4 Benefits of Investing in Supplier Relationship Management (SRM)

Key Takeaways:

Strong supplier relationships are a cornerstone of resilient, cost-efficient supply chains.

The quickest way of getting there is by investing in Supplier Relationship Management (SRM).

SRM’s key principles go beyond managing contracts.

From securing better pricing to fostering supplier innovation, a well-structured SRM strategy is all about building partnerships that drive long-term success.

But what exactly makes it so valuable?

In this article, we’ll explore four key benefits that make SRM a strategic investment rather than just an operational necessity.

Investing in supplier relationship management saves you money in the long run.

Favoring strong, collaborative relationships over more transactional ones helps organizations keep their spend in check while uncovering cost-saving opportunities.

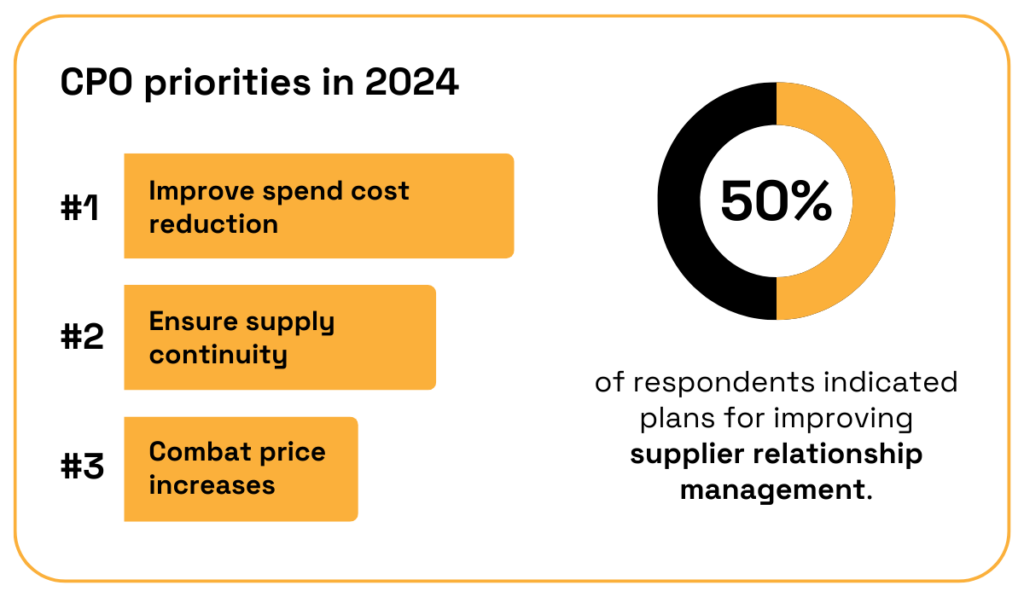

And, according to the latest CPO Agenda, reducing costs is once again the top priority for procurement leaders.

When asked about the strategies to meet this and other priorities, half of the surveyed CPOs cited improvements in supplier relationship management.

Illustration: Veridion / Data: The Hackett Group

So, how exactly does SRM lead to cost savings?

On the most basic level, proactive supplier management enables greater insight into each relationship’s cost and value.

For instance, conducting regular performance evaluations, which are an essential part of SRM, gives you the data that drives successful negotiations and overall decision-making.

Here’s how Global Real Estate Advisor, Elizabeth Mesa, explains it:

“With regular evaluations, you [also get] leverage for contract renegotiations in the future, potentially sourcing better pricing and more favorable terms that will contribute to cost savings.”

But it’s not just about reducing procurement costs based on supplier performance.

Focusing on supplier experience and building long-term relationships encourages suppliers to offer better deals, discounts, and new opportunities.

As HICX’s Chief Marketing Officer, Anthony Payne, points out, these efforts bring various benefits and, ultimately, lead to significant cost savings.

Illustration: Veridion / Quote: HICX

In other words, a simple shift toward a more collaborative attitude can quickly lead to better pricing and other perks.

While supplier discounts are important, nurturing closer relationships with your suppliers also helps your business streamline specific processes and reduce operational costs.

A reliable long-time supplier is more likely to suggest design changes or propose replacing one type of material with an equally durable, yet cheaper alternative.

And it’s not the only way of uncovering new cost-saving opportunities.

Many large organizations actively encourage joint innovation.

Volkswagen (VW) is a prime example of a company leveraging supplier innovation to reduce costs.

As the chief patron of IZB, Europe’s top fair for automotive suppliers, VW actively seeks cost-effective solutions from its suppliers.

