Supplier Management — The Ultimate Guide

Key Takeaways:

Have you ever struggled with poor supplier performance, miscommunication with vendors, or a lack of visibility into your partners?

If yes, you have to improve your supplier management.

Today, we will cover everything you need to know about effective supplier management—what it is, why it matters, and the common mistakes to avoid.

By the end, you’ll know how to overcome any issues in your own supplier management processes and maximize the value of your vendor relationships.

Let’s begin with the basics.

Supplier management encompasses a set of processes that allow organizations to choose, qualify, onboard, transact, and collaborate effectively with the right suppliers.

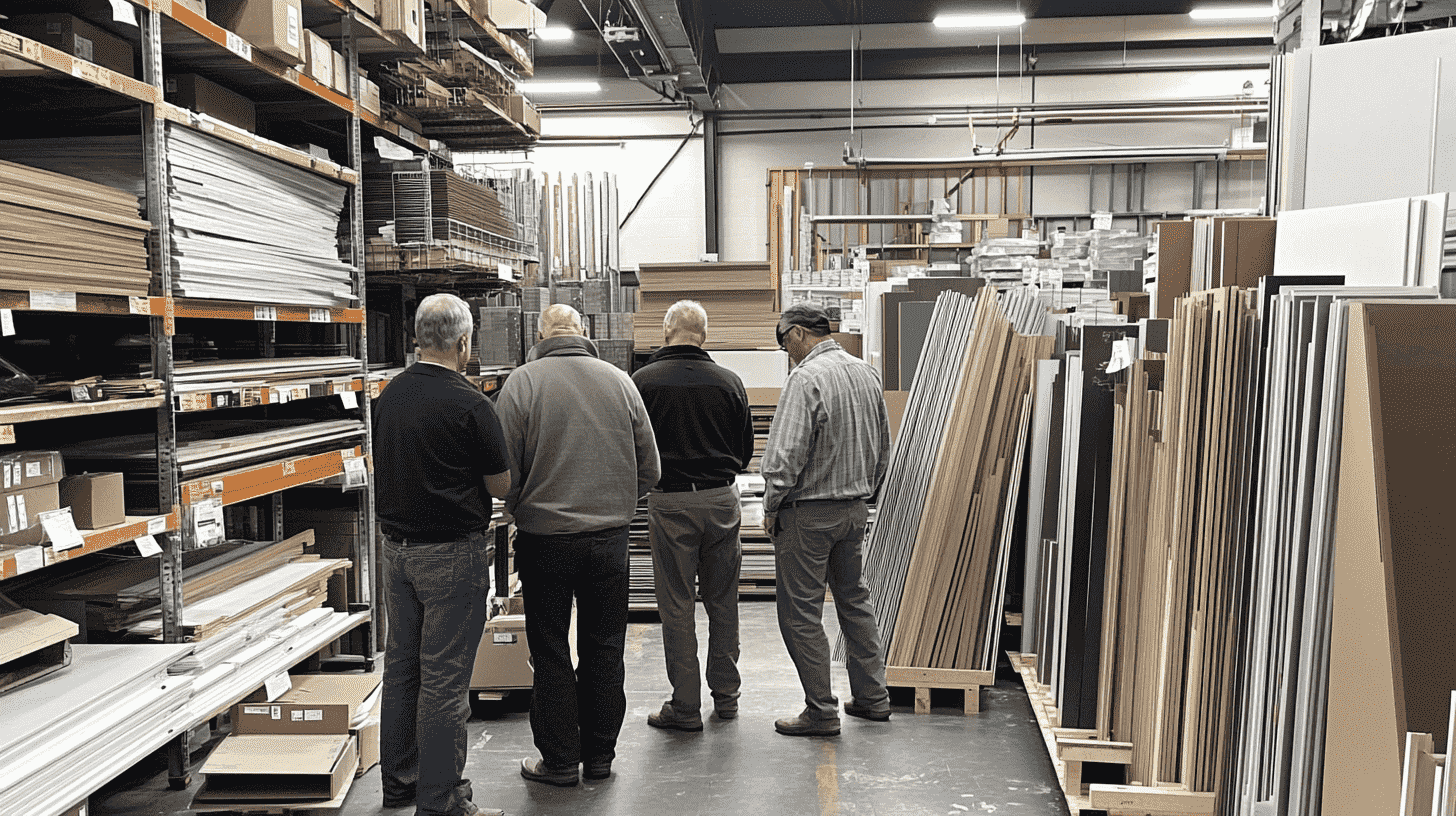

While it may sound quite straightforward, it’s a multifaceted process involving many different phases:

Source: Veridion

As you can see, today, supplier management isn’t just about simple buyer-supplier transactions like it used to be.

Anja Allen, Partner at the technology consulting practice EY, explains how supplier management evolved over time:

“Vendor management has evolved from basic contract, SLA [service level agreement], and financial management to a multidisciplinary capability that is focused on preventing value leakage in partnerships, maximizing the value of partnerships, and managing the long-term risk for the organization.”

