5 Tips for Procurement Cost Savings to Know About

Achieving cost savings while maintaining the quality of products and services sourced from suppliers is a perpetual goal of procurement executives, category managers, and other procurement professionals.

Cost savings often come as a result of increased efficiency and optimized organizational workflows. Then, companies are able to improve their profitability and gain a competitive edge in their industry.

This article will cover five tips you can apply to your procurement department if you want to achieve cost savings.

So read on to establish cost-effective procurement processes.

To determine whether there are some areas for implementing cost-saving measures, you can benchmark your procurement costs against industry standards.

These standards provide a comparative framework for companies to assess their procurement processes and cost structures against those of their industry peers.

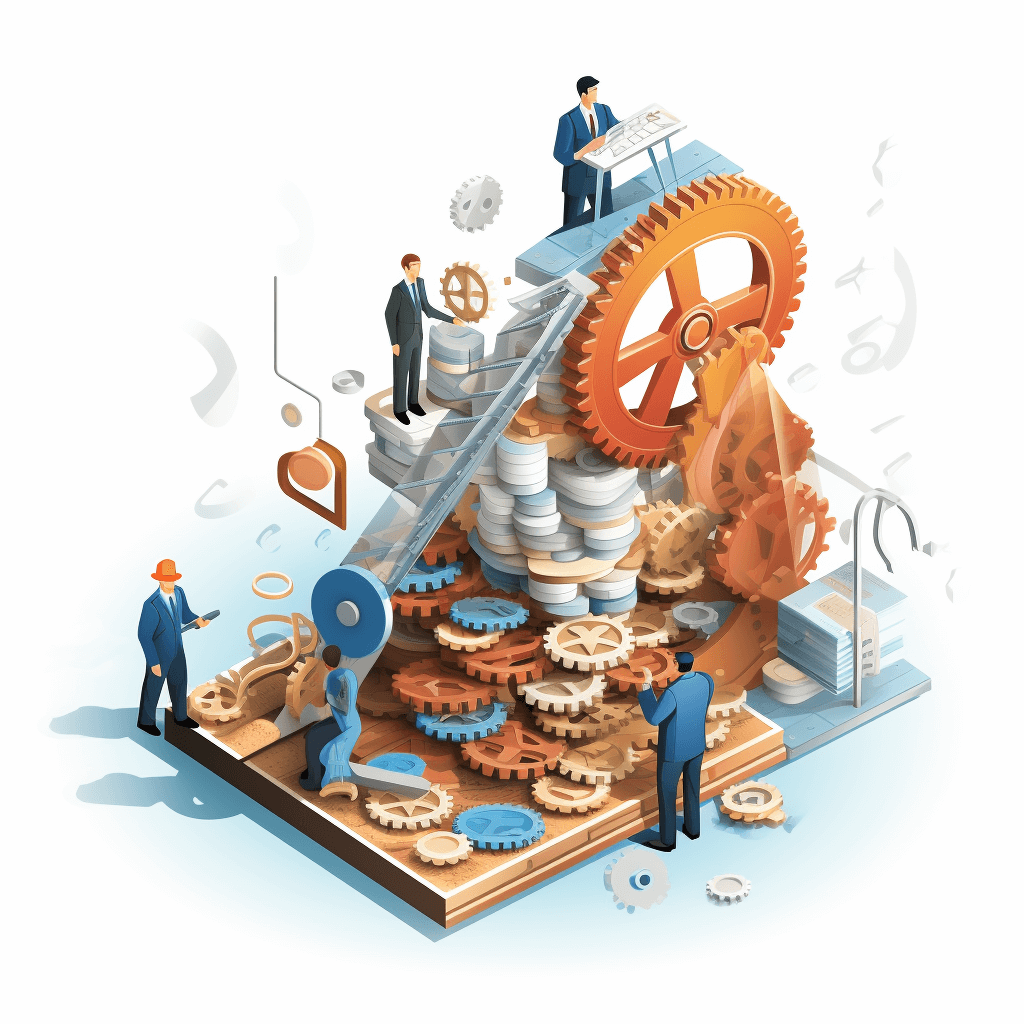

For example, let’s consider a company that manufactures automotive parts and sources various materials for their production.

Source: AEG

Such a company would consider the average cost per unit of specific types of materials used in the production of automotive parts as an industry standard.

Comparing these benchmarks (average cost per unit) against your own procurement costs for the same materials provides valuable insights into the competitiveness and efficiency of your sourcing strategies and indicates where cost savings can be achieved.

