11 Statistics On Supplier Sourcing You Need to Know

In this article, we explore 11 statistics highlighting the latest trends, challenges, and opportunities in supplier sourcing.

These figures provide valuable insights, including the most popular cost-saving strategies and how companies leverage suppliers to navigate supply chain risks.

We’ll also give you an insight into how suppliers feel about the current state of sourcing and supplier-buyer relationships.

So, read on—some of this information might help take your sourcing efforts to the next level.

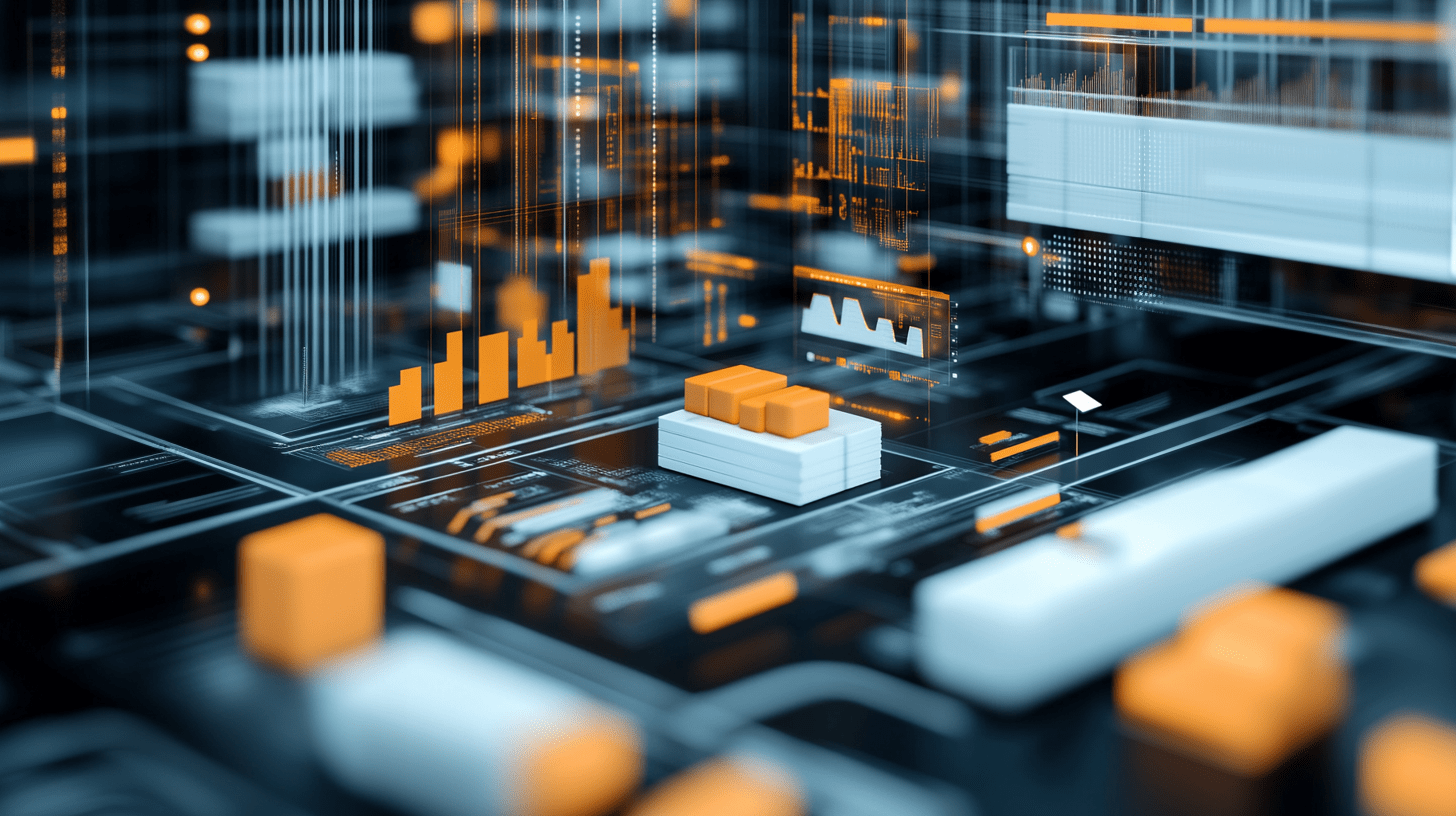

This statistic comes from the 5th edition of PwC’s Digital Procurement Survey, which gathered feedback from procurement experts at 1,000 companies across nearly 60 countries on five continents.

And all of them agree: sourcing ranks among the top three priorities, alongside procurement performance and digital transformation.

Illustration: Veridion / Data: PwC

According to the survey, this isn’t the first time sourcing ranked so high on the top purchasing concerns list.

In fact, it continues to be a priority year after year.

The reason for that is simple.

Sourcing professionals realize that the suppliers they choose don’t just affect costs but can influence the entire business.

With the right partners, organizations can unlock innovation, insider knowledge, and even better product quality.

In essence, supplier sourcing nowadays goes beyond securing small, immediate wins and tries to build long-term relationships that help businesses manage risks and stay competitive.

Yet, despite its significant importance, some companies still struggle to master it.

