9 Key Steps of the Procurement Cycle

Procurement is crucial in any organization, especially in large enterprises.

But procurement is more than just buying products and services—it’s about making smart, strategic choices.

And it’s precisely a well-structured procurement cycle that will help you get what your business needs on time, at the best price, and from the most reliable suppliers.

In this article, you’ll discover the nine key steps of the procurement cycle.

Understanding and implementing these steps will streamline your procurement process, cut costs along the way, and boost your overall procurement efficiency.

Ready to transform your procurement process?

Let’s dive in.

The first step in the procurement cycle is identifying your business needs.

This initial phase is crucial because it sets the foundation for the entire process.

So, what exactly does this mean for you?

It means understanding precisely what goods or services your organization requires to operate smoothly.

To do this effectively, collaborate closely with various departments.

Talk to colleagues in sales, production, and administration to gather detailed information about their specific needs.

Whether it’s raw materials for production, office supplies, or specialized services, knowing exactly what is needed ensures a solid foundation for the procurement process.

Why?

Because accurate identification of needs across departments prevents mistakes like over-ordering or under-ordering, as well as emergency purchases that often end up being too costly.

Marlene Paola Molina, an expert with over 20 years of experience in supply chain management, explains that such collaboration between departments allows organizations to properly plan purchases on time:

Illustration: Veridion / Quote: LinkedIn

At this point, you and other stakeholders should pinpoint what you need, in what quantities, and within what budget.

Samuel Elmer, Director of Global Procurement at the Gemological Institute of America, adds:

“In my experience, the most important step after the identification of the need is the creation of a plan. In this step, stakeholders are identified, timelines are established, special circumstances are identified, expectations are communicated, and the anticipated outcome is visualized. The planning stage is key to the overall success of the procurement.”

All in all, engaging with all departments and stakeholders ensures a comprehensive understanding of your organization’s needs and serves as the bedrock of an efficient and effective procurement cycle.

Once you’ve identified your business needs, the next step is to obtain the approval to purchase the required goods or services.

This step ensures that every purchase aligns with your organization’s budget and strategic objectives.

