5 Technologies That Are Revolutionizing Supplier Sourcing

Today, more than ever before, procurement teams face immense pressure to increase efficiency, find cost-saving opportunities, and minimize supplier risks.

Choosing the right suppliers is crucial in this respect, as it impacts everything from product quality and cost to delivery times and customer satisfaction.

Meeting these demands in a complex global market can be a real challenge.

However, existing and emerging technologies can help procurement professionals handle these complexities with ease and confidence.

If you want to explore these systems, this article is for you.

In the following sections, we’ll look at five key technologies transforming how businesses find and manage their suppliers.

Let’s get started.

Artificial intelligence has been in the spotlight for a while now, and for good reason.

After all, its ability to analyze information and learn from patterns has found many applications in boosting efficiency across various industries.

When it comes to supplier sourcing in particular, AI truly shines in terms of processing vast amounts of data associated with potential suppliers.

As Chin Tee Teo, former global supply chain director at Philips, explains, AI far surpasses human capabilities in this area.

Illustration: Veridion / Quote: LinkedIn

While procurement teams possess that key human touch and experience, AI’s ability to simultaneously analyze data from global markets and conduct searches based on multiple criteria, such as cost, location, and more, is simply unmatched.

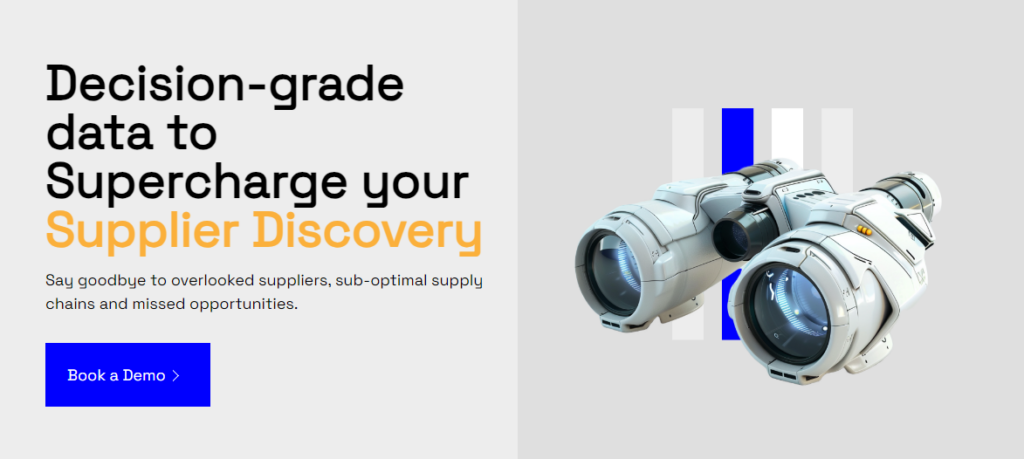

To illustrate the benefits of this technology, let’s look at Veridion, our very own supplier sourcing service.

Source: Veridion

Veridion uses AI and Machine Learning (ML) algorithms to provide access to a database of over 100 million companies, complete with key attributes like business size, location, sustainability insights, and more—all neatly categorized and tagged.

Our data is refreshed weekly and is easily accessible through our powerful Search API.

Take a look at the video below for a demonstration of how it works.

Source: Veridion

With just a few key criteria, which can be entered using natural language, you can get almost instant results and discover the right suppliers for your organization’s needs.

But AI’s potential in this field doesn’t stop there.

