How to Reduce Vendor Concentration Risk In Your Supply Chain

Key Takeaways:

Keeping your vendor list short might seem simpler and more efficient at first, but, ultimately, it exposes you to all kinds of trouble down the line.

If any of your vendors face financial, operational, or similar issues, you’ll experience these issues firsthand through supply disruptions, pricing imbalances, and a host of other unforeseen problems.

This is called vendor concentration risk.

So, if you feel like this is something your company might be experiencing, keep on reading.

We’ll walk you through five proven strategies to address this problem, complete with actionable tips, research-backed insights, and expert advice.

Let’s get started.

To identify the most reliable suppliers, capable of supporting your business through supply chain disruptions, it’s important to assess how they handle various crises.

We’d all like to believe we can rely on all suppliers equally, but experience shows otherwise.

Toyota, for example, learned this lesson in 2021, after an earthquake in Fukushima exposed differences in supplier preparedness, as noted by a company spokesperson:

Illustration: Veridion / Quote: Automotive Logistics

However, you don’t want to wait until a disaster hits to find out how your suppliers will respond.

So, how can you distinguish the reliable suppliers from those that might not be prepared?

You make a proactive effort to review suppliers’ business continuity (BC) and/or disaster recovery (DR) plans in advance.

Essentially, BC/DR plans outline specific steps to be taken to ensure that operations keep running smoothly amidst potential threats to a company.

As such, they can tell you a great deal about a supplier’s resilience, in turn helping you make informed decisions about which vendors to engage with—and to what extent.

Lisa-Mae Hill, an Information Security Specialist at Venminder, a provider of third-party risk management solutions, explains what information these documents usually include:

“When you think of business continuity and your vendor, it covers things like what would they do in the event of a loss of personnel, if their facilities or services were down; what their planning with public entities such as emergency services is like, and communications with their own identified key vendors, their clients like you, employees and the media.”

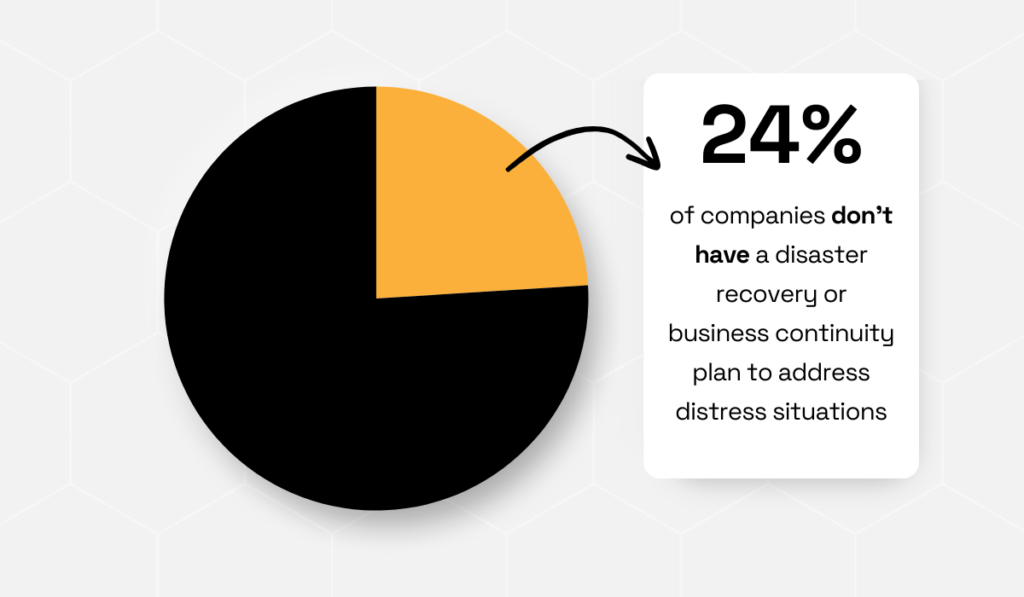

However, not every vendor has an effective BC/DR plan in place.

