5 Trends In Supplier Relationship Management

Key Takeaways:

We enter the new year with no shortage of external supply chain uncertainties, challenges, and potential disruptions.

How will companies around the globe adapt to these rapidly changing circumstances?

How will these shifts affect their supplier relationship management (SRM)?

While the answers remain uncertain, one thing is clear: organizations already embracing key SRM trends are better equipped to navigate future complexities.

In this article, we’ll explore five SRM trends that help companies build resilience and stay competitive in a quickly evolving world.

Regardless of the industry you are in, the concept of building mutually beneficial supplier relationships isn’t new.

It has long been a cornerstone of success in industries where strategic partnerships are crucial, such as automotive, aerospace, tech, and FMCG.

However, when the pandemic hit, it really highlighted the risks of having purely transactional relationships with suppliers even in those industries.

Simply put, companies with closer supplier relations found it much easier to overcome COVID-related disruptions.

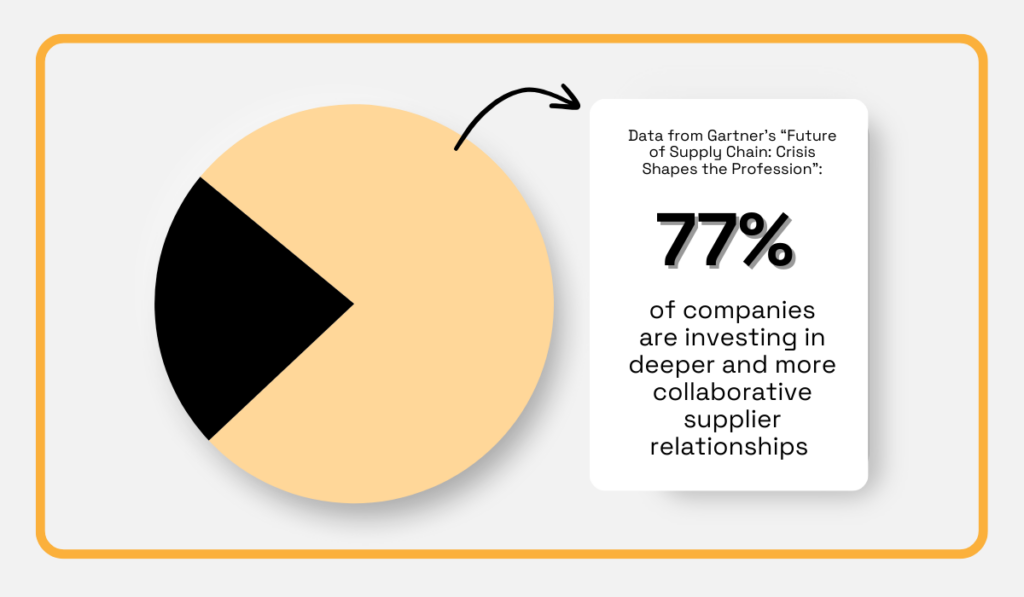

This realization drove a further mindset shift, as reflected in a 2021 Gartner report:

Illustration: Veridion / Data: Gartner

As illustrated above, more than three out of four surveyed CPOs reported investing in closer relationships based on mutual value.

Four years later, the pandemic is behind us, but other global challenges and market disruptions persist, from geopolitical tensions to economic uncertainty.

Hopefully, the companies in Gartner’s survey followed through and prioritized building mutually beneficial supplier-buyer relationships in the meantime.

But what do such relationships typically involve?

For starters, building mutually beneficial relationships requires moving beyond price negotiations to focus on collaboration, shared goals, and long-term value creation.

A great example comes from Tesco Ireland, which secured multi-year contracts worth €200 million with its strategic suppliers.

Source: Tesco Ireland

This commitment provided suppliers with stability and long-term visibility, allowing them to invest in growth, innovation, and meeting Tesco’s evolving needs.

Joe Manning, Commercial Director at Tesco Ireland, explained the reason for this move:

Illustration: Veridion / Quote: Tesco Ireland

So, what does Tesco gain in return?

The company can rely on a consistent supply of high-quality products from its suppliers, leading to a more resilient supply chain with fewer disruptions.

Additionally, increased supplier loyalty can prove invaluable in times of crisis.