This evolution has been both necessary and beneficial.

Modern, strategic supplier management unlocks a variety of advantages for companies, from better preparedness for disruptions to significant cost savings.

The 2024 State of Flux survey confirms this.

It shows that 92% of business leaders already have a defined and fully documented business case for supplier management.

Moreover, they point to numerous tangible benefits as a result, including the following:

Illustration: Veridion / Data: State of Flux

Clearly, supplier management is a vital component of both procurement and modern business strategy.

Let’s take a closer look at what this process involves.

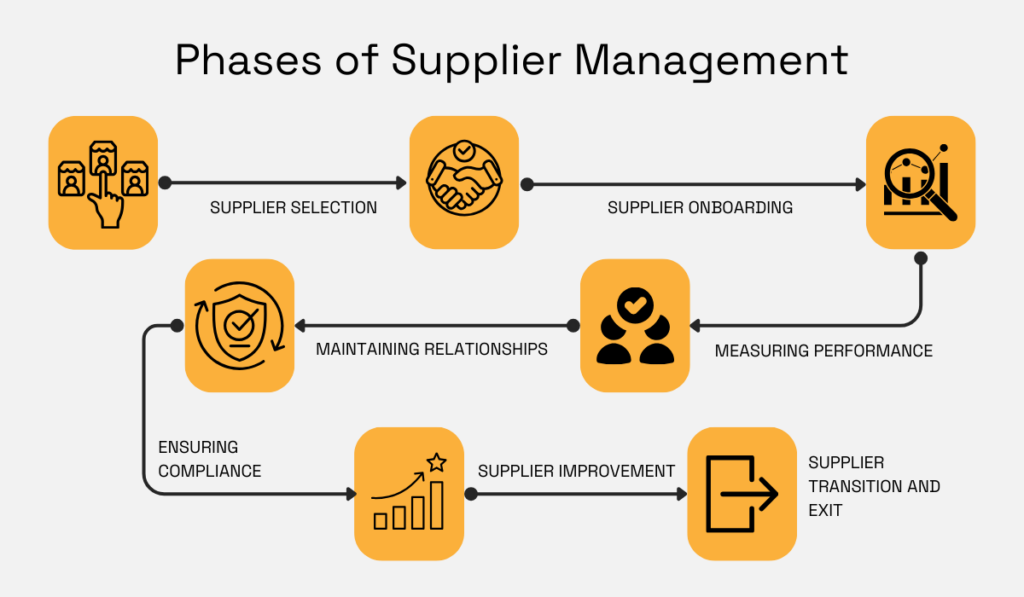

Supplier management can be divided into four core elements, as illustrated here:

Source: Veridion

Let’s break it down.

First up is supplier lifecycle management.

This process involves managing every phase of a vendor’s journey with your organization, from the first interactions to the eventual conclusion of the commercial relationship.

The key here is to treat these relationships consistently throughout the whole journey and not simply focus on cost savings or meeting your immediate needs.