A KPMG survey of Romanian companies across industries confirms this.

When asked if they had a disaster recovery or business continuity plan for crises, such as a pandemic, 24% of respondents said no.

Illustration: Veridion / Data: KPMG

If your business relies on an already small pool of suppliers, this kind of unpreparedness could spell trouble for you too.

This is why it’s so important to evaluate these documents.

But, what should you look for?

According to Hill, you should check if your supplier’s BC plan aligns with your needs and covers some key elements.

Specifically, the BC plan should address:

And remember: evaluating suppliers’ disaster preparedness is not a one-time task.

Rather, it’s an ongoing process, aimed at making sure your suppliers stay prepared as risks evolve.

Think of it as an insurance policy for your supply chain—one that pays dividends when disaster strikes.

To stay ahead of risks, you need fresh and accurate data.

It should cover all aspects of your suppliers’ performance, financial health, and external risk factors like geopolitical instability or natural disasters.

Without this kind of risk intelligence, you’re flying blind.

You won’t see potential vulnerabilities in the supply chain or changes in vendor performance, which can, ultimately, prevent you from making data-driven decisions.

For companies relying on a small pool of suppliers, the stakes are even higher. One weak link could spell disaster.

A great example of a company that takes risk intelligence very seriously is Coca-Cola HBC.

According to their website, staying ahead of trends and risks is paramount for their business continuity:

“Every day, we source, manufacture and deliver products and services that comply with laws, regulations, internal standards, and high Quality and Food Safety benchmarks. We stay ahead of trends and emerging risks using our internal expertise and external partnerships.”

To achieve this, they use various sources of risk intelligence.

For instance, they have dedicated tools for tracking geopolitical risks, suppliers’ sustainability risks, financial risks, and even water-related risks.

Coca-Cola truly understands that data is king when it comes to proactively managing disruptions.

After all, how can you manage what you don’t know?

So, where can you find risk intelligence?

It’s available in a variety of places, including:

| Public sources | Publicly available third-party threat intelligence like data breach sites, corporate websites, and product/company review platforms |

| Private sources | Fee-based services and websites such as credit reporting agencies, financial review platforms, and legal action databases |

| Regulatory bodies | Organizations and frameworks like the CCPA (California Consumer Privacy Act), GDPR (EU General Data Protection Regulation), and HIPAA (Health Insurance Portability and Accountability Act) |

| Industry partnerships | Various industry-specific information-sharing centers (ISACs), like The Healthcare Information Sharing and Analysis Center (H-ISAC) for healthcare and pharmaceuticals or The Legal Vendor Network and Theorem Legal for law firms |

| Vendors themselves | Insights can also be gathered directly through questionnaires and surveys |

While these sources are invaluable, they, for the most part, require manual analysis, which can be both time-consuming and labor-intensive.

However, you can also use AI-powered supplier data platforms like Veridion to streamline the risk assessment process.

Using machine learning to process billions of websites and petabytes of data weekly, Veridion delivers reliable, up-to-date information on suppliers, service providers, and products worldwide.

And it does so in minutes.

Source: Veridion

This dramatically reduces the manual effort while still delivering extremely powerful insights.

Veridion data provides everything you need, from detailed location information to corporate family structures, enabling you to improve decision-making and efficiently manage risks.

Source: Veridion

For example, Veridion’s data mapping helps you trace dependencies and assess the impact of supply chain issues.

Or, you can monitor financial health indicators to gauge the vendor’s financial stability.

With Veridion, gathering risk intelligence is no longer a chore—all you need to know about your suppliers is right at your fingertips.

For companies with a limited supplier base, it’s an absolute must.

After all, if your suppliers can’t deliver, neither can you.

Sometimes, no amount of planning and research can fully prepare us for disruptions.

That’s why negotiating flexible contracts is absolutely vital.

Flexible agreements offer some leeway when things go wrong, protecting companies from being locked into deals that no longer reflect the realities of the market.