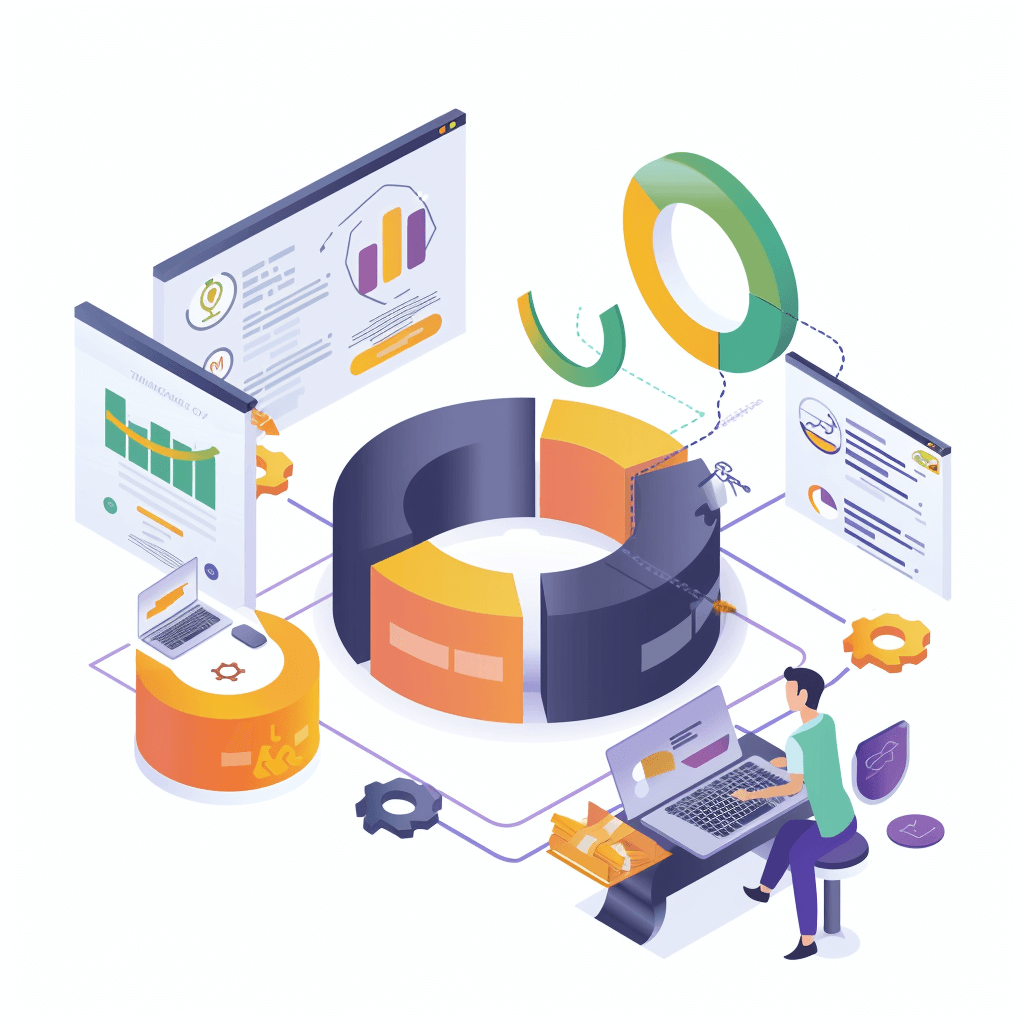

Typically, this involves raising a purchase requisition.

In this document, you outline the items needed, their quantities, estimated costs, and the department requiring these products or services.

Source: NetSuite

This requisition is then submitted to the relevant authorities within your organization for approval.

But why is this approval process necessary in the first place?

Simply put, it serves as a control mechanism to prevent unauthorized spending and ensure financial accountability.

However, manually requesting approvals can be time-consuming and can unnecessarily prolong your procurement cycle.

This is where procurement automation tools come in handy.

Using procurement management tools can streamline this process significantly.

They allow you to:

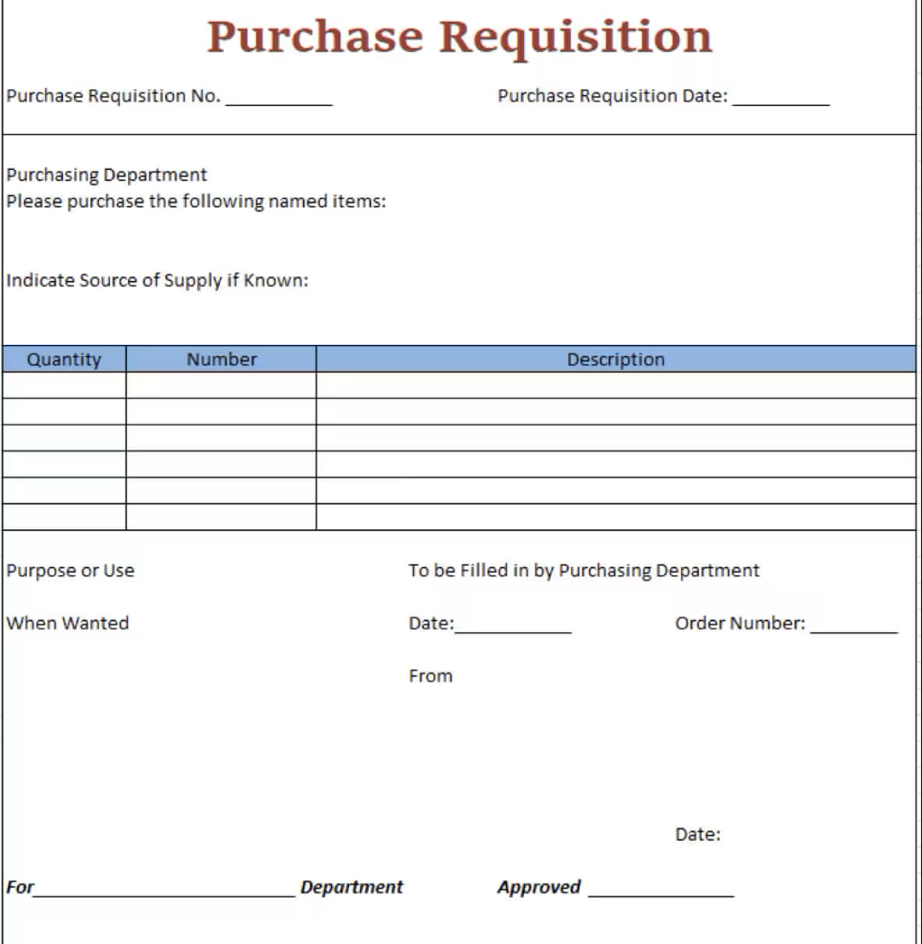

Here’s an example of one such software.