This ensures you select high-quality suppliers from the get-go and keeps them performing at their peak the entire time.

Then, there is supplier performance management, which focuses on measuring, analyzing, and managing vendors’ performance.

As such, this process allows you to identify and address potential issues before causing harm to both parties.

Yessica Feng, Director of Business Development at Yearstar Care, a reusable medical textile manufacturing vendor, explains why this is so important:

Illustration: Veridion / Quote: LinkedIn

In doing so, you minimize your own risks, boost visibility across your operations, and create greater value for your products or services.

Supplier relationship management (SRM) is the third component of supplier management.

This part of supplier management focuses on nurturing and maintaining strong buyer-supplier partnerships to boost collaboration, innovation, and, potentially, improved service.

Sometimes, you can even unlock preferential treatment, which is particularly valuable during challenging times.

Nicholas Fiorentino, CEO of The Meatery, experienced this firsthand.

Thanks to his vendors, his company completely avoided the consequences of beef shortages.

Illustration: Veridion / Quote: Shopify

Lastly, supplier risk management focuses on identifying, assessing, and mitigating supplier-related risks to ensure resilience and agility.

That’s right: suppliers can both mitigate risks and be their source.

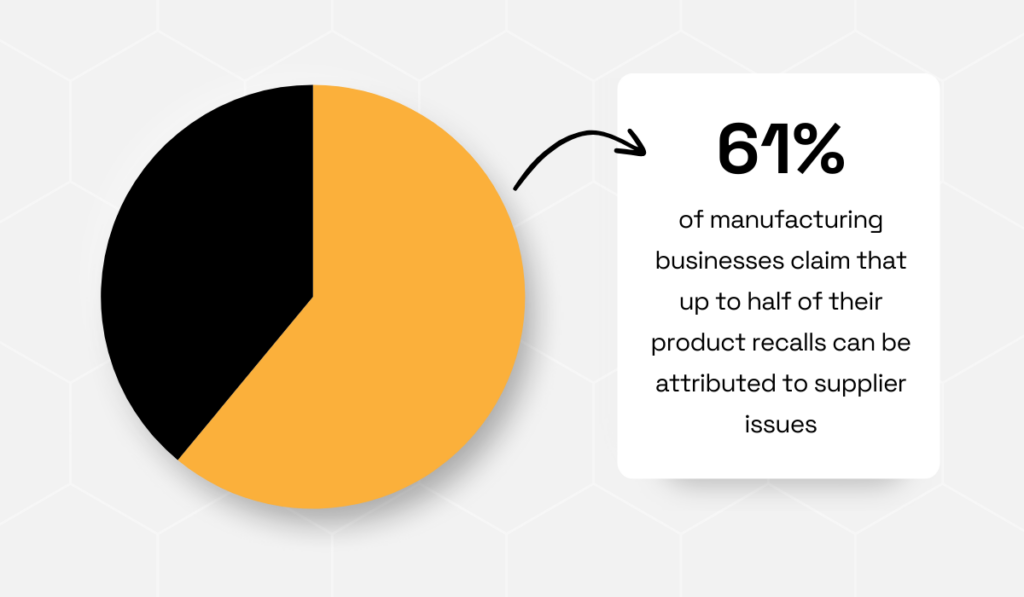

For example, a 2024 survey by Hexagon shows that 61% of manufacturing businesses attribute up to half of their product recalls to suppliers.

Illustration: Veridion / Data: Hexagon

The role of risk management is to prevent these types of incidents.

It helps you identify problematic areas in advance, develop informed contingency plans, and stay resilient.

All in all, managing suppliers is a complex task, with each of these four elements requiring focused attention and effort.

But it’s definitely worth it.

When you do it right, you can cultivate strong partnerships, minimize disruptions, and unlock greater value throughout the supply chain.

When it comes to tracking supplier KPIs as part of your supplier management efforts, there’s an abundance of options to choose from.

Don’t try to track all at once, though.

