The Role of AI in Supplier Risk Management

Key Takeaways:

AI is slowly transforming every aspect of procurement, and supplier risk management is no exception.

But what specific role does AI play in this process?

That’s what we’ll explore in this article.

We explore all aspects of AI-powered risk control, including key use cases, benefits, and challenges.

We’ll also examine how some of the world’s largest companies leverage this technology.

After reading, you’ll be equipped with actionable tips to implement the technology more effectively.

First, let’s dive into some of the most common use cases of AI in supplier risk assessment.

Generative AI (GenAI) refers to AI systems that create content, including text, images, and more based on input prompts, powered by advanced models like GPT (for text) and diffusion models (for images).

These systems process amounts of data beyond human capability, synthesize information, identify patterns, and provide actionable insights.

In supplier risk management, where decisions hinge on analyzing massive volumes of information, GenAI is a game-changer.

Traditionally, this data complexity is precisely what made risk control so challenging.

Fraser Hill, VP of International Digital Enablement at Lockheed Martin, a global security, defense, and aerospace contractor, elaborates:

Illustration: Veridion / Quote: Zip

Unlike humans, AI can handle complex datasets effortlessly, which can help with vendor selection and risk mitigation strategies.

More specifically, GenAI can quickly analyze both historical and current supplier data, and even generate risk scenarios to help businesses visualize and prepare for potential disruptions.

No wonder that big companies like Google use it.

Jennifer Moceri, Google’s Global Procurement VP and CPO, explains how this technology empowers them to be more proactive in their decision-making:

Illustration: Veridion / Quote: CPOstrategy

All in all, GenAI improves decision-making in many different ways.

It not only makes it faster, but it also uncovers what human eyes might miss, enabling procurement leaders to make more strategic, value-driven choices.

Whether it’s selecting the right suppliers or planning for future uncertainties, artificial intelligence ensures organizations stay resilient and competitive in this highly volatile market.

Using advanced technologies like statistical modeling and machine learning, predictive analytics evaluates supplier data and external risk factors to forecast potential risks.

For instance, Lenovo relies on this tech to predict the likelihood of late deliveries.

Jack Fiedler, Lenovo’s VP of Digital Transformation of the Global Supply Chain & Infrastructure Solutions Group, explains how this helps them stay ahead of disruptions:

Illustration: Veridion / Quote: Forbes

Given that Lenovo collaborates with over 2,000 vendors, having such a tool proved invaluable.

By forecasting suppliers’ operational disruptions, Lenovo can easily allocate resources and scale production accordingly, consistently meeting customer demand.

This is the biggest advantage of predictive analytics: it allows procurement teams to identify early warning signals and proactively prepare for possible issues before they escalate.

Nari Viswanathan, Sr. Director of Product Segment Marketing at Coupa, a spend management platform, provides an example of what happens when you don’t have this capability:

Illustration: Veridion / Quote: Supply Chain Digital

With predictive analytics, scenarios like this finally become preventable.

This technology provides businesses with the foresight needed to stay agile and avoid being blindsided by unexpected supply chain disruptions.

Natural Language Processing (NLP) combines computational linguistics, machine learning, and data science to process and analyze large volumes of text or speech data.

This is particularly valuable for tracking vendor risks, which are often hidden within unstructured data such as news articles, social media posts, and various reports.

For instance, NLP can detect adverse events—like lawsuits, accidents, or bankruptcies—reported in the news or even evaluate sentiment in social media mentions about a vendor.

This comes in handy if you want to stay ahead of, for example, reputational risks.

Maria Alonso, Head of Account Management & Founder of the advertising agency, Fortune 206, elaborates:

Illustration: Veridion / Quote: Forbes

Similarly, companies like Audi, Volkswagen, and Porsche use NLP to identify environmental, social, and governance (ESG) risks.

The tool they’ve implemented can examine supplier-related news from publicly available sources and social networks in over 50 languages across 150 countries.