Naturally, this simple example fails to illustrate the complexities involved in procurement benchmarking.

A typical challenge is collecting comparable and reliable external data to benchmark your procurement costs against.

Ideally, it would be best to establish collaborative relationships with trusted industry peers for information exchange, but this may not always be feasible.

In some cases, you can gather industry-specific reports and market studies as these sources can offer insights into prevailing industry practices, cost structures, and performance metrics.

Of course, there are also consulting firms specializing in procurement benchmarking services, such as The Hackett Group.

Source: The Hackett Group

As you can see, their experts can conduct customized benchmarking studies and provide tailored recommendations based on industry-specific benchmarks.

This outsourced expertise can sometimes be crucial for efficient benchmarking, which requires not only access to accurate data but also the ability to interpret and apply these insights strategically.

To quote Mélani Flores, procurement expert at The Hackett Group:

“To generate strong comparisons, organizations need to have the right kind of data. This should then be coupled with picking the right indicators, having an understanding of what it is they want to benchmark, and ensuring fair comparability in order to make effective use of the data.”

Another practical approach is to leverage specialized procurement platforms and software that aggregate industry-specific data that can be used for benchmarking.

Overall, benchmarking allows companies to assess their procurement performance against industry standards, providing a clear picture of their standing in terms of cost efficiency and identifying areas where cost savings can be achieved.

You should regularly review the contracts with your existing suppliers to identify and take advantage of cost-saving opportunities.

Regular reviews ensure that supplier contract terms and pricing structures remain favorable and competitive as your needs, external market conditions, and industry benchmarks change over time.

For instance, if market reports indicate that the price of raw materials has decreased, the company can use this information to renegotiate existing contracts for better rates.

This is exactly what Vistry, a leader in the UK housebuilding sector, did in early 2023, after the prices of construction materials experienced an aggregate 2% drop over three months, as discussed in the article shown below.

Source: Building

By the same token, if benchmarking reveals that other suppliers offer more favorable terms, contracts can be renegotiated, or alternative suppliers explored.

Similarly, if the volume of procurement from specific suppliers has grown over time, you can take advantage of any contract provisions concerning bulk discounts or leverage your increased purchasing power to renegotiate the contract.

Other cost-saving measures that might arise from regular contract reviews include:

So, how can you ensure you’re able to keep track of supplier contracts and these cost-saving opportunities?

For starters, establish a systematic contract review process.

If you find it hard to organize this internally, know that there are procurement specialists specializing in contract management and optimization whose expertise can be leveraged.

Source: Limitless Technology

In any case, this process should establish clear protocols and timelines for regular contract reviews to ensure that procurement teams stay informed about contract terms and pricing structures, enabling them to identify potential areas for improvement.

Moreover, regular contract reviews should involve key stakeholders to ensure that all aspects are considered.

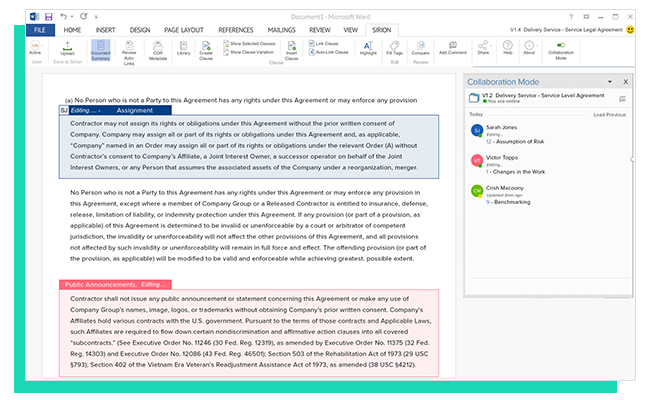

Lastly, if you are not already using contract management software to enhance visibility and streamline the review process, consider doing so.

Such solutions provide a centralized digital repository for all contracts and can streamline the review process by providing instant access to contracts, tracking their status, and generating reports and alerts.

One good example of such a solution is Sirion.

Source: Sirion

It allows users to reduce time-to-contract, review contracts, change clauses, identify missing clauses, and much more.

To recap, regular contract reviews are a must for procurement teams who want to leverage potential cost savings to ensure supplier contracts stay favorable and competitive over time.

While procurement departments in large enterprises may not directly manage inventory, their collaboration with other departments is instrumental in optimizing overall supply chain efficiency and achieving cost savings.

