What Is a Supplier Risk Assessment Framework

Key Takeaways:

Supplier risks vary widely, from delayed deliveries to more complex risks related to financial health, regulatory compliance, and even environmental or geopolitical challenges.

In recent years, these risks have amplified due to the pandemic, wars, geopolitical affairs, and cybersecurity breaches.

This is why having a supplier risk assessment framework matters: it allows your company to assess each supplier based on the unique risks that could impact your supply chain.

Today, we will break down everything you need to know about supplier risk assessment frameworks, so let’s get into it.

A supplier risk assessment framework is a structured methodology that guides companies in identifying, assessing, managing, and monitoring supplier risks.

It provides guidelines for assessing risks from the initial stages of considering a supplier, throughout the relationship.

The framework typically covers:

Yes, it seems like a lot of work.

And, truth be told—it is.

But wouldn’t you agree that having clear, written guidelines makes it much easier to follow?

And don’t worry, you don’t have to write all these guidelines yourself.

There are already established risk assessment frameworks that you can use to help you.

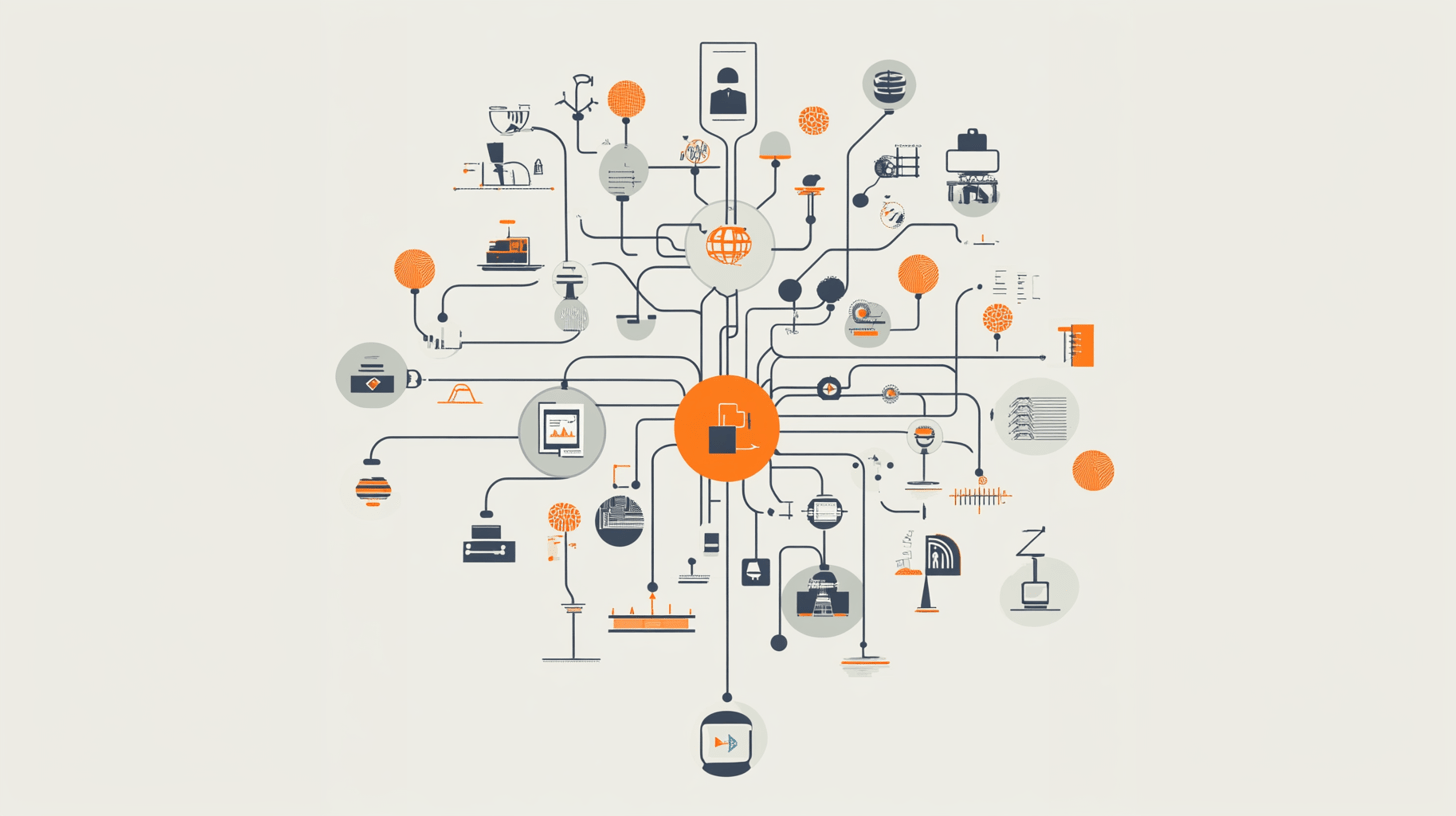

Consider Cisco—a global technology leader whose supply chain resilience relies on a comprehensive risk assessment framework.

Nghi Luu, Cisco’s former Senior Director of Supply Chain Risk Management, explains the risks they face and their approach to risk assessment:

Illustration: Veridion / Quote: Cisco

When it comes to supplier-related risks, Cisco’s approach is both systematic and holistic.

They assess suppliers through a series of formalized business reviews, vetting them upfront and then conducting regular supplier risk assessments on performance, financial stability, quality, and security.

To identify security and cybersecurity supplier risks, Cisco leverages globally recognized risk management frameworks such as the NIST Cybersecurity Framework and ISO 20243.

We will explain these and other types of useful risk assessment frameworks later.

