Why You Need a Good Supplier Management Plan

Key Takeaways:

What does your current supplier management strategy look like?

Is it an inconsistent, case-by-case process or an organized effort with well-managed and clear goals?

As you can imagine, the second option is essential for efficient operations, and in this article, we’ll outline exactly why.

We’ll explore five important reasons why planning out your supplier management practices beforehand can bring significant benefits throughout your supply chain and procurement processes.

Let’s dive in.

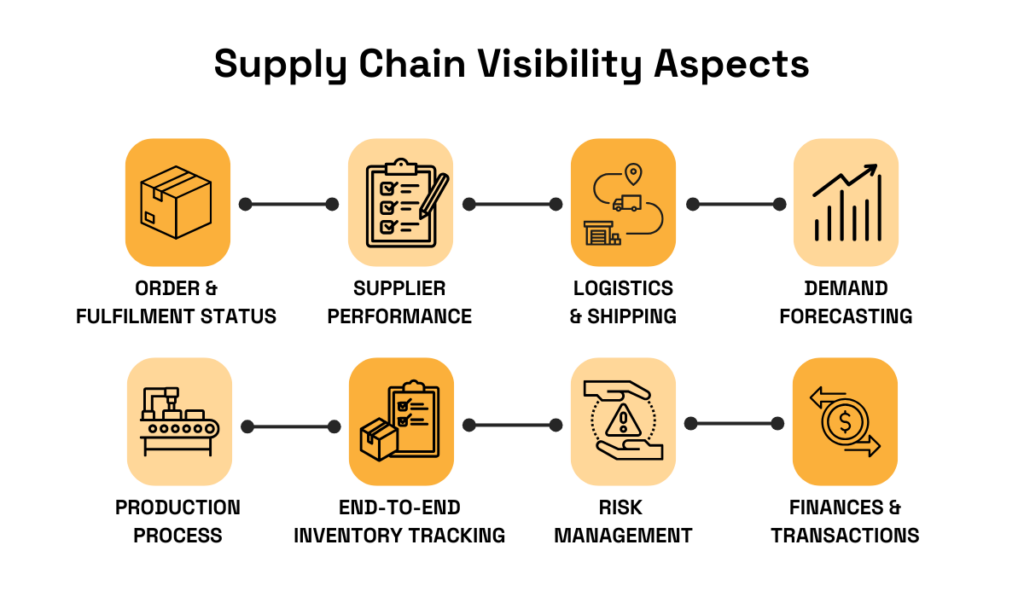

Transparency and process visibility are essential components across modern supply chains.

They’re crucial for everything from identifying potential bottlenecks and managing risks to optimizing your overall procurement efficiency.

Specifically, “visibility” means having a clear understanding of every stage in your supply chain, from production processes and raw material sourcing to product delivery.

Source: Veridion

Of course, developing a supplier management plan is an essential step in improving this visibility.

After all, any strategy you develop will take into account several aspects of the supply chain, including:

| Supplier performance | Measured with KPIs such as on-time delivery rates, quality metrics, and compliance adherence. |

| Inventory levels | Tracking stock levels in real time to avoid shortages or overstocking. |

| Delivery schedules | Closely monitoring inbound and outbound shipments to ensure timely delivery. |

A supplier management plan that incorporates these aspects directly enhances visibility by providing a structured framework for collecting and analyzing data.

But the relationship between planning and visibility goes both ways.

Greater visibility provides the data needed to refine and improve your supplier management plan, creating a positive feedback loop.