The key lies in working closely with internal stakeholders to anticipate procurement needs more accurately and prevent unnecessary inventory purchases, overstocking, and stock-outs.

If you want to achieve this, actively engage with business units responsible for inventory management, such as a supply chain or operations department.

This collaborative approach enables you to adapt your sourcing strategies based on real demand, leading to more accurate predictions and significant cost savings.

Software can help a lot in this regard, too.

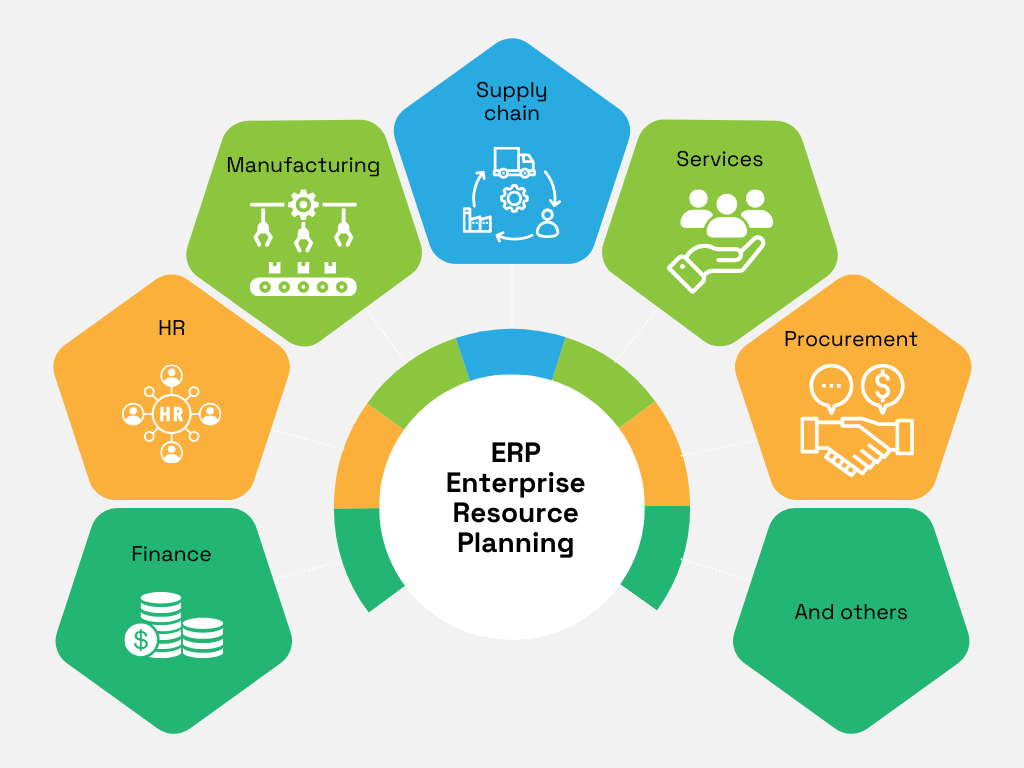

By utilizing an enterprise resource planning (ERP) system and similar software tools and fostering strong communication channels, you can tap into valuable historical data and insights provided by other teams.

Source: Veridion

There are different tactics that enhance inventory efficiency and minimize unnecessary expenditures you can use.

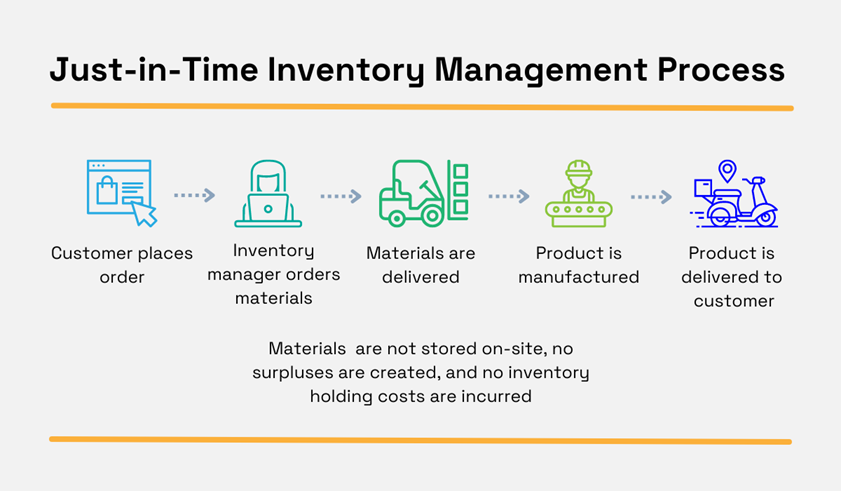

For instance, Just-in-Time (JIT) inventory management practices acquiring goods exactly when they are needed in the production process, reducing excess inventory carrying costs.