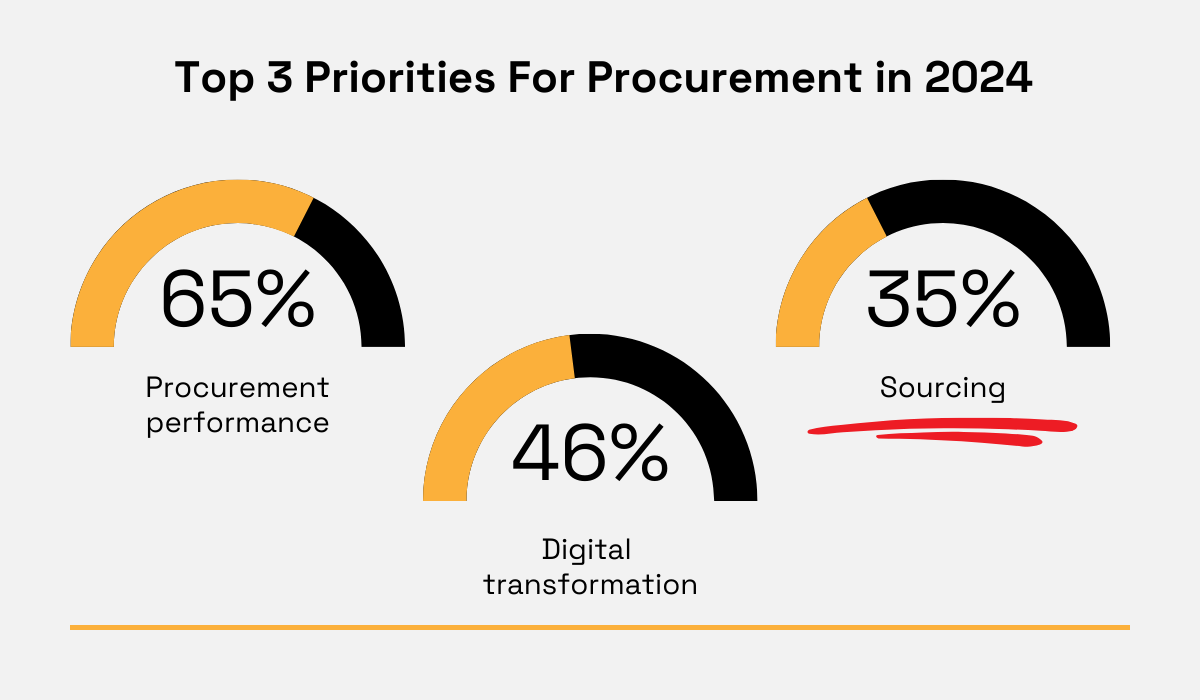

Keelvar’s Voices of Sourcing 2024: The AI & Automation Boom report takes a closer look at the challenges and planned innovations of modern procurement teams.

One of the report’s standout findings reveals that complex sourcing processes hold back 17% of procurement departments.

At first glance, 17% might not seem like a significant number.

But when you factor in other obstacles procurement departments face, like increasing workloads and declining workforce, it demonstrates the strain procurement currently experiences.

Illustration: Veridion / Data: Keelvar

Complexity can come from anywhere.

For example, differing priorities across departments can complicate decision-making, while lengthy approval processes involving multiple stakeholders may cause delays.

On top of that, many companies still rely on manual, ineffective methods—like using Google for supplier discovery—which only adds to the inefficiency.

Ultimately, all of this slows down sourcing professionals.

It makes it harder for them to meet deadlines and quickly respond to fast-changing business needs.

That’s unfortunate because procurement teams genuinely want to contribute more value to their companies, but they often get bogged down by repetitive, time-consuming tasks.

The following statistic proves this.

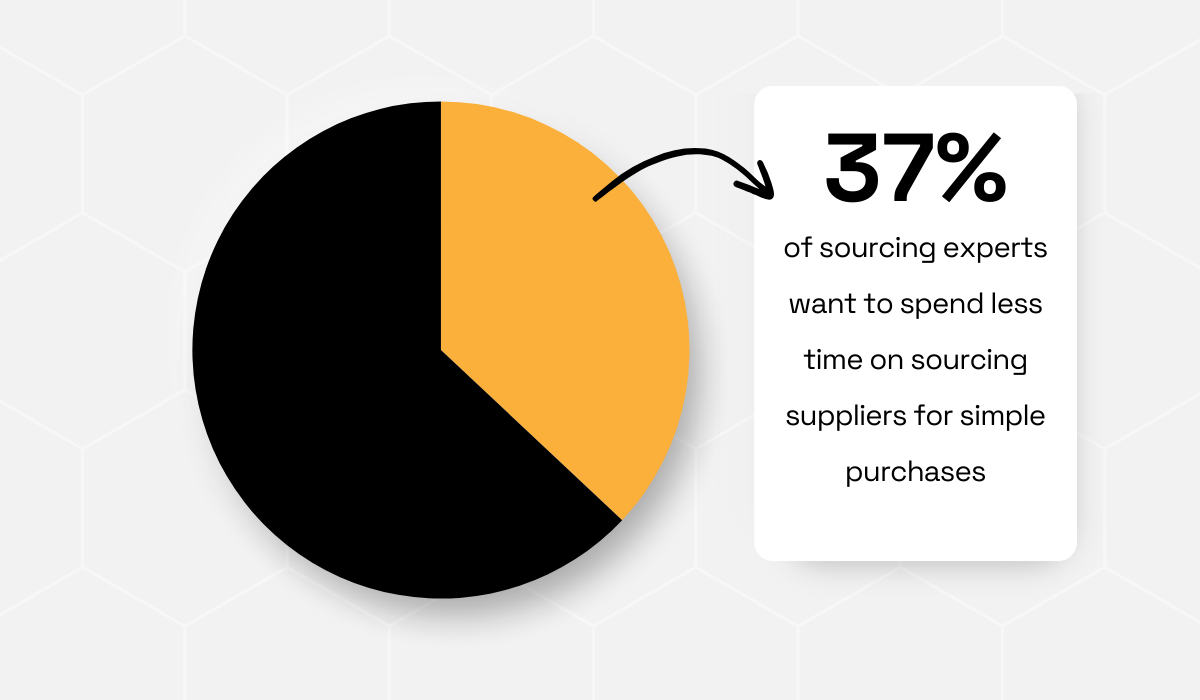

The 2024 State of Procurement Report by Amazon Business reveals that many procurement teams want to spend less time sourcing suppliers for simple purchases.

