6 Tips for Successful Supplier Optimization

Key Takeaways:

With supply chain disruptions as the new normal, supplier optimization matters more than ever.

It helps organizations improve visibility, enhance planning, and make faster, smarter sourcing decisions, ultimately reducing risk and increasing resilience.

In this article, we’ll explore six strategies that can help you optimize supplier operations and build a supply chain that’s ready for anything.

When optimizing suppliers, it’s all about what you can predict will happen and acting proactively to keep your organization ready for what’s coming.

This includes everything from shifts in customer demand to supply constraints and external shocks like tariffs, natural disasters, or geopolitical conflict.

That’s why proactive supply chain planning focuses on anticipating disruptions that could impact cost, continuity, or customer satisfaction, and not just reacting to them.

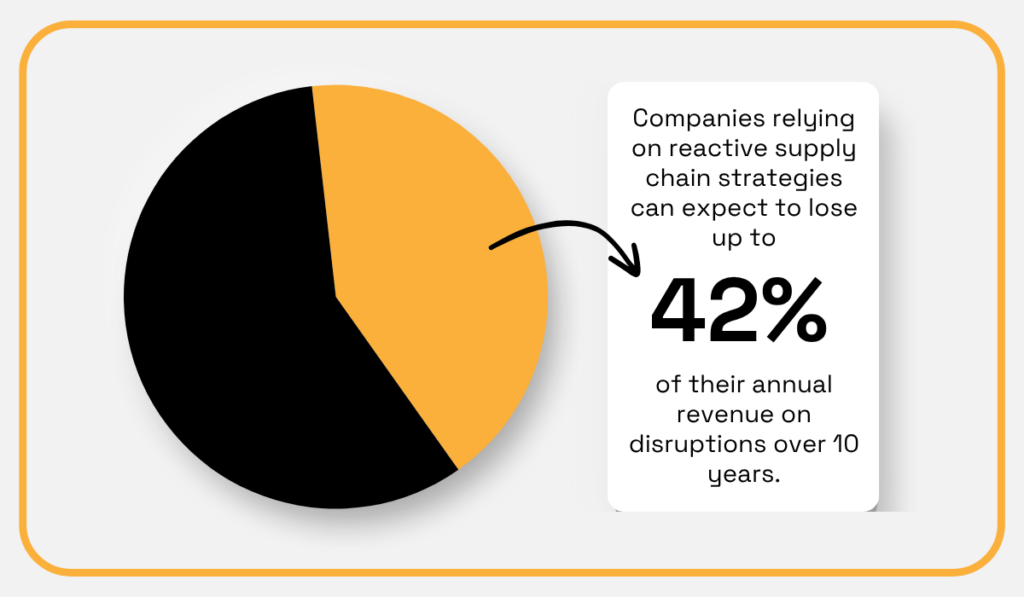

In fact, a McKinsey report found that companies relying on reactive supply chain strategies could lose more than 4% of annual revenue, adding up to an average of 42% over a decade.

Illustration: Veridion / Data: McKinsey

To avoid such losses, organizations are investing in smarter, more forward-looking supply chain strategies.

Put differently, proactive planning can take many forms, including:

Let’s take demand forecasting as an example.

While historical sales data still matters, leading companies now leverage additional signals to sharpen their forecasts.

For instance, Coca-Cola uses weather forecasts to anticipate surges or drops in regional beverage demand, as discussed in the article shown below.

Source: Smith Institute

With this approach, Coca-Cola can proactively adjust distribution strategies ahead of heat waves to ensure product availability and maximize sales.

On the flip side, if forecasts predict heavy rain during a national holiday, Coca-Cola can launch targeted promotions or discounts to stimulate lower-than-expected demand.

This same data-driven approach to planning can also be used to anticipate supply constraints, assess regional risks, or reallocate resources based on real-time disruptions.

The key to optimizing supplier operations is acting early before issues become costly.

And with today’s “unpredictability” forecast, planning ahead isn’t optional.

It’s the foundation for supply chain success.

Of course, planning runs smoother and decisions become smarter when all relevant data is accessible in one place.