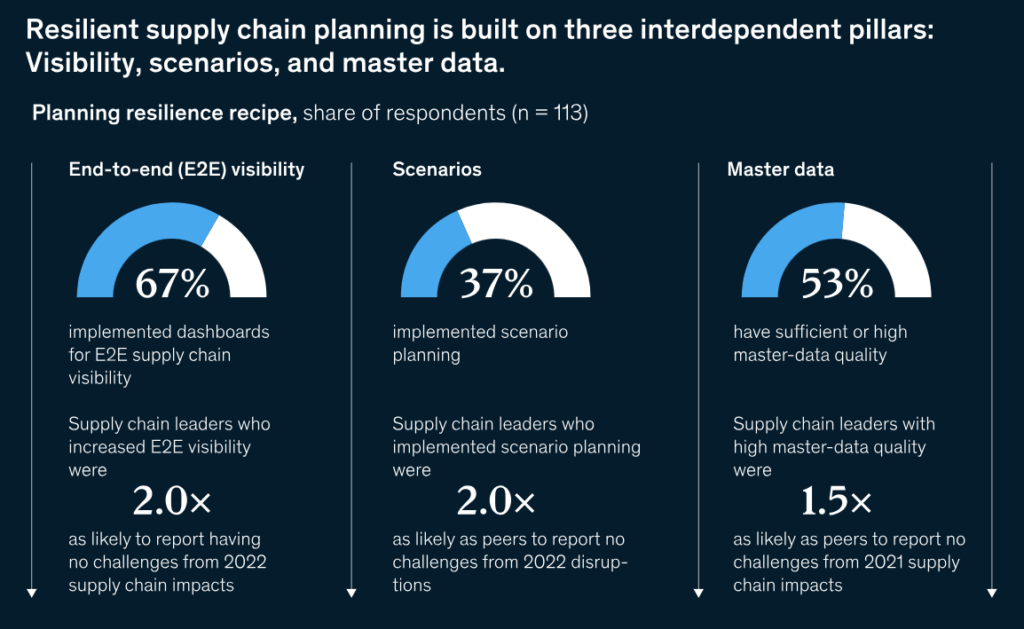

In fact, according to McKinsey data, the vast majority of supply chain leaders say that the main pillar of resilient supply chain planning is establishing end-to-end visibility.

Source: McKinsey

To see what we’re talking about in action, consider the case study of Hope for Justice and their partnership with Exiger, a supply chain risk management firm.

This partnership arose from the need for a more robust supplier risk management plan—one that prioritized visibility into ethical sourcing practices and labor conditions.

By working with Exiger, Hope for Justice gained access to advanced analytics, which enabled them to map their supply chains, identify potential vulnerabilities, and implement more effective monitoring processes.

Illustration: Veridion / Source: SCB

This case study effectively demonstrates how a focus on visibility can, and often should, be a core component of a successful supplier management plan.

In this instance, the initial plan increased visibility, which subsequently uncovered hidden issues, necessitating more thorough supplier management and sourcing changes to create a more ethically sound supply chain.

So, a good supplier management plan and supply chain visibility are closely connected, and working on either can improve your overall operations.

A good supplier management plan can lead to better organizational decision-making.

In fact, we’ve already discussed one key way this happens—through increased visibility.

Digging deeper into this, a big part of any effective supplier management plan is consolidating an organization’s supplier data and thoroughly monitoring various supplier metrics.

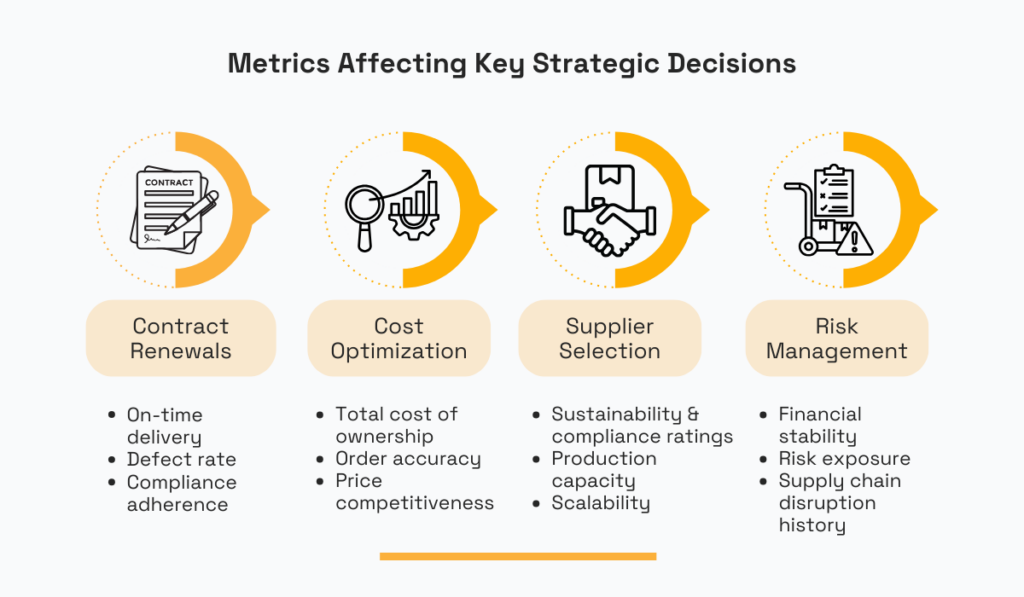

If you look at the following image, you can see some strategic decision areas to which these metrics are directly related.

Source: Veridion

For example, data on supplier price competitiveness and total cost of ownership can inform cost optimization decisions, allowing businesses to identify and negotiate better pricing models.

