5 Biggest Goals of Supplier Relationship Management

Key Takeaways:

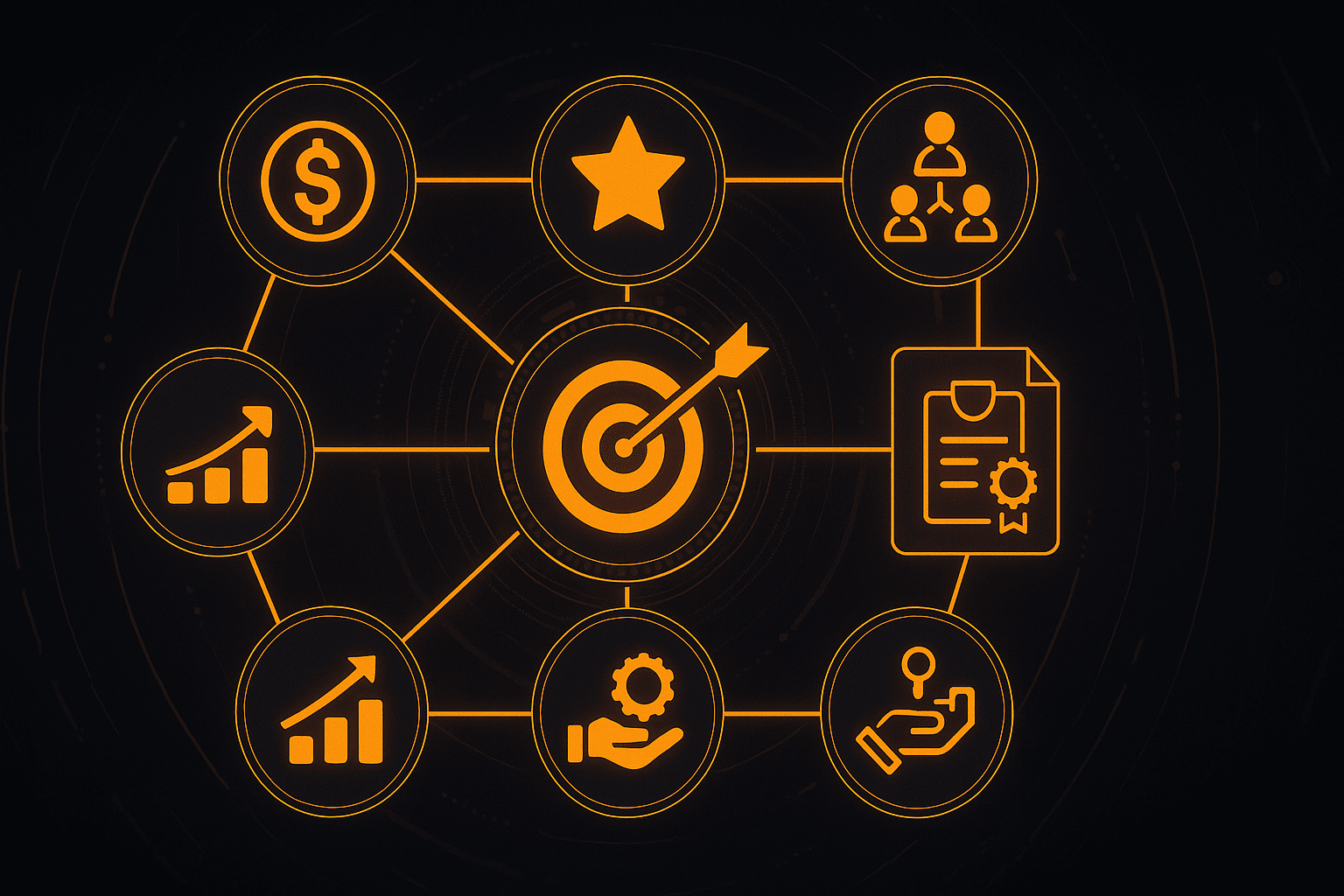

With 61% of procurement leaders citing supplier collaboration as their top value-creation strategy, it’s clear that Supplier Relationship Management (SRM) is about much more than managing contracts and chasing lower prices.