Finally, a boost to its reputation, marketing, and overall business performance can also be significant.

Of course, generating mutual benefits between buyers and suppliers can take many other forms, such as:

However, trust remains a challenge in building strong relationships.

Suppliers may hesitate to share proprietary data or cost models, making collaboration difficult.

That’s why open communication, clear expectations, and cultivating close relationships are essential.

Ultimately, making suppliers your strategic partners rather than just transactional counterparts is no longer optional.

It’s a trend that’s here to stay.

The trend of leveraging technology to enhance collaboration with suppliers is also not new.

Tools like supplier portals and supplier management software began gaining traction in the late 2000s and became mainstream by the mid-2010s.

This shift was largely driven by the rise of cloud-based software, which simplified the implementation of supplier collaboration platforms.

In contrast, connecting suppliers through legacy, on-premises software was far more complex and resource-intensive.

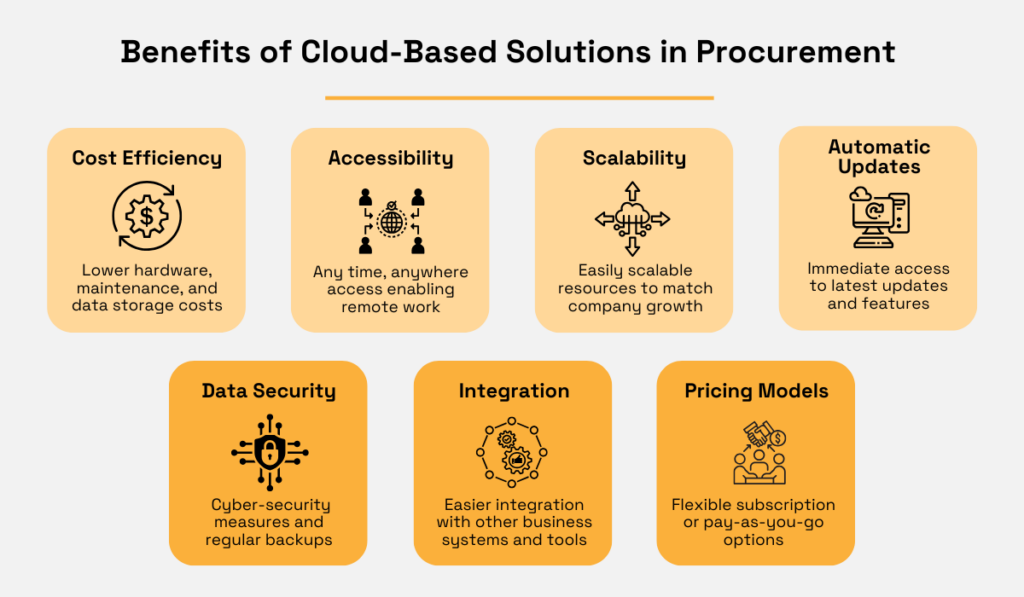

The advantages of cloud-based platforms, shown below, have fueled their widespread adoption across industries, including supplier relationships.

Source: Veridion

With such benefits over on-premises systems, one would think that everybody jumped on the cloud-based wagon.

However, companies are sometimes slow to move, so cloud software currently holds about 40% of the procurement market.

Among procurement solutions leveraging the cloud, almost 19% is held by supplier management software.

There are many options, so let’s focus on two primary ones—supplier portals and SRM software.

To put it simply, supplier portals are centralized hubs for communication between your company and suppliers.

Typically, suppliers can access purchase orders, submit invoices, update compliance documents, and track payments—all in real-time.

