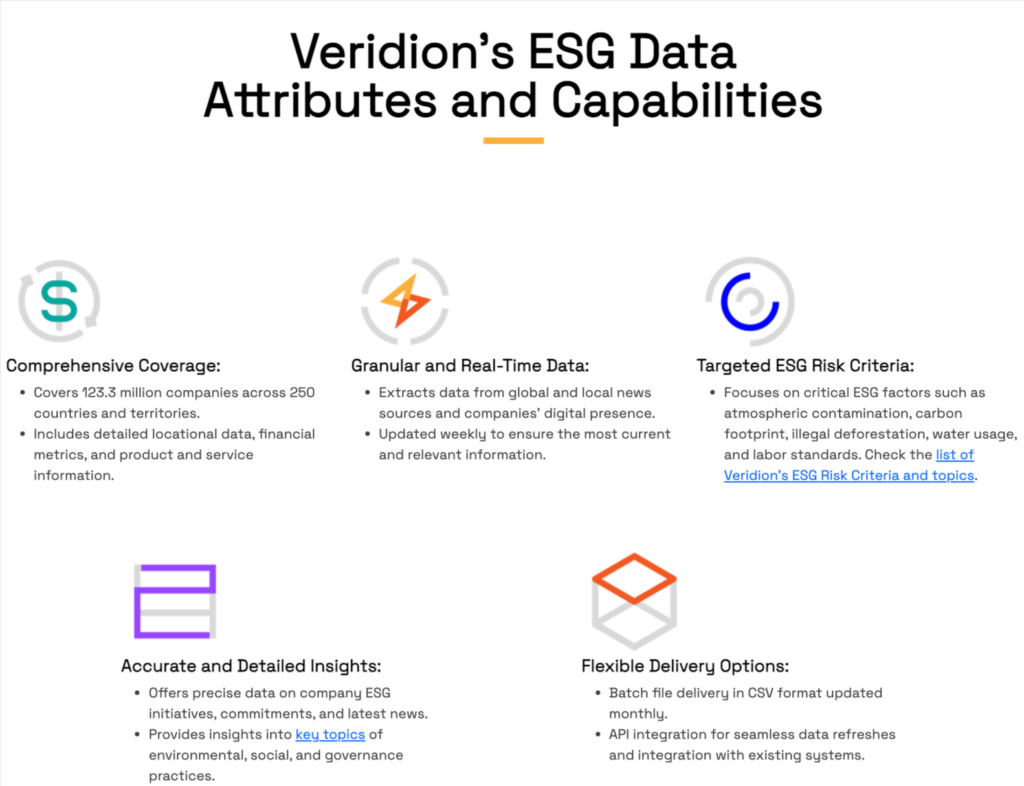

That’s where supplier data platforms like Veridion come in.

Veridion monitors millions of operating companies across hundreds of geographies, updating its database weekly, with an extensive validation process to ensure the highest data accuracy.

Source: Veridion

But our data isn’t just accurate, fresh, and broad—it’s also extremely detailed.

Here’s just a portion of the ESG criteria Veridion tracks:

This comprehensive data supports evaluations of suppliers’ greenhouse gas (GHG) emissions, biodiversity risks, human rights violations, and more.

And thanks to our real-time ESG News and Sustainability Commitments Data, you can easily detect risk and assess how serious your suppliers really are about their ESG targets.

Keep in mind that sustainability isn’t a trend—it’s a requirement.

Ignoring it can destroy your reputation, lose customer trust, and even land you in court.

But with the right tools, you can mitigate risk and lead the way toward a more responsible and resilient supply chain.

Forgoing visits to supplier facilities means missing an opportunity to verify their capabilities and practices firsthand.

This is a big mistake because suppliers sometimes misrepresent their production capacity or quality standards, leading to significant challenges once a contract is in place.

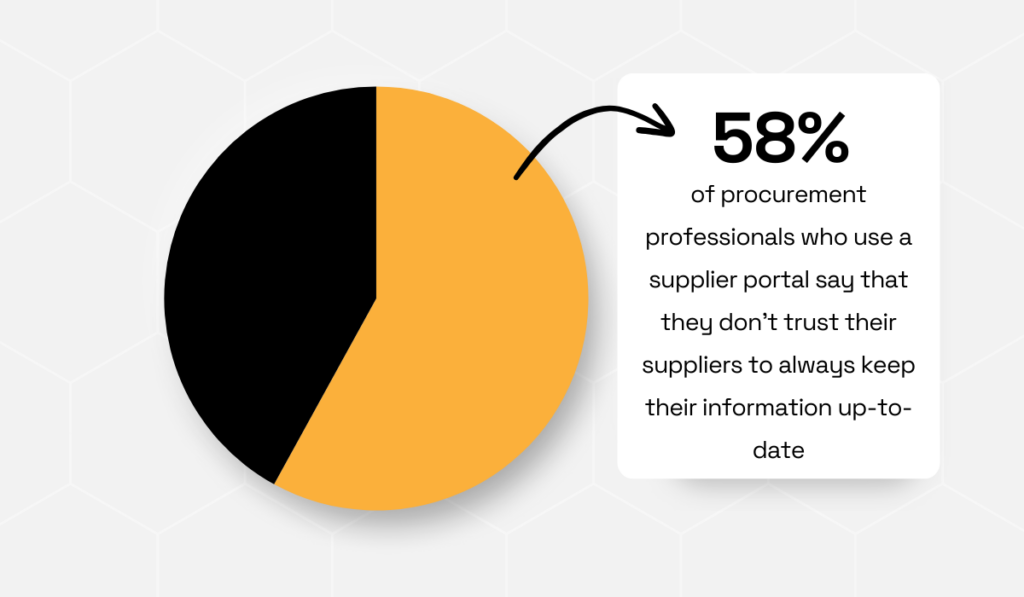

The 2020 TealBook survey proves that vendors aren’t always the most reliable source of information.

Namely, 58% of procurement professionals using supplier portals admitted they don’t fully trust suppliers to keep their information up-to-date.

Illustration: Veridion / Data: TealBook

And what happens when you work with unreliable supplier data?

Dior recently found out.

One of their leather bag suppliers was charged with illegal labor practices, including forcing workers to sleep on factory premises and endure excessively long hours.

While Dior was reportedly unaware of these issues, they still faced considerable public backlash, illustrating the risks of relying only on vendor-provided information.

Source: Fortune

Here’s the bottom line: as a buyer, you need to know what’s really happening behind the scenes.

This is where on-site visits come into play, helping you uncover potential red flags and ensuring your standards are met.

After all, seeing is believing, especially when it comes to supplier evaluation.

Have you ever caught yourself making any of these supplier evaluation mistakes?

Hopefully not!

But even if you did, there’s no need to worry—there’s always time to make improvements and turn things around.

Here’s the secret: success starts with reliable supplier data.

Whether it’s insight into ESG practices, financial stability, process quality, or safety standards, you need the full picture to make smart decisions.

So, take your time, equip yourself with the right tools to gather accurate data, and you’ll be well on your way to avoiding these mistakes in the future.