Facing growing competition and a prolonged crisis, VW placed even greater importance on uncovering innovative and cost-effective solutions from suppliers during the fair’s latest edition.

Source: All-About-Industries

With its shift toward electric vehicles (EVs), VW is prioritizing gigacasting, a manufacturing technique pioneered by Tesla.

A likely partner in this transition is Gestamp, a long-time VW supplier and recipient of its Best Supplier Award.

Gestamp’s “gigastamping method” addresses the biggest drawback of single-piece EV castings: high repair costs.

If a partnership is confirmed, this innovation could significantly lower production costs, reduce energy consumption, and improve efficiency for VW.

But remember, none of it would be possible without investing in supplier relationship management.

Effective SRM enables businesses to secure good pricing and unlock more solutions to reduce operational costs.

Strong supplier relationships open room for process optimization.

As we’ve already established, SRM enables organizations to map high-performing suppliers bringing in the most value.

This means you can focus on partners with the expertise to introduce improvements, optimize workflows, and increase efficiency.

But efficiency isn’t just about capability—it also requires ongoing communication, another core element of strong supplier relationships.

When communication is clear and consistent, suppliers can help you identify and address potential issues before they escalate, thereby reducing delays and disruptions in operations.

However, some common obstacles hinder communication and reduce efficiency.

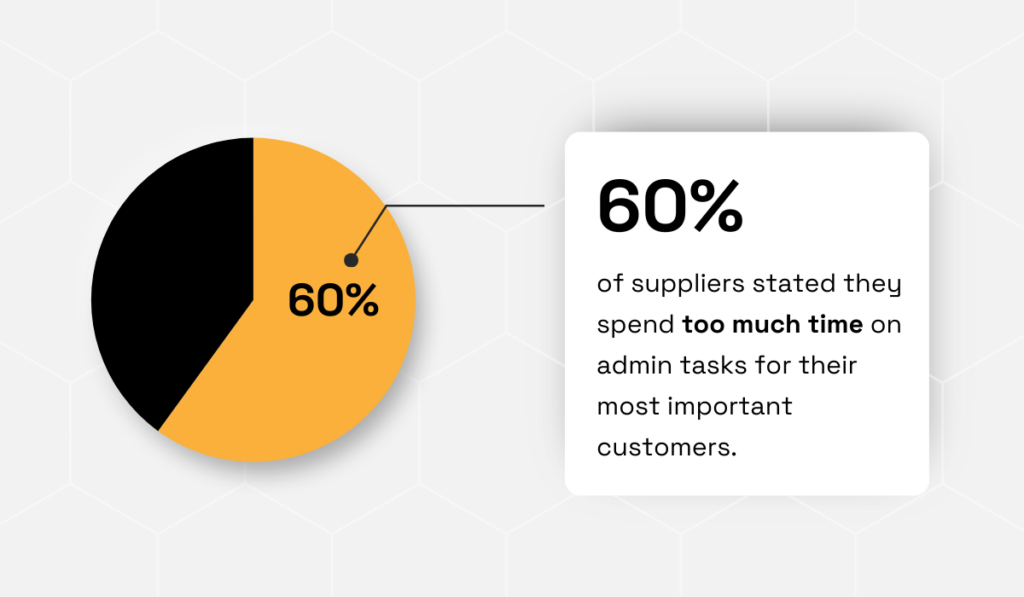

According to HICX’s survey, having to handle too many admin tasks is proving particularly disruptive to suppliers.

Illustration: Veridion / Data: HICX

On average, they need to access 8.4 different systems just to serve their most important customers.

Too many touchpoints slow processes down, create unnecessary friction, and lead to frustration on both sides.

By prioritizing supplier relationship management, organizations can eliminate these inefficiencies, integrate smarter workflows, and establish clearer communication channels.

Alberto Nairo A. Frota, General Manager at Brazil-based Plug Solar Energia, highlights this people-centric approach, emphasizing that hearing and valuing supplier experience is key to guaranteeing smoother operations.

Illustration: Veridion / Quote: LinkedIn

When companies actively work with suppliers to reduce inefficiencies, the results can be substantial.