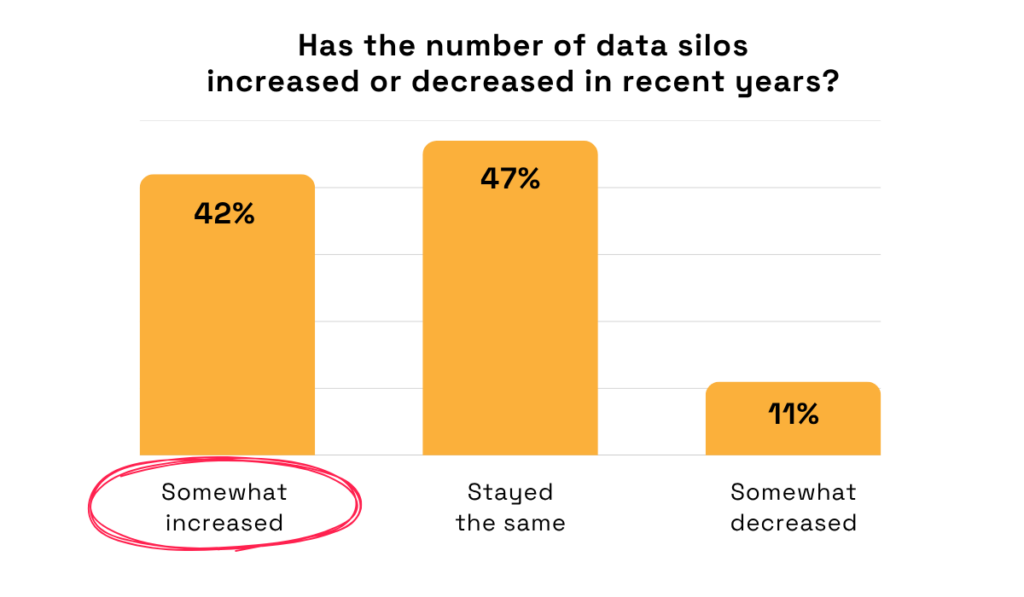

However, data silos remain a common challenge, making it difficult to get a full picture of procurement spend, supplier performance, risk exposure, and inventory availability.

As a result, decisions are delayed or made based on incomplete information.

A 2023 industry study by XPLM highlights this persistent issue:

Illustration: Veridion / Data: XPLM

To break down these silos, companies are adopting centralized supplier data platforms that integrate information from ERP systems, procurement tools, and external databases.

By consolidating supplier profiles, contract terms, risk assessments, and performance data into a single source of truth, organizations can enhance decision-making, eliminate duplication, and gain full visibility across their supply base.

But centralized data doesn’t just support smarter decisions. It also creates a foundation for automation and advanced analytics.

Here’s an example of a platform designed to, among other things, centralize all supplier data:

Source: HICX

Naturally, supplier data centralization can be a slow and complex process, depending on organizational size, legacy systems, and procurement complexity.

For example, Dole Sunshine Company faced a traditional, decentralized procurement structure, especially with indirect suppliers.

In response, they launched a program to digitize, centralize, and standardize procurement processes in 2020.

One year later, Dole’s Director of Global Indirect Categories and Procurement Excellence, Naissa von Pein, said:

Illustration: Veridion / Data: Supply Chain Digital

She added that this approach enabled a more strategic way to source relevant categories, improving overall supplier optimization.

By centralizing data, organizations like Dole reduce manual effort, streamline sourcing activities, and gain clearer insight into supplier relationships.

Although data centralization can be resource-intensive and time-consuming, it lays the foundation for smarter, faster decisions that directly support supplier optimization.

It also empowers companies to build stronger supplier relationships and more effectively monitor performance, which we’ll explore further in the following two sections.

The idea of building collaborative, mutually beneficial relationships with suppliers isn’t new.

It remains a cornerstone of supplier optimization: close supplier relationships are often the most effective strategy for improving outcomes.