Source: Procurify

Automating the approval process speeds things up, reduces the risk of errors, and improves transparency.

In other words, incorporating automation at this stage ensures that your procurement cycle is both swift and compliant with your organization’s policies, setting a solid groundwork for subsequent steps.

Now that you know what you need to purchase and have the approval to do so, the next critical step in the procurement cycle is finding potential suppliers.

These suppliers must be able to deliver what you need, when you need it, and within your budget.

Of course, to create a list of suitable suppliers, you need accurate and up-to-date data.

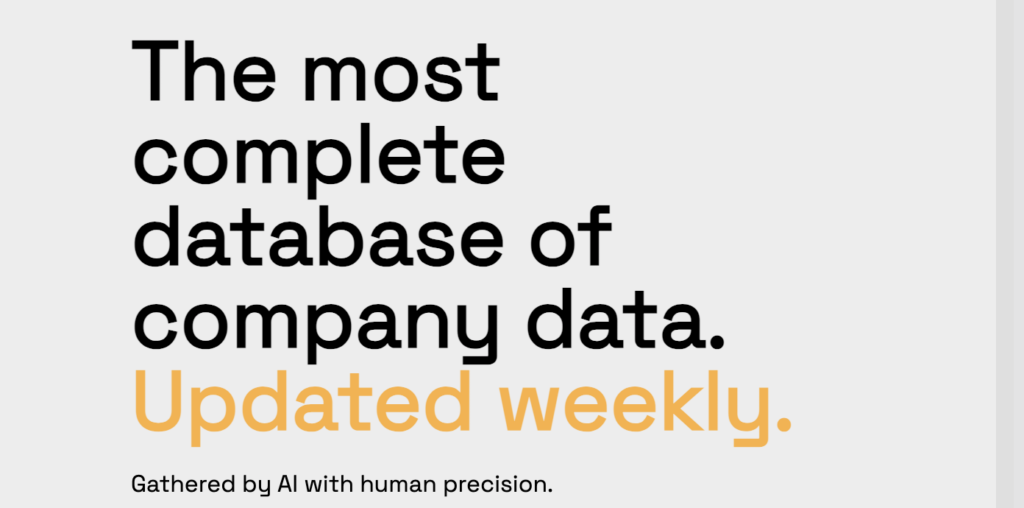

This is where big data platforms, like our Veridion, become invaluable.

Veridion provides access to the largest database of global suppliers, ensuring you find the perfect match for your needs.

Source: Veridion

The process is straightforward: using Veridion’s company search service, you input the criteria your suppliers must meet.

These criteria can include specific product details, geographical locations, certifications, and even environmental, social, and governance (ESG) criteria.

For example, if you need eco-friendly pallet manufacturers in a specific location that are also ISO-certified, Veridion can quickly generate a list of suppliers meeting these requirements.

Source: Veridion

In minutes, you can compile a comprehensive list of potential suppliers who match your exact specifications, significantly reducing the time traditionally spent on supplier searches.

This means you can say goodbye to lengthy supplier searches that take months and, instead, get accurate, up-to-date supplier information almost instantly.

Once you’ve compiled a list of potential suppliers that meet your criteria, the next step is gathering detailed information from them.

How do you do this?