Instead, clearly outline your specific objectives and needs, and then select appropriate metrics that will help you bring you closer to your goals.

That said, here are some common supplier KPIs to get you started:

| Defect Rate | The number of orders containing defective products divided by the total number of orders placed. |

| Lead Time | The average number of days it takes a supplier to deliver goods after an order is placed. |

| Order Accuracy | The percentage of orders delivered with 100% accuracy, calculated as the number of accurate orders divided by the total number of orders. |

| Competitiveness | A comparison of the price of an order placed with one supplier against alternative suppliers. |

| Contract Compliance | Measures how closely contracted parties adhere to the terms outlined in the agreement. |

| Supplier Responsiveness | Evaluates how quickly a supplier responds to queries, issues, or requests. |

| Supplier Risk Score | A comprehensive assessment of a supplier’s risk profile, incorporating factors such as financial stability, geographic risks, and more. |

These metrics are a strong starting point for evaluating the quality and reliability of your suppliers.

Over time, you can expand the list by incorporating additional ones tailored to your evolving requirements, such as sustainability, innovation, or agility.

If you’re interested in learning more, take a look at our article dedicated to metrics for assessing supplier performance across different categories.

Now, let’s explore some of the most common supplier management errors and how to avoid them.

Delayed or inconsistent payments to suppliers lead to strained relationships, potential disruptions, and other kinds of issues.

This might seem like common sense—yet the problem occurs all too often.

PJ Bain, CEO of the supply chain finance solutions provider, PrimeRevenue, Inc., knows this very well because many of their customers are suppliers and vendors:

Illustration: Veridion / Quote: SupplyChainBrain

Additionally, he notes that 60% of suppliers need to contact customers between one and ten times a month to check on payment status, while over 10% must follow up more than ten times monthly.

This highlights how many suppliers face significant challenges due to their clients’ inconsistent payment practices.

But this issue doesn’t just affect suppliers—it also negatively impacts buyers.

