7 Key Questions to Ask During Supplier Evaluation

Evaluating suppliers is simultaneously the most important and most challenging part of procurement.

It requires you to look beyond the surface-level criteria and ask the questions that will reveal whether a supplier is truly the best match for your organization.

But what questions should you be asking?

We’re here to help you with that.

In this article, we’ll discuss seven key questions to ask during supplier evaluation and explain why they’re so important.

By the end of it, you’ll know exactly what to pay attention to if you want to make the most informed supplier decisions.

Here’s the first question.

You want each supplier to meet product quality.

So it’s essential to ask how they ensure the consistent delivery of high-quality products.

Ensuring your suppliers have rigorous quality control measures minimizes the risk of receiving defective products.

This also prevents the negative consequences that go hand in hand with poor quality, like customer dissatisfaction and brand reputation damage.

To inquire suppliers about this, there are two key areas to start with:

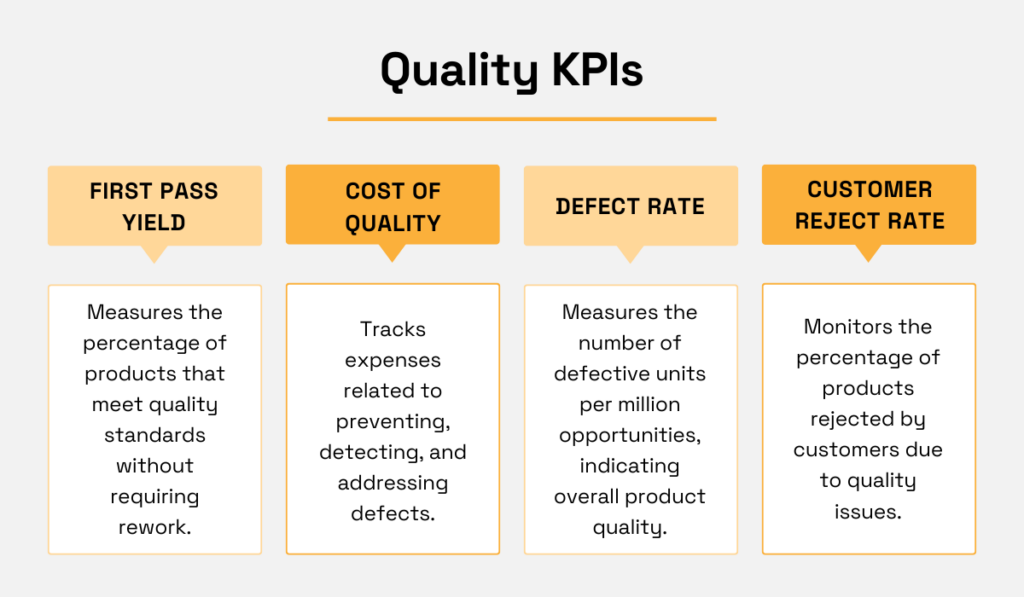

Suppliers committed to providing only the highest quality will be measuring their performance using KPIs like the ones you can see below.

Source: Veridion

Regarding certifications, it’s good to ask whether they hold the well-known ISO 9001 one, or perhaps some industry-specific certifications.

When it comes to obtaining ISO certifications, suppliers will have to go through a certification body and annual surveillance audits for them to be renewed.

Making the effort to remain certified signals that they’re committed to maintaining high standards in quality management.

So, if they’re able to provide information on this, that’s a green flag.

But, since supplier evaluation should be an ongoing activity, it’s also essential to consistently work with suppliers to improve their quality performance.

Take Honda, a world-renowned vehicle manufacturer for example.

Their VP of purchasing David Nelson, emphasizes the importance of continuous collaboration between their purchasing and parts quality departments, and the suppliers.

Illustration: Veridion / Quote: Cutting Tool Engineering

On top of that, Nelson explains, whenever one of their suppliers has a new part or process, Honda sends their team to evaluate it.

That way, any potential issues are addressed early, and Honda ensures that the new approach aligns with their quality expectations.

Overall, asking your suppliers about how they ensure consistent product quality is a crucial element of every thorough supplier evaluation.

So, if you want to maintain high standards in your supply chain, don’t forget to ask it.

Making sure that your suppliers’ products meet your quality standards won’t mean much if they’re not delivered within the agreed-upon timeframe.

Timely delivery of goods can be especially challenging in times of increased demand and unforeseen disruptions.

Yet, you want to ensure business continuity and continue meeting your customers’ expectations.