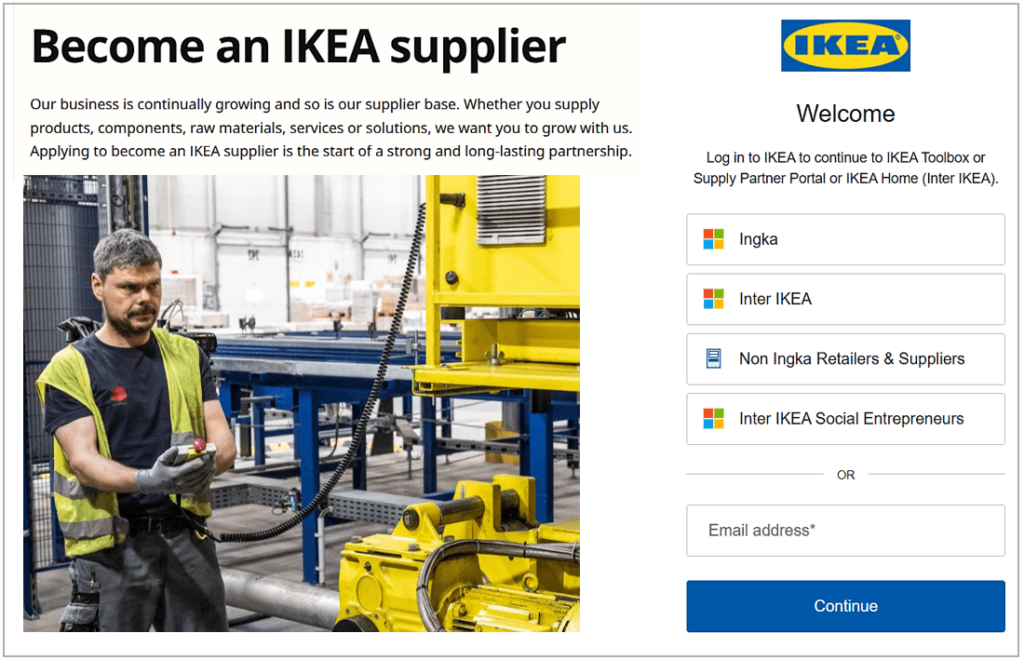

Supplier portals, such as IKEA’s, streamline supplier onboarding, eliminate manual processes, and significantly reduce errors.

Source: IKEA

In addition to enhancing transparency, these portals facilitate smoother communication, ensuring that both parties are aligned on critical processes and expectations.

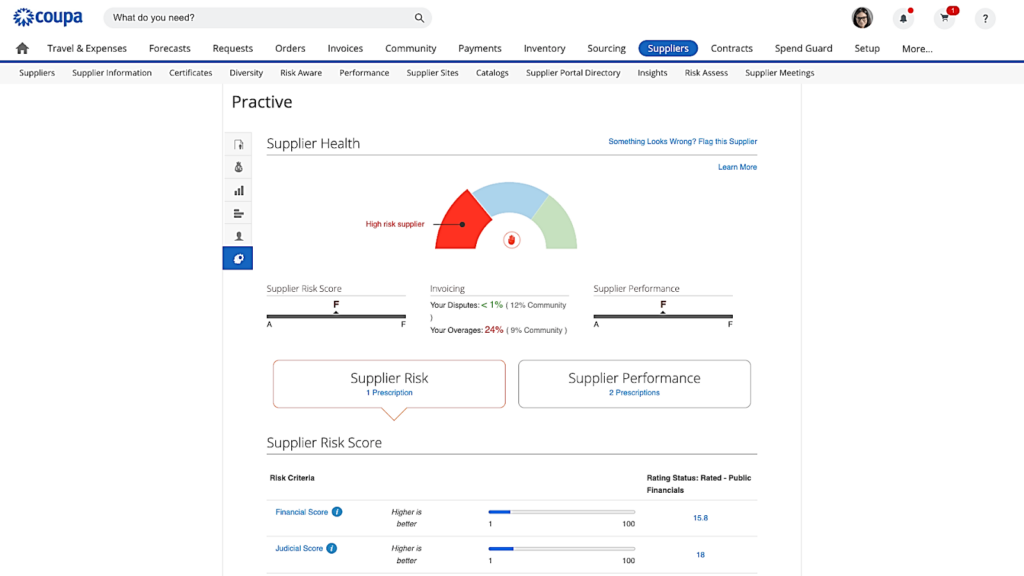

On the other hand, Supplier Relationship Management (SRM) software takes collaboration a step further by providing deeper insights into supplier relationships.

SRM platforms offer robust tools for tracking supplier performance, managing risks, and analyzing supplier data to support informed decision-making.

Notable examples?

Solutions like SAP Ariba, Tradeshift, Ivalua, Jaggaer, and Coupa.

Source: Coupa

Many SRM solutions are available either as standalone platforms or as part of all-in-one procurement software packages.