Moreover, insights into a supplier’s capacity and scalability can significantly influence supplier selection, ensuring alignment with future growth projections and minimizing potential supply chain disruptions.

However, unlocking these insights hinges on the quality of your supplier data.

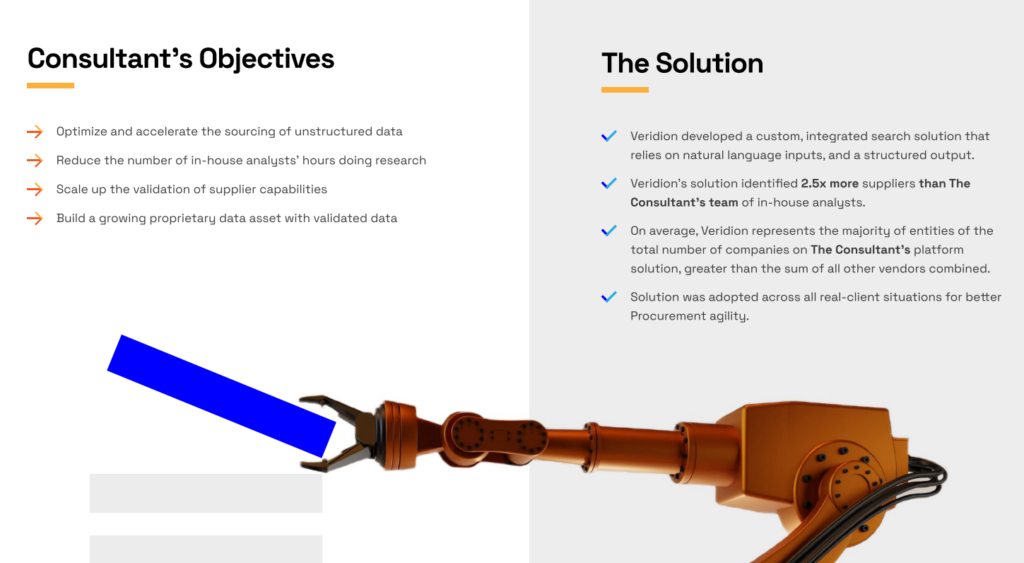

As an example, consider the challenges faced by a global consulting company and how they successfully addressed them using AI-powered business data from Veridion.

Among its various issues, this firm needed to scale up its supplier capabilities validation and optimize sourcing with fewer in-house analysts.

Source: Veridion

Veridion’s AI-powered supplier sourcing service drastically transformed its operations, helping it discover 2.5 times more potential suppliers than before.

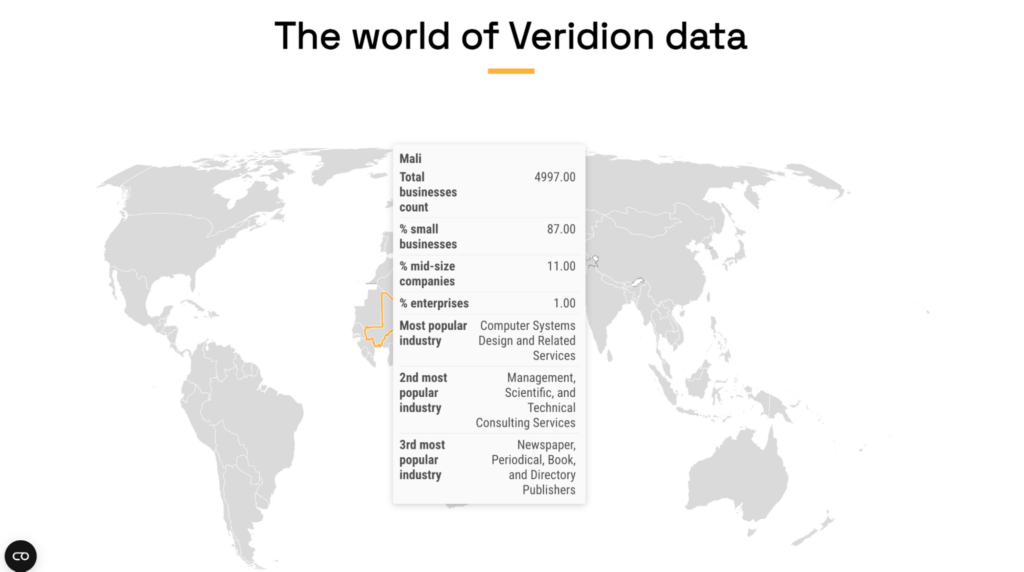

Veridion facilitated this process with our massive database of over 120 million companies worldwide, easily accessible through our Search API and Match & Enrich API.