Lucy Larkin, a Partner in Baringa’s Consumer Products & Retail Practice, a consultancy that specializes in financial services, climate risk, and more, agrees:

Illustration: Veridion / Quote: Raconteur

After all, risks can evolve quite rapidly, often throwing supply chains into chaos.

The COVID-19 pandemic provided stark evidence of this, demonstrating the need for contracts that are built for adaptability and capable of addressing even the most unthinkable scenarios.

Clare Francis, Commercial Team Partner and Global Board Member at a multinational law firm, Pinsent Masons, elaborates:

“The fluctuation in demand for products before and after lockdown was vast. Many businesses saw a significant increase in demand occurring very quickly and giving little time to adapt or change processes. […] For businesses, this volume volatility presents operational challenges requiring the implementation of new processes to manage stock and inventory. However, it is frequently also an issue in supply chain contracting, as the contract needs to support changes in practice.”

Even though the immediate crisis of COVID-19 has passed, the risks are far from over.

Geopolitical conflicts, environmental disasters, and other unforeseen challenges can still disrupt suppliers’ ability to meet performance standards.

Flexible contracts are a safety net against such underperformance, ensuring businesses are better prepared for future uncertainties.

So, when drafting or revising contracts with suppliers, consider some of these strategies:

| Shorter contract terms with regular review option | Long-term contracts might feel secure, but shorter ones with regular check-ins let you pivot when the market shifts |

| Exit or renegotiation clauses | Include options to renegotiate or walk away if your supplier isn’t performing or if market conditions change |

| Volume flexibility clauses | Add clauses that allow you to adjust order volumes in response to fluctuating demand |

| Clear Service-Level Agreements (SLAs) and performance metrics | Define performance standards upfront and tie them to contract renewals or adjustments |

These measures establish clear expectations from the start, setting the stage for more resilient and agile procurement efforts.

It’s a great way to keep disputes and risks to a minimum.

The purpose of a contingency plan is to ensure critical operations continue during and after a crisis, helping you minimize its impact and recover faster.

Take Walmart, for example.

During the recent U.S. port strike that shut down key ports on the East and Gulf Coasts, Walmart had backup suppliers ready to go.

According to their spokesperson, they always plan and prepare for such disruptions:

Illustration: Veridion / Quote: Quartz

This ultimately helped them secure the key goods, giving them a massive competitive edge, especially with the holiday season around the corner.

So, to create an efficient contingency plan and unlock such resiliency for yourself, follow these steps:

Source: Veridion

First, perform a thorough supplier risk assessment that will answer the following questions:

Here, you should also define your risk tolerance, i.e., the maximum loss you’re willing to absorb.

Then, it’s time to create a specific backup plan for each risk.

This can be:

This is, essentially, the core of your contingency plan as coming up with the right strategy can truly make all the difference for your business continuity.

However, this is far from the final step in contingency planning.

From here, you’ll need to establish crisis communication channels, such as email or phone chains, for quick exchange of vital information during disruptions.

Naturally, you’ll also want to ensure your team is well-trained to implement the plan effectively when disruptions occur.

After all, even the best plans fail without proper execution.

Lastly, don’t forget to regularly review and update your plan to reflect the changes in your goals, needs, and market conditions.

Supplier-related risks are constantly evolving—and so should your contingency plans.

If you’re concerned about being too reliant on a single vendor, diversifying your supplier base can be a smart move.

Expanding the number of vendors for key materials and services—also known as multi-sourcing—ensures that if one supplier faces disruptions, others can step in.

As a result, business continuity stays intact.