When it detects a sustainability risk in the supply chain, automotive manufacturers are immediately alerted, enabling their procurement teams to implement proactive countermeasures.

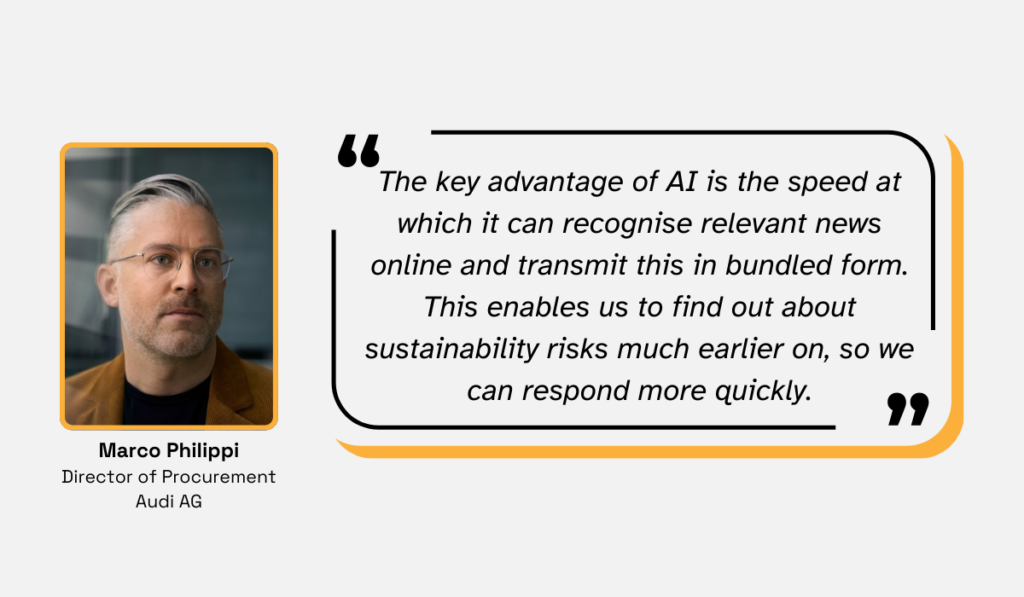

Marco Philippi, Director of Procurement at Audi AG, says that the biggest benefit of this technology is speed.

Illustration: Veridion / Quote: Supply Chain Digital

There’s no need to manually comb through endless risk intelligence sources.

NLP gets the job done much faster—surfacing insights they’d never catch on their own.

Now, let’s see how exactly procurement teams can benefit from this technology.

As mentioned, AI excels at processing vast amounts of data and assessing suppliers across various risk factors, such as financial health, compliance, or overall performance.

As you might imagine, this dramatically accelerates the supplier vetting process.