Investing in SRM means building partnerships that strengthen your supply chain and future-proof operations, protecting your business in the long run.

Let’s explore five critical SRM priorities and why they’re essential for navigating today’s volatile, high-stakes market.

Moving beyond transactional interactions to establish long-term, trust-based partnerships is one of the core goals of supplier relationship management.

And it’s easy to understand why.

Strong supplier relationships offer far more than good pricing and occasional discounts.

They help you unlock mutual value, foster innovation, and ensure resilience in times of disruption.

And the data backs this up.

Deloitte’s 2023 CPO survey found that 61% of procurement leaders view supplier collaboration as a key value-enabling strategy.

Illustration: Veridion / Data: Deloitte

The logic is simple.

When buyers and suppliers share information, risks, and rewards, they achieve more together than they ever could through purely transactional arrangements.

A great example of this principle is Siemens.

The company recognizes that innovation doesn’t happen in isolation. Instead, it can emerge from any part of the extended value chain.

That’s why Siemens actively involves suppliers in its innovation strategy through programs like the Supplier Innovation Platform and the Open Call for Innovation.

Source: Siemens

These platforms give suppliers a chance to pitch ideas, respond to challenges, and collaborate on new solutions.

As explained in this video overview, Siemens combines digital tools with a range of different methods:

“We provide internet-based platforms such as the “Supplier Innovation Platform” or “Open Call for Innovation”, and we’re also piloting AI-based market scanning platforms. In addition, there are multiple methods to foster and encourage supplier innovation, such as Core/Non-Core workshops, Innovation Days, Co-creation events, just to name a few.”

Of course, not every business has Siemens’ scale or resources.

But the lesson is universal:

To build productive, lasting partnerships, you need to create the right conditions.

This starts with two-way communication, supplier-friendly processes, and reducing the administrative burdens that often stifle collaboration.

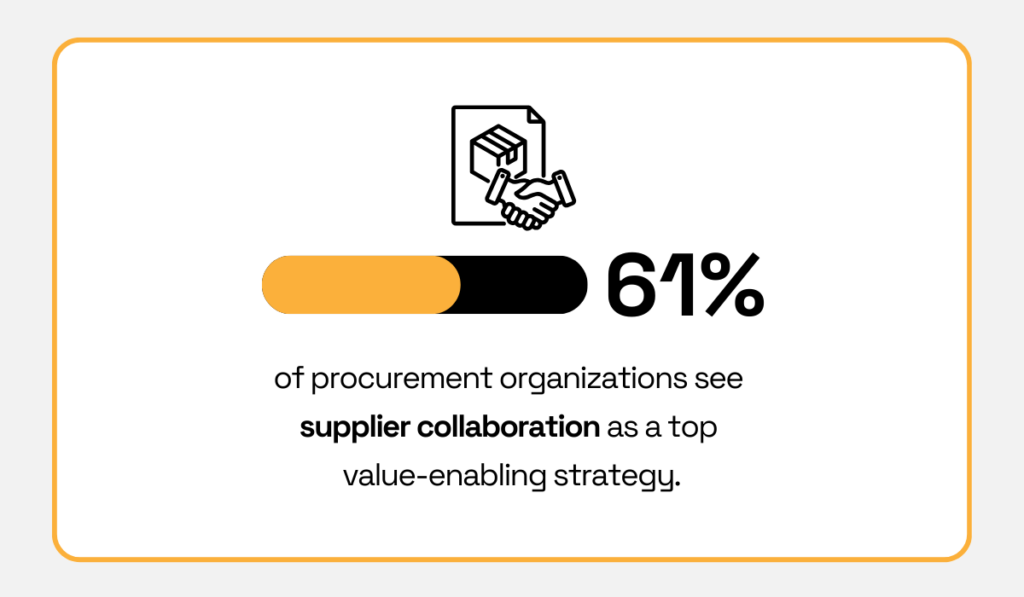

HICX’s annual voice of the supplier survey shows the effect of this burden.

Namely, 60% of suppliers say their most important customer expects them to handle excessive administration.

Meanwhile, 44% of suppliers report being too stretched to volunteer new ideas.