This flexibility allows you to integrate SRM with complementary tools, such as e-sourcing and spend analysis systems, creating a cohesive ecosystem for managing supplier relationships.

Challenges in accepting such solutions include the price, resource-intensive implementation, and ensuring user adoption in your company and with your suppliers.

Additionally, data accuracy and consistency are critical, as incomplete or outdated information can undermine the effectiveness of SRM systems.

Lastly, SRM platforms are increasingly integrated with other technologies (e.g., AI, blockchain), so this trend of digital transformation is only going to continue and become more sophisticated.

With all the hype surrounding artificial intelligence (AI), one might assume this technology is newly developed.

However, the practical applications of machine learning (ML), a subset of AI, first began to take shape already in the 1980s.

Fast forward to today, and ML algorithms and AI models power everything from search engines to self-driving cars.

In procurement, these technologies have become critical enablers of automation and innovation.

Procurement teams can leverage AI to automate routine tasks, improve decision-making, and predict supplier risks, ultimately boosting efficiency and driving cost savings.

Given these capabilities, it’s no surprise that procurement professionals are increasingly looking to integrate AI tools into their sourcing strategies.

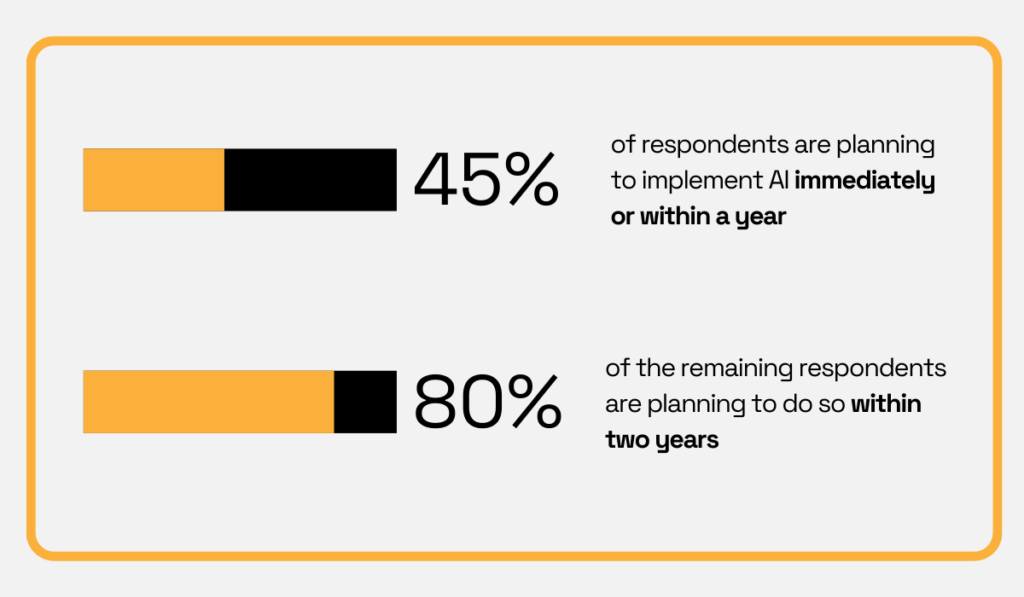

This 2024 Amazon Business survey confirms this:

Illustration: Veridion / Data: Amazon Business

Clearly, CPOs are highly interested in AI but remain cautious, especially regarding the latest, still evolving advancements.

However, many AI-driven solutions have already proven their value.

For instance, machine learning (ML) algorithms are routinely used in procurement software and data systems to automate time-consuming tasks like invoice matching and supplier vetting.

When it comes to supplier management, AI tools can:

Take Veridion, our supplier data platform, as an example.

Source: Veridion

Veridion leverages the power of AI through its proprietary ML bots that continuously search the internet, collecting data on all businesses with an active web presence.

This provides your team with access to a comprehensive, weekly updated, global database of suppliers.

As you might imagine, this opens up a world of possibilities.

For starters, when your team is looking for a new supplier, all they need to do is enter specific criteria and receive a shortlist of eligible suppliers in seconds.

You can see how this process works here:

Source: Veridion on YouTube

In addition to quickly identifying potential suppliers, Veridion’s data enables your team to evaluate them and assess risks more efficiently, simplifying the selection process.