That is why you need to ask your suppliers whether they’re able to maintain delivery schedules under challenging circumstances, and how they manage to do so.

The findings of BCI’s 2023 Supply Chain Resilience Report further underscore the importance of this.

Namely, the majority of organizations stated that their immediate suppliers were the ones that caused disruptions in the supply chain.

Source: BCI

If you don’t want your organization to be part of that statistic, ask your suppliers whether they have contingency plans—such as alternative suppliers or transportation routes—in place.

Aside from this, gauge their use of technology, as it plays a key role in ensuring timely deliveries even under unfavorable circumstances.

Sai Pothuri, a global logistics and supply chain professional, explains:

Illustration: Veridion / Quote: LinkedIn

So, if your (potential) suppliers inform you that they use these advanced technologies, that is a good sign.

Such tools help them anticipate fluctuations in demand, monitor the progress of their shipments, and quickly react to disruptions.

All of this translates into enhanced supply chain resilience—and that is exactly what you want.

Once you’ve verified that a supplier can provide high-quality goods and deliver them to you on time in the face of challenges, it’s time to talk about pricing.

And by that, we don’t mean just getting the information about the product base price.

They also need to be able to break down the full cost structure, including things like:

Sue Robinson, Chief Executive of the National Franchised Dealers Association (NFDA), representing car and commercial retailers, agrees.

“Transparent pricing structures are crucial. Dealers should seek suppliers who provide clear and comprehensive pricing information, helping to avoid unexpected costs and budgetary challenges.”

Aside from helping you decide whether the offered price is within your budget, a clear understanding of the pricing structure can also help you negotiate a better deal.

This was exactly the case for the Silent Pool Distillers.

This company uses tin strips to seal their gin bottles, so when the price of tin went up by 400%, their suppliers increased the price of seals.

Due to this, the distillery’s founder and managing director Ian McCulloch asked the supplier for a breakdown of the pricing structure.

Illustration: Veridion / Quote: Raconteur

Had he not asked for more details, he wouldn’t have been able to negotiate this deal that worked out for both of them.

Namely, while Silent Pool Distillers reduced the price increase, the supplier still got to maintain their profit margin.

This example showcases something very important:

By encouraging suppliers to be transparent about their pricing structure during the evaluation process, you not only ensure you stay within budget but also maximize value for money.

The next question aims to understand the supplier’s sustainability commitment.

Why asking about their sustainable practices matters is clear: sustainability is becoming increasingly important to consumers and regulatory bodies alike.

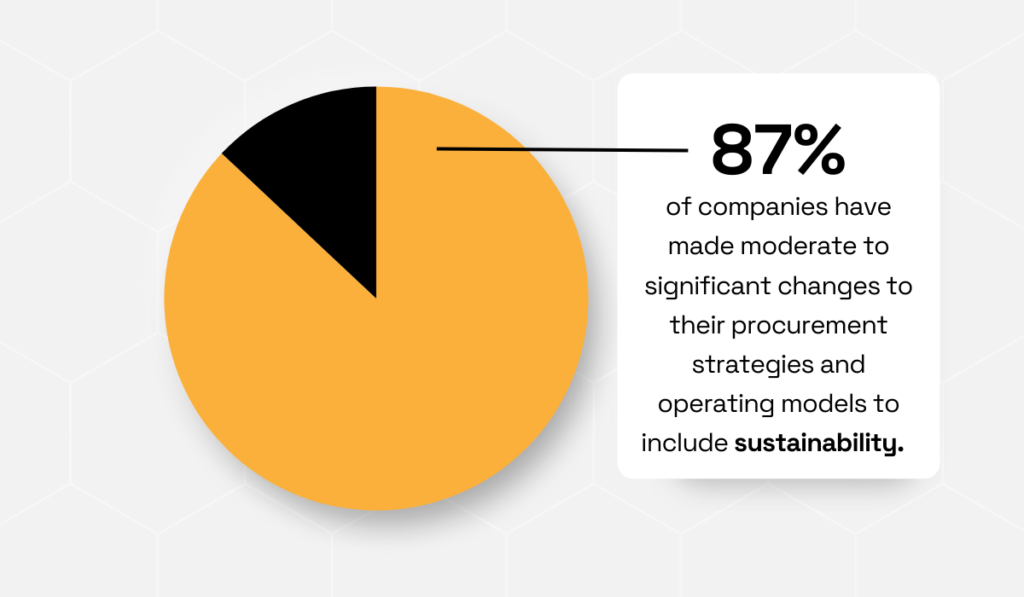

Research shows that more and more organizations are becoming aware of this, and are adopting changes to meet sustainability goals.