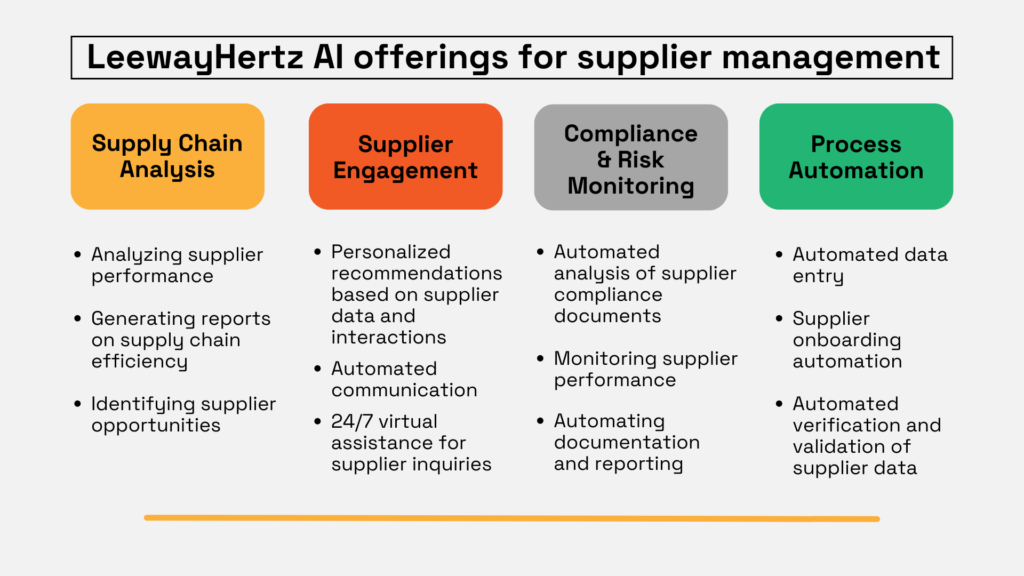

For instance, the AI consulting and development company LeewayHertz has various offerings in terms of AI-powered supplier sourcing and management.

Illustration: Veridion / Data: LeewayHertz

As you can see, the options are endless and can be applied throughout the sourcing process, even extending to supply chain improvement and supplier management.

The benefits are clear.

On one hand, you get efficiency gains by automating tasks like supplier monitoring, data entry, and even vendor onboarding.

On the other, AI also offers data processing advantages, such as identifying unique sourcing opportunities and extracting risk and compliance insights from data.

In short, AI is revolutionizing supplier sourcing by enabling faster, more informed decisions and, ultimately, more efficient supply chains.

When you hear “blockchain,” you might immediately think of cryptocurrencies like Bitcoin.

You might even wonder why we’re discussing this technology in the context of supplier sourcing.

Well, blockchain is much more than just cryptocurrencies.

It’s actually a combination of technologies that work together to create reliable chains of information, ensuring transparency and security in tracking transactions and assets.

Some of the key technologies that make up blockchain include:

When it comes to supplier sourcing and management, blockchain can create a safer and more streamlined process through a combination of benefits illustrated below.

Source: Veridion

For starters, this technology streamlines the procurement process by eliminating intermediaries.

And, as all transaction data is immutably recorded in a shared place, accessible by anyone, this leads to greater transparency and trust between buyers and suppliers.

Also, blockchain enables accurate traceability of supplies, making it easier to verify the origin and authenticity of goods.

This is essential for ethical sourcing and compliance with quality standards.

With sensor integration, you can even get real-time tracking of product conditions like temperature and humidity, which are crucial for sensitive goods.

Finally, smart contracts—a key feature of blockchain—automate tasks like payments and order fulfillment in supplier sourcing, reducing delays and human error, and ultimately leading to more efficient procurement processes.