For now, remember that a supplier risk assessment framework is a policy or set of guidelines on what supplier risks to assess, how to gather the data, and how to consistently evaluate suppliers.

When done right, it ensures you work with reliable suppliers, keeping your supply chain resilient.

While we’ve already hinted at some benefits of a supplier risk assessment framework, let’s get into the specifics.

Here are three key reasons why you need it.

Identifying and managing supplier risks becomes much easier—and more reliable—when you’re following a consistent process.

That’s exactly what a supplier risk assessment framework provides.

Instead of reacting to risks as they arise, this framework helps you proactively assess suppliers, standardizing everything from what data you collect to how you evaluate it.

A solid supplier risk assessment framework answers essential questions upfront:

With these steps defined, you will, first of all, save time.

Second, you will ensure that you’re evaluating each supplier in the same category against the same standards, whether it’s for financial stability, cybersecurity, or regulatory compliance.

Finally, you will gather only the relevant and accurate data for an objective risk assessment.

With that in mind, let’s focus for a moment on supplier questionnaires.

For many standard risk assessment frameworks, they are a key method for obtaining data directly from suppliers.

Here are examples of different types of questionnaires:

Illustration: Veridion / Data: UpGuard

As you can see from this list (which is by no means exhaustive), frameworks span various areas, from cybersecurity and data privacy to modern slavery and ESG standards.

The point is: with such standardization, you ensure that the process is unified for every supplier, which makes data collection and risk analysis easier.

However, we do have to mention the challenge of data credibility here.

For example, if you rely solely on supplier questionnaires to gather their risk data, how do you confirm that the provided information is accurate?

This is particularly concerning when we know that suppliers are not always the most reliable sources.