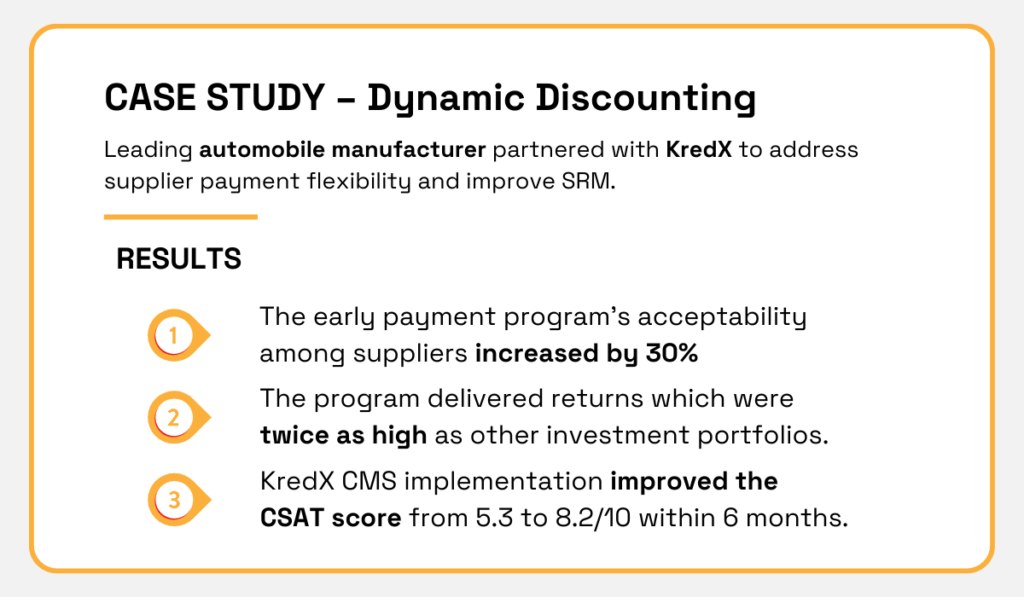

KredX’s case study illustrates this well.

The unnamed automobile manufacturer had introduced an early payment program to minimize supply chain disruptions.

However, it soon became clear that manual processes and a flat discount rate discouraged suppliers from participating in it.

Acting on supplier feedback, the company overhauled its system, introducing a cloud-based platform with minimal intermediaries and greater transparency.

These improvements not only enhanced efficiency but also strengthened supplier engagement.

Illustration: Veridion / Data: KredX

A similar focus on supplier collaboration can be seen in logistics.

FedEx, for example, has developed FedEx Surround, an advanced AI-driven solution that provides real-time visibility into shipments.

By integrating predictive analytics and sensor technology, this logistic supplier helps its clients prevent potential disruptions before they occur, ensuring faster and more reliable deliveries.

This allows companies to streamline logistics, avoid costly delays, and improve overall supply chain efficiency.

All because they have a good partnership with FedEx.

In the end, it’s a reinforcing cycle.

Improving SRM leads to more efficiency, and high efficiency helps maintain strong strong relationships.

Organizations that invest in SRM can minimize operational bottlenecks, unlock new efficiencies, and create more agile, responsive supply chains.

Building lasting relationships with your suppliers ensures you’re the first in line for new products and services that provide a competitive edge.

While supplier relationship management isn’t a guarantee of innovation, it creates a solid foundation for it in several ways.

As we’ve already discussed, SRM helps organizations identify high-value suppliers who have the potential to contribute to major industry advancements.

These suppliers can offer innovations that go beyond the current scope of the business agreement.

By empowering these strategic suppliers to focus on future improvements, organizations foster a collaborative environment where both parties work together toward mutual benefits.

As such, it’s no wonder that suppliers see collaboration and innovation as an essential part of cultivating stronger ties with their customers, with 15% citing they want more such initiatives.

