Supplier Evaluation: Best Practices to Follow

Key Takeways:

Effective supplier evaluation distinguishes reliable suppliers, ensuring a dependable, high-quality, and cost-effective supply chain.

That’s why we’re sharing five game-changing best practices to enhance your supplier evaluations from start to finish.

We’ll break down why each practice matters, show you how to put them into action and share some real-life examples.

Let’s jump right in.

Before you even start evaluating suppliers, you should have an understanding of what you expect from them.

Why is this important?

Because setting clear expectations serves as a foundation for successful supplier evaluation.

If you outline your requirements now, it’ll be easier to develop objective and consistent KPIs to evaluate vendors’ capabilities, monitor their performance, and make data-driven decisions later on.

Remember, supplier assessment isn’t solely about price.

You should match these criteria with the company’s broader mission, vision, and business goals.

This means defining expectations across multiple dimensions, such as:

| Quality Standards | product requirements, inspection and testing protocols, and acceptable defect tolerances |

| Delivery and Logistics | lead times, critical deadlines, and on-time delivery benchmarks |

| Ethical Standards | expectations for labor practices, anti-corruption policies, and diversity initiatives |

| Risk Management | contingency planning, data security, and other risk mitigation strategies |

Once you define these expectations, document these expectations clearly and concisely.

Many companies now share supplier expectations publicly on their websites, ensuring complete transparency even before partnerships begin.

For instance, Boehringer Ingelheim, a global pharmaceutical leader, developed a Supplier Code of Conduct detailing their social and environmental expectations.

Their CPO, Michael Betke-Hornfeck, explains the importance of these standards on their website.

Illustration: Veridion / Quote: Boehringer Ingelheim

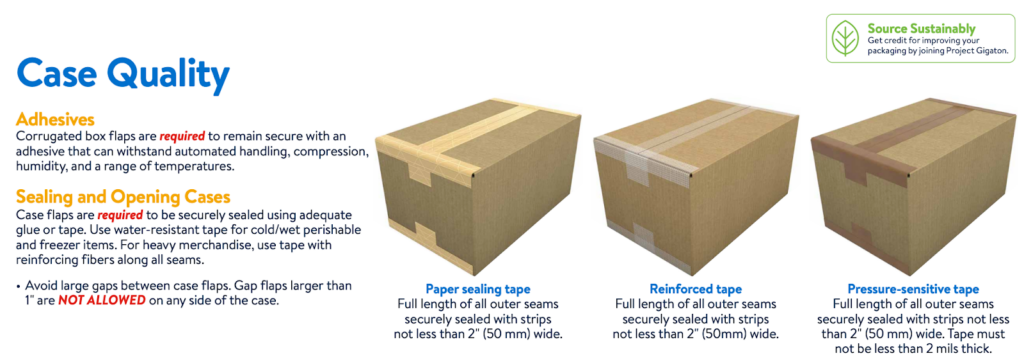

Another great example is Walmart.

They provide extremely detailed packaging guidelines every vendor must comply with to ensure consistent quality and efficiency.

Here’s just a small excerpt from this document.

Source: Walmart

Finally, Vard, a world leader in specialized shipbuilding, expects its suppliers to adhere to its Vision Zero safety initiative, focusing on accident prevention and maintaining high safety standards:

“Health, Safety and Environment (HSE) is our first priority and we expect our suppliers to be committed to our company-wide effort Vision Zero, aimed at avoiding any mishaps, for our people as well as the environment. As a supplier to VARD you must comply with applicable laws and regulations. When working at VARDs premises, we are all ONE team, and we expect that you follow our internal rules and regulations contributing to a safe working environment for all of us.”

Ultimately, having your requirements outlined in such a straightforward way benefits each party.

Suppliers know exactly how they will be assessed, while buyers gain standardized, objective, and relevant criteria for supplier evaluation.

Research is at the core of effective supplier evaluation.

It provides insights into vendors’ performance history, financial stability, and capabilities, improving your understanding of their reliability.

And the more data you have, the clearer—and more complete—your picture of their performance will be.