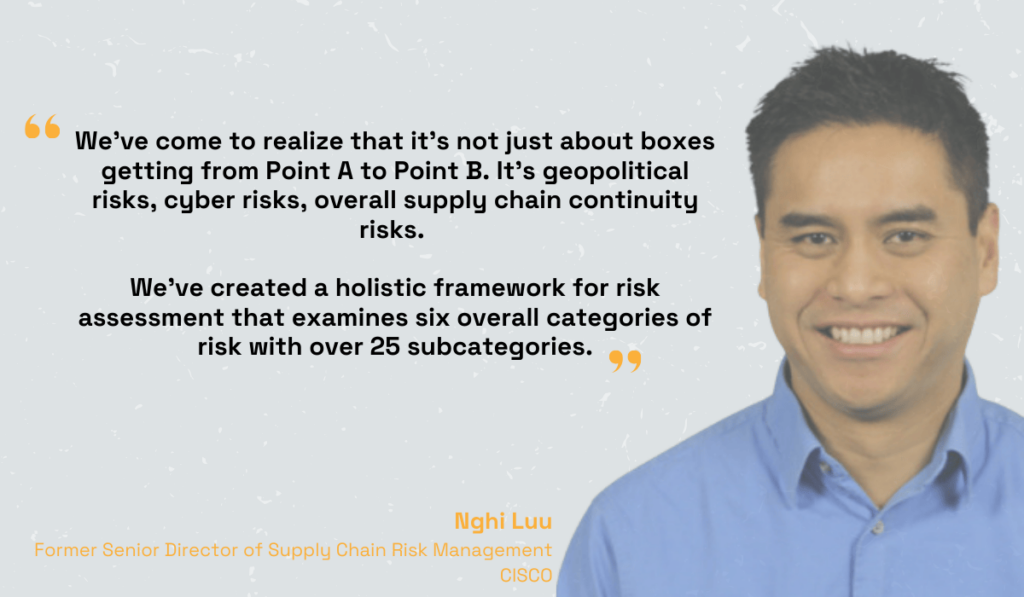

TealBook’s research reveals that a significant majority (93%) of procurement and supply chain leaders have faced negative consequences due to incorrect or misleading information about their suppliers—that they’ve got directly from suppliers!

Illustration: Veridion / Data: TealBook

And almost half of these leaders (47%) encounter such issues frequently or regularly.

This is where big data platforms come to the rescue: both by providing you with fresh and accurate supplier data and for continuous supplier risk assessment.

Take our Veridion, for example.

With the help of AI and machine learning, Veridion continually scraps the internet for real-time supplier data.

Source: Veridion

Besides supplier firmographic data, Veridion brings insights into specific risks like FOCI (Foreign Ownership, Control, or Influence), operational disruptions, and ESG concerns.

Moreover, Veridion can even let you set custom filters to find and assess suppliers based on the factors that matter most to you.

Later, you can use Veridion for third-party risk management through real-time alerts about changes in supplier business activities.

Source: Veridion

Having this level of structure means that, instead of scrambling to gather information, you have a streamlined, reliable way to track supplier risk over time.

And, when risks are identified early, you can prevent issues before they impact your supply chain.

Strong, transparent, and mutually beneficial relationships with your suppliers are key to a resilient supply chain.

Risk and supply chain leaders are well aware of this.

According to WTW’s Global Supply Chain Risk Report, 54% of them believe improving supplier and customer relationships has the greatest impact on managing supply chain risks.

Illustration: Veridion / Data: WTW

A strong supplier risk assessment framework fosters exactly this kind of collaboration.

How?

By ensuring suppliers understand what is expected of them and how their performance will be measured, which in turn sets clear expectations and builds trust.

This creates a foundation for both parties to work together to address challenges and find solutions, ultimately leading to long-term, stable, and productive relationships.

A great example of this approach is IKEA’s IWAY Standard, which not only defines its supplier code of conduct but also outlines its supplier risk assessment framework, largely based on supplier audits.

Stefano Bizioli Galli, Senior Sustainability Compliance Auditor at IKEA, describes the approach this way:

Illustration: Veridion / Quote: IKEA

So, how does IKEA achieve this?

Before starting a new supplier relationship, IKEA conducts a thorough risk assessment to ensure the supplier meets IWAY requirements.

These assessments examine various risk types, including:

Once suppliers are onboard, they are expected to meet the basic IWAY standards within one year.