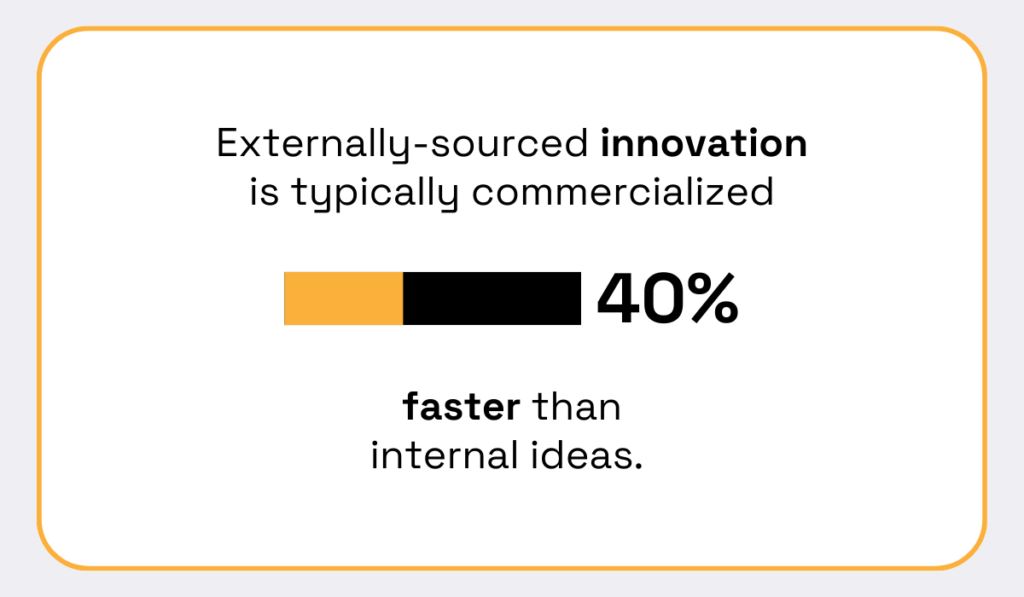

Collaboration can also accelerate time to market.

McKinsey’s research found that externally sourced innovation is commercialized 40% faster on average than in-house developments.

Illustration: Veridion / Data: McKinsey

Bringing an innovative idea to the market often requires fresh insights into highly specialized fields, but the potential knowledge gap can be quickly bridged with supplier expertise.

This also means fewer delays from in-house trial and error.

As a result, organizations can bring new products and services to market faster, which is a key motivation for encouraging supplier collaboration.

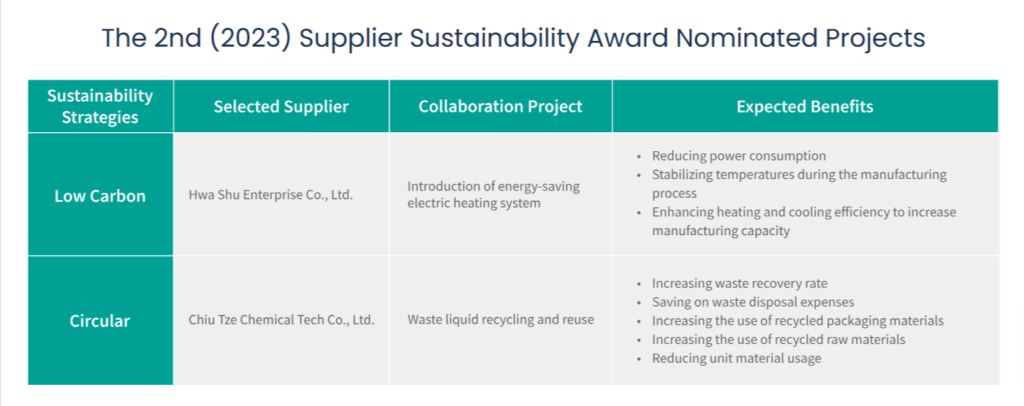

For example, ASE Technology’s supplier sustainability award requires suppliers to submit a detailed proposal for a collaboration project with the company.

Source: ASE Global

This way, both the organization and the supplier have a clear outline of expected results and a plan for how they will achieve key objectives.

While these and similar programs give a strong nudge toward innovation, collaboration doesn’t happen based on good ideas alone.

Multiple studies point out that knowledge-sharing is directly linked to the existing trust between buyers and suppliers.

Illustration: Veridion / Quote: Santa Catarina State University

And the quickest way to foster this trust is by prioritizing long-term supplier relationships and investing in SRM.

A prime example of this is Toyota, which has positioned itself as a leader in the automotive industry by involving its suppliers in innovative projects.

Toyota has long believed that keeping doors open to new suppliers, especially game-changers from diverse fields, is important.

But what truly sets the company apart is the mutual trust developed through long-standing partnerships.

This is directly reflected in the company’s relationship with its leading supplier, DENSO, which eventually led to the establishment of a joint R&D venture.

Source: Toyota

In essence, the development of critical next-generation components can only be entrusted to key strategic partners.

Keep in mind that the surest way of building those critical relationships and navigating new ones is by relying on proactive supplier relationship management.