The findings of the 2024 Sustainable Procurement Report are a testament to this.

Illustration: Veridion / Data: Ignite

Working with suppliers that meet sustainability standards should, therefore, be non-negotiable.

To achieve this, you need to find out what the supplier is doing to reduce their environmental impact, and whether they’re using eco-friendly materials and processes.

You can also ask whether they hold certifications from the ISO 14000 family, or ask for details about their carbon footprint reduction efforts, waste management practices, and resource conservation.

But the truth is, finding out whether your suppliers truly take sustainability seriously is often easier said than done—even for major companies like H&M and Zara.

Source: Supply Chain Dive

Namely, these fashion giants found themselves at the center of a scandal earlier this year due to their suppliers’ poor sustainability practices.

The investigation into the matter found that the cotton provided by their suppliers was being grown on stolen and deforested land in Brazil.

To make matters worse, this happened even though supplier audits have been conducted, and yet, none of these issues were flagged.

Given that stories like this are coming out more and more frequently, going the extra mile to ensure your suppliers are truly following sustainable practices is a necessity.

Thankfully, there are tools out there—like our Veridion—that can help you with that.

Veridion is a multifaceted data platform that provides its users with the freshest, most accurate business data, covering millions of companies around the globe.

Source: Veridion

Veridion also recognizes the role that Environmental, Social, and Governance (ESG) factors play in supplier evaluation.

So, we provide comprehensive, accurate, and real-time ESG data on your suppliers, both current and prospective.

Source: Veridion

We use advanced AI technologies to monitor millions of companies with an online presence, tracking changes to their operations on a weekly basis to help you ensure you’re working only with those that meet your sustainability criteria.

Simply enter the company’s name and operating location, and we’ll deliver the supplier information you need—including details on their net zero targets, certifications, and any adverse or controversial media.

You can also explore our ESG criteria list to see the data points we can provide in just minutes.

There’s no denying that verifying the sustainability of your suppliers’ practices should be an essential part of supplier evaluation.

So, go the extra mile to make sure your new partners truly meet your sustainability criteria.

This goes hand in hand with the sustainability practices we just covered.

While the sustainability factor is more focused on the environmental impact of your suppliers’ operations, ethical sourcing and labor compliance focus on producing goods under fair and humane conditions.

And, with modern slavery being such a big issue today, it’s only natural you want to ensure that your organization doesn’t work with suppliers that participate in it.

How big is the issue?

The research brief on modern slavery in global supply chains has the answer.

Illustration: Veridion / Data: Justice and Care

With that in mind, it’s important to approach inquiries about a supplier’s labor practices with genuine intent, not just as a formality.

As Koray Köse, Chief Industry Officer of Everstream Analytics, puts it:

“It’s not just a checkbox exercise where you say that you are compliant. It is an affirmation of your product quality, brand, and innovation that speaks to the customers and the choices they make.”

So, when you’re evaluating suppliers, make an effort to thoroughly verify their health and safety standards adherence, fair wage practices, labor laws, and safe and inclusive working environments.

This is an area where it’s best to ask the supplier to provide the relevant documentation and combine it with unbiased data from independent third-party sources.

Jane Broberg, Chief HR Officer for Basware, a cloud-based purchase-to-pay solution, explains why being thorough when asking these questions is so crucial.

Illustration: Veridion / Quote: CPO Strategy

The importance of taking your suppliers’ adherence to fair labor practices seriously cannot be overstated.

Not only does it help make sure that your organization doesn’t contribute to the issue of modern slavery—it can also safeguard you from reputational damage and legal risks.

In other words, being diligent about this benefits everyone, so make fair labor practices a non-negotiable part of your supplier evaluation process.

Providing clients with updates and feedback and being responsive when it comes to addressing issues is another key trait to look for in a supplier.

So, instead of assuming that a supplier will naturally communicate as expected, ask about their communication approach explicitly.

Why?

Because effective communication enables the quickest possible resolution of potential issues and contributes to a healthy, trust-filled business relationship.

Gavin Semrow, CEO and Founder of Ai Restoration, a building exterior remediation company, agrees with this, explaining that good communication skills are what he values the most in suppliers:

“Communication and honesty, and being available to talk with us about products, needs and deliverables, etc., when needed. Also, setting real expectations—knowing and stating truly when something will be available or delivered.”

To gauge how well a supplier matches your communication style, ask about their preferred communication channels, response times, and escalation procedures for urgent issues.