Illustration: Veridion / Data: HICX

When red tape gets in the way, even the strongest supplier relationships falter.

In short, building long-term supplier partnerships means moving beyond contracts and compliance toward open dialogue, shared innovation, and genuine mutual value.

The result is a stronger, more agile, and more competitive supply chain.

Reliable, high-performing suppliers are the backbone of any successful procurement operation.

But building and maintaining a dependable supply base doesn’t happen by accident.

It requires clear expectations, ongoing evaluation, and structured support.

This is where SRM takes center stage.

At its core, SRM helps organizations enhance supplier performance by providing the tools and frameworks needed to track, assess, and improve how suppliers deliver against key business objectives.

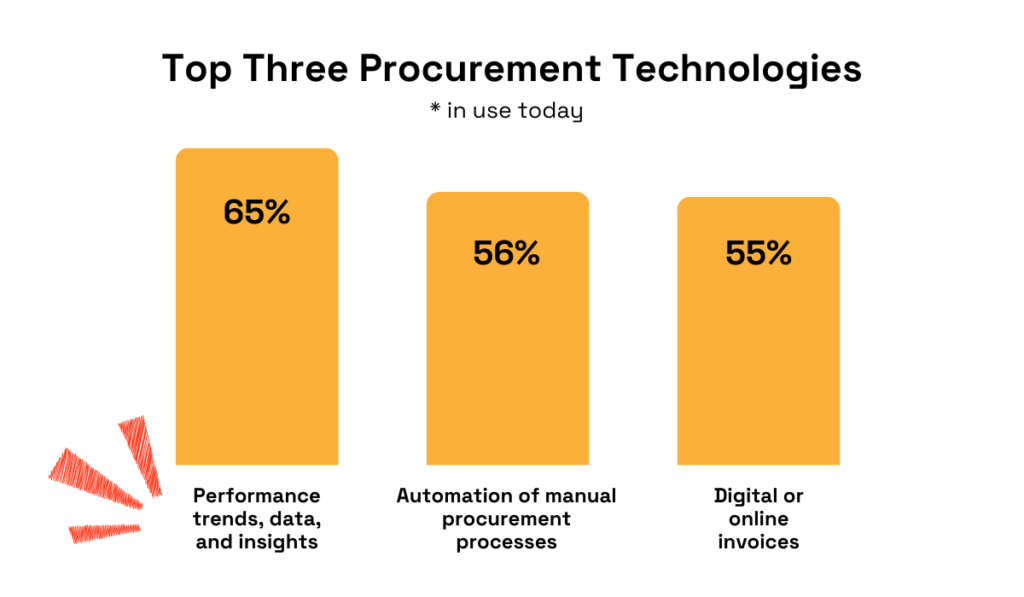

This importance is reflected in how companies adopt procurement technology.

According to the latest Amazon Business survey, 65% of organizations now use analytics and performance tracking tools to monitor supplier output.

Illustration: Veridion / Data: Amazon Business

But there’s something else you need before jumping to technology.

The first step in driving supplier performance is establishing relevant KPIs.

Depending on your organization’s goals, they might include:

SRM enables a structured approach to defining these metrics, communicating expectations, and opening the door to regular performance discussions.

It also facilitates benchmarking across your supplier base, helping you identify which partners deliver the most value, and where there’s room for improvement.

Digital solutions now make it easier to address what has traditionally been a challenge in SRM: reliably tracking performance data and turning it into action.