For managing existing suppliers, you can keep their profiles up to date with the latest external data alongside internal system information.

Moreover, Veridion’s market intelligence allows you to benchmark suppliers against competitors, generating valuable insights to refine your strategy.

Likewise, it also serves as a source of fresh information in the areas of sustainability and risk management.

This is just one example of how embracing AI-powered automation can transform procurement processes.

As AI technologies continue to evolve, the possibilities for procurement teams will only grow—but many impactful solutions are already within reach.

Today, sustainability is no longer optional.

Growing concerns about climate change, human rights, and community impact are driving businesses to take action.

Customers, investors, and regulators are also increasing pressure, pushing companies to prioritize suppliers who:

As a result, procurement teams must align supply chains with these values.

This trend highlights procurement’s evolving role—not just as a cost center but as a driver of long-term environmental, social, and economic value.

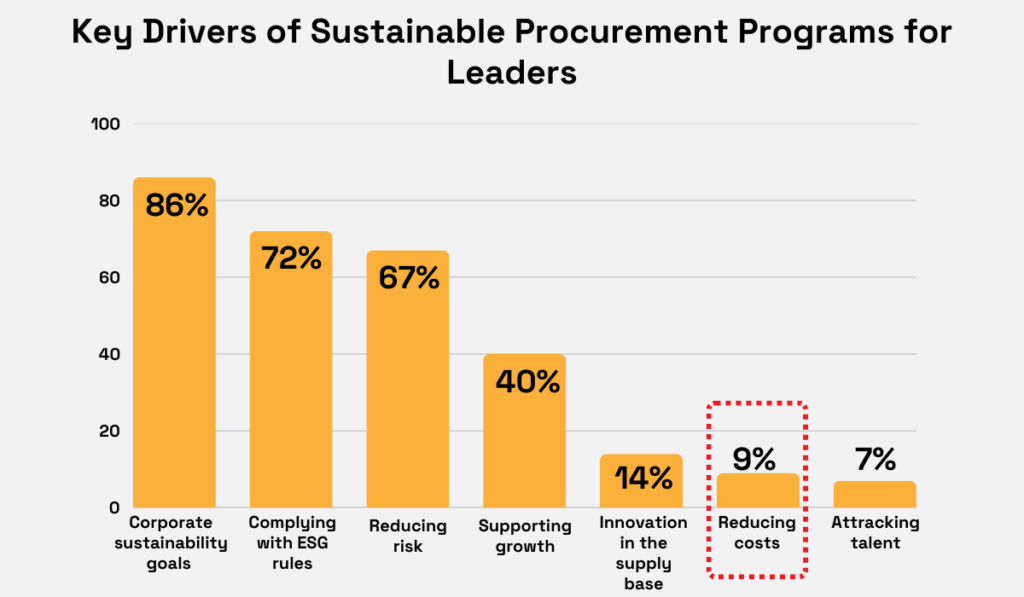

Cost savings are now a lower priority compared to sustainability goals, compliance, risk mitigation, and supplier development.

This is reflected in a survey of key drivers of sustainable procurement among business leaders.

Illustration: Veridion / Data: EcoVadis

These priorities also reflect a growing recognition that, much like mutually beneficial relationships, sustainable procurement practices are essential for creating long-term business value.