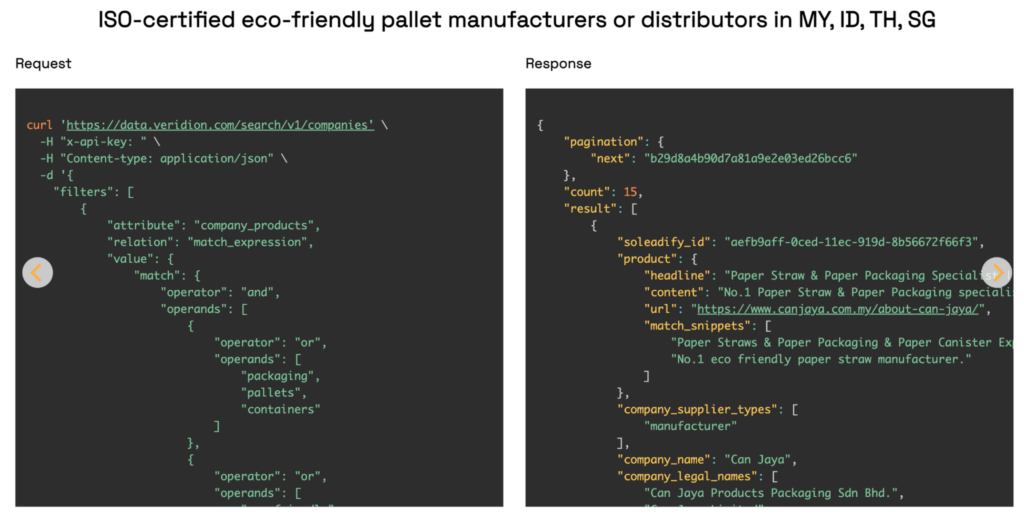

Through RFX processes, which encompass requests for proposals (RFPs), requests for quotes (RFQs), and requests for information (RFIs).

Source: Veridion

In a nutshell, RFPs let you ask suppliers for comprehensive proposals that show how they can meet your needs and at what cost.

RFQs, on the other hand, focus on getting specific price quotes for goods or services, while RFIs gather general information about the suppliers’ capabilities and qualifications.

These documents help you compare suppliers based on cost, quality, delivery times, and how well they meet your specific requirements.

And keep in mind that the price shouldn’t be the only factor in choosing a vendor, either.

Instead, make sure to consider the supplier’s reputation, production capacity, communication skills, and overall quality.

Also, note how quickly they respond to your RFXs.

However, sending out these requests manually and waiting for responses can be time-consuming and resource-intensive.

This is where procurement management software comes in handy once again.

These tools automate the creation and distribution of RFPs, RFQs, and RFIs, allowing you to send requests electronically and track responses in real time.

These platforms also help you compare suppliers by providing analytics and insights that aid in making informed decisions.

All in all, using procurement management software speeds up the information-gathering process and improves efficiency and transparency.

This ensures you make well-informed supplier selections that align closely with your organization’s goals and requirements.

After gathering detailed information from potential suppliers, the next crucial step is to choose the best fit and negotiate the contract terms.

Effective negotiation is key to ensuring that these terms meet your organization’s needs while fostering a positive, mutually beneficial relationship.

To negotiate successfully, make sure to follow these best practices:

Source: Veridion

First, prioritize your needs.

Clearly define what is the most important for your organization.

Is it pricing, payment terms, delivery schedules, or perhaps quality standards?

Knowing your priorities helps you focus on what matters most during negotiations.

Second, aim for win-win solutions.

Engage in open, collaborative discussions rather than imposing demands.

By asking questions and understanding the supplier’s perspective, you can find opportunities for mutual benefit.

As negotiation trainer and CEO of Negotiation Ninja, Mark Raffan, advises:

“Instead of directing and dictating change which a lot of procurement people do, start asking more questions. Start asking more questions of the salesperson to say: “Okay. If you were going to improve this relationship, if you were going to improve this business, how would you do it?” Once you can start asking questions and listening more, then you can start to discover where the opportunities actually lie.”

In other words, building rapport and understanding with the supplier can lead to better relationships and business outcomes.

Third, set clear expectations.

Clearly outline performance standards, compliance requirements, and dispute resolution procedures within the contract.

This transparency minimizes risks and ensures both parties know what is expected.

Lastly, be flexible.

While it’s important to protect your organization’s interests, be open to compromises that support your strategic goals and strengthen the supplier relationship.

Flexibility can lead to better deals and long-term partnerships.

All in all, effective negotiation formalizes the expectations and responsibilities of both parties and provides a solid legal foundation.

By establishing clear, mutually beneficial terms, you will set the stage for a productive supplier relationship.

This will reduce misunderstandings and disputes and foster a collaborative partnership that aligns with your organization’s objectives.

Once you’ve hammered out the contract terms and both parties are in agreement, it’s time to take the next big step: formally awarding the contract to your chosen supplier.

This isn’t just about signing paperwork—it’s about cementing a partnership that will drive your organization forward.