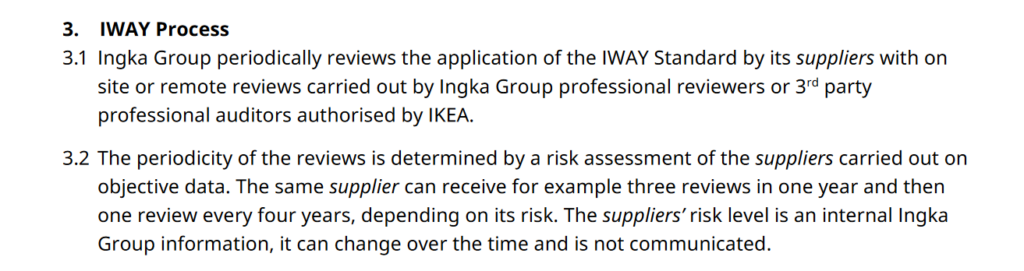

And IKEA assesses that through audits, as they describe in the official document:

Source: Ingka

Over time, as suppliers improve, they are encouraged to meet higher standards, such as IWAY Advanced or IWAY Excellent.

The bottom line is that this structured, cooperative approach to supplier risk assessment helps IKEA maintain high standards across its supply chain but also empowers suppliers to improve and innovate.

It’s a win-win for both sides.

In addition to improving relationships, a supplier risk assessment framework also ensures that suppliers adhere to regulatory requirements.

By formalizing and standardizing the compliance process, rather than relying on ad hoc checks, companies can ensure that suppliers remain compliant with key regulations.

This includes data protection laws like GDPR, environmental standards, labor rights laws, and many other rules and regulations.

IKEA’s approach, for instance, focuses heavily on ESG compliance.

Through audits, IKEA ensures that its suppliers comply with labor laws, child labor regulations, wage standards, and workers’ rights.

Assessing suppliers through these factors reduces the risk of legal violations and ensures ongoing compliance over the course of the supplier relationship.

Source: Veridion

Similarly, Jabil—a global manufacturing solutions provider—uses a detailed cybersecurity risk assessment framework.

This ensures that suppliers protect critical data and systems by adhering to strict cybersecurity standards such as:

Jabil also mandates cyber insurance for suppliers, conducts regular audits, and requires subcontractors to meet the same stringent standards.

This way, it protects itself from violating data protection laws.

All in all, by implementing a robust risk assessment framework, companies like IKEA and Jabil ensure compliance and create a consistent, transparent way to manage regulatory obligations across their entire supply chain.

This guarantees that suppliers meet legal, regulatory, and industry standards, mitigating risk and protecting the company’s reputation.

As mentioned earlier, you don’t need to build your own supplier risk assessment framework from scratch.

Depending on which risks are most critical to your business, you can choose from a range of established frameworks.

These frameworks vary, covering everything from general risk management to more specialized areas like cybersecurity or environmental impact.

Here’s an overview of some key frameworks and how each can support your supplier risk assessment.