Source: Veridion

Along with that, Veridion offers real-time alerts for any key changes in supplier data or activities, especially when related to potential risk areas.

That, in turn, empowers organizations to have all the necessary information to make better and faster supplier management decisions.

In any case, proper planning, especially when combined with the right data, can unlock critical insights for optimizing your operations.

Effective supplier management plans not only optimize day-to-day operations but also prepare you for the worst, building greater supply chain resilience.

After all, disruptions can happen at any time, especially in today’s volatile market.

These can range from raw material shortages and geopolitical events to natural disasters and unforeseen circumstances.

And if you’re unprepared, disruptions can come with significant costs.

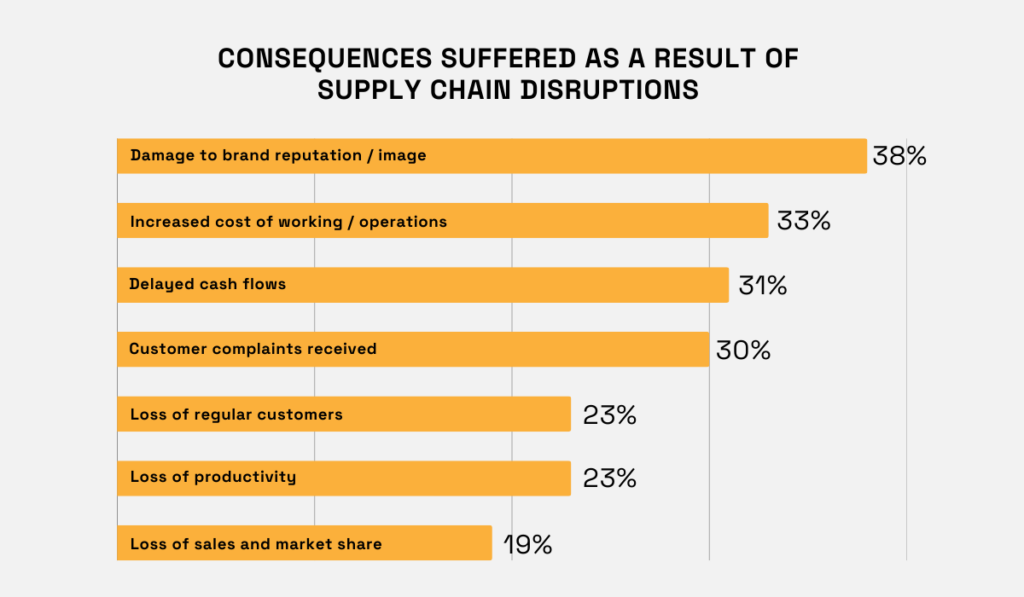

A 2021 Economist report sponsored by GEP explored some of the top consequences organizations face as a result of supply chain disruptions.

Illustration: Veridion / Data: The Economist

As you can see, even large firms are not immune to the reputational and financial damage that can stem from supply chain disruptions.

While a well-structured supplier management plan can help mitigate these consequences, many common practices are implemented without thorough preparation.

In fact, a practice may seem sound at first glance, but it can actually make your supply chain more vulnerable to unforeseen issues.

For example, consider what Dr. Shereen Nassar, Global Director of Logistics Studies & Supply Chain Management Programmes, identifies as an often-seen practice among supply chain managers.

Illustration: Veridion / Quote: Logisym

While consolidating suppliers might initially appear to streamline operations and potentially reduce costs, this strategy is ill-equipped to handle unexpected disruptions.

Dr. Nassar emphasizes that diversifying suppliers, such as by maintaining dual or multiple suppliers, is crucial for building resilience and reducing an organization’s dependency on just a few key partners.

Therefore, it’s beneficial to avoid seemingly common-sense approaches and instead strategically plan for resilience.

One helpful approach is to examine practices followed by other successful organizations.

