5 Winning Tips for Successful Supplier Management

Key Takeaways:

Supplier management is essential for successful procurement.

But getting there is no easy feat.

Many procurement professionals find it challenging to tackle supplier-related inefficiencies or refine existing strategies while juggling different priorities.

That’s why we’ve compiled five winning tips that will help you elevate your supplier management game, regardless of your organization’s size.

If you’re ready to unlock new levels of efficiency, cost savings, and supplier collaboration, this article is your blueprint for success.

Let’s get started.

You can’t manage suppliers without accounting for your whole supply chain.

The best way to explain why is to take