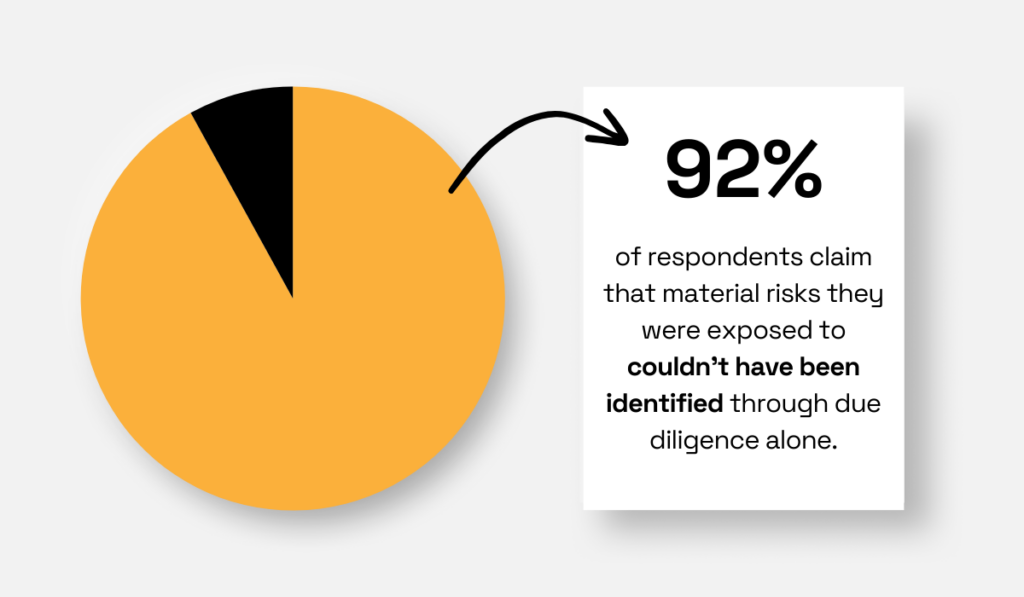

Effective SRM enhances risk deterrence by fostering transparency, ensuring compliance, and improving overall supplier reliability.

Stronger collaboration means businesses are in a better position to proactively address vulnerabilities, from supply chain disruptions and quality issues to suppliers’ financial instability.

This is especially advantageous when research confirms how difficult it is to uncover risks in the first place.

Namely, Gartner’s report shows that over 90% of organizations were impacted by material risks that couldn’t have been identified by relying solely on due diligence.

Illustration: Veridion / Data: Gartner

In such cases, prioritizing SRM and continuous supplier performance monitoring goes a long way toward identifying and countering emerging risks.

Let’s examine a recent high-profile data breach case in the UK.

Unknown attackers gained access to a part of the UK Armed Forces payment network, compromising the personal information of over 225,000 UK military members.

Source: Dark Reading

Since the system was operated by an external contractor, the UK’s Secretary of State for Defence placed most of the blame on them, also announcing a special security review.

While a more thorough vetting process might have flagged evidence of potential failings earlier, we can trace the core issue back to poor communication and a static approach to risk.

If the UK Military and Shared Services Connected Ltd had been more transparent about potential vulnerabilities and worked together, they could have mapped key risks and established contingency plans.

This is what a well-structured SRM strategy prioritizes.

Open communication, regular check-ins, and joint risk assessments make it easier to identify vulnerabilities ahead of time and adopt the best countermeasures.

Monitoring for changes is another core part of supplier relationship management.

Chris Audert, Gartner’s Vice President & Chief of Research within Assurance Practice, explains that it was never more important than today.

Illustration: Veridion / Source: Gartner

This can seem particularly challenging given the shifting nature of risk, but it’s not impossible.

While strong supplier relationships foster transparency and help mitigate some risks, businesses today can further strengthen their defenses with advanced risk management tools and data services.

Our Veridion is one of these solutions.

With unparalleled coverage and fresh TPRM data updated weekly, Veridion enables businesses to detect emerging risks in real-time—often before vendors are even aware of them.

Source: Veridion

By integrating such proactive monitoring into SRM strategies, companies can move beyond reactive risk management and further reduce exposure to disruptions.

To sum up, SRM acts as a critical risk deterrent, helping you safeguard long-term success.

When done right, supplier relationship management creates a ripple effect across your entire business, driving efficiency and profitability.

As such, the benefits we explored today—from cost savings and efficiency gains to risk mitigation—shouldn’t be viewed purely individually.

Rather, they are interconnected results of a well-executed SRM strategy.

So, if you’re reconsidering your SRM strategy, now is the time to prioritize open communication and trust-building.

By doing so, you can transform your key supplier relationships into valuable partnerships that provide a lasting strategic advantage.