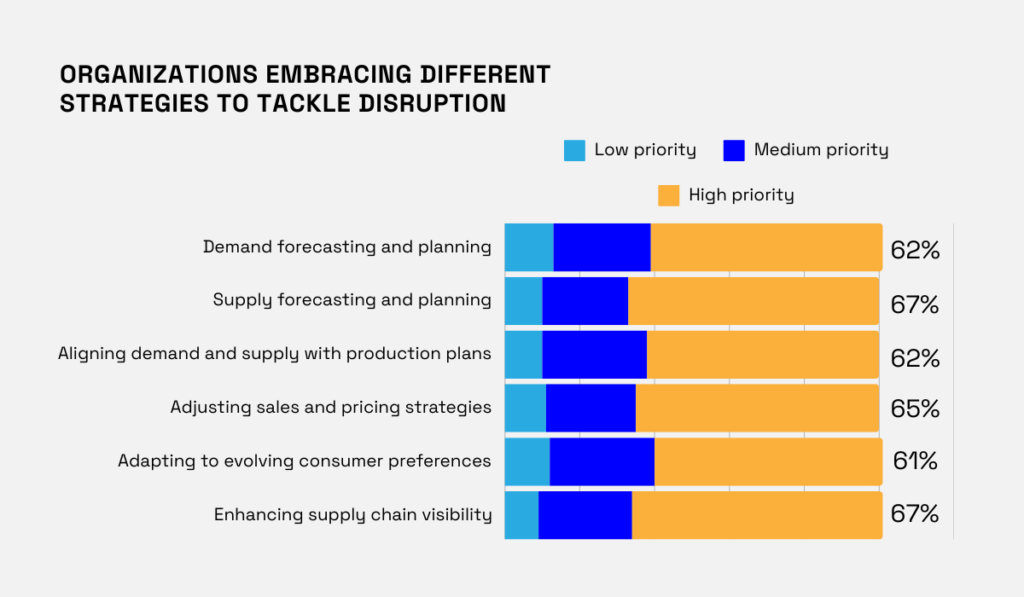

Take a look at the following list of strategies from a survey conducted by the Economist Impact.

Illustration: Veridion / Data: Economist Impact

As you can see, supply and demand forecasting are top priorities together with enhancing visibility, and with good reason.

Accurate forecasting allows businesses to anticipate potential imbalances between supply and demand, enabling proactive adjustments to inventory levels and production schedules.

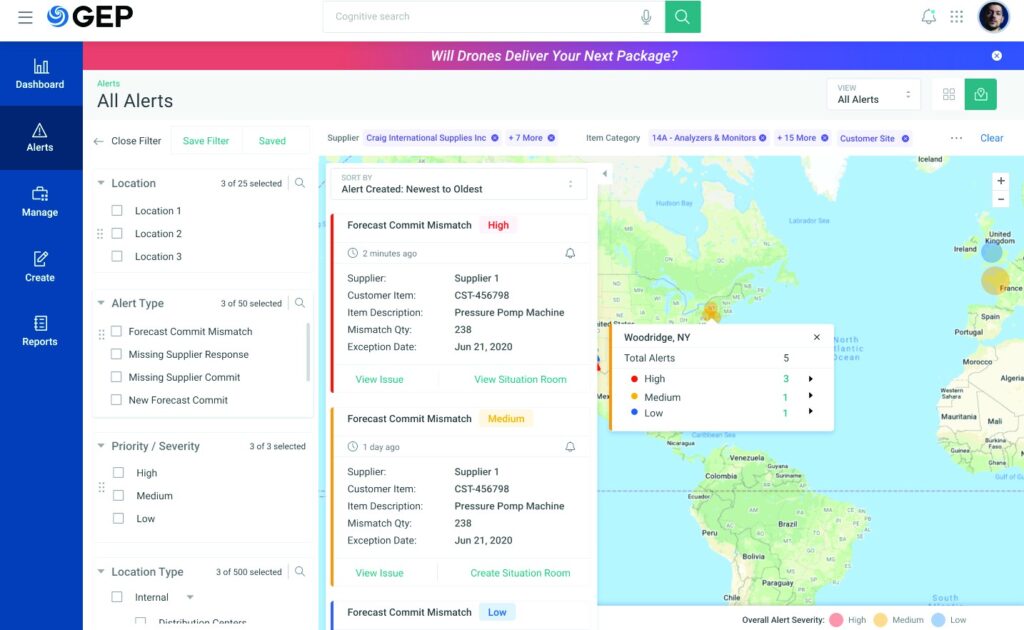

Today, many systems, such as GEP NEXXE, can facilitate these forecasts and provide real-time alerts when mismatches between forecasted and actual demand happen.

Source: GEP

On top of that, GEP NEXXE offers advanced analytics and machine learning capabilities to refine forecasting accuracy and provide deeper insights into potential disruptions.

With tools like these, plus a well-defined management plan tailored to your needs, building a resilient supply chain is very achievable.

The previous sections have demonstrated how effective supplier management planning can significantly improve operations.

These improvements often translate into tangible benefits, including cost savings, improved efficiency, and increased resilience across the entire supply chain.