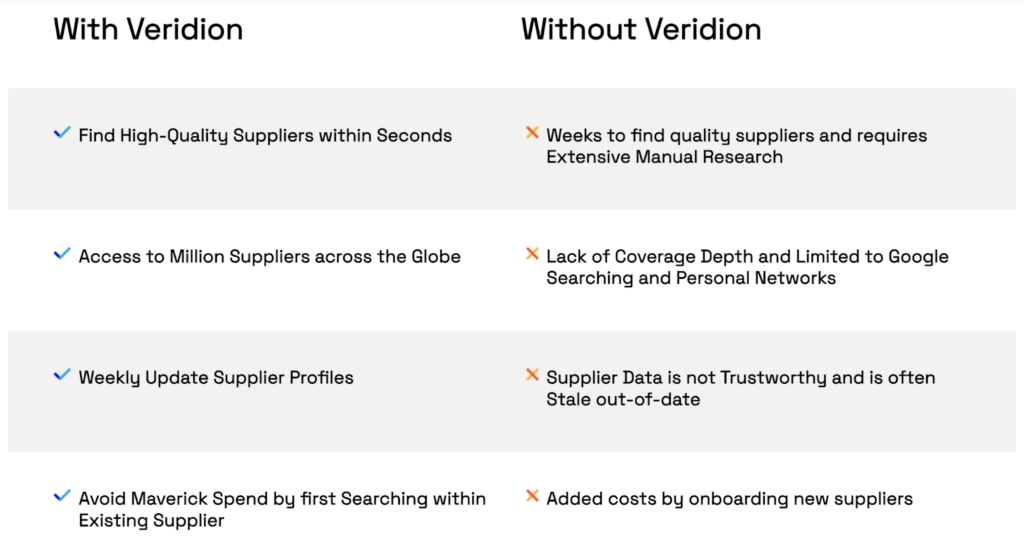

Take Veridion, our AI-enabled supplier data platform, as an example.

Using advanced machine learning models, we process petabytes of data and scan billions of websites every week to bring you the insights you need—fast.

Whether you’re looking to:

Veridion will support your decision-making through the entire process.

Our technology can analyze risks tied to FOCI (Foreign Ownership, Control, or Influence), regional instability, product-specific concerns, ESG compliance, and more, with unmatched speed and coverage.

Source: Veridion

The result?

You save valuable time, reduce risk exposure, and stay agile in an unpredictable market.

Source: Veridion

Yes, supplier risks may be constant and ever-evolving, but with AI, it’s much easier to keep up.

Unlike traditional risk management that relies on periodic reviews—leaving room for potential blind spots—AI provides real-time insights, ensuring that emerging risks are promptly detected.

This is particularly important in today’s global supply chain environment, which is as complex as it is unpredictable.

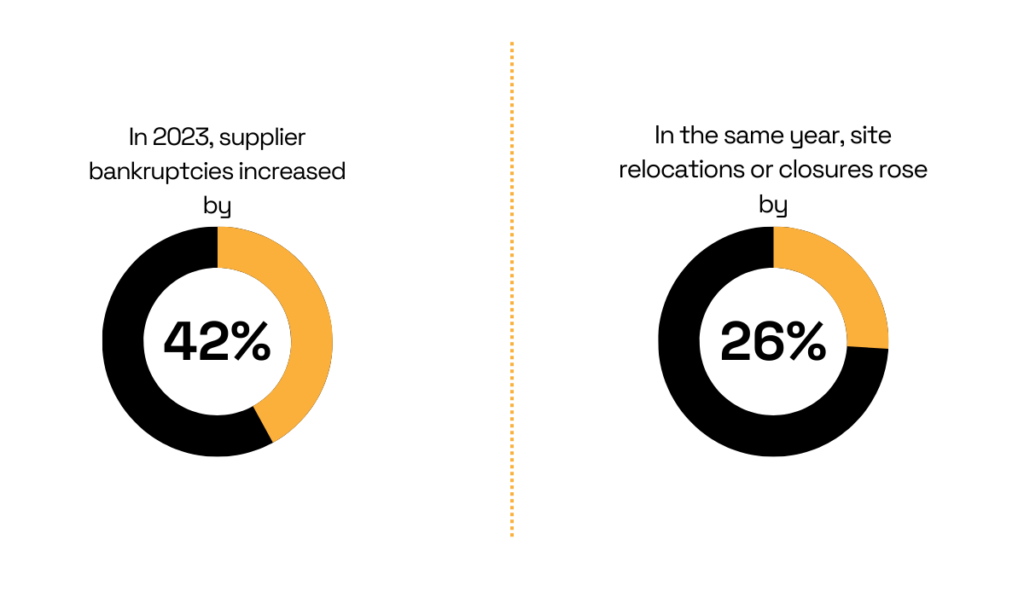

A 2024 report by Sphera shows just how severe the current situation is.

In 2023, high inflation rates in the EU and the U.S. significantly eroded suppliers’ purchasing power, leading to a 43% increase in supplier bankruptcies.

At the same time, site relocations or closures also shot up by 26%.

Illustration: Veridion / Data: Sphera

That is just one aspect of market volatility.

However, thanks to AI, it’s possible to stay ahead.