However, since good communication is a two-way street, make sure to be transparent about your communication preferences, too.

This helps set expectations from the get-go and creates a strong foundation for collaboration.

Conversely, a lack thereof can break your supplier relationships.

Don’t believe us?

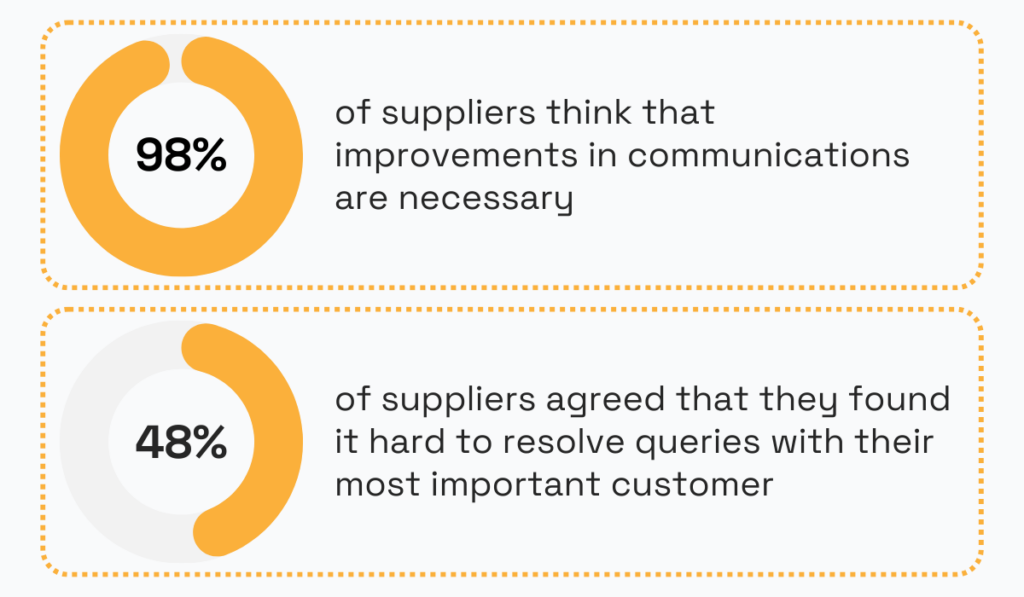

Take a look at the results of the Voice of the Supplier Survey, showcasing how suppliers feel about customer communication.

Illustration: Veridion / Data: HICX

As you can see, issue resolution can’t hinge only on your suppliers’ communication skills. You need to ensure timely and clear communication on your end, too.

Ultimately, successful collaboration relies on shared responsibility and effective communication from both parties.

So take the time to understand how your supplier prefers to communicate and work together to establish a common ground.

Supplier evaluation is an excellent opportunity to assess a supplier’s commitment to staying ahead of industry trends.

When considering a new supplier, you want to think long-term and ensure that they’re able to grow with you.

This means you need to ask them what steps they’re taking to incorporate innovation and adopt new technologies and processes.

But why is this important?

Aside from what we just mentioned, suppliers who innovate can also expose you to new, more efficient, cost-effective, or advanced products, propelling your business forward.

This happened when Unilever partnered with Arzeda, a biotechnology company.

Source: Unilever

Together, they developed enzyme innovations that:

It is safe to assume that Arzeda’s commitment to innovation was one of the reasons why this consumer goods giant decided to partner with them.

This begs the question, how can you assess whether your prospective suppliers have this kind of forward-thinking approach, too?

Here are some questions you can ask:

The way they answer these and similar questions will help you understand whether they’re a good fit for your organization.

One factor to pay special attention to is the supplier’s use of innovative technologies like automation or artificial intelligence to improve their products and services.

Brandon Rael, a global digital transformation and commerce expert, explains why.

Illustration: Veridion / Quote: Castlefield Recruitment

If your suppliers show they’re familiar with these technologies and are actively incorporating them to develop new and advanced products, that is a good sign.

After all, innovation is essential for them to stay competitive and meet your evolving needs.

By asking the right questions, you can easily identify forward-thinking partners who will do just that.

We hope that this article has provided you with some guidance on what to pay attention to during your supplier evaluations.

Ultimately, supplier evaluation isn’t just about ticking boxes and getting the task of the way.

It’s an opportunity to ask the right questions about matters like product quality, reliability, innovation, and sustainability, all of which are crucial to the success of your operations.

By asking these questions, you’re not only identifying the best partners today.

You’re also investing in a supply chain that is going to be resilient, efficient, and aligned with your values for years to come.