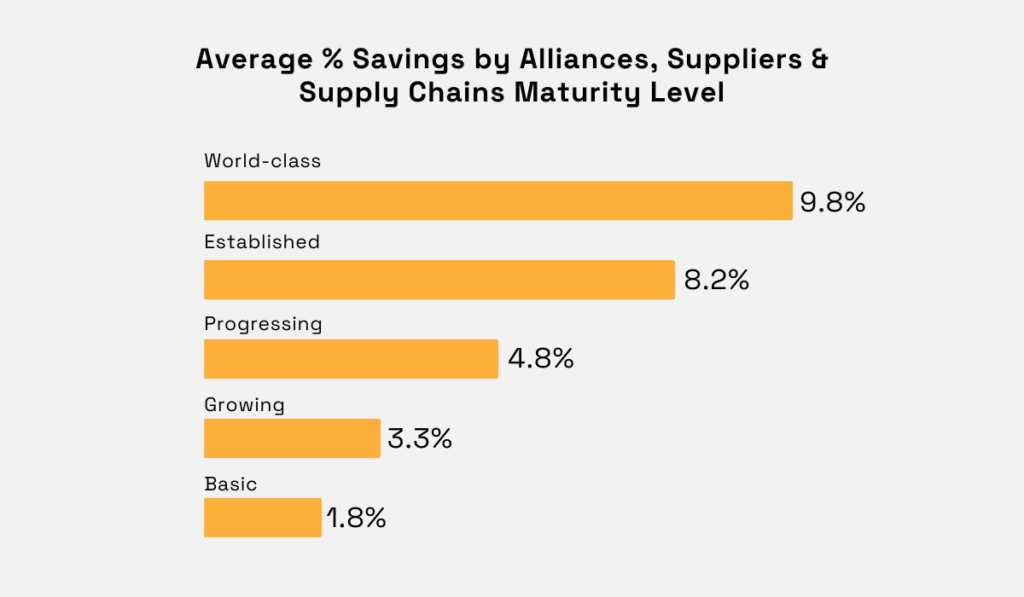

As an example, let’s consider some data from 4C Associates, a leading commercial, supply chain, and operations consultancy.

Their 2023 Procurement Reinvented annual report examined the advantages that organizations with more mature and established supplier and supply management processes have over their competitors.

Among other findings, their data revealed a strong correlation between the maturity level of these management processes and the amount of cost savings achieved.

Take a look at the data below.

Illustration: Veridion / Data: 4C Associates

Organizations with world-class management practices achieved 9.8% cost savings compared to only 1.8% savings for those with basic maturity.

On average, that means organizations with a World-Class Supplier & Supply Management maturity enjoyed 5.4 times more savings than those with a Basic maturity.

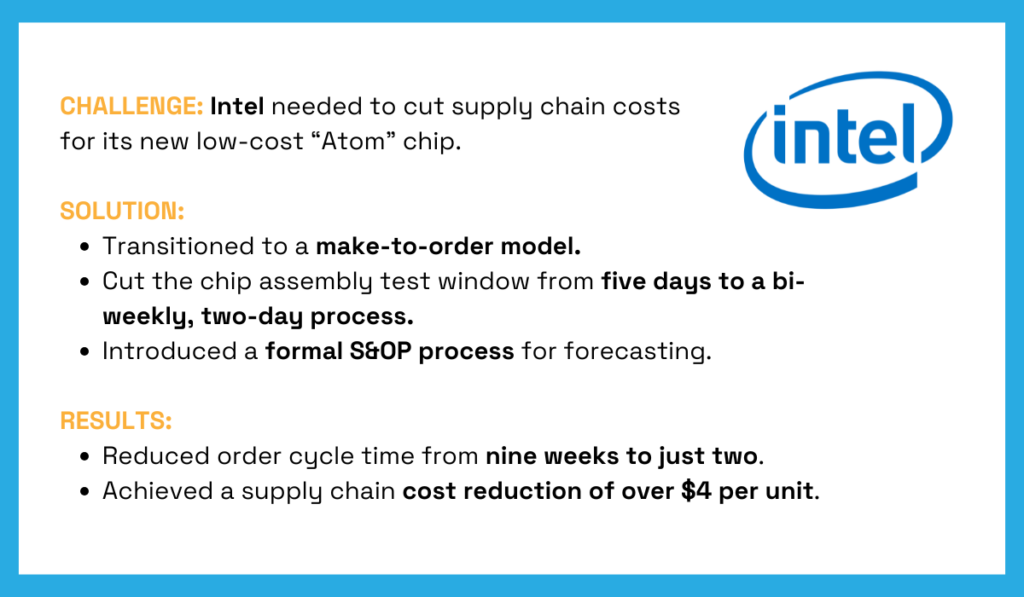

Let’s now examine a successful example of operational improvement: Intel’s strategy for its low-cost “Atom” chip.