With its ability to constantly monitor suppliers and markets, AI empowers us to spot problems early, adapt quickly, and fix issues before they snowball into costly disasters.

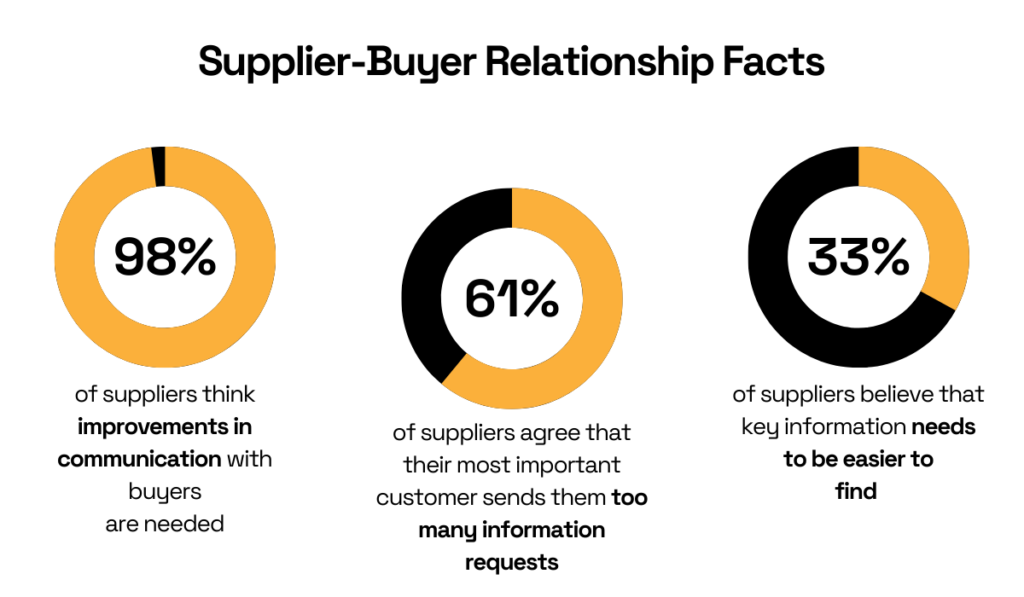

AI facilitates transparent, real-time communication between buyers and suppliers, contributing to improved collaboration among the two parties.

For example, AI-enabled procurement platforms can automatically update stakeholders on critical information, such as order statuses, production changes, and delivery schedules.

This, in turn, contributes to shorter response times and much more seamless coordination.

According to the 2024 HICX survey, that’s exactly what vendors want from their customers.

Namely, 98% of suppliers believe improvements in client communication are overdue.

Moreover, 61% of them report that their most important clients overwhelm them with excessive information requests, while 33% struggle to find key data when they need it.

Illustration: Veridion / Data: HICX

Implementing AI can help address these challenges, ensuring everyone has the right information at their fingertips.

As a result, both parties can work together to manage risks more effectively, building a stronger, more resilient supply chain.