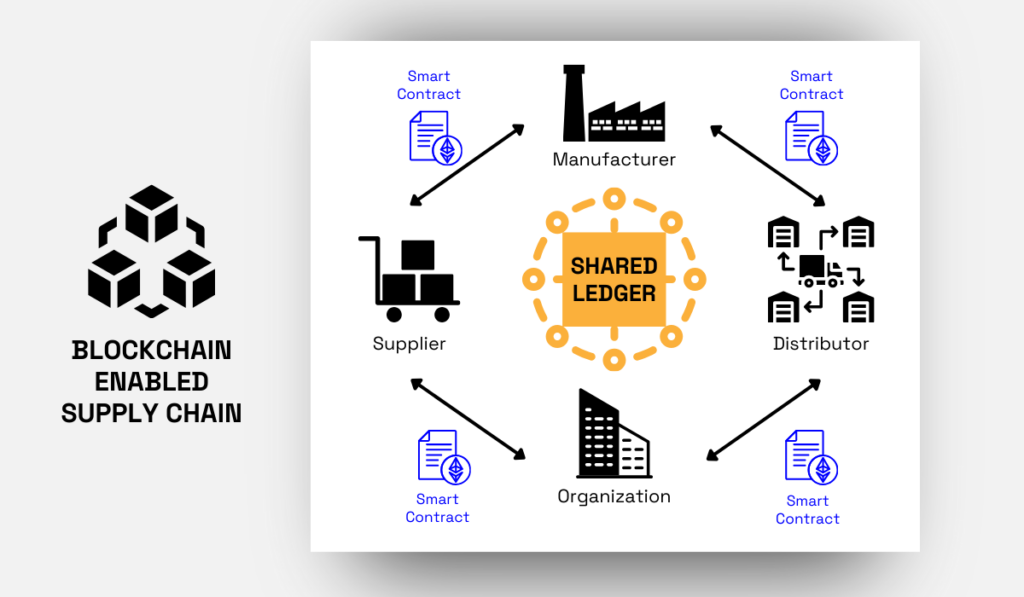

Let’s visualize a fully blockchain-enabled supply chain.

Source: Veridion

As you can see above, every operation is managed and visible on a shared ledger that records every transaction and movement of goods.

Smart contracts connect each participant in the supply chain: the supplier, manufacturer, distributor, and organization procuring the goods.

This setup fosters transparency and trust, as all parties have access to the same information.

This level of transparency allows for better sourcing optimization.

More specifically, procurement teams can accurately track and identify bottlenecks, manage supplier performance, and make data driven sourcing decisions accordingly.

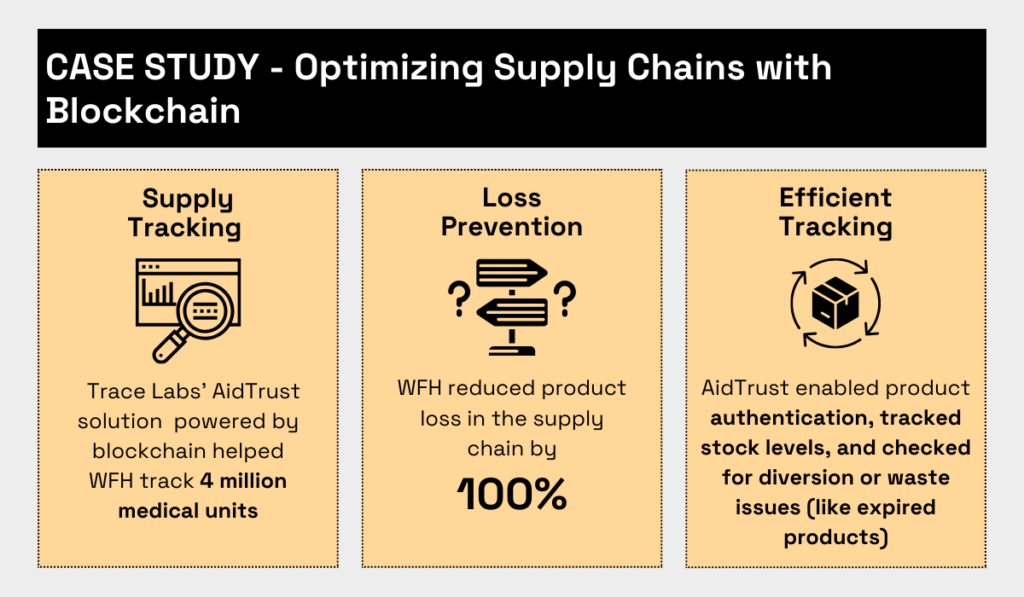

Take a look at the findings of the case study conducted by the World Federation of Hemophilia (WFH), an NGO that donates medicine to developing countries.