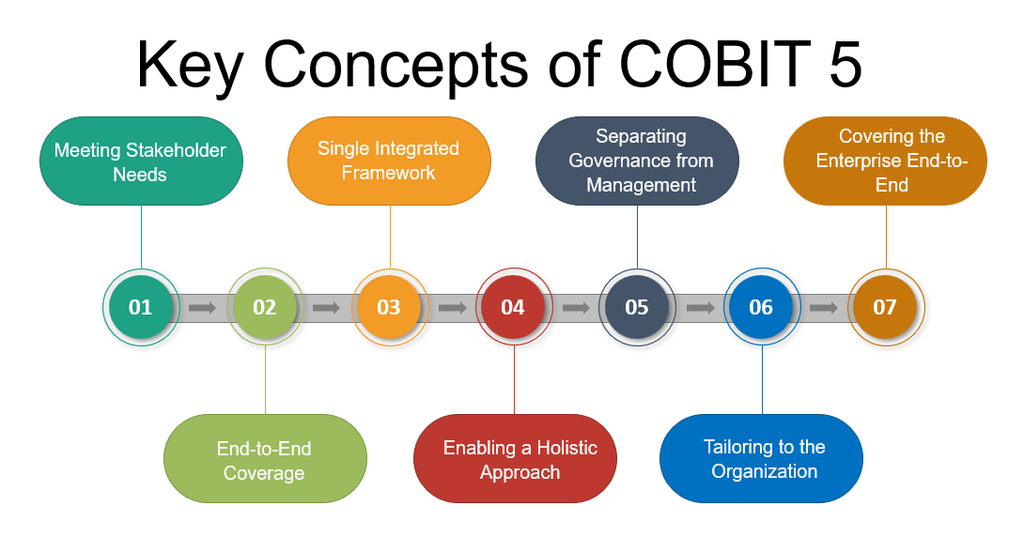

COBIT 5 is a comprehensive framework for supplier risk management, covering all the steps from sourcing and procurement to offboarding.

It helps you identify potential supplier risks, assess their likelihood and impact, create strategies to mitigate them, and continuously monitor those risks.

Here are COBIT 5’s main principles:

Source: ITSM Docs

This framework is ideal if your business relies on technology or data-heavy suppliers and ensures that IT governance remains a priority.

ISO 31000 is a broad, adaptable framework that guides risk management across any organization.

It provides principles and processes to help you identify, assess, and manage risks, but it doesn’t prescribe a one-size-fits-all method.

Instead, it allows you to tailor the framework to your company’s specific needs.

It’s flexible enough to integrate into your existing processes while giving you a clear structure for effective risk management.

Hans Læssøe, former Senior Director of Strategic Risk Management at LEGO, explains how he used ISO 31000 to build a custom risk management framework for the company:

“ISO 31000 was and is very flexible as it does not tell you how to do things – just entice you to get them done. I leveraged this (i.e. exploited it to the fullest) by doing what I wanted to do the way I wanted to do it – whilst vigorously promoting this as being ISO standard (the company was ISO compliant on several other standards already). And I wasn’t even cheating – I was truly basing my efforts, vocabulary, taxonomy, etc. on the ISO standard. ISO gave me a lever that helped me get a good start.”

By adapting ISO’s principles to LEGO’s needs, Læssøe created a robust system that was both compliant with international standards and tailored to LEGO’s unique challenges.

This shows how ISO 31000 can help you create a risk management process that works for your business.

This framework focuses on managing supplier information security risks.

It sets the guidelines for assessing a supplier’s data access, incident history, and ability to meet your security standards.

By requiring ISO 27001 compliance in your supplier contracts, you can ensure that they adhere to strict information security practices, reducing the likelihood of costly data breaches or cyberattacks.

This framework is especially needed today.

In 2023, supply chain-related cybersecurity issues rose by 62%, according to a report by Sphera.

Illustration: Veridion / Data: Sphera

Cyber incidents can lead to significant delays, data loss, and even factory shutdowns.

So, ensuring that your suppliers comply with standards like ISO 27001 can protect your business from these risks.