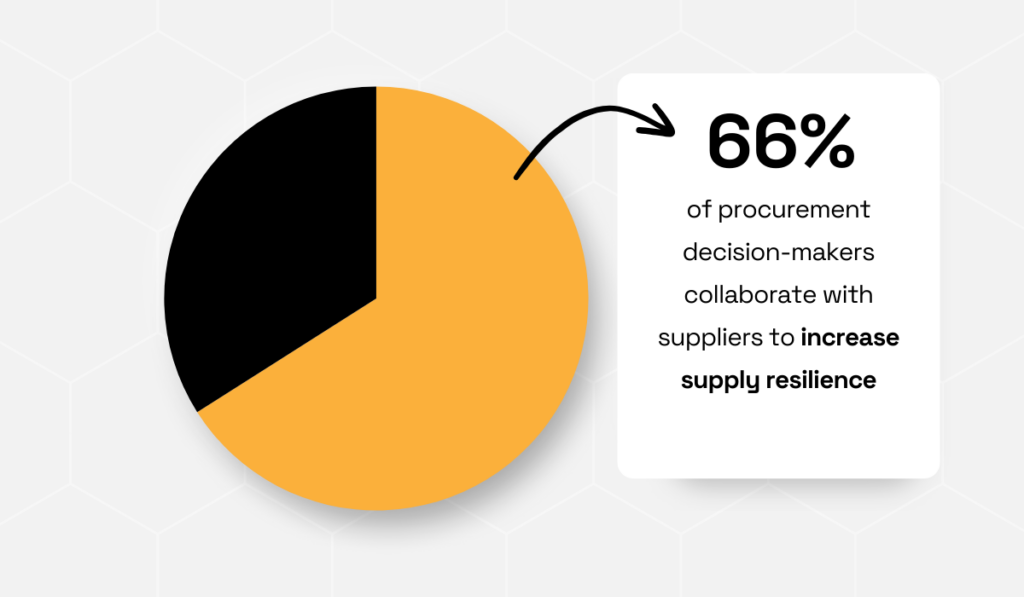

In fact, a 2022 Ivalua report revealed that 66% of procurement professionals already work closely with suppliers to improve resilience—proof that supplier-buyer partnerships are the foundation of effective risk management.

Illustration: Veridion / Data: Ivalua

By using AI, maintaining and growing these partnerships becomes significantly easier, with better alignment on goals and reduced risk of miscommunication.

Of course, AI isn’t without its challenges.

Let’s explore some of them and see how these issues can be addressed.

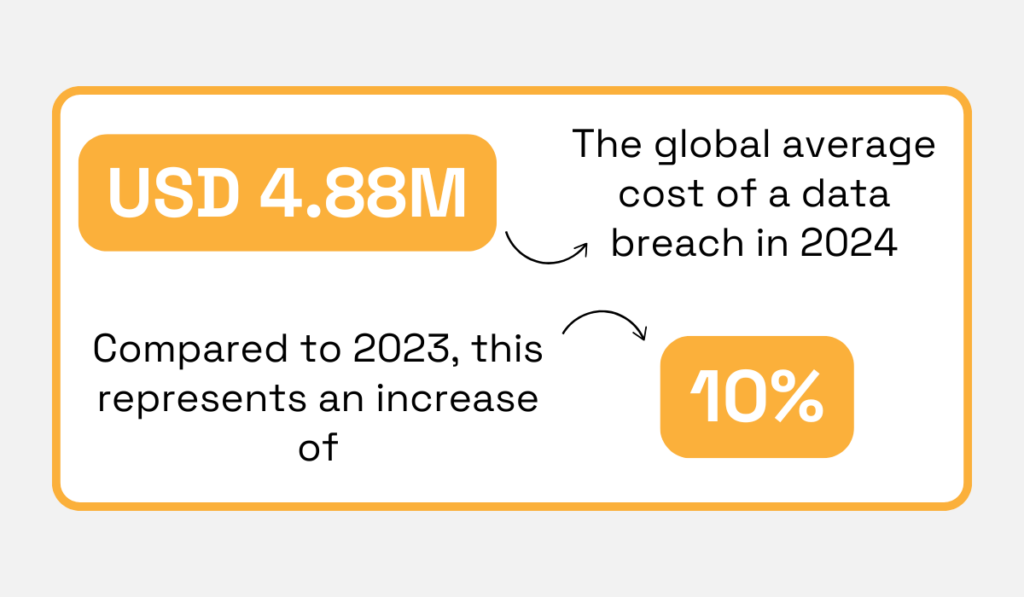

AI systems often handle sensitive supplier data, such as credit scores, production capacities, and other confidential information, raising concerns about data privacy and security breaches.

And these concerns are well-founded.

Inadequate data protection measures can easily lead to data leaks, legal penalties, and a considerable loss of trust from suppliers.

Did you know that, according to IBM’s recent report, the average cost of a data breach can reach as high as USD 4.88 million?