Illustration: Veridion / Data: Gartner

WFH faced challenges with product tampering and inefficient tracking.

But, by implementing Trace Labs’ AidTrust solution, powered by blockchain, they were able to:

So, while it may not yet be widely familiar in this context, blockchain technology has the potential to revolutionize how businesses find and manage suppliers, leading to more resilient and transparent supply chains.

Digging deeper into supplier sourcing technology, we come to augmented reality (AR).

AR technology uses advanced cameras and AR headsets to overlay digital information onto the real world, enhancing the user’s perception of reality by adding computer-generated images or data to a live view.

This technology blends the physical and digital worlds, providing an interactive and immersive experience.

The procurement and supply chain industry is no stranger to AR.

In fact, DHL tested AR in its warehouse operations back in 2015, achieving significant efficiency gains.

Source: DHL

While the benefits of AR in warehousing are evident, you might wonder how this technology aids in supplier sourcing.

Well, AR proves particularly useful in facilitating Factory Acceptance Tests (FATs).

In case you’re not familiar, FATs are crucial inspections conducted by buyers at a supplier’s manufacturing facility to verify that equipment meets specified requirements.

These tests ensure that any defects are identified and corrected before supplier contracts are finalized, minimizing costly downtime or risks down the line.

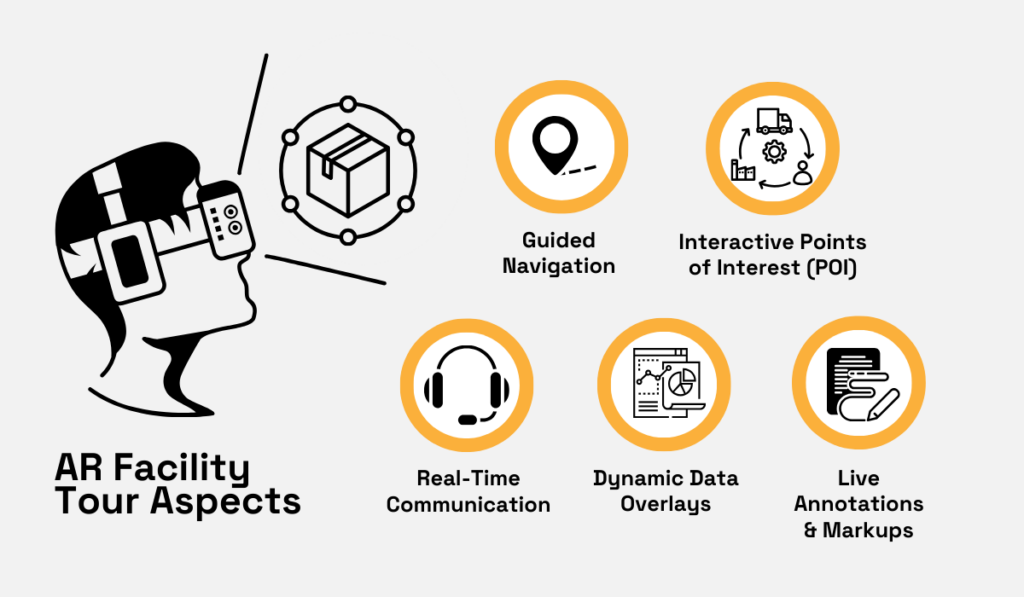

So, instead of requiring in-person visits, AR enables virtual facility tours with several unique advantages shown below.

Source: Veridion

During a virtual tour, an employee at the supplier’s facility wears a camera and headset, allowing the buyer to participate from anywhere in the world.