Out of more than 3,000 procurement decision-makers worldwide, 37% expressed this desire.

Illustration: Veridion / Data: Amazon Business

The same percentage of procurement teams also believe they waste too much time contacting vendors for information, updates, or corrections.

Sourcing teams are clearly fed up with these routine, low-value tasks, especially when it comes to small purchases that don’t directly affect production.

And who can blame them?

Instead of focusing on strategic, value-driving sourcing activities, they’re bogged down by processes that could easily be automated.

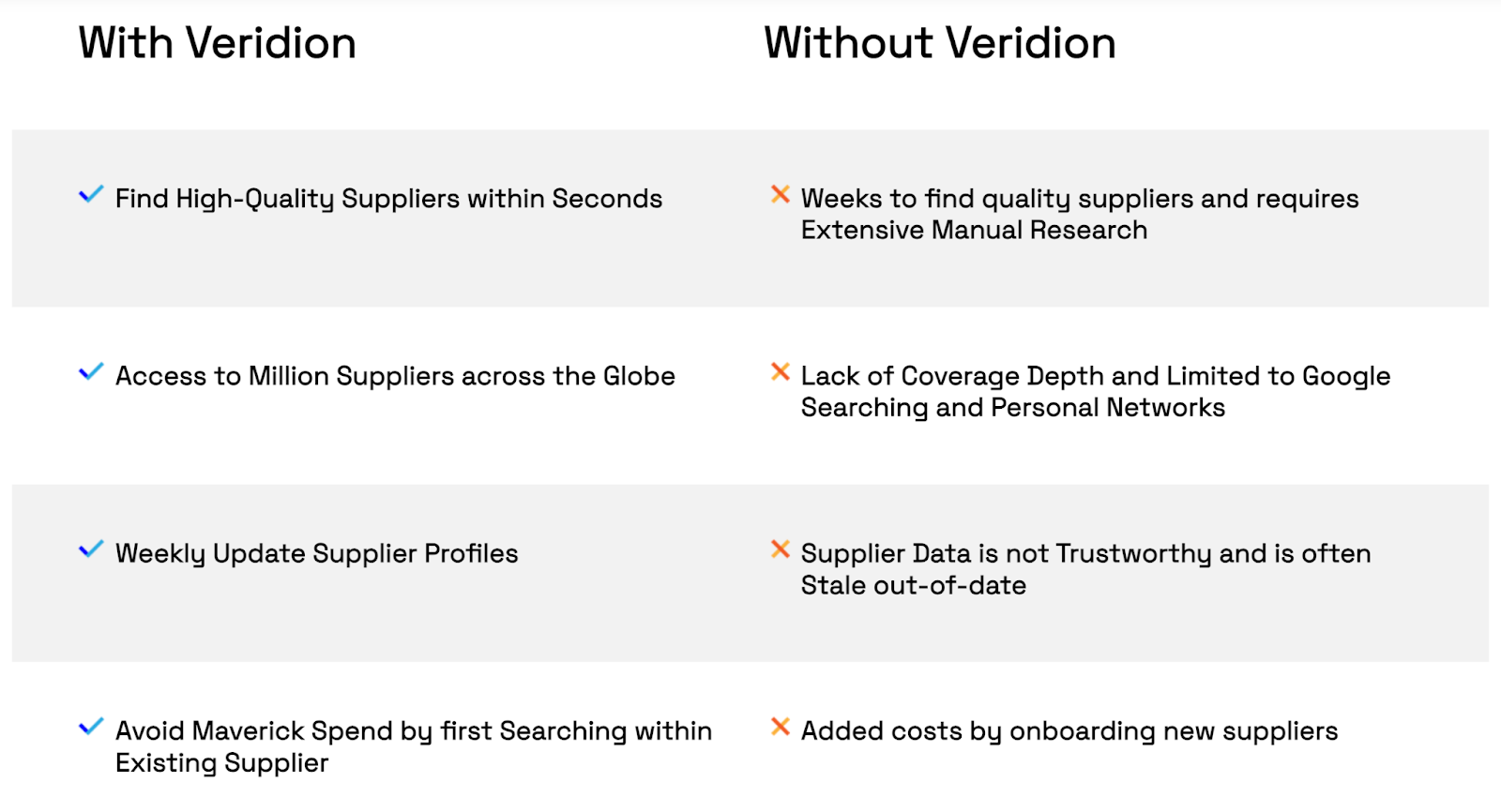

For instance, with AI-powered supplier discovery platforms like Veridion, sourcing professionals can quickly gather reliable data on suppliers from around the world—be it for simple purchases or critical ones.

Source: Veridion

This eliminates the need for manual supplier searches, evaluations, and comparisons.

You just input your specific criteria, and the system provides a list of suitable candidates within moments.

Today, there’s really no need to spend weeks on a process that, with the right tools, could be done in minutes—and with better results.