But, where do you find this data?

Your internal supplier intelligence sources, like ERPs or source-to-pay platforms, are always a good starting point.

They consolidate all vendor information—contracts, catalogs, purchase orders, invoices, etc.—into a single, accessible platform.

No wonder big companies like Coca-Cola love such systems.

Illustration: Veridion / Quote: Coca-Cola EP

These insights are extremely valuable.

They show how successful your partners are in meeting your needs, making your research process more well-informed and data-driven.

Still, internal data alone isn’t enough.

For a true 360-degree view, you’ll need some external data as well, whether it’s from suppliers’ own websites, market research agencies, or some other external sources.

Volkswagen Group, for example, uses AI to monitor supplier-related news from publicly available media and social networks, specifically for ethical and sustainability evaluations.

Ullrich Gereke, Head of Procurement Strategy for the company, notes that this technology has significantly improved their research process and, consequently, supplier performance:

“We are meeting our responsibility for ensuring a sustainable and fair supply chain – we established sustainability criteria for our suppliers on a contractual basis as long ago as 2014. […] By partnering with [a market intelligence platform], we now have another tool to uncover and investigate potential violations, thereby contributing to improved social and environmental conditions at our suppliers’ production sites.”

Indeed, AI-powered platforms effectively supplement internal data. They offer information that would otherwise be too hard (or even impossible) to find.

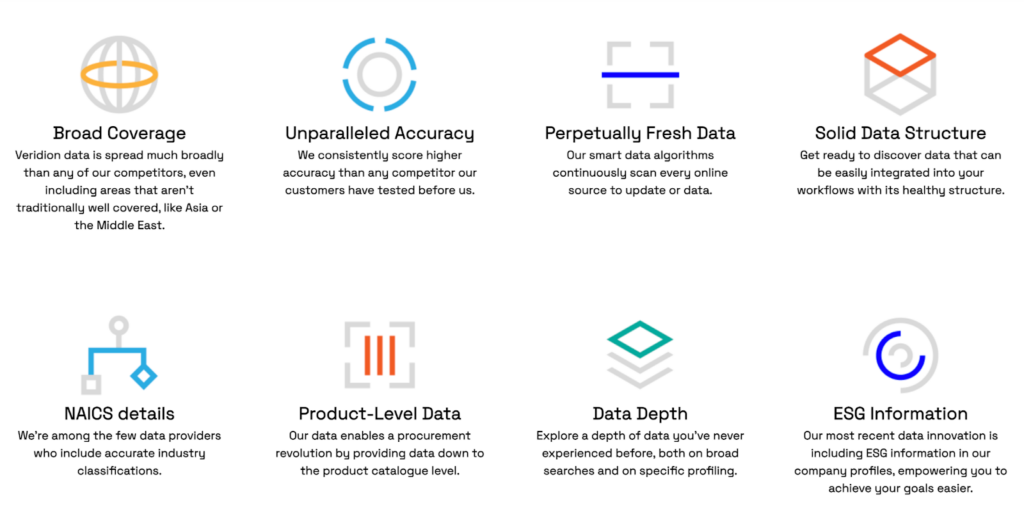

That’s something our Veridion does very well.

Veridion scans billions of websites every week to provide its users with extensive global coverage and enriched company profiles.

Source: Veridion

These profiles include all the crucial details, from location information to corporate family structures, keeping buyers completely in the loop about suppliers’ business activities.

Whether you’re analyzing financial health, ESG practices, or other key metrics, Veridion provides the deep insights manual research can’t match.