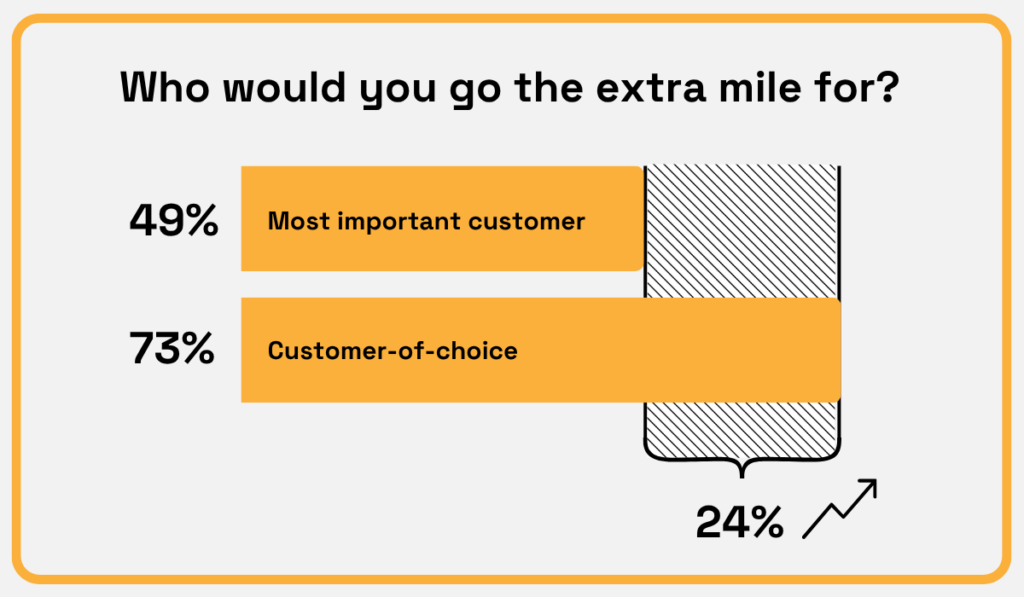

After all, it’s human nature to go the extra mile for those who show us respect and value our contributions.

Conversely, when suppliers feel like replaceable cogs in a machine, your optimization efforts are unlikely to deliver their full potential.

A HICX survey reveals a significant gap between how suppliers respond to their biggest customer versus their preferred customer:

Illustration: Veridion / Data: HICX

The 24% difference in supplier engagement highlights a key distinction: is the supplier treated as a transactional vendor or a valued partner?

Naturally, there are many ways to build stronger supplier relationships.

But the foundation is consistent: clear expectations, open communication, and a collaborative mindset.

Once that foundation is in place, partnerships can be deepened through:

For example, the Austrian supermarket chain SPAR offers suppliers the opportunity to become preferred partners.

How?

By providing incentives such as access to its broader partner network and performance-based rewards.

Source: SPAR

From launching supplier innovation projects to forming joint ventures, the goal remains the same: build stronger relationships that align supplier capabilities and foster mutual growth.