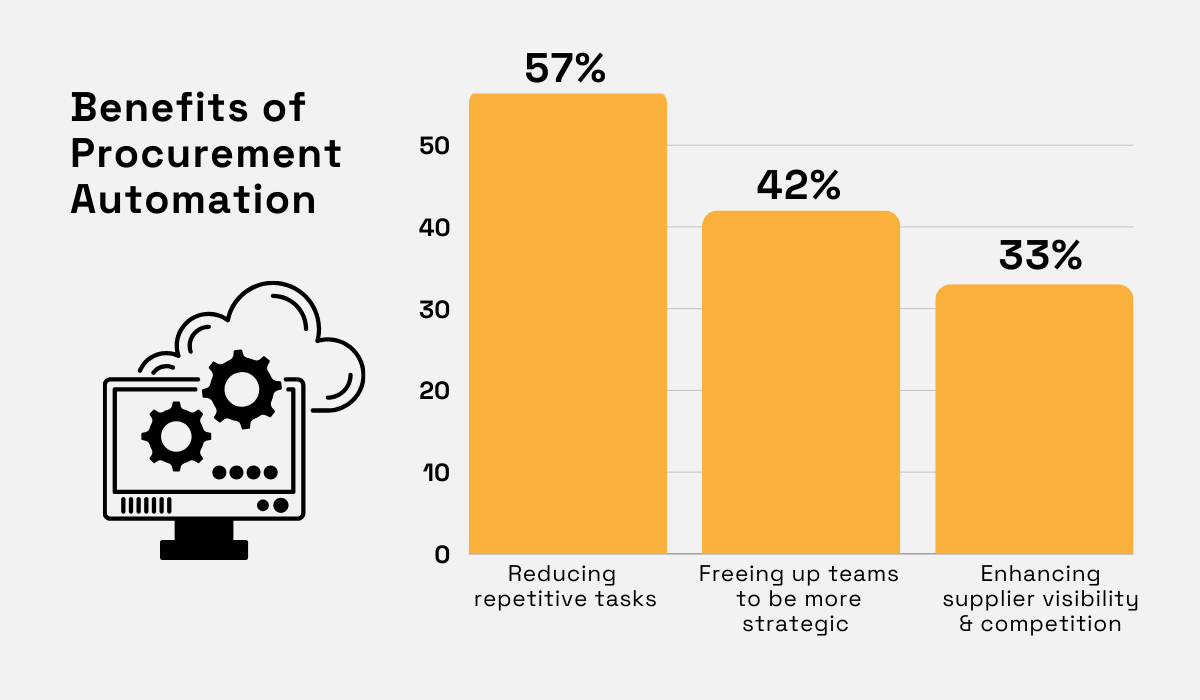

Many companies have already recognized the benefits of automation and have streamlined some of their sourcing workflows.

So, what’s the biggest benefit they’ve noticed?

The next statistic will tell you.

The Keelvar survey shows that 33% of business leaders see increased supplier visibility and competition as key benefits of automation.

Illustration: Veridion / Data: Keelvar

This finding isn’t surprising.

Today, access to rich and reliable vendor data is an absolute must.

It empowers companies to make better choices, shield themselves from supply chain risk, and stay ahead of the competition.

Siemens is a perfect example.

After realizing that traditional supplier discovery methods could no longer keep up with their increasingly complex needs or supply chain volatility, Siemens decided to automate the process.

Michael Klinger, Corporate Supply Chain Manager at Siemens, explains that technology is now vital to their workflows.

Illustration: Veridion / Quote: Scoutbee

With the improved visibility, they can quickly identify new potential suppliers—without needing expert knowledge or extensive training.

This shift has reduced their workload by up to 90%.

Klinger summarizes it perfectly:

“Good decisions are based on the maximum amount of information available.”

And he’s absolutely right.

The more you know about your vendors, the smarter and more strategic your sourcing decisions can become.

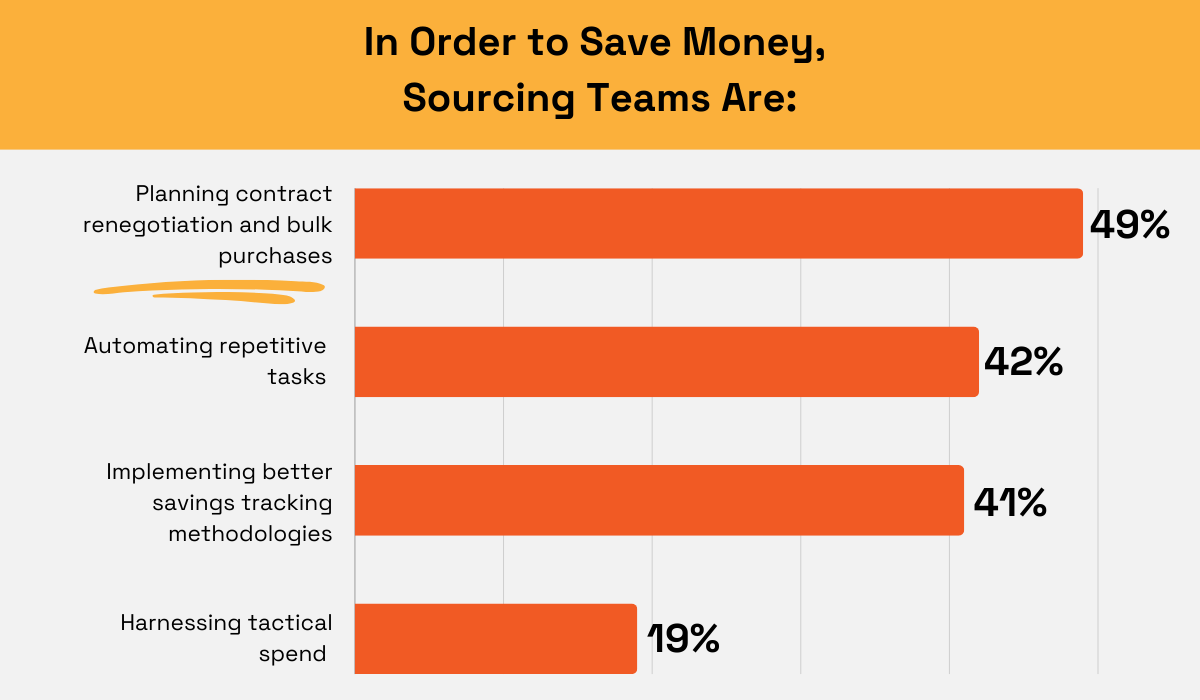

Strategic initiatives like contract renegotiation and bulk purchasing are currently the go-to strategies for cutting costs, according to the Keelvar survey.