While previous chips were priced around $100 per unit, the Atom chip was designed to be much more affordable, selling for approximately $20 per unit.

Unfortunately, traditional cost-cutting methods, such as reducing packaging or distribution expenses, were not viable due to the chip’s high value-to-weight ratio, and already optimized logistics.

Instead, Intel focused on optimizing supplier management and inventory processes.

Illustration: Veridion / Data: Logistics Bureau

Intel’s improvements in demand forecasting, implemented through a formal Sales & Operations Planning (S&OP) process, along with a make-to-order operational model, helped them achieve their cost reduction goal and drastically reduce order cycle time.

This example demonstrates how working closely with suppliers and implementing collaborative planning processes can be a highly effective strategy for operational improvements.

Beyond collaboration, thorough evaluation and supplier monitoring are essential for continuous improvement.

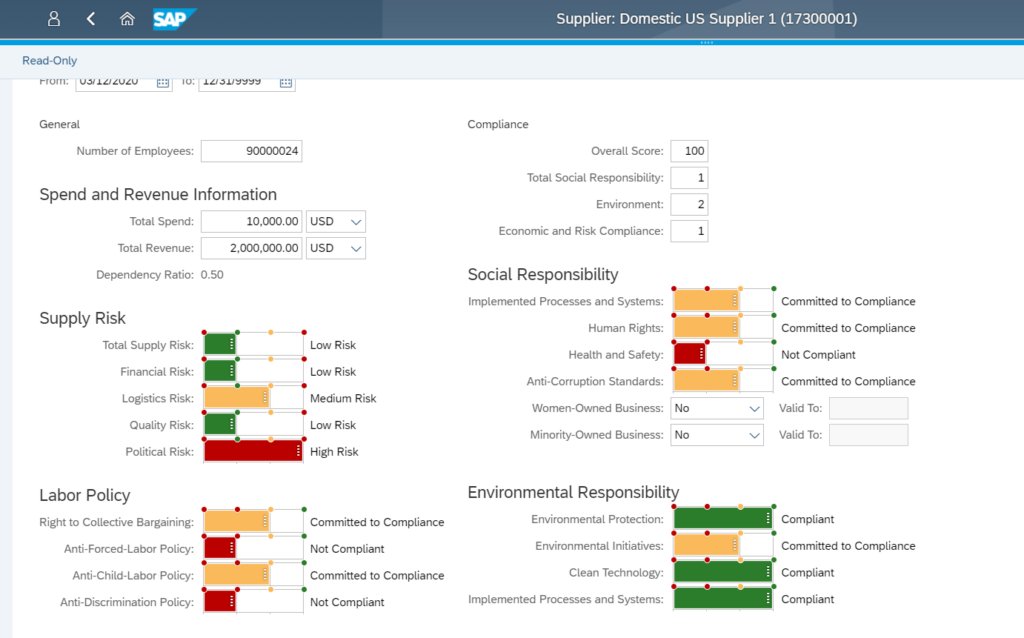

Systems like SAP S/4HANA can play a crucial role in this process.

SAP S/4HANA is an ERP system that, among other features, enables businesses to collect all necessary supplier data in a centralized location, as illustrated below:

Source: SAP

They can also help track compliance and risk factors, monitor performance, and generate comprehensive supplier evaluation scores, facilitating data-driven decision-making and continuous improvement efforts.

Overall, with a balanced approach of collaboration and vigilant supplier monitoring, organizations can achieve significant operational improvements.

Finally, a well-executed supplier management plan ensures your suppliers meet increasing demand as your business grows.