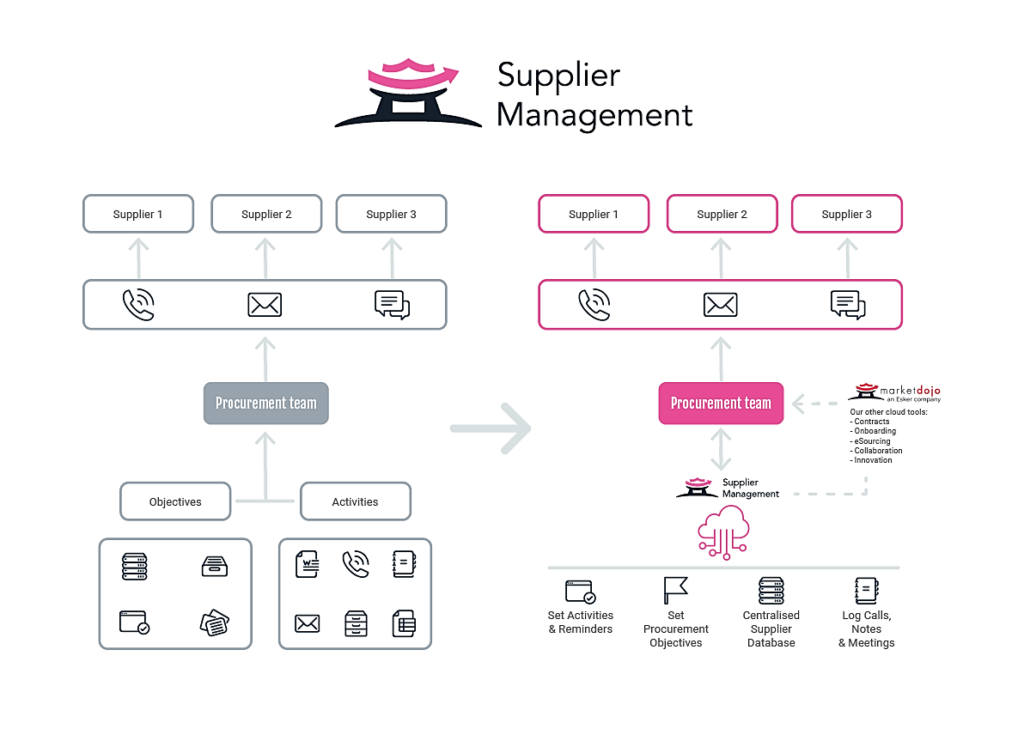

Managing this kind of collaboration is far easier with Supplier Relationship Management (SRM) software, which helps track performance, mitigate risks, and generate insights that support strategic decision-making.

Notable SRM platforms include Ivalua, Jaggaer, Coupa, and Market Dojo.

The image below illustrates how SRM tools centralize key functions—such as communication, monitoring, and performance tracking—to simplify supplier management.

Source: Market Dojo

Such tools allow your team to actively manage and continuously monitor supplier relationships over time.

When supported by the right systems and mindset, strong supplier relationships drive greater resilience, innovation, and long-term value.

One of the biggest advantages of SRM software is its ability to support ongoing supplier performance monitoring, which brings us to our next tip.