The buyer can communicate with the employee, guiding them through the facility.

The real power of AR lies in its ability to provide interactive points of interest, where buyers can click on specific equipment to access detailed information or specifications.

Also, dynamic data overlays on key pieces of equipment offer real-time performance data and insights.

To visualize this, take a look at Nsflow, an AR platform, and the depiction of their AR facility tour service.

Source: Nsflow

To further illustrate the benefits of AR-enabled FATs, let’s compare them to traditional FATs.

| Traditional FAT | AR-Enabled FAT | |

|---|---|---|

| Location | On-site at the supplier’s facility | Remote, accessible from anywhere |

| Setup Time | Longer due to logistics and travel | Quick setup with AR device |

| Interaction | In-person only | Real-time with annotations |

| Inspection Detail | Limited to on-site expertise | Enhanced with data overlays |

| Documentation | Manual, with photos and notes | Automated recording and screenshots |

| Flexibility | Limited response to issues | Instant flagging and follow-ups |

| Cost Efficiency | Higher costs due to travel and accommodation | More cost-effective, no travel needed |

Essentially, AR-enabled FATs offer a more efficient, flexible, and cost-effective approach compared to traditional on-site inspections.

Overall, AR is currently used in niche use cases, but it has the potential to transform how buyers assess suppliers and conduct inspections, leading to more informed decisions and improved sourcing outcomes.

Next, let’s explore a technology that can automate our day-to-day sourcing activities: Robotic Process Automation, or RPA.

RPA uses software robots to automate repetitive, rule-based tasks, freeing up human employees for more strategic work.

We can imagine it as a digital assistant that can perform tasks like data entry, form filling, and report generation with speed and accuracy.

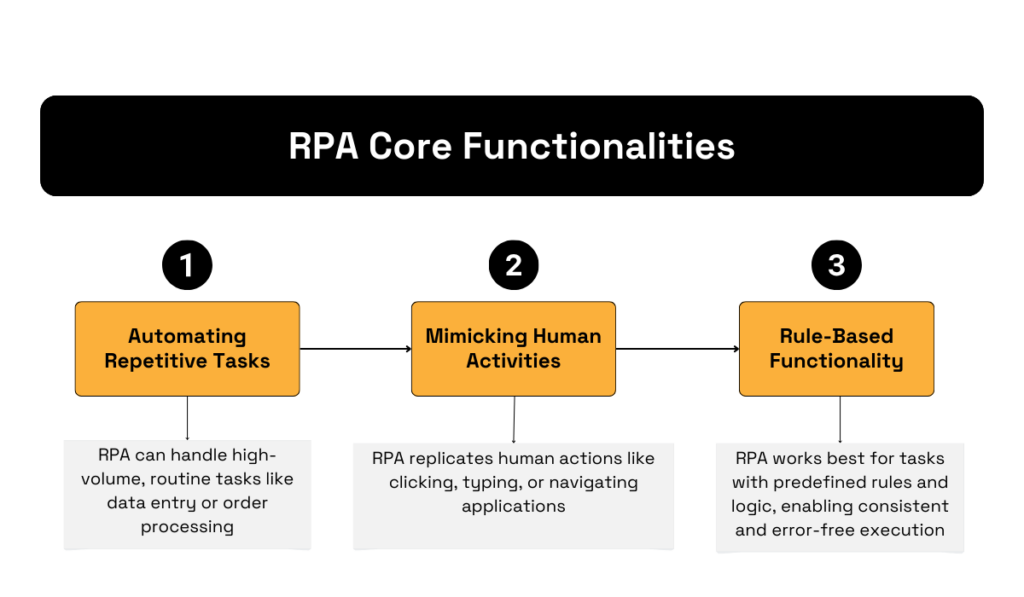

The three core functionalities of RPA are illustrated in the image below.

Source: Veridion

As we can figure out from RPAs definition, its core goal is to automate repetitive and routine tasks, especially those with consistent, predefined rules and logic.