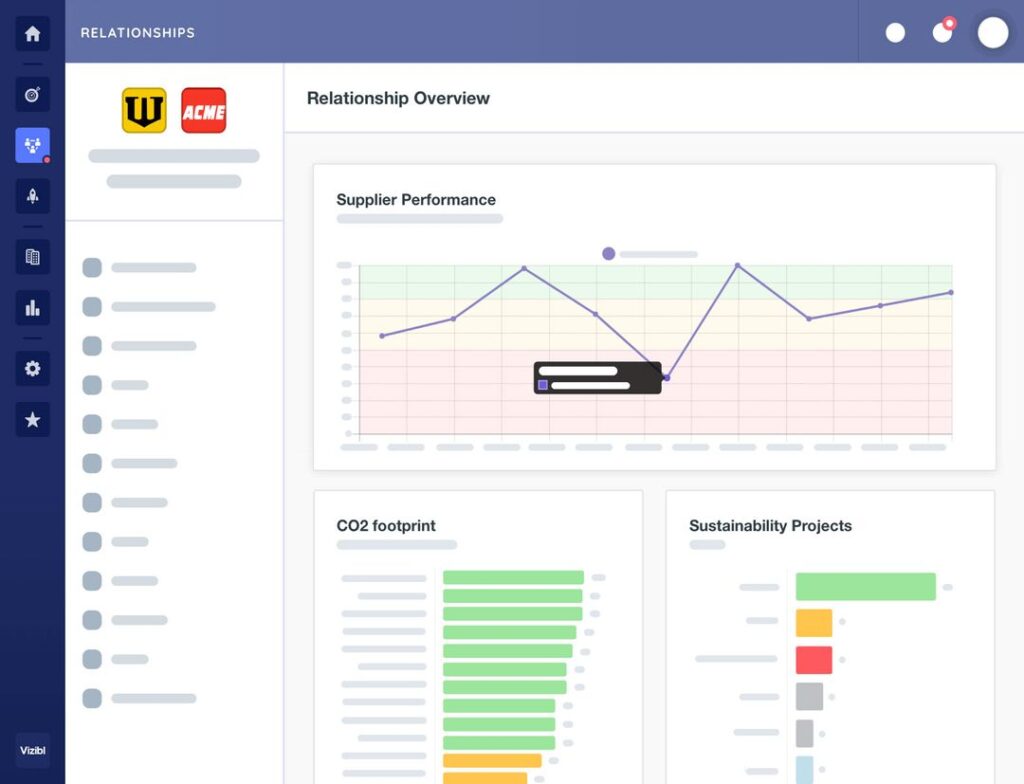

Modern supplier collaboration platforms like Vizibl offer clean, interactive dashboards with color-coded performance benchmarks, shown below:

Source: Vizibl

One glance at the graph, and procurement teams can instantly spot whether suppliers are exceeding expectations or falling short.

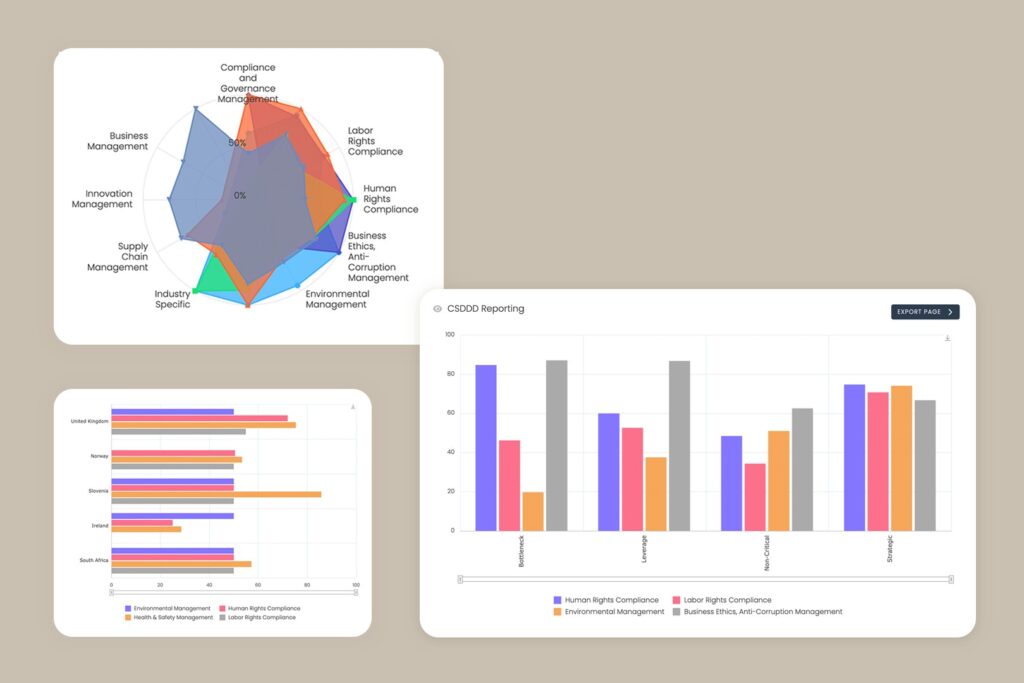

Other tools, such as Kodiak Hub, take analytics a step further by offering flexible reporting options and visualizations tailored to different procurement goals.