Illustration: Veridion / Data: Keelvar

One possible reason for the appeal of these tactics is that, if done right, they can go beyond mere cost savings and actually help strengthen supplier relationships.

Bulk purchasing is particularly effective in this context.

It involves ordering larger quantities of a certain product to get discounts from suppliers.

As such, this strategy benefits both parties: buyers enjoy lower prices, while suppliers secure long-term commitments.

It’s an excellent way for buyers to show that they are invested in maintaining the relationship and to build trust and reliability on both sides.

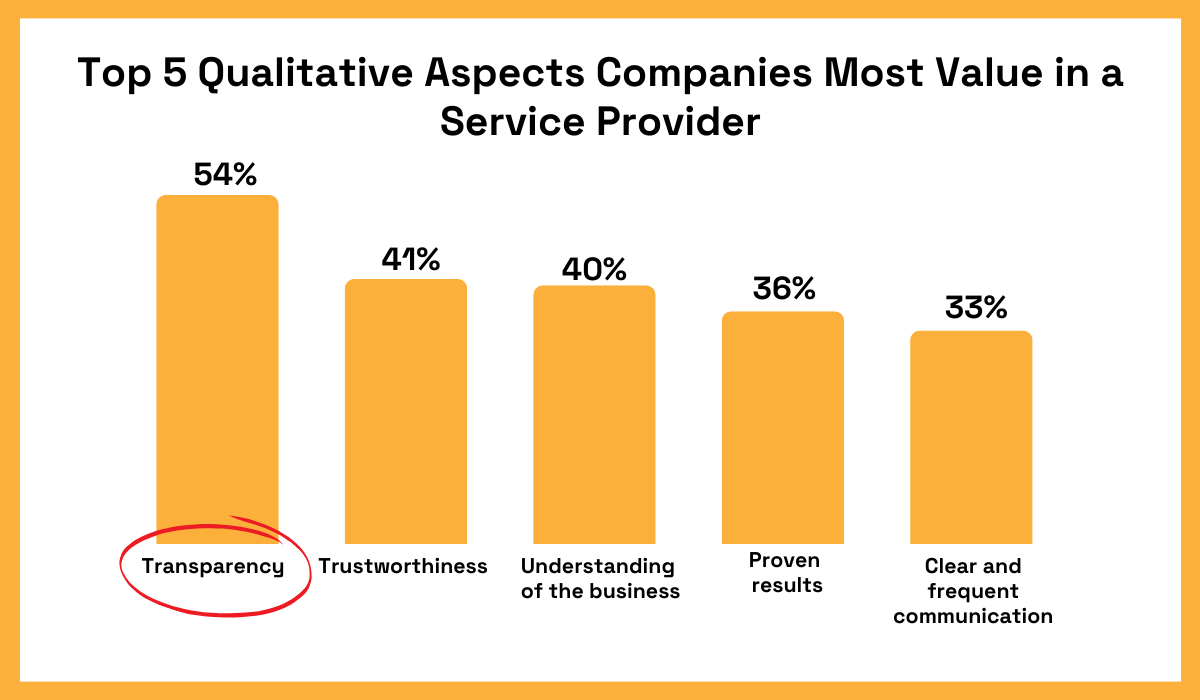

When it comes to vendor qualities, transparency ranks highest, according to the 2022 Deloitte Global Outsourcing Survey.

Illustration: Veridion / Data: Deloitte

The reason behind this is clear: transparency builds trust.

When suppliers are open about their processes, materials, or practices, companies feel confident in the quality and integrity of what they receive.

This matters now more than ever, as businesses increasingly prioritize sustainability and social responsibility.

For many, knowing exactly where their products come from or how they are produced is non-negotiable.

Take Unilever, for example.

Every one of their agricultural crop suppliers must follow the Unilever Sustainable Agriculture Principles.

According to the company, these principles promote the transparency needed to ensure they only partner with suppliers who support their sustainability goals:

“We use these Principles to assess and benchmark third-party agricultural standards, codes, assessments, and programs across diverse geographies and farming systems to ensure they meet our commitments to sustainable, responsible, and transparent production.”

Now, while transparency is extremely important for successful buyer-supplier relationships, it alone can’t protect companies from supply chain disruptions.

So, what else are companies doing to mitigate these risks?

Read on to discover.