RPA achieves this by mimicking human activities, from basic clicks and typing to navigating applications and moving the mouse.

Now, let’s examine how RPA can be integrated into supplier sourcing.

Source: Veridion

Essentially, RPA can be applied wherever repetitive work exists, from purchase order (PO) and contract creation to supplier data extraction and verification for due diligence, risk assessment, compliance checks, and even invoice processing.

Contract management is a particularly strong use case for RPA.

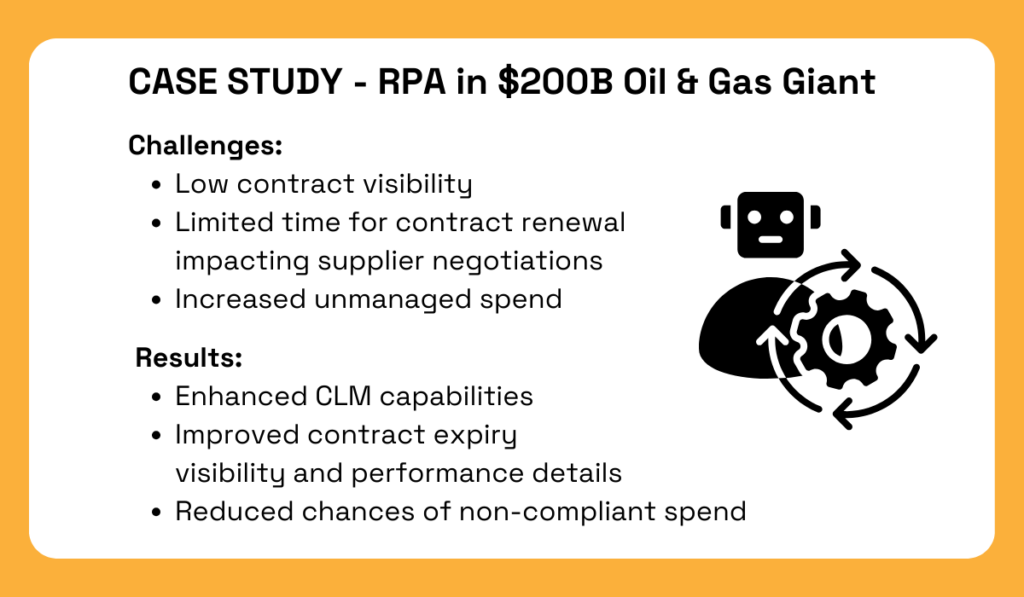

For example, the image below breaks down how an Oil & Gas giant with over 200 billion USD in revenue utilized RPA for supplier contract management.

Illustration: Veridion / Data: GEP

This case study highlights the company’s challenges with contract visibility and renewal.

These issues hindered their supplier negotiations by limiting their leverage and insight into contract terms, ultimately increasing their unmanaged spend.

By implementing RPA to automate key processes, the company significantly enhanced its overall contract lifecycle management, realizing cost savings and greater contract visibility.

Overall, this technology offers immense potential for streamlining those small and repetitive sourcing tasks that take up resources unnecessarily.

Finally, let’s explore the power of predictive analytics.

This technology combines statistical algorithms and machine learning techniques to analyze historical data, identify patterns, and forecast future outcomes.