Illustration: Veridion / Data: IBM

This just goes to show how high the stakes are.

Therefore, AI adoption must be approached with careful planning and proactive risk mitigation, just like they do at Coca-Cola.

Their Senior Director of Digital Transformation Kim Harris explains that the company is revising its data security policies to align with the evolving capabilities of AI:

“We have a robust process internally around IT and data security assessments. However, we need to modernize the content of those assessments and what they are looking for now in the age of AI, to ensure that we are assessing the right things, at the right time, because of the rapidly changing environment.”

In addition to this, they are collaborating with their legal department to ensure compliance and thorough vetting of AI technology vendors:

“We’re also working with legal to ensure the correct frameworks, terms and conditions are in place for any contracts as well. This ensures that any deals we strike with any of these providers have got the right, robust legal terms behind it.”

Remember, when you venture into something as new and transformative as AI, some obstacles are inevitable.

That’s why it’s important to tread cautiously and assess risks before taking any significant steps.

Integrating AI-driven risk management systems with existing ERPs, supply chain management solutions, and other digital procurement tools isn’t always easy.

It requires technical expertise, time, and financial resources, which can make the process quite complicated.

In fact, AI integration is a challenge for a majority of businesses, according to the 2024 MuleSoft survey.

A concerning 95% of them report that integration issues slow down AI adoption, while 62% feel their organizations are not well-equipped to fully harmonize data systems to effectively use AI.

Illustration: Veridion / Data: MuleSoft

Why is this a problem?

Because poor integration creates data silos, disrupts system efficiency, and limits AI’s ability to provide actionable supplier risk assessments.

After all, AI algorithms are only as effective as the information they analyze.

If they can’t access data from existing systems, the quality and reliability of AI-generated insights suffer.

So, how can you address this obstacle?

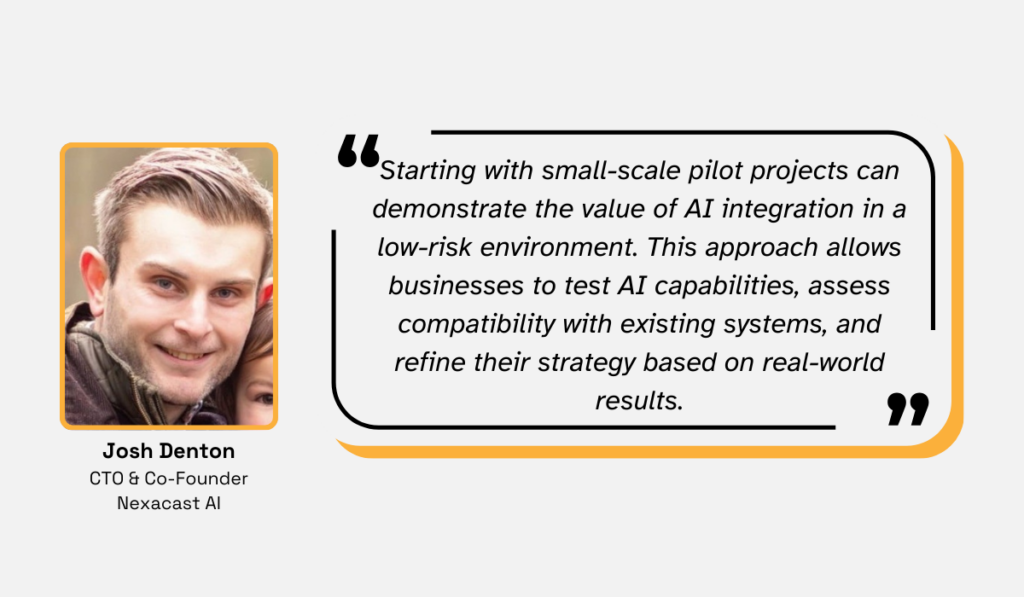

Start small, as Josh Denton, CTO and Co-Founder at Nexacast AI, an AI-powered business optimization platform suggests:

Illustration: Veridion / Quote: LinkedIn

Using AI for a smaller project first is a great way to evaluate your integration capabilities and determine whether full-scale implementation is feasible.