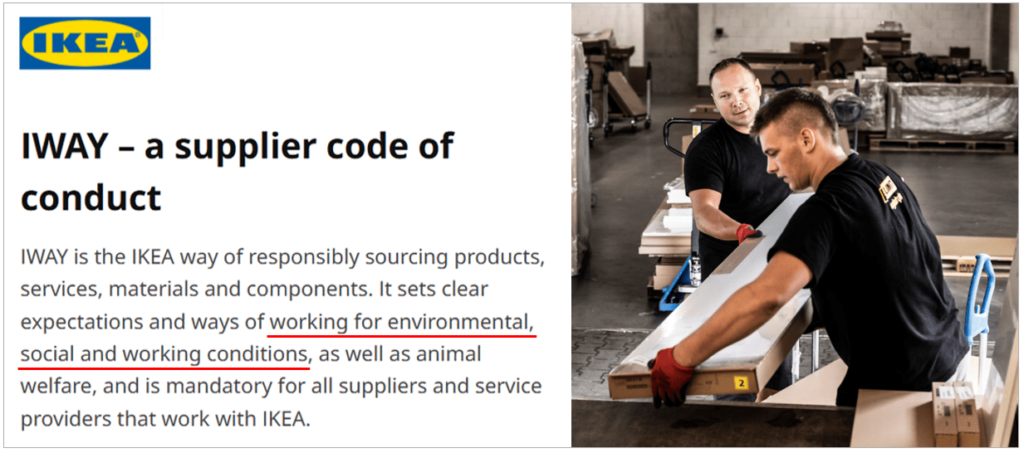

IKEA is a prime example of a company committed to sustainability through supplier partnerships.

From the start, IKEA sets clear expectations for its suppliers, outlined in its Supplier Code of Conduct, known as IWAY (IKEA Way on Purchasing Products, Materials, and Services).

Source: IKEA

With its focus on local sourcing, environmental stewardship, and fair labor practices, IKEA achieves benefits for both the company and its suppliers.

For IKEA, working with sustainable suppliers helps reinforce its brand as an ethical, environmentally responsible business.

It also ensures a more resilient supply chain, reduces compliance and reputational risks, and meets the growing consumer demand for sustainable products.

These efforts contribute to IKEA’s long-term sustainability goals, including carbon reduction and achieving circularity in its product lifecycle.

For suppliers, partnering with IKEA opens access to a larger, more stable market and a reliable partner.

As suppliers adopt sustainable practices, they improve operational efficiency, unlock cost-saving opportunities, and enhance their business prospects.

We’ll close this section with a quote from Pete Davis, CEO of GreenPrint, a global environmental technology company:

“Defending and preserving our planet is not only the right thing to do, it’s good business.”

As sustainability continues to reshape supplier relationships, companies that embrace these responsible practices will be well-positioned for long-term success.

The rising complexity of global supply chains has made effective risk management more crucial than ever.

Challenges such as trade wars, regulatory changes, geopolitical conflicts, and natural disasters threaten supply chain continuity, often resulting in costly disruptions.

At the same time, issues like cyberattacks and fluctuating commodity prices amplify uncertainty, demanding a more proactive approach to mitigating risk.

To adapt, companies are recognizing that risk management must evolve from a periodic exercise into a continuous process.

Historically, organizations have relied on a point-in-time approach to supplier risk management.

This involved conducting extensive due diligence at the start of a relationship and recertifying suppliers at regular intervals.

However, Chris Audet, research director at Gartner, highlights that an iterative approach to third-party risk management is the new imperative:

Illustration: Veridion / Quote: Gartner

He’s essentially saying that new risks constantly emerge, so monitoring them should be a continuous, dynamic process rather than a static, point-in-time effort.

This shift toward continuous risk management is driving the adoption of advanced technologies like predictive analytics and risk monitoring tools.

By analyzing supplier performance, geopolitical trends, and market conditions in real-time, such tools can help your team identify potential risks before they materialize.

For example, you can instruct Veridion to keep tabs on specific supplier risks, such as financial instability, sustainability concerns, or political turmoil in their country/region.

If any of these risks are detected, you get a real-time alert.

Source: Veridion

Clearly, having such risk-relevant information enables your team to act quickly and take necessary precautions to mitigate potential disruptions.

Of course, proactive risk management goes beyond leveraging data-driven tools.

Many companies are diversifying their supplier bases to reduce the risks associated with over-reliance on a single vendor or region.

Additionally, organizations are developing contingency plans, such as pre-approved alternate suppliers, to ensure seamless operations during disruptions.

Collaborating with suppliers to establish joint risk mitigation plans has also proven effective, enabling both parties to respond to unforeseen challenges more efficiently.

In summary, supply chain risks are here to stay.

As they evolve, prioritizing proactive risk management practices becomes essential for maintaining resilience and operational continuity in an unpredictable landscape.

Looking at these five key SRM trends, it’s clear that companies already embracing them are better positioned to navigate the complexities of today’s supply chains.

Whether focusing on mutually beneficial relationships, prioritizing sustainability, leveraging technology, or integrating AI, these strategies strengthen resilience, efficiency, and competitiveness.

By adopting or expanding these approaches, your organization can address challenges, create long-term value, and build stronger supplier relationships.