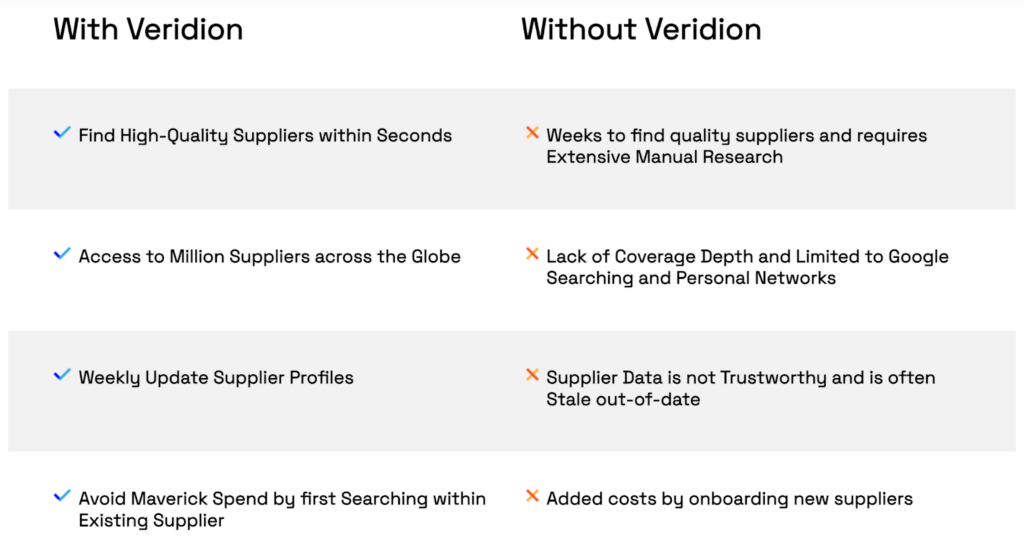

Remember, when you rely on manual research, you’re not just slower. Your reach is limited, and the data you find isn’t always reliable, either.

Source: Veridion

In contrast, with tools like Veridion, you quickly unlock accurate and detailed vendor insights.

It’s a perfect tool for supplier analysis in this era of highly volatile supply chains.

Involving multiple departments ensures all aspects of supplier relationships are thoroughly evaluated, offering a well-rounded perspective.

Patrick Gilgour, Managing Director at Protiviti, a global firm providing IT consulting, summarizes supplier evaluation perfectly:

Illustration: Veridion / Quote: CIO

It’s not enough to evaluate suppliers across diverse criteria. It’s equally important to find the right people to assess those criteria.

For instance, engineering can evaluate technical capabilities, while finance assesses cost-effectiveness and financial stability.

When all these perspectives come together, you get a full 360-degree view of your suppliers.

That said, facilitating collaboration among departments can be challenging.

Having them communicate effectively and share data can easily get messy, time-consuming, and frustrating.

This is where technology, such as source-to-pay (S2P) or supplier management platforms, becomes invaluable.

These tools serve as a centralized hub for collaboration, ensuring that all stakeholders access the same data. Ivalua is one such example.

Source: Ivalua

The result of using these tools is fewer errors, reduced miscommunication, and more synchronized, detail-oriented evaluations.

Here’s one successful example of that.

Bill Mertz, former VP of Enterprise Supply Chain at the IT company, CACI International, shares how the ability to easily share and access data through their S2P platform was a total game-changer:

Illustration: Veridion / Quote: Ivalua

At the end of the day, supplier evaluation is too important to leave to one person or one department.

It needs to be a team effort.

Only that way can organizations gain a more accurate view of their suppliers and make decisions that benefit the entire enterprise.

During supplier evaluation, focus on suppliers committed to long-term partnerships rather than short-term transactions.

That way, you ensure you don’t work just with the vendors with the best prices, but with those that can help you maintain smooth operations and minimize risks.

Take it from Pratt & Whitney, a leading American aerospace manufacturer.

In 2014, they committed to $6 billion in long-term supply contracts to secure critical materials needed to support production growth for the upcoming decade.

Danny Di Perna, their Senior VP of Engineering and Operations at the time, explained how thinking long-term is key to ensuring uninterrupted production and meeting future demands:

Illustration: Veridion / Quote: American Machinist

Long-term relationships not only safeguard operations but also support broader business goals.

Just look at Vestas, a global leader in renewable energy.

As per their website, their ambitious business objectives depend on strong, collaborative supplier partnerships.

In 2022, they partnered with LM Wind Power, a leading manufacturer of wind turbine blades, to develop and manufacture blades for V172-7.2 MW wind turbines.