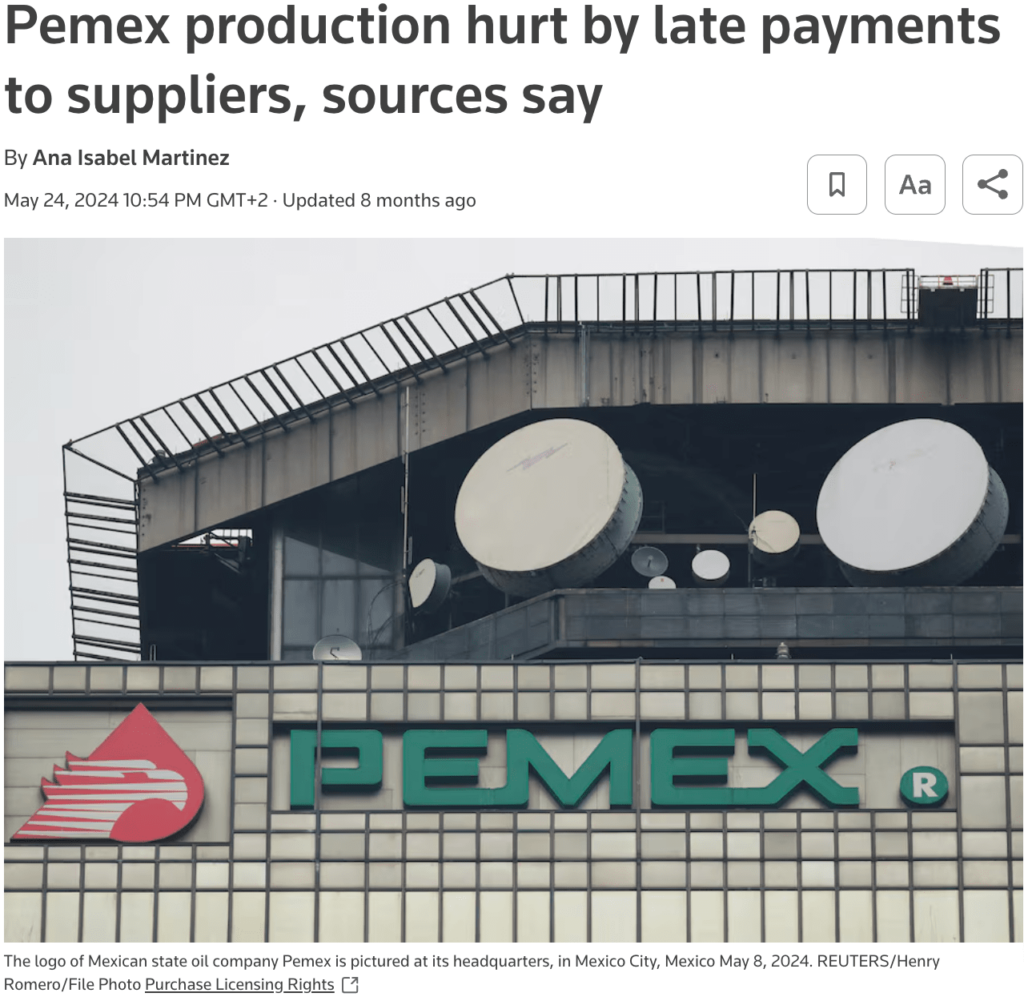

Take it from Mexican state energy company Pemex, which has faced significant setbacks due to delayed payments to service providers.

In April 2024, Pemex’s crude oil and condensate production fell 6% year-over-year to 1.75 million barrels per day.

The reason?

Sources cite unpaid service providers as a major factor, with some companies partially or fully halting work for Pemex.

Source: Reuters

So, what’s the lesson here?

Procurement teams need to make timely payments and proactive communication about delays a priority.

However, this isn’t always easy, especially with clunky, outdated payment or spend management systems.

Manually tracking receipts and payment histories isn’t just incredibly time-consuming—it also leads to errors and reduced visibility.

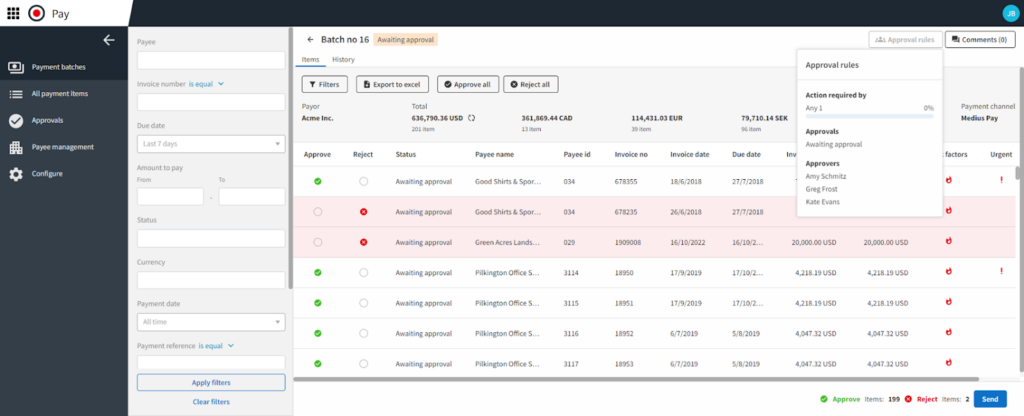

To mitigate this problem and ensure your suppliers get paid on time—every single time—it’s best to automate vendor payments with a dedicated digital solution.

As shown below, these systems track, centralize, and streamline every part of the process—from invoice to execution.

Source: Medius

More specifically, they automate approvals, maintain accurate records, and send reminders when a payment is due.

With these tools, missing a payment is practically impossible.

But this isn’t where the benefits of automation end.

Managing suppliers with outdated methods, like spreadsheets, often leads to inefficiencies, errors, and limited visibility throughout the entire process.

As a result, you end up with incomplete or inaccurate supplier data, making it difficult to assess their performance and reliability.