Source: Kodiak Hub

Flexible views and customization support enable faster decision-making, more productive supplier conversations, and targeted supplier development.

However, while tools are invaluable, performance improvement still depends heavily on the quality of the relationship itself.

Before you can address underperformance or collaborate on new initiatives, suppliers need to feel safe sharing their constraints, challenges, and improvement ideas.

Without trust, performance discussions remain surface-level and reactive.

Procurement consultant and trainer Olga Catena emphasizes the need for creating a culture of openness where suppliers feel comfortable voicing concerns and feedback.

Illustration: Veridion / Quote: LinkedIn

Those deep conversations drive the real improvements, beyond what the metrics alone can capture.

To sum it all up, yes—technology helps you track supplier performance.

But it’s the mindset of transparent, collaborative relationships that ultimately moves the needle.

Reducing risk isn’t just a byproduct of good supplier relationships.

It should be a proactive, strategic goal embedded within every SRM program.

Yet in practice, many organizations still treat risk management as a one-off task, often limited to supplier onboarding and initial due diligence.

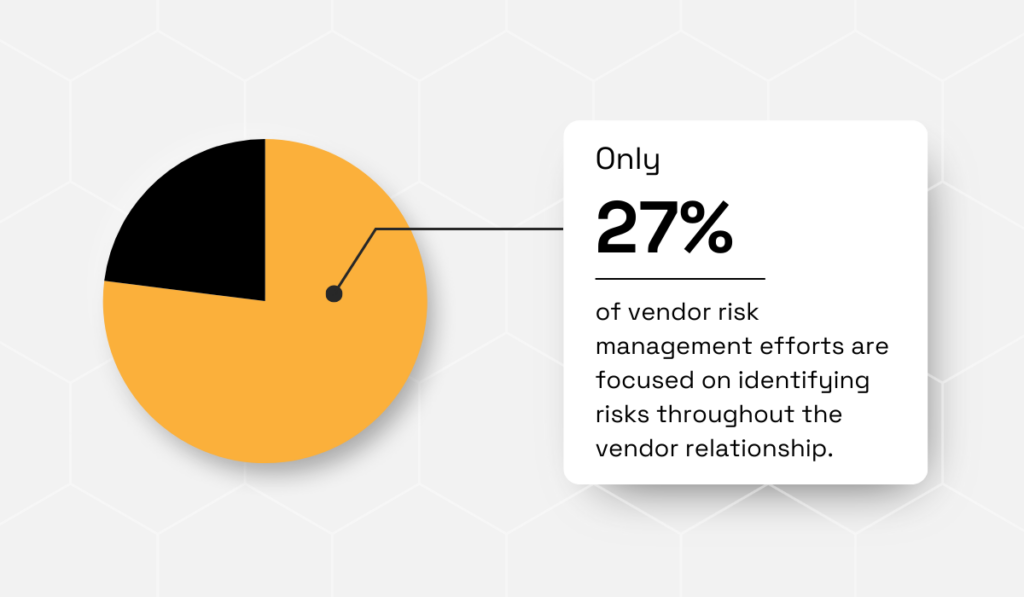

Gartner’s research highlights this gap.

While risk identification is a priority during onboarding, only 27% of risk management activities occur during the ongoing supplier relationship.

Illustration: Veridion / Data: Gartner

This is both a missed opportunity and a major vulnerability, especially considering how volatile global supply chains have become.

Deloitte’s latest CPO survey ranks supplier resiliency and supply continuity as one of the top three business risks.

Without ongoing risk monitoring and risk mitigation strategies in place, organizations remain exposed.