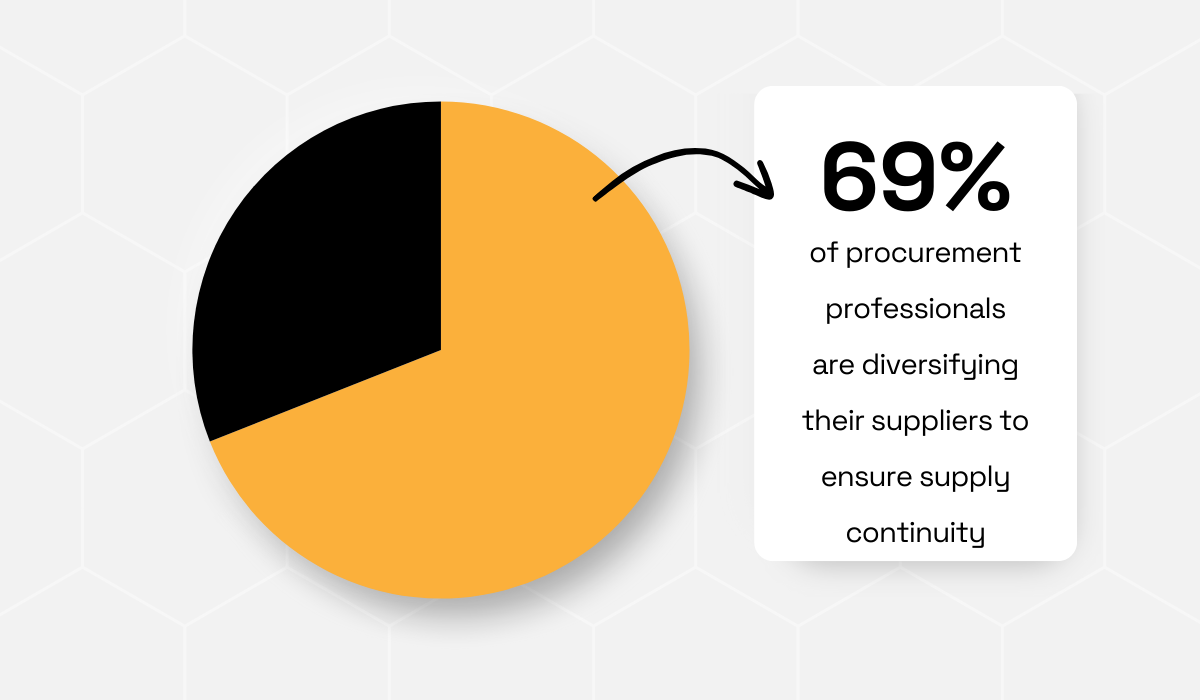

The 2024 Global State of Procurement & Supply survey by CIPS reveals that the majority of procurement leaders are diversifying their suppliers to ensure supply continuity.

Illustration: Veridion / Data: CIPS

And they are likely making the right choice.

Working with only a limited number of vendors may seem convenient, but it’s a risky strategy.

Especially now, amid global conflicts, labor shortages, unpredictable demand, and other disruptions.

Take the vanilla supply chain, for example.

Although it’s mostly exported from Madagascar, suppliers are urging buyers to look elsewhere as this expensive spice faces potential shortages.

Prossy Tumushabe, Executive Director of the Association of Vanilla Exporters of Uganda Limited, elaborates:

“Government interference, weather events, and other unexpected impacts can all affect the vanilla supply chain. Food and beverage brands, along with chefs, can stabilize their supply and increase business flexibility by sourcing vanilla from multiple countries of origin.”

But it’s not just vanilla buyers who should listen to his advice.

Whether you’re in tech, manufacturing, retail, or any other industry and sector, diversifying your supplier base is definitely a smart strategy.

It is a safety net, helping companies stay agile and resilient in an increasingly volatile market.

Another trend revealed by the CIPS survey is the growing emphasis on sustainability and socially responsible practices within procurement.

As it turns out, 77% of organizations have already implemented an ethical sourcing policy.

On top of that, the majority of surveyed professionals (78%) believe that environmental, social, and governance (ESG) issues are seen as important within their companies.

Illustration: Veridion / Data: CIPS

This is particularly pronounced in larger companies, with 84% recognizing the importance of ESG, compared to 70% of smaller firms.

The rise in ethical sourcing is primarily driven by increasing consumer and stakeholder demand for transparent and fair corporate behavior.

Consumers, in particular, are becoming more conscious of the origins of the products they buy, and expect brands to align with their values.

But, don’t think this is just a passing phase.

In many countries, ethical and sustainable procurement is actually becoming a legal requirement.

We now see governments enforcing more and more regulations—and sourcing teams already feel their impact.

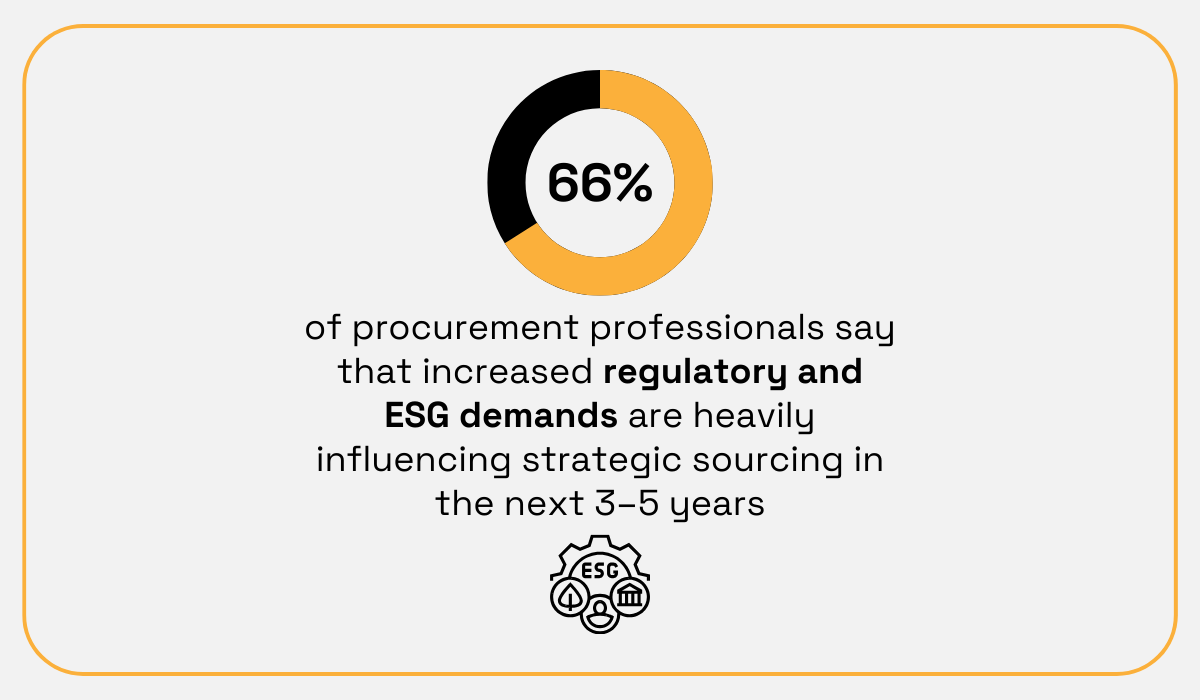

The 2024 Future of Procurement report by KPMG shows that 66% of procurement professionals believe increasing regulatory and ESG demands will heavily impact strategic sourcing over the next 3–5 years.