Mohammad Shuaib Khan, Procurement & Purchasing Manager at ASIA Prime General Contracting Co. LLC, emphasizes this point:

Illustration: Veridion / Quote: LinkedIn

Why is this step so crucial?

In the simplest terms, because awarding the contract marks the beginning of your supplier relationship.

It’s the moment where clarity is key—every detail needs to be documented thoroughly to ensure both sides are on the same page regarding their roles and responsibilities.

Effective communication and meticulous documentation at this stage set a strong foundation for what comes next.

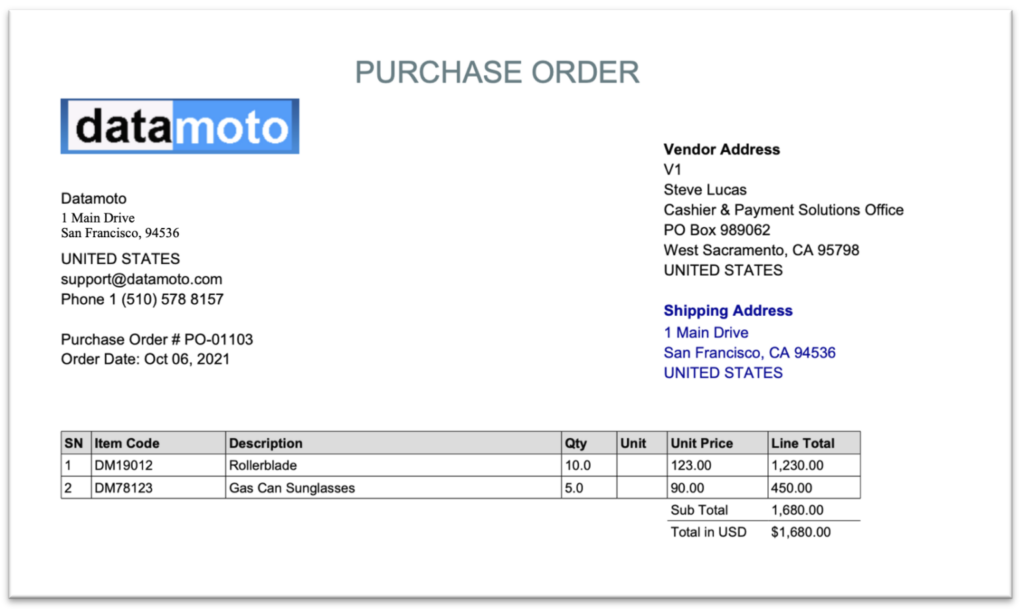

Issuing the purchase order to the chosen supplier is the next logical step—the official green light—confirming the order details and laying out the agreed terms and conditions in black and white.

Source: DataMoto

By solidifying the agreement and sending out the purchase order, you’re finally making it official.

And it goes without saying that, by awarding the contract thoughtfully, you pave the way for seamless execution and mutual growth.

So, make sure to thoroughly evaluate suppliers, negotiate terms, and only then award the contract.

After you have awarded the contract and sent the purchase order, the products you procured finally arrive.

Receiving the goods or services is a pivotal step in the procurement cycle.

But it’s about more than just accepting the delivery—it’s time to verify quality and quantity to ensure the received products match the agreed-upon specifications.

This involves carefully inspecting the delivered items to confirm they meet your standards.

At this point, any discrepancies or issues should be also promptly communicated and resolved with the supplier.

On top of that, accurate documentation of the goods received is essential, as it supports effective inventory management and ensures financial accuracy in your records.

In other words, this documentation proves that the delivered items align with the purchase order and contract terms, reducing potential disputes.

By meticulously managing this process, you will maintain quality control and uphold accountability.

This safeguards your procurement process, strengthens supplier relationships, and enhances organizational efficiency.

So, make sure to go through each and every delivery in detail.

Once you’ve received the goods, it’s time to pay your supplier.

Of course, after you have verified that the delivered items meet the agreed-upon specifications and ensured that the supplier’s invoice matches the purchase order.

And guess what?

Using procurement management software enhances this process, too, allowing for faster and more accurate matching of deliveries, purchase orders, and invoices.

Source: Planergy

Timely and accurate payment processing is vital for maintaining strong supplier relationships.