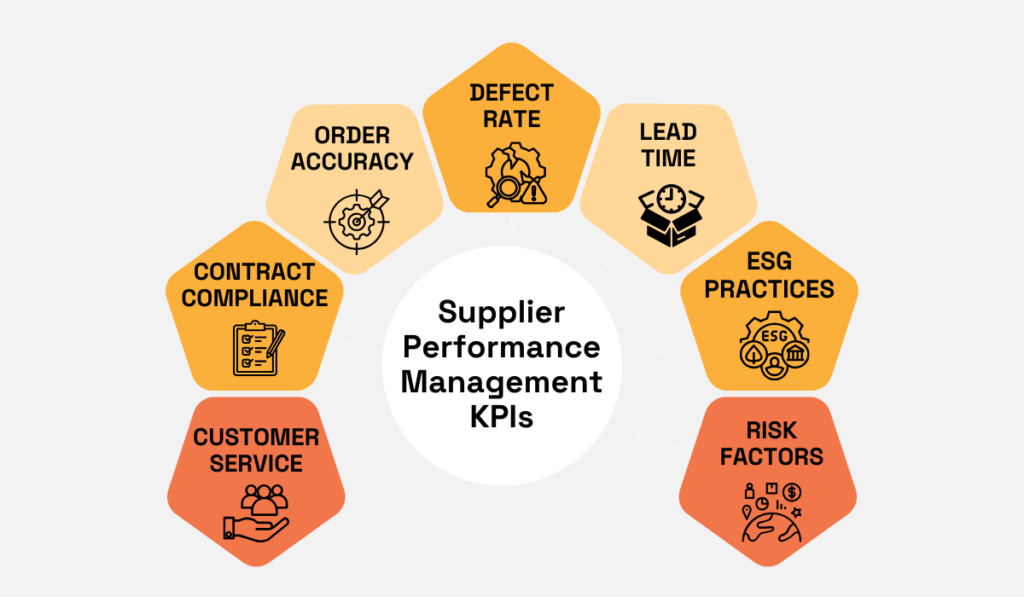

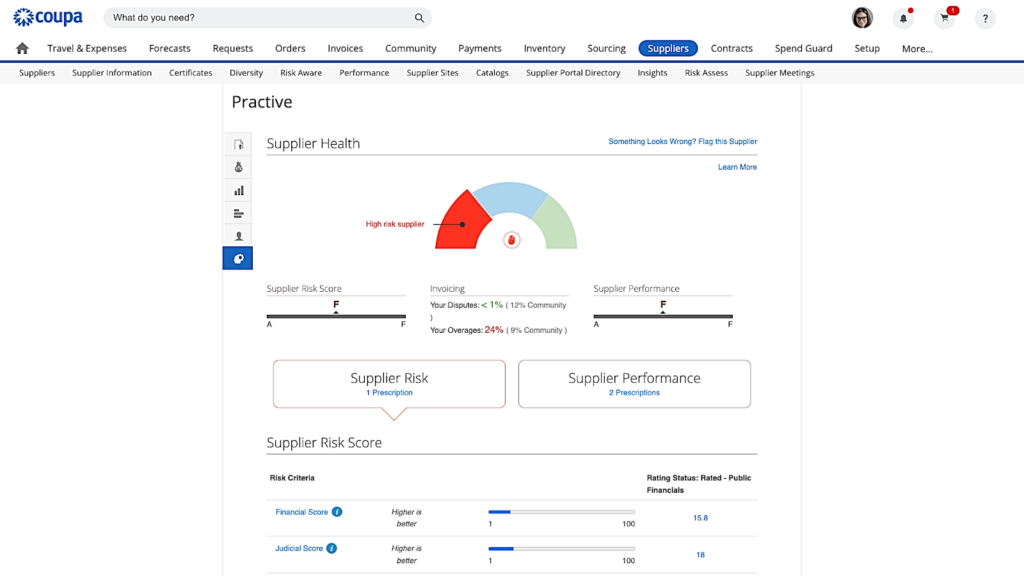

Consistent performance monitoring is critical for successful supplier optimization.

After all, you can’t improve what you can’t measure.

Without reliable tracking, issues like late deliveries, quality defects, or contract noncompliance can slip through the cracks until they escalate.

That’s where the SRM platforms mentioned earlier come in.

They give procurement teams the ability to monitor key supplier performance indicators (KPIs) in real time.

These typically include metrics like order accuracy, lead time, ESG practices, and other critical factors, as shown in the image below.

Source: Veridion

Tracking these and other KPIs over time allows your team to identify underperforming suppliers early and take corrective action.

SRM platforms use performance dashboards and alerts to highlight risk trends, such as late shipments, rising defect rates, or declining ESG scores.

These insights help you address problems collaboratively with the supplier or reconsider your relationship.

Source: Coupa

Monitoring also enables continuous improvement by supporting regular performance reviews and setting clear expectations that lead to better outcomes for both buyer and supplier.

Take delivery delays, for instance.

If a manufacturer notices that a supplier is consistently late, they can take informed action.

This can translate to launching a delivery improvement initiative, introducing a secondary supplier, or gradually phasing the underperforming vendor out.

As Chris Audet, Chief of Research at Gartner, emphasizes, proactive monitoring is key to managing supplier risk over time:

Illustration: Veridion / Quote: Gartner

By establishing clear performance benchmarks and monitoring them regularly, procurement teams can:

When paired with diversification and dual-sourcing strategies, performance monitoring becomes a cornerstone of supplier optimization.

Ultimately, it lowers costs, minimizes risk, and creates opportunities for improved efficiency and innovation.

We’ve already mentioned tools that centralize supplier data and SRM platforms that support performance monitoring and relationship building.

But these are just the tip of the iceberg, reflecting the crucial role technology has in enabling more efficient, data-driven supplier optimization.

Thanks to advances in machine learning (ML) and, more recently, generative AI, procurement teams now have access to automation tools for nearly every use case.

In fact, experts at consulting firm KPMG estimate that up to 80% of procurement activities could be automated using these technologies:

Illustration: Veridion / Quote: KPMG

The reason for such high estimates of automation potential is simple: modern technologies now support automation at nearly every stage of the supplier lifecycle.