This exposes you to all kinds of risks, from increased costs and drops in quality to late deliveries.

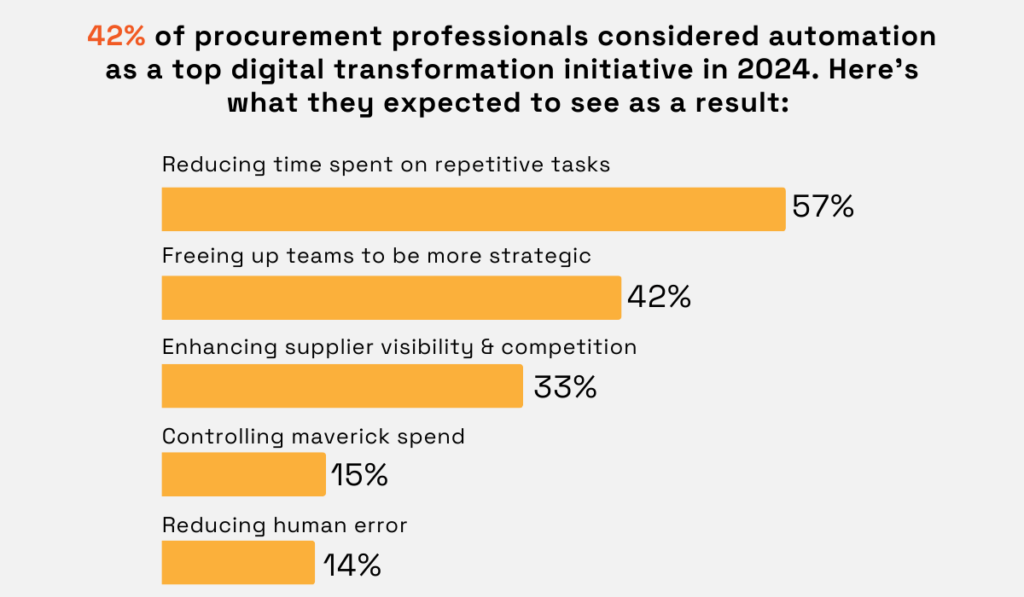

It’s no surprise, then, that Keelvar’s 2024 survey highlights automation as a top digital transformation initiative for 42% of procurement professionals.

Here are some of the key benefits they expect to gain:

Illustration: Veridion / Data: Keelvar

This is exactly what you miss out on when you choose to rely on outdated systems and methods.

Instead of streamlining workflows and repetitive tasks, you end up wasting time searching for information and putting out avoidable fires.

So, what solutions automate supplier management?

One tool worth considering is Source-to-Pay (S2P) software.

S2P solutions provide a centralized platform that acts as a single source of truth, enabling organizations to manage all spending and supplier relationships from one place.

With features like automated PO management and advanced analytics, S2P systems streamline operations while improving your decision-making.

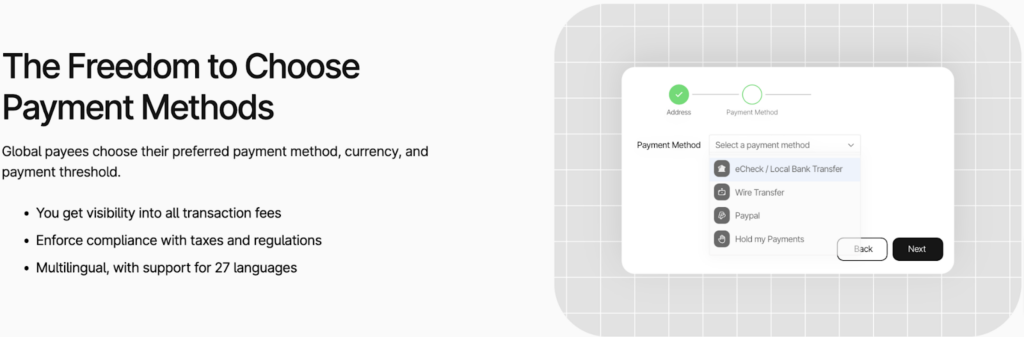

Many platforms also include self-service registration to suppliers, which allows them to update their own information, as in the example below:

Source: Tipalti

This even further improves efficiency and minimizes the risk of miscommunication.