According to Tommy Rahbek Nielsen, Executive VP & COO of Vestas, these strong partnerships allow them to leverage suppliers’ extensive knowledge to deliver high-quality solutions to their clients:

“This new partnership highlights how we are increasingly collaborating with partners in a flexible setup to scale efficiently and build on the foundations we have established across our global supply chain. We aim to leverage LM Wind Power’s proven and extensive engineering and manufacturing capabilities coupled with their global footprint to support our customers with high-quality sustainable energy solutions meeting all Vesta’s standards.”

So, how do you figure out who among your suppliers is truly dedicated to a longstanding partnership?

That mostly depends on your organization’s own goals and needs.

To find out who’s the right fit, assess factors that are relevant for you, whether it’s effective communication, innovation capabilities, or ESG practices.

For Mustansir Paliwala, Director of Business Development at EQUANS, a world leader in multi-technical services, for example, reliability is that critical factor.

Illustration: Veridion / Quote: Forbes

After all, consistently delivering the right products or services on time is a non-negotiable starting point for any durable relationship.

Assessing suppliers for their ability to innovate and adapt to changing market conditions or technological advancements is essential.

Why?

Because those who can easily adapt can also help their buyers adapt when faced with disruption or the need for technological advancements.

A prime example is Apple’s relationship with Taiwan Semiconductor Manufacturing Co. (TSMC), the world’s largest contract chipmaker.

In 2023, TSMC used cutting-edge 3-nanometer process technology to develop the M3, M3 Pro, and M3 Max chips for Apple.

These next-generation chips were the first to leverage this technology.

As a result, the new MacBook Pro and iMac’s performance and versatility were taken to a whole new level, with superior speed and efficiency.

In fact, Johny Srouji, Apple’s Senior Vice President of Hardware Technologies, described these chips as the most advanced chips ever built for a personal computer.

Illustration: Veridion / Quote: Channel News

Naturally, by collaborating with such an innovative partner, Apple solidified its reputation as a leader in personal computing innovation.

However, supplier adaptability doesn’t manifest itself only through technological innovation.

Agility in responding to shifts in demand is equally important.

For instance, 3M, the American multinational conglomerate, demonstrated extraordinary adaptability during the COVID-19 pandemic.

Facing an unprecedented surge in demand for N95/FFP2 respirators—widely regarded as the highest-quality option for infection protection—3M quickly doubled production to 1.1 billion units per year across its global manufacturing facilities.

Mike Roman, 3M’s Chairman and CEO, noted at the time:

Illustration: Veridion / Quote: CNBC

This rapid scaling ensured the company could meet its commitments to buyers and support their needs during a global crisis.

Such reliable and responsive partners are invaluable during periods of uncertainty.

So, to evaluate a vendor’s adaptability, start by assessing their business continuity plans.

Lisa-Mae Hill, Information Security Specialist at Venminder, a provider of third-party risk management solutions, explains what these plans are:

“business continuity(…)covers things like what they would do in the event of a loss of personnel, if their facilities or services were down; what their planning with public entities such as emergency services is like, and communications with their own identified key vendors, their clients like you, employees and the media.”

Essentially, they serve as blueprints for how suppliers manage unexpected disruptions or major changes, demonstrating their reliability and ability to mitigate risks effectively.

Here are some key elements you should look for:

Overall, evaluating supplier adaptability is an excellent tactic for identifying flexible, resilient suppliers who can serve as valuable long-term partners.

After all, a good supplier isn’t just supposed to deliver the product today; they need to keep delivering in the face of future supply chain disruptions as well.

The main takeaway from this article is clear: supplier evaluations must go beyond surface-level metrics like cost.

Sure, cost matters, but seasoned procurement professionals know that the right suppliers can offer so much more to the company.

To uncover this potential, they assess suppliers using a broad range of metrics, bring in input from other departments, and leverage diverse sources of supplier intelligence, both internal and external.

By following this approach, you don’t just identify suppliers who meet your immediate needs.

You also uncover those who have the vision, resilience, and capabilities to support your future goals and shield your organization from disruptions.