From supplier discovery and qualification to performance monitoring and risk detection, these tools reduce manual effort, minimize delays, and improve accuracy.

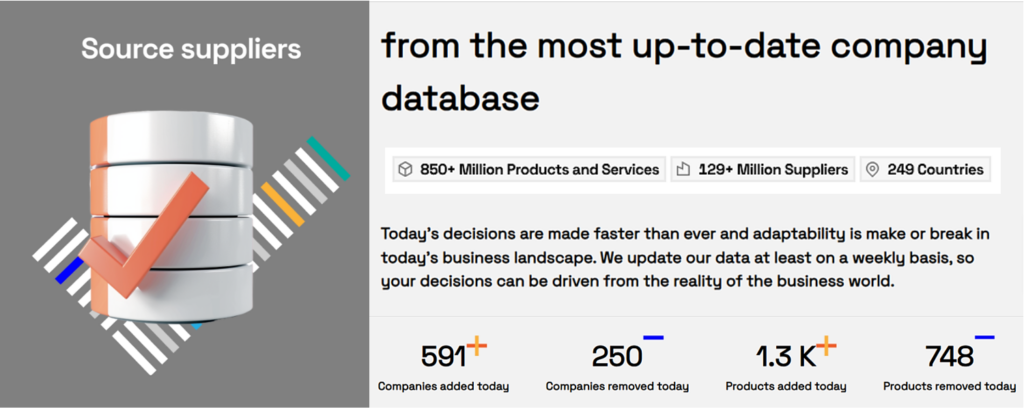

Take finding new suppliers, for example.

Traditionally, sourcing suitable suppliers could take weeks or months of research and manual vetting.

Now, AI-powered platforms like Veridion can deliver a curated list of suppliers in seconds, based on real-time, regularly updated company data.

Source: Veridion

McKinsey estimates that solutions like Veridion can cut supplier discovery time by over 90%.

Similar efficiency gains can be achieved with other automation tools—for example, supplier onboarding software can reduce onboarding time by up to 80%.

And these technologies don’t just digitize and simplify manual processes.

They also deliver valuable insights into suppliers and the broader market.

Ultimately, they empower procurement teams to make faster, data-driven decisions, reduce risk, and optimize supplier sourcing, performance, and overall relationships.

Strategic outsourcing to strengthen your supplier network involves partnering with specialized external providers to manage specific supply chain functions.

This can range from outsourcing production (contract manufacturing), logistics, or customer service to outsourcing the entire supplier discovery and relationship management.

Just like the outsourcing models vary, so do the goals.

For instance, many companies seek expertise or capabilities they lack or find too costly or complex to develop in-house.

A common example is third-party logistics (3PL) providers.

Companies of all sizes use them to outsource warehousing, packing, shipping, and inventory management.

With many local and international 3PL options available, review platforms like Gartner Peer Insights can help evaluate providers.

Source: Gartner

Another benefit of outsourcing is that it allows companies to focus on their core business while leveraging the expertise and economies of scale offered by external partners.

In supplier management, this could mean outsourcing tasks such as:

But beyond operational support, outsourcing can also accelerate business growth.

When companies expand into new markets or scale rapidly, outsourcing becomes a strategic enabler.

As Peter D. Gibbons, former EVP of Global Supply Chain Operations at Starbucks, puts it:

Illustration: Veridion / Data: Supply Chain Exchange

Of course, outsourcing does carry some risk of overreliance and cost inflation.

However, in many cases, it also transfers certain risks to external providers—typically through contract provisions related to performance, liability, and compliance.

When chosen strategically and managed effectively, outsourcing can enhance flexibility, reduce operational burden, and strengthen your overall supplier network.

The key lies in balancing internal capabilities with external support to ensure alignment with broader supply chain goals.

Optimizing supplier operations is not a one-time fix.

Rather, it’s an ongoing process that requires the right combination of strategy, tools, and partnerships.

From proactive planning and data centralization to leveraging technology and strategic outsourcing, each of the tips we laid out in this article plays a role in supplier optimization.

By aligning these tactics with your organization’s broader business goals, your team can reduce risk and costs, as well as unlock long-term value and innovation across your supply chain.