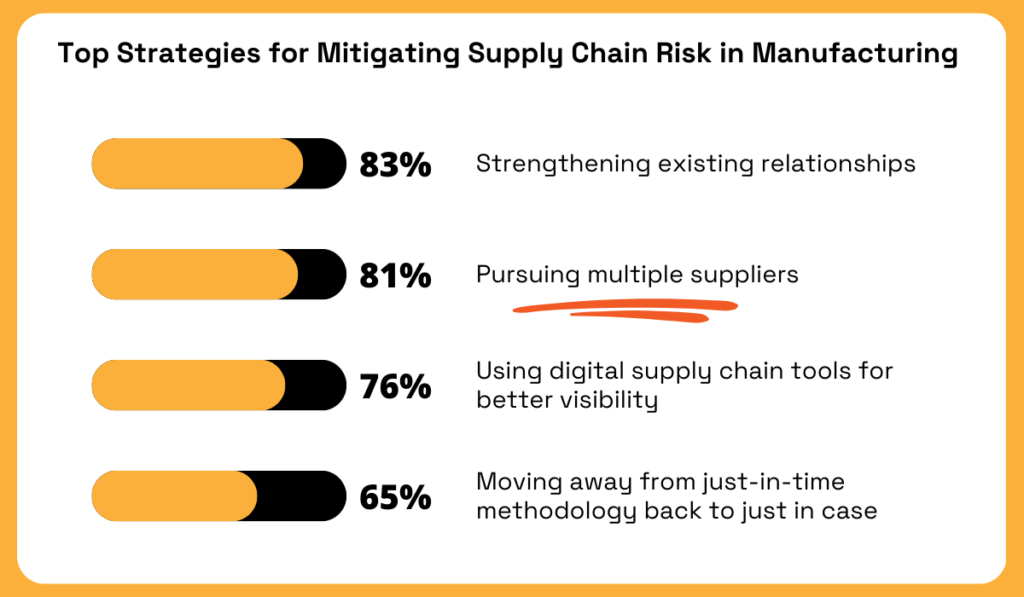

According to a 2022 Deloitte survey, this is the second most common strategy for navigating supply chain disruptions in manufacturing, with 81% of companies reporting its use.

Illustration: Veridion / Data: Deloitte

But supplier diversification is equally effective in other industries, too.

Take, for example, West Pak Avocado, a company that grows and distributes premium avocados.

They recently added Colombia to their global multi-sourcing strategy, and the move is already set to deliver significant benefits.

For one, sourcing from Colombia offers much shorter lead times, Kellen Newhouse, Vice President of Sourcing and Farming Operations at the company, says:

Illustration: Veridion / Quote: AndNowUKnow

This is something you can’t achieve with a small supplier base.

Since you depend on this limited number of vendors, they are the ones who have control over delivery schedules, which can easily lead to delays and operational disruptions.

With diversification, that problem is solved.

And here’s another problem diversification solves: goods shortage.

According to Newhouse, the company’s recent move will ensure a year-round supply of avocados, helping them more easily meet customer demand:

“The timing of the two seasons—late spring through summer and again in the fall through early winter—helps fill gaps in supply to customers with a year-round avocado program. It also helps augment supply for peak events such as Cinco de Mayo and the big game in February.”

Companies procuring seasonal products like fruits, vegetables, or spices, are particularly prone to concentration risk.

However, by diversifying, businesses can allocate orders to different vendors throughout the year, ensuring consistent availability.

But how do you find the right suppliers, especially on a global scale?

That’s where AI-powered supplier intelligence platforms come in handy yet again.

These tools don’t just track vendor risks—they help you discover new suppliers as well.

You simply input your criteria, and the platform scans the internet, delivering a curated list of suppliers that meet your specific needs.

Source: Veridion

It’s faster, smarter, and far more efficient than doing it all manually.

As you can see, you’ve got plenty of options when it comes to reducing vendor concentration risk.

Granted, combining all the strategies we’ve covered delivers the best results, but there’s no need to overwhelm yourself from the get-go.

Instead, start small by assessing the vendors you’re already working with.

Can they handle unexpected disruptions? Is there room for contract renegotiation?

If yes, they can be included in long-term business plans.

If not, it might be time to explore new partnerships and diversify.

Whatever you choose to do first, remember this: the foundation of any efficient strategy is reliable data.

So, before making any big decisions, make sure you’re equipped with the tools that will deliver the data you need!