Illustration: Veridion / Data: KPMG

Indeed, these demands will drastically change how supplier sourcing and procurement overall are handled.

Think about it.

ESG regulations require businesses to ensure their manufacturing processes and suppliers meet environmental standards and promote social responsibility through fair wages and supplier diversity.

Naturally, this adds a lot more complexity to the supplier sourcing process.

Finding vendors that meet all these criteria while also ensuring internal compliance is undoubtedly a lot of work.

Nevertheless, noncompliance is not an option.

It leads to heavy penalties, severe legal repercussions, and, in some cases, reputational damage.

For sourcing teams, the pressure has never been higher.

Their job isn’t just to find necessary products at the lowest price anymore.

They also have to protect companies from costly legal risks.

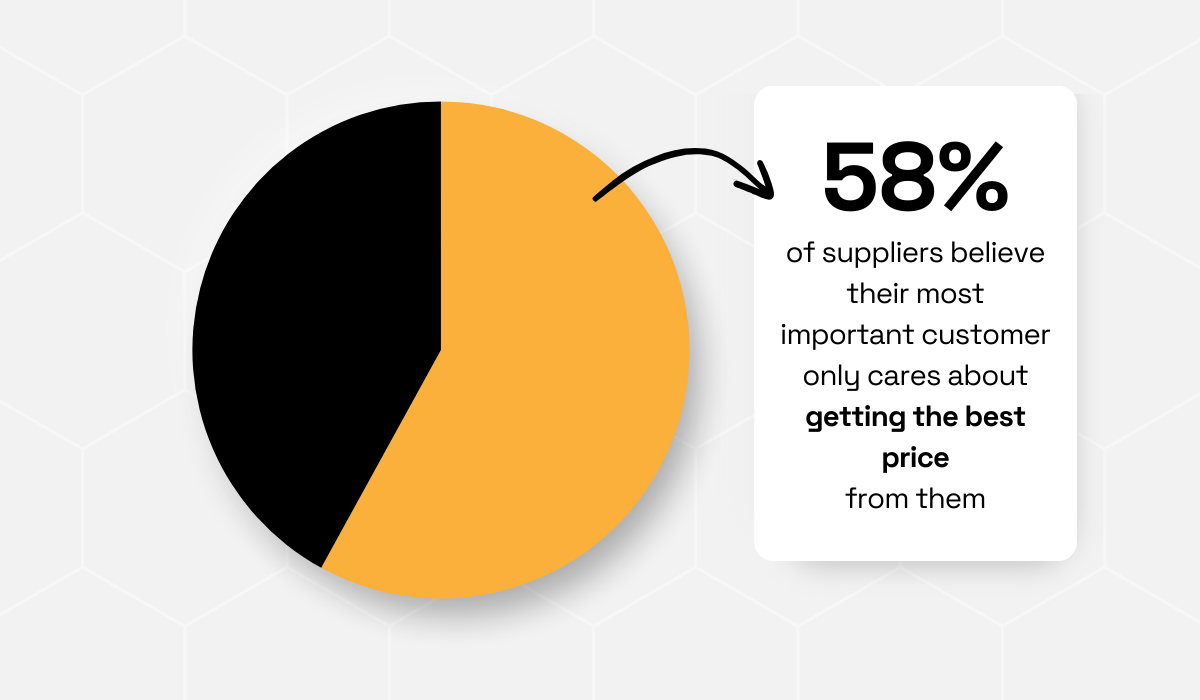

So far, we’ve looked at supplier sourcing only from the buyer’s perspective, but what about the suppliers themselves?

What do they think about the current state of supplier-buyer relationships?

Luckily, the Voice of The Supplier survey by HICX provides valuable insights from their viewpoint.

Despite all the talk about sustainability, compliance, and transparency, 58% of suppliers believe buyers still care most about one thing: cost savings.

Illustration: Veridion / Data: HICX

Why do suppliers feel this way?

It likely has to do with how buyers behave.