So, it’s crucial to adhere to your organization’s payment policies and procedures to ensure compliance and avoid complications.

But, efficient payment processing also plays a key role in managing cash flow and maintaining budget control.

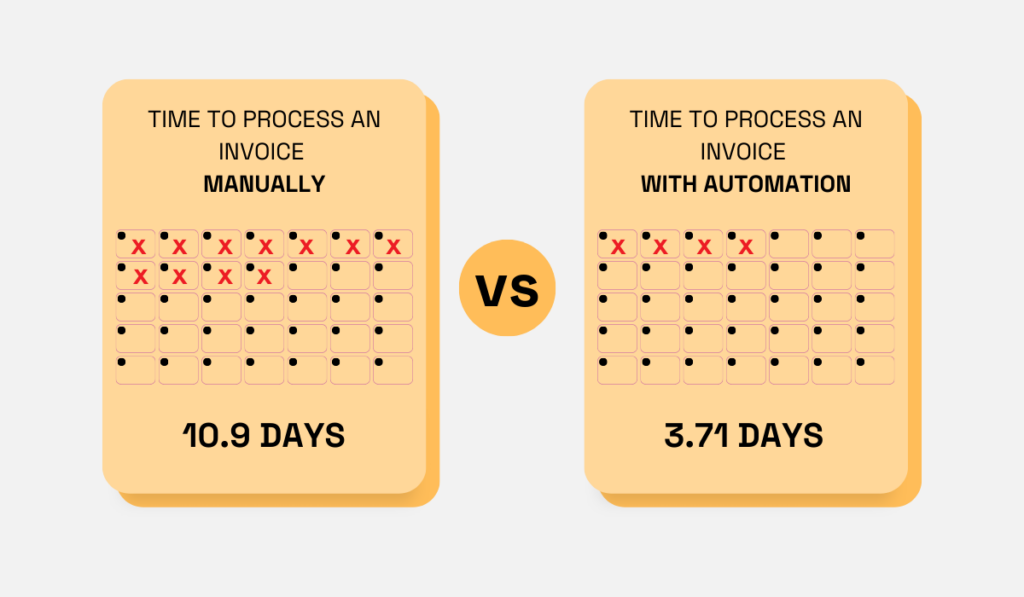

Automating this process is highly recommended.

Why?

Because, according to the Ardent State of ePayables 2022 report, manually processing a single invoice takes an average of 10.9 days, whereas an automated system reduces this duration to just 3.71 days.

Illustration: Veridion / Data: Medius

Additionally, organizations that fully automate payment processing save an average of $14.93 per invoice processed compared to those relying on manual processing.

So, that’s a huge time and money saver, and it reduces errors that come with manual invoice processing!

This streamlined approach to payment processing also ensures your suppliers get paid promptly, and everything stays on course, strengthening your partnerships and supporting your organization’s goals.

You might think that, once you have the goods and you’ve paid for them, that’s the end of it.

But that mindset overlooks valuable opportunities.

The final step in the procurement cycle is, in fact, to regularly review supplier performance.

This involves monitoring how well suppliers adhere to contract terms, assessing the quality of goods or services delivered, and evaluating overall satisfaction with the supplier relationship.

Here are some essential key performance indicators (KPIs) to track and analyze:

Source: Veridion

Such regular performance reviews help pinpoint areas for improvement and ensure suppliers continuously meet your expectations.

They also guide future procurement decisions and nurture strong, enduring supplier relationships.

To learn more about why you should never end your procurement cycle without this step, take a look at our article explaining the benefits of regular supplier performance management.

All in all, when you actively assess supplier performance, you can enhance your current operations but also drive strategic growth and long-term success in procurement.

The procurement cycle might seem long and complex, with many steps involved.

But, if you want to purchase the best products and services at the best price and from the best suppliers, you must invest time and effort into the process.

However, as we’ve demonstrated, procurement automation can make this cycle shorter and more efficient.

By leveraging tools like procurement management software and supplier sourcing platforms, you can significantly streamline the procurement cycle while enhancing accuracy and efficiency.

It’s also important to note that not every purchase will require all 9 steps.

Still, following this structured approach to procurement will help you streamline operations, cut costs, and boost overall efficiency.

So, embrace these steps whenever possible to ensure your procurement process is as effective and efficient as it can be.