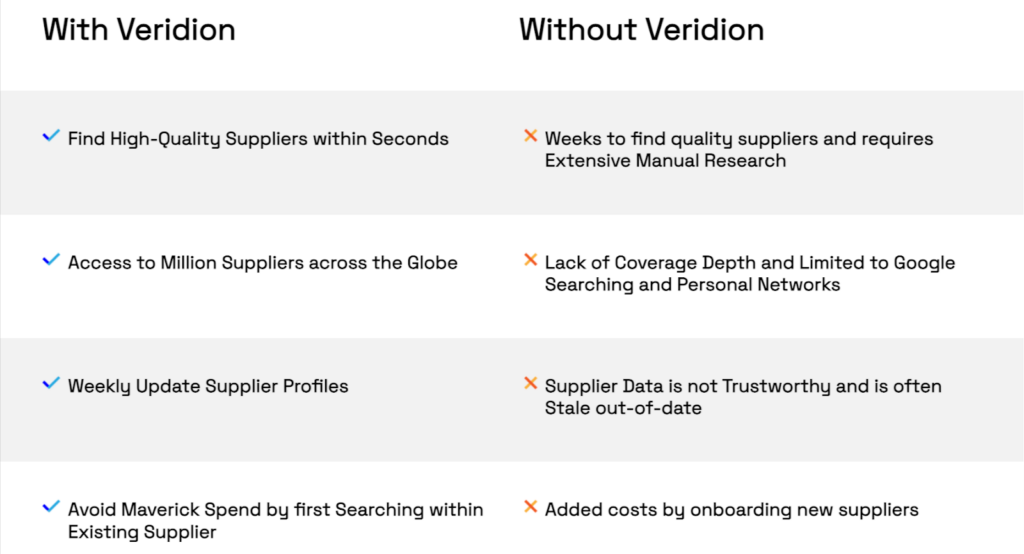

Moreover, when it comes to supplier selection and evaluation, consider a supplier data platform like Veridion.

Instead of manually scouring the internet or poring over records, Veridion delivers all the supplier information you need in moments.

Source: Veridion

Drawing from a vast database of millions of suppliers and products worldwide, Veridion provides insights ranging from basic company and product information to financial stability data and more.

You can use this data in multiple scenarios:

After all, accurate, fresh, actionable data is the cornerstone of effective supplier management, and Veridion ensures you have everything you need to succeed at your fingertips.

Failing to consider your suppliers’ ESG (Environmental, Social, and Governance) performance is another big supplier management mistake.

It can damage your company’s reputation, lead to regulatory non-compliance, and alienate your customers, investors, and other key stakeholders.