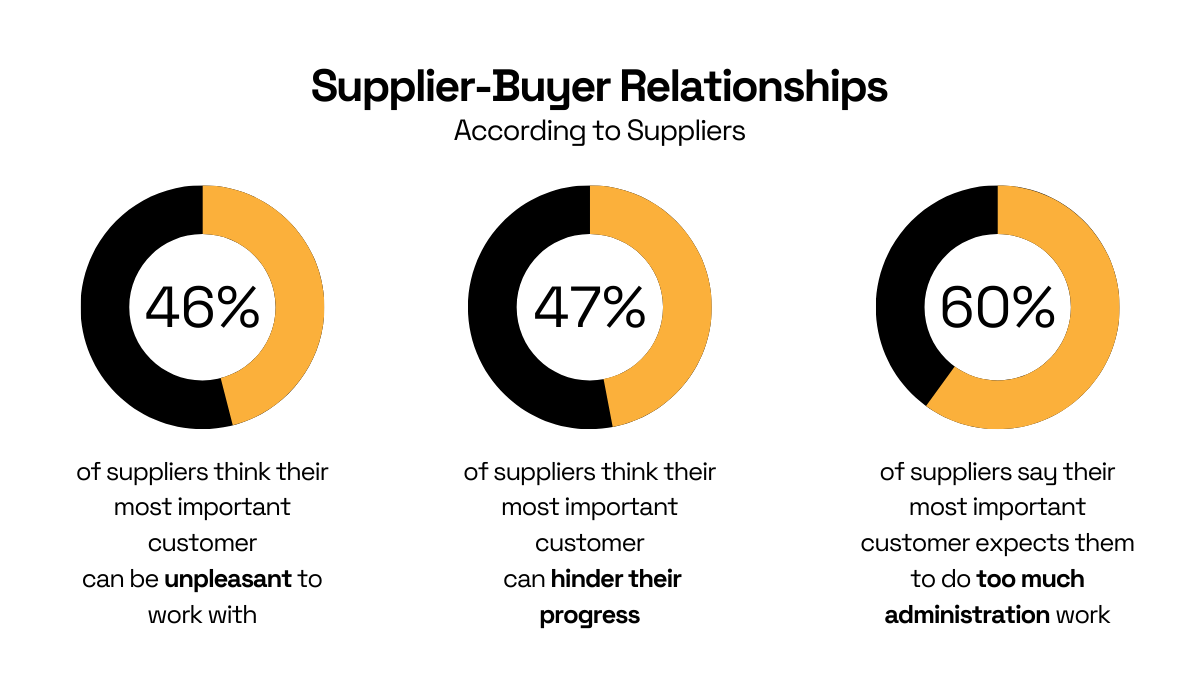

The numbers back this up: 46% of suppliers say their most important customer can be unpleasant to work with.

Additionally, 47% of vendors feel that their key customer actually hinders their progress.

And to make matters worse, 60% of suppliers agreed that the key customers expect them to handle too much administrative work just to collaborate.

Illustration: Veridion / Data: HICX

All of this ultimately sends a clear message to vendors: buyers aren’t really aiming for collaborative, mutually beneficial partnerships.

That’s unfortunate—especially because the next statistic shows suppliers are more than willing to step up and support their clients if given the chance.

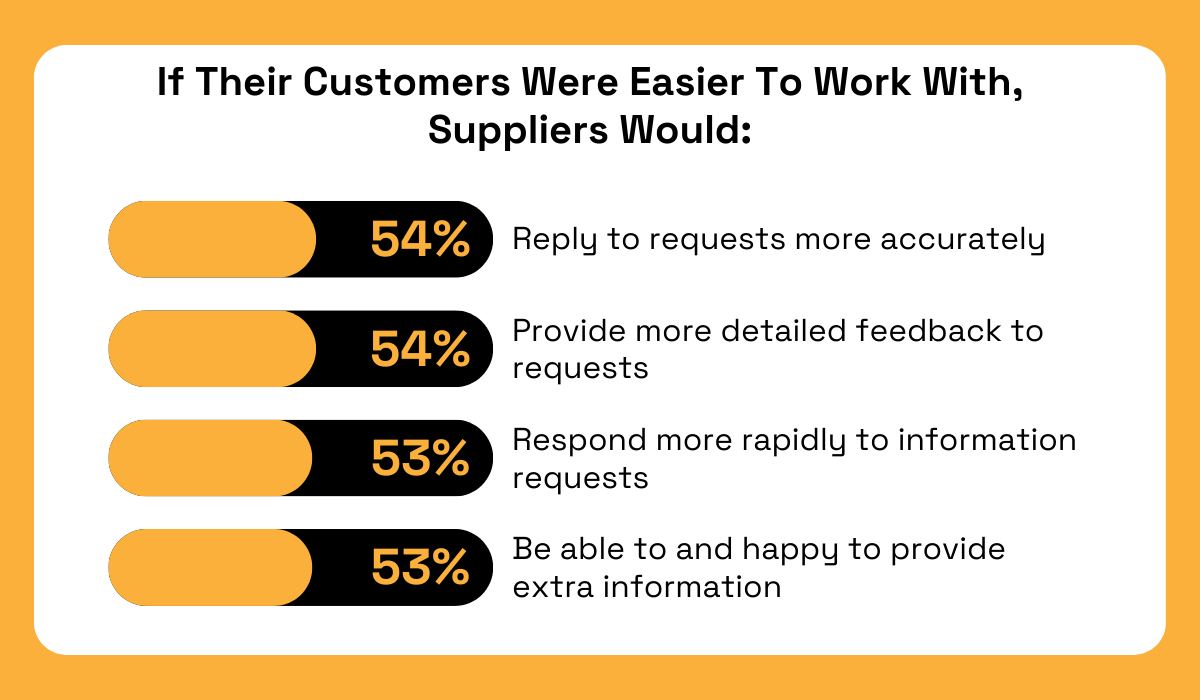

When asked how their behavior would change if their customers were easier to work with, 53% of suppliers said they would be able—and happy—to provide additional information.

Many suppliers also indicated they would respond more accurately to requests, offer more detailed feedback, and reply more quickly to data and information inquiries.

Illustration: Veridion / Data: HICX

In short, communication between vendors and buyers would dramatically improve if companies prioritized supplier engagement and relationships.

And a supplier who’s motivated to go the extra mile can make a big difference, especially in today’s unpredictable times.

David Andrea, Principal at Plante Moran, one of the largest audit, tax, consulting, and wealth management firms in the United States, agrees there needs to be more collaboration between these two sides:

Illustration: Veridion / Quote: Automotive Logistics

Remember, your suppliers are the key to greater agility and resilience.

But it’s up to you to nurture these partnerships and unlock their full potential.

Overall, it’s clear that supplier sourcing is currently undergoing a significant transformation.

Simply finding suppliers who offer the right product at the right time and price is no longer enough.

Today, procurement plays a critical, strategic role in driving broader company goals—and that requires strong, reliable partners whose values and practices align with your own.

That’s why we’re seeing a greater emphasis on building long-term relationships with suppliers.

And as the market faces the ever-expanding range of risks, these partnerships will only become more essential to future success.