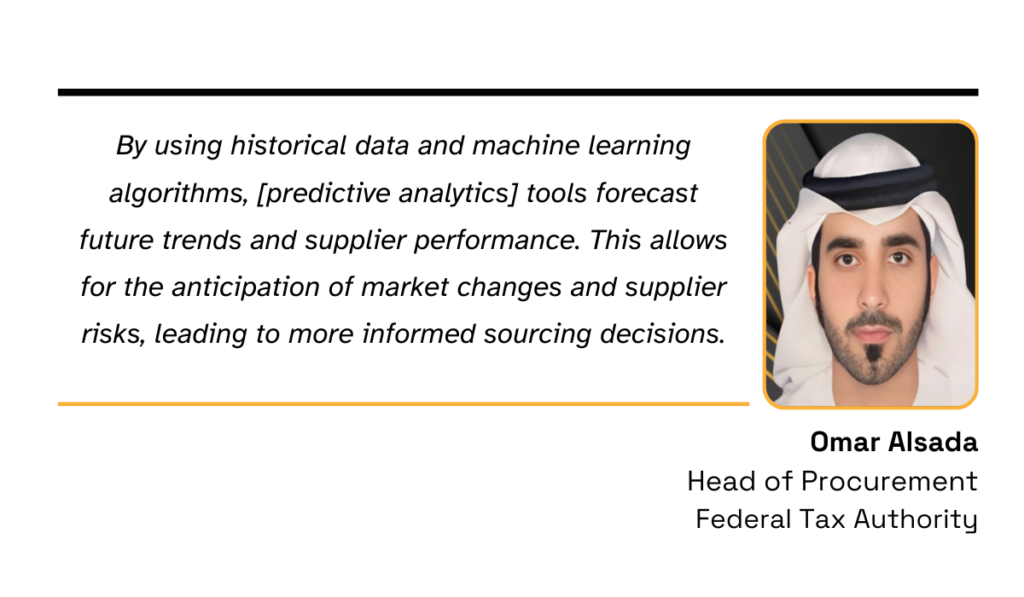

Omar Alsada, Head of Procurement for a federal tax authority, highlights the value of predictive analytics:

Illustration: Veridion / Quote: LinkedIn

By leveraging historical data on suppliers, you can predict their performance, potential risks, financial stability, and even anticipate potential disruptions or delays.

But how do you use this information?

Well, you can use it to identify reliable suppliers, negotiate better contracts, and ensure timely delivery of goods.

Ultimately, this can lead you to increased supplier accountability and quality.

It’s worth noting that leading global supply chain organizations are already harnessing the power of predictive analytics.

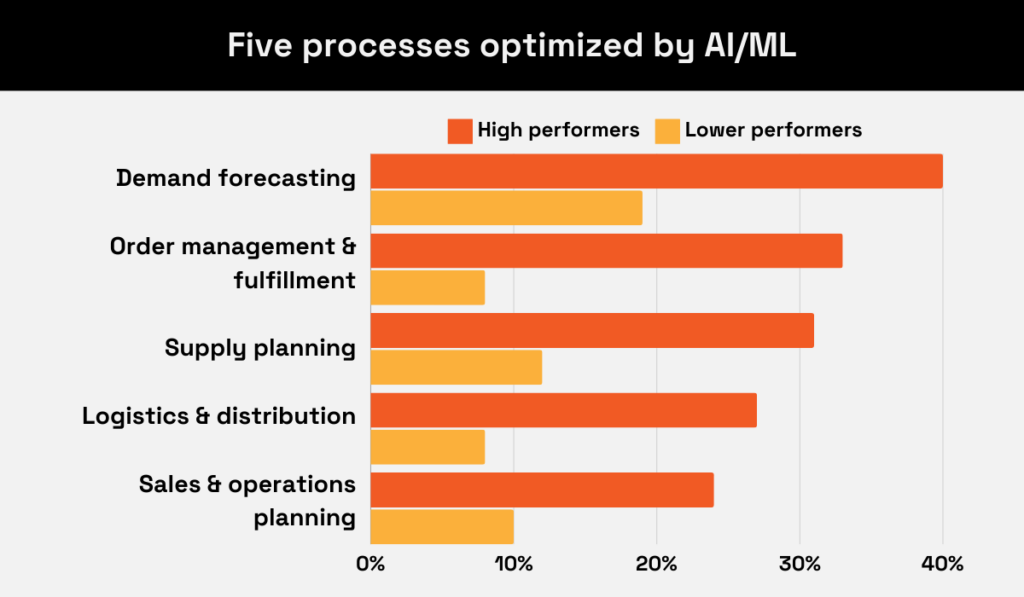

According to a 2024 Gartner report, both high-performing and lower-performing companies utilize AI and ML primarily for demand forecasting.