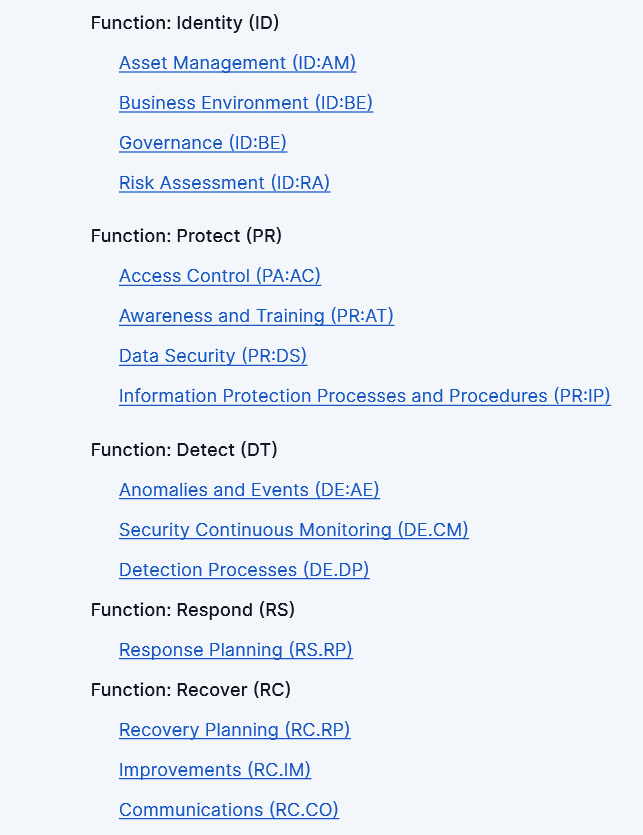

If data privacy and regulatory compliance are critical to your business, the NIST Cybersecurity Framework is essential for your company.

NIST CSF provides structured controls that allow you to evaluate a supplier’s cybersecurity preparedness through the five levels: Identity, Protect, Detect, Respond, and Recover.

You can see these levels outlined below:

Source: UpGuard

Many organizations build vendor questionnaires around NIST controls, helping ensure that suppliers meet high standards for data security and regulatory compliance.

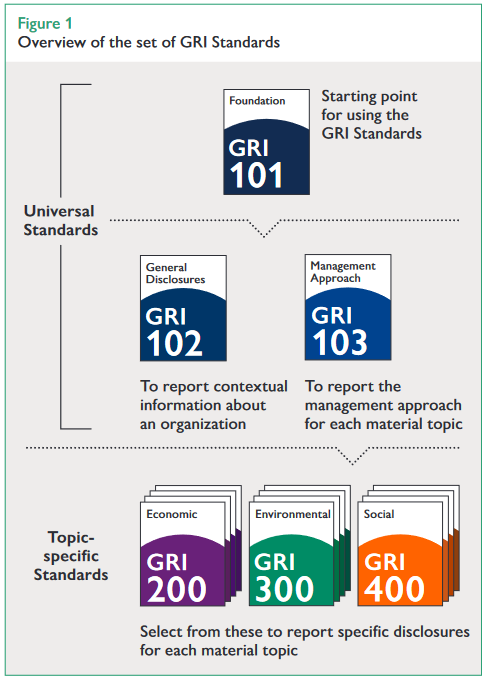

The GRI is one of the most widely recognized ESG frameworks.

It offers modular standards that allow you to address various aspects of sustainability, including labor practices, environmental policies, and social impacts.

Below, you’ll find a brief overview of the standards:

Source: WAP Sustainability

GRI’s adaptability makes it well-suited for companies seeking broad ESG oversight across their supply chains.

The CSRD is a new, mandatory framework for larger organizations operating in the EU.

It requires companies to report on sustainability, so investors and stakeholders can better understand risks and performance.

For supplier risk assessment, the CSRD helps by giving clear, standardized information on suppliers’ ESG practices.

This makes it easier to spot potential risks in your supply chain and ensure you’re working with responsible partners.

In the end, each of these frameworks has the same ultimate goal:

To help you assess supplier risks and ensure that you work with suppliers who comply with laws and pose the fewest risks possible.

Hopefully, we made it clear that supplier risk assessment frameworks are essential tools for structuring and standardizing supplier risk management.

You don’t need to rely on just one framework—many companies combine different approaches to address various types of risk.

What matters most is establishing a structured process that enables you to identify risks, assess them accurately, and take action to mitigate them.

By integrating this framework into your company culture, you’ll create a robust, standardized approach to supplier risk assessment.

This, in turn, will ensure you work with suppliers who meet your criteria, align with your business requirements, and don’t expose your operations to unmanageable risks.