In this process, the company relies on frequent (daily, weekly, bi-weekly, etc.) deliveries from trusted suppliers whose contracts include provisions for timely and precise JIT deliveries.

Source: Veridion

Companies can leverage JIT practices to the extent that no materials are stored on the production site, thereby eliminating surpluses, minimizing waste, and incurring no inventory holding costs.

Another inventory management tactic where procurement teams can collaborate with other departments is setting reorder points.

Departments handling inventory should be encouraged to identify and establish optimal reorder points to replenish inventory just in time, avoiding stockouts or overstock situations at the same time.

Overall, the effective collaboration between procurement teams and other departments in closely monitoring inventory can yield substantial cost savings.

By leveraging historical data and insights from internal stakeholders, and implementing efficient inventory management tactics, you can enhance your procurement processes, save costs, and maintain a lean and agile supply chain.

You can significantly enhance cost savings in procurement by strategically consolidating your orders with other departments.

This collaborative approach involves combining procurement needs with those of different departments within the company when that is not the case.

For example, a company’s IT department may be ordering its inventory from the same supplier as you are, but through different contracts and delivery intervals.

By consolidating those orders, the company can achieve cost savings through quantity discounts and joint deliveries.

In that case, you could capitalize on the benefits of bulk orders, reducing your overall procurement costs.

As illustrated below, bulk shipping tends to be more cost-effective than individual shipments since shipping carriers generally provide discounted rates for larger volumes.

Source: HugePOD

Therefore, consolidating orders enables companies to optimize shipping costs by benefiting from economies of scale.

This is particularly advantageous for items with lower individual shipping weights or those that can be bundled together efficiently.

As mentioned in our example, another benefit of order consolidation is the opportunity to negotiate quantity discounts with suppliers.

Suppliers are often willing to offer a reduced price for larger order volumes, recognizing the value of consistent and substantial business.

And merging orders from different departments might just cause you to pass the threshold needed for a quantity discount.

In summary, the strategic consolidation of orders across different departments offers multiple cost-saving opportunities that companies can leverage to benefit not only from reduced shipping costs and quantity discounts but also from a synchronized and streamlined supply chain.

A strategic focus on risk management in procurement is essential for achieving cost savings.

This is also paramount for ensuring the stability of the supply chain, particularly in the face of unforeseen challenges such as pandemics, natural disasters, and geopolitical conflicts that can have significant financial repercussions.

To accomplish this, leverage advanced data analytics tools.

AI-powered tools, for instance, play an increasingly crucial role in helping procurement departments identify potential risks and detect changes in a supplier’s business activity.

Thanks to them, procurement specialists can set proactive measures to avoid unexpected costs and maintain a resilient supply chain.

For example, our supplier sourcing enabler tool, Veridion, can help you identify potential suppliers and assess their risk profile by providing fresh, weekly updated information.

Source: Veridion

Our database consists of over 80 million companies around the globe.

Veridion’s Complex Search API enables you to identify potential suppliers within minutes using criteria like company size, location, industry classifications and certifications, compliance with ESG (Environmental, Social, and Governance) standards, etc.

Likewise, our Match & Enrich API and powerful database can be used to enrich your existing supplier database and provide more comprehensive risk assessments.

Source: Veridion

Both functions enable better supplier risk assessments, so you can make informed decisions based on the most current information, and avoid unnecessary risks.

Naturally, this is also extremely important when disaster strikes and one of your suppliers is temporarily or permanently prevented from fulfilling their contractual obligations, and a new supplier needs to be found as soon as possible.

All in all, efficient procurement risk management, empowered by the right methods and tools, is crucial for safeguarding the company against potential disruptions, ensuring supply chain resilience, and achieving sustained cost savings.

The five tips we covered today, from comparing your procurement costs with industry standards to focusing on risk management, can help your company realize cost savings across all organizational levels.

They require a strategic approach to managing supplier contracts, inventory, and purchase orders as well as leveraging technology to establish data-driven workflows aimed at reducing costs and extracting more value out of procurement.

The end result you get is optimized procurement processes, increased efficiency, and higher profitability.