Illustration: Veridion / Data: Gartner

Analyzing historical data on demand allows businesses to anticipate future needs more accurately.

This, in turn, informs supplier sourcing decisions, ensuring that the right quantities of goods are procured from the right suppliers at the right time.

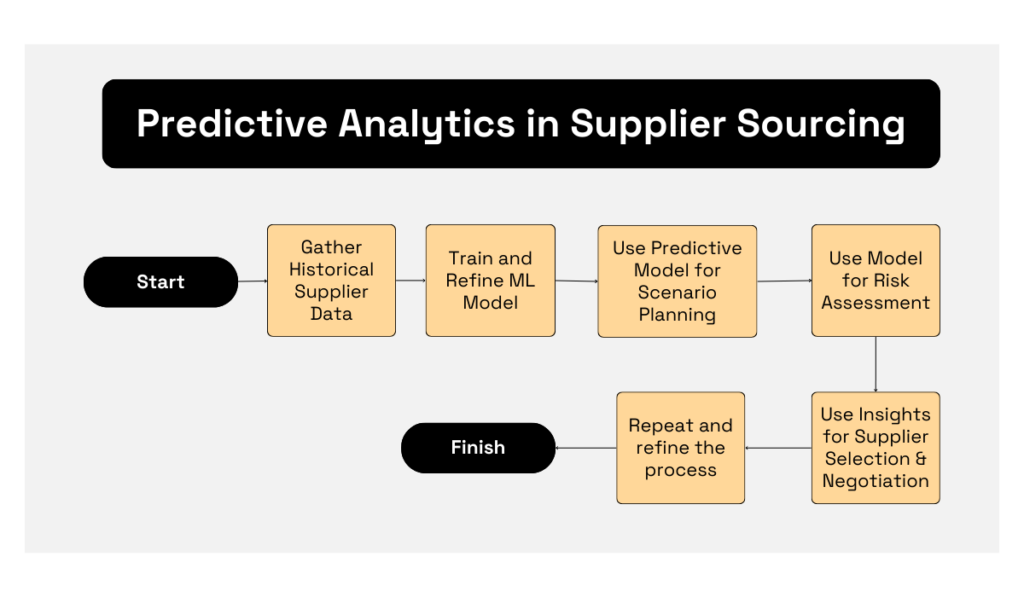

To illustrate how predictive analytics is applied in sourcing in general, take a look at the illustration below.

Source: Veridion

The process begins with gathering and cleaning data to train machine learning models.

These models are then used for scenario planning, which involves simulating different situations to evaluate potential outcomes, and for risk assessment, which identifies potential disruptions or challenges.

These insights then inform both supplier selection and negotiation strategies.

For example, imagine a company sourcing a critical component for their product.

Predictive analytics might reveal a particular supplier has a history of late deliveries during a specific season.

Using this knowledge, the procurement team can proactively seek alternative suppliers or negotiate stricter delivery terms to mitigate potential disruptions.

In essence, predictive analytics empowers procurement teams to move beyond reactive decision-making and embrace a proactive, data-driven approach.

As you can see, this is an exciting time for procurement, with technology opening doors to new levels of efficiency and insight.

We’ve explored how AI, blockchain, AR, RPA, and predictive analytics are revolutionizing supplier sourcing.

Hopefully, you now have a better understanding of how these technologies can address common supplier sourcing challenges and drive significant improvements.

By embracing these advancements, you can streamline and automate your sourcing process, make more informed vendor decisions, and even predict future challenges.

Ultimately, all of these benefits lead to a thoroughly vetted and more effective supplier base, giving your organization a competitive edge.