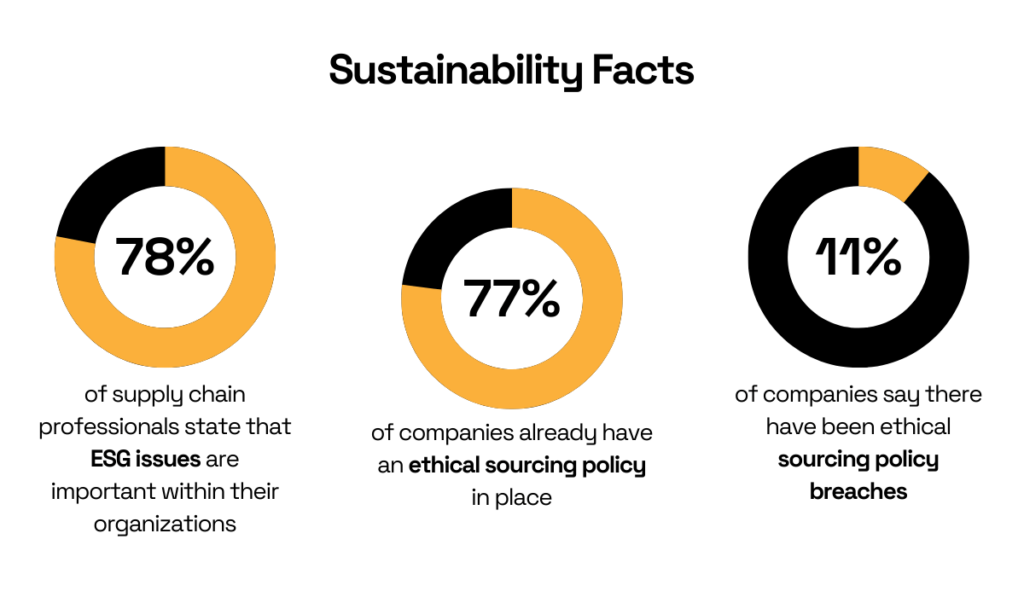

The CIPS 2024 survey confirms that ESG isn’t just a passing trend.

As it turns out, 78% of supply chain professionals state that ESG issues are important within their organizations, with 77% reporting already having an ethical sourcing policy in place.

However, 11% of those with such policies admit there have been breaches.

Illustration: Veridion / Data: CIPS

To minimize such breaches, you can’t just focus on your internal practices—you need to monitor your suppliers as well.

Their sustainability is your sustainability.

And if they fall short, your company could face significant consequences, too.

For example, in 2018, Greenpeace accused 25 major brands, including Nestlé and Unilever, of sourcing palm oil from a supplier linked to deforestation.

Source: Greenpeace

The accusations led to reputational damage, investor concerns, and forced the companies to reevaluate their supply chains.

They also had to sever ties with the supplier until they could prove compliance, while also seeking alternative sources in the interim.

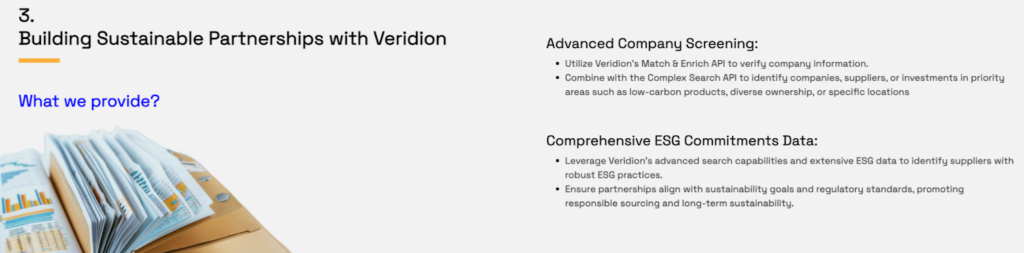

To avoid such issues, it’s best to integrate ESG criteria into your supplier selection process from the get-go and monitor compliance consistently.

While this may seem somewhat complex, supplier data platforms like Veridion make the process significantly easier and more effective.

For instance, Veridion offers primary data on company activities, such as net-zero targets, certifications, or adverse and controversial media.

This data is sourced from global and local news channels in multiple languages, ensuring no detail is overlooked.

Source: Veridion

Similarly, our detailed insights into the products and services can be used to ensure compliance with regulations such as the Carbon Border Adjustment Mechanism (CBAM) and the EU Green Taxonomy.

Source: Veridion

With Veridion, confirming everyone in your supply chain works sustainably and responsibility is easy.

So, don’t worry about ESG compliance ever again.

Use our data to monitor your suppliers and stay green, compliant, and successful.

Never underestimate the power of effective supplier management.

When done right, it can unlock significant cost savings, mitigate risks, drive innovation, and deliver countless other benefits.

The secret lies in automating repetitive, time-consuming tasks and relying on accurate, trustworthy data.

By doing so, not only will you boost overall operational efficiency, but you’ll also build stronger supplier relationships and set your company up for even greater success.