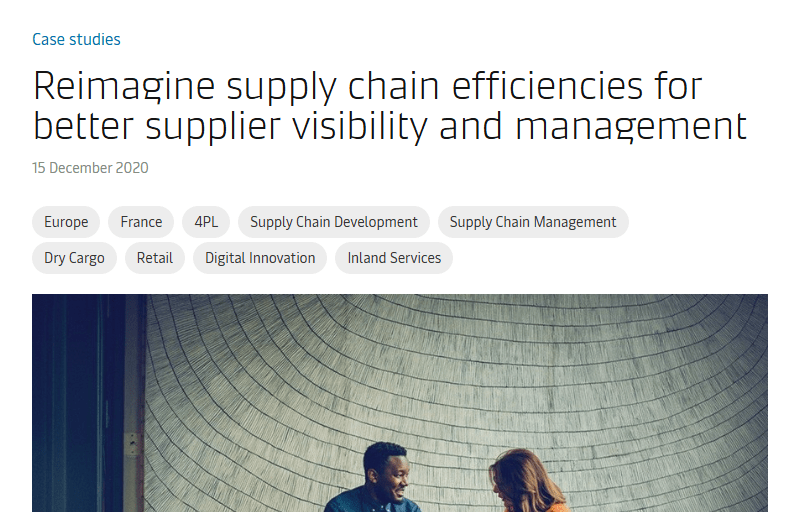

For example, consider how Maersk, a global leader in container shipping, implemented a supply chain management strategy for an online retailer.

The retailer faced several challenges, including issues with supplier oversight, origin supply chain control, and logistics.

All of these issues drained resources that could have been invested in growth and core operations.

Source: Maersk

Maersk collaborated with the organization to create a comprehensive strategy, supported by their services and software system, aimed at achieving the following:

As a result of this thorough plan, the retailer saw a 51% improvement in on-time delivery rates for prioritized orders, and a significant improvement in overall supplier performance.

For example, overall on-time rates for booking and delivery increased by 20%.

Supplier collaboration is another aspect that significantly contributes to growth.

As Shelly van Treeck, CPO of Kellogg’s, explains, this practice can drive mutual growth and create stronger, more resilient partnerships.

Illustration: Veridion / Quote: State of Flux

She emphasizes the need for suppliers who understand and are aligned with your long-term objectives.

This relationship-first approach is a great way to improve supplier performance and even increase innovation through collaboration.

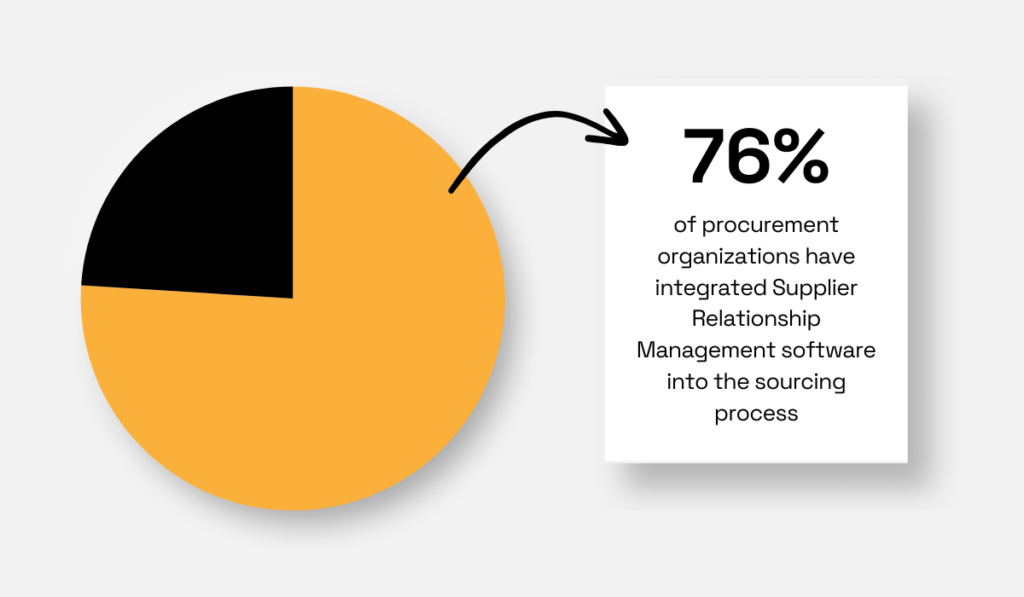

It comes as no surprise, then, that most procurement organizations utilize supplier relationship management (SRM) software.

Illustration: Veridion / Data: KPMG

Some of these platforms include:

These platforms streamline communication through supplier portals, provide performance management dashboards to track key metrics, offer risk management tools to mitigate potential disruptions, and automate key communication workflows.

This, in turn, frees up resources that can be reinvested in growth initiatives, allowing businesses to scale their operations more effectively and achieve long-term objectives.

And there you have it—five key reasons why you need a good supplier management plan.

As you saw from the examples, a well-defined plan provides better supply chain visibility, supports informed decision-making, and builds resilience against disruptions.

It also unlocks opportunities for continuous improvement and allows for more effective business scaling.

Hopefully, you now have a better grasp of the importance of proactive supplier management and the numerous advantages it brings.

Your next step?

Take time to evaluate your current approach and consider optimizing your strategies to drive greater success.