Industry leaders are addressing this by integrating structured risk management practices directly into their SRM programs.

As supply chain risk expert Björn Hartong points out, the risks are evident, but so are the opportunities for those who invest in long-term resilience.

Illustration: Veridion / Quote: BCI

So, what does integrated risk management look like in the SRM context?

It means moving beyond one-off checks and incorporating tools and practices that support ongoing visibility and responsiveness, such as:

Visualization tools can help procurement teams see risk hotspots and monitor suppliers that need extra attention.

Even something as simple as an Excel-based heat map can be a powerful tool for identifying disruptions and weak points, as the video below illustrates:

Source: Log-hub on YouTube

But tools alone aren’t enough.

The foundation of effective risk management is trust and transparency.

Suppliers must feel comfortable disclosing risks—whether it’s a sourcing issue, a production delay, or a compliance concern.

A strong example is Lush’s decision to eliminate natural mica from its supply chain.

When one of their suppliers changed ownership and could no longer guarantee that no child labor was involved, Lush made the difficult but necessary decision to switch to synthetic mica.

As Gabbi Loedolff, Director of Buying at Lush, explained, the lack of audits and verifiable reports meant that the supplier couldn’t achieve the level of transparency they required.

Illustration: Veridion / Quote: Lush

Lush’s decision shows that good SRM isn’t about blind trust.

It’s about accountability, transparency, and the willingness to take action when values or standards are compromised.

When done right, SRM turns risk management into an active, continuous process.

It transforms supplier relationships into a powerful line of defense against disruption and reputational harm.

One of the most important SRM goals is ensuring that procurement efforts align with broader organizational priorities.

Whether the goal is market expansion, innovation, or ESG compliance, SRM provides the visibility and relationships needed to support those evolving goals.

Darren Lynch, VP for Consulting at GEP, compares procurement to a set of levers.

Illustration: Veridion / Quote: Supply Chain Digital on YouTube

Supplier relationships are one of those levers, and SRM provides the visibility and control to pull them in a way that complements the overall business strategy.

In practical terms, that means transforming procurement from a cost center into a strategic function.

For instance, when cost efficiency is the objective, SRM tools help identify underperformance, inefficiencies, and pricing discrepancies.

These insights then inform supplier negotiations, contract renewals, and rationalization strategies, helping reduce costs without compromising quality or service.

But that’s hardly the only strategic lever you can pull.

Supplier relationship management can also accelerate product innovation and business growth, as seen through Procter & Gamble’s Connect+Develop program.

Source: P&G Connect Develop

Today, over 35% of P&G’s product innovations come from external partners, demonstrating the power of collaborative supplier relationships.

However, this shift wasn’t incidental.

In the early 2000s, the company faced significant growth challenges and eventually partnered with a growth strategy consulting firm, Innosight, to systematize its approach.

This move created space for ideas from suppliers, research institutions, and other external contributors.

In the words of P&G’s former executive Nathan Estruth, this provided P&G with the essential raw materials for growth.

Illustration: Veridion / Quote: Innosight

But the benefits of such alignment don’t stop at product development.

Suppose an organization’s strategic goal is to expand into new markets.

In that case, SRM tools make it easier to identify, evaluate, and nurture supplier relationships in those regions, well before a formal market entry.

This proactive supplier engagement reduces operational risk and ensures supply continuity from day one.

Ultimately, aligning procurement with organizational goals means shifting the function from reactive and transactional to proactive and strategic.

SRM is what makes that shift possible by turning supplier insights and partnerships into levers for business growth, innovation, and long-term value.

Sustainability is now a business imperative.

And SRM plays a critical role in helping organizations meet their environmental and social responsibility goals.

A structured SRM strategy provides the framework to enforce ESG standards across the supply chain through supplier audits, codes of conduct, and performance data tracking.

Take Lindström Group, a company offering sustainable services across multiple industries.

Their Director for Sustainable Procurement, Kristiina Tiilikainen, explains that responsible, reliable, and sustainable supplier partnerships are simply non-negotiable.

Illustration: Veridion / Quote: Lindström Group

Tiilikainen adds that while some of the Group’s ESG requirements are universal, specifics often depend on the supplier’s facility type.