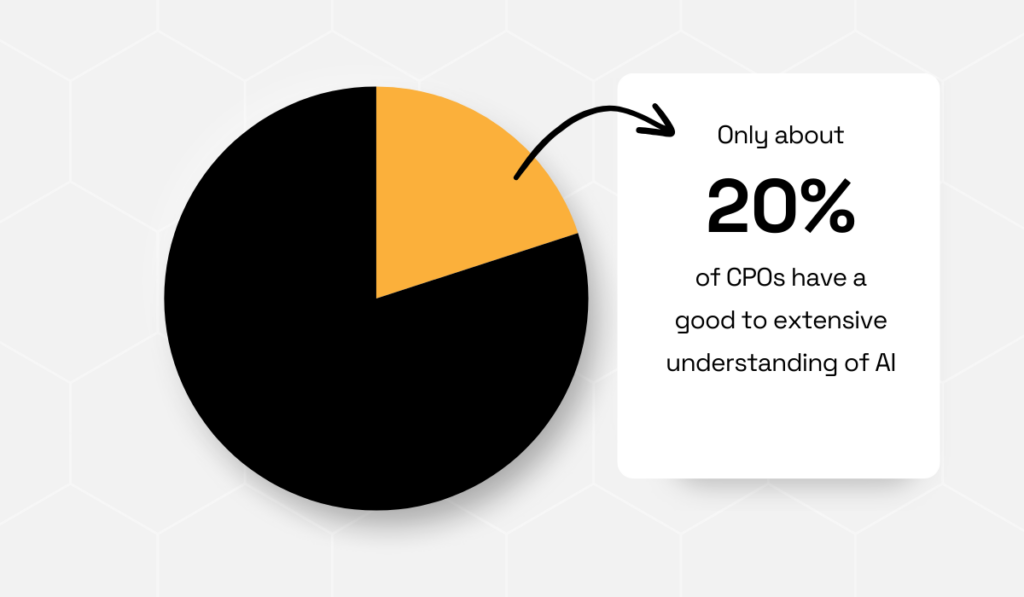

Implementing and managing AI systems requires expertise in data science, machine learning, and supply chain management—skills that are lacking in many organizations.

A 2024 Deloitte survey highlights the extent of the issue, revealing that only 20% of CPOs feel confident in their understanding of AI.

Illustration: Veridion / Dara: Deloitte

Meanwhile, 71% admit to having limited to moderate knowledge, and 9% have almost no understanding at all.

The issue is this: without adequate expertise, organizations risk poor implementation, misinterpretation of AI outputs, and overall suboptimal use of the technology.

So, to address this challenge, Peter Bloom, Head of Strategic Sourcing and Procurement at digital collaboration platform, Miro, suggests proactively educating employees:

“If we can be more proactive in educating our employees, and giving them better information that we think is relevant to them, that puts us in a position where we’re spending less time answering the same questions over and over and over again. It also means we can all focus on more value-added exercises, like using AI to standardize negotiating contracts.”

When we demonstrate how AI can benefit employees in practical ways, rather than discussing it in abstract terms, they are more likely to understand and implement it correctly.

Although bridging the skills gap can’t happen overnight, it’s still an investment worth making.

AI-savvy teams are better equipped to unlock the true potential of this technology, transforming it from a simple buzzword into a strategic ally.

It’s clear that AI is set to transform supplier risk assessment forever—and for the better.

However, if you’re eager to implement this tech right away, do your due diligence first and ensure you have all the necessary elements in place.

Get your team on board, ensure they’re properly trained, and set up clear policies to use AI efficiently.

Once you’ve got everything in place, start a pilot project.

With some patience and effort, you’ll soon unlock the full potential of AI, strengthening your supply chain and reaping the rewards of more resilient operations.