For example, pollution audits may be unnecessary for a sewing plant but vital for fabric manufacturers handling chemicals and wastewater.

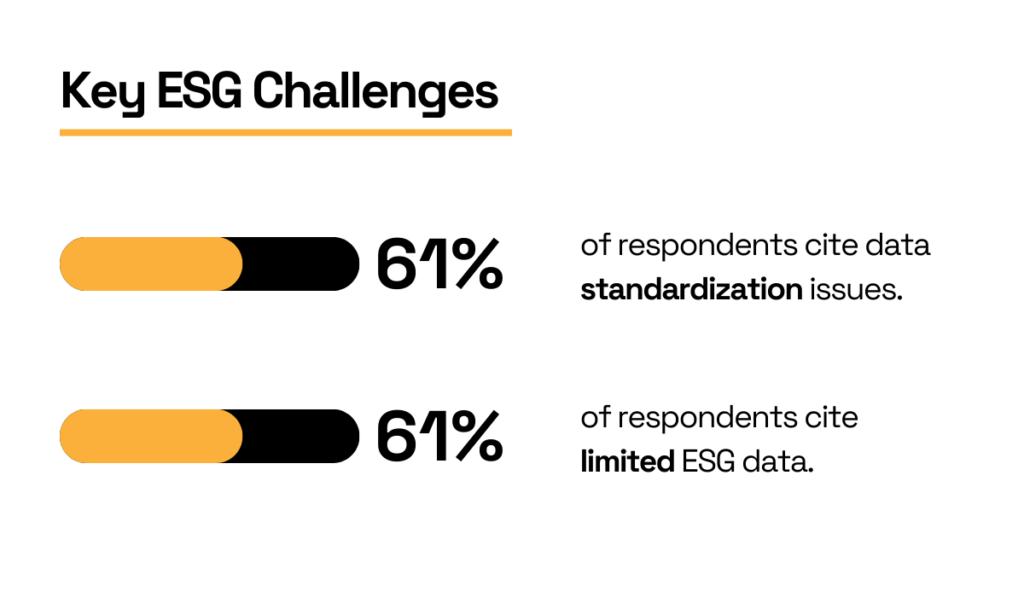

Yet, audits alone aren’t enough, in large part due to tightening regulations and scattered data.

The same Kroll survey revealed that 61% of companies struggle with a lack of ESG data standardization, while an equal share also cite limited access to reliable data.

Illustration: Veridion / Data: Kroll

These challenges make it difficult to compare suppliers fairly, assess risks, or report accurately.

Regulatory complexity adds to the pressure.

Dr Roger Barker, Director of Policy at the Institute of Directors (IoD), explains that the explosion of ESG frameworks and ratings has created as much confusion as clarity:

“The rapid proliferation of the ESG industry, in terms of things like ESG ratings and reporting standards, has also given rise to some scepticism and confusion.”

Regulatory changes, non-unified standards, and complex reporting demands create uncertainty, and supplier relationships are no exception.

In this environment, specialized ESG data providers streamline SRM processes by analyzing data from multiple internal and external sources.

AI-powered solutions like Veridion, for example, offer up-to-date supplier profiles, ESG metrics, and predictive risk insights—all refreshed weekly for accuracy.

Source: Veridion

Beyond monitoring, Veridion also helps companies expand their supplier base responsibly.

Veridion’s Scout supplier discovery tool allows teams to search for new suppliers based on specific ESG and operational criteria, even in highly specialized or niche categories.

Source: Veridion

When ESG goals are embedded directly into SRM processes—from supplier discovery and onboarding to audits and performance reviews—procurement becomes a key driver of sustainable business.

This kind of SRM can help you build a responsible, resilient supply chain that supports long-term value creation.

Smart supplier relationship management is far more than a checklist of KPIs or a path to better pricing.

It’s a framework for shaping a supplier base that drives resilience, fosters innovation, and champions shared responsibility.

By pursuing these five goals with the right balance of technology, transparency, and trust, your procurement team can unlock value far beyond transactional savings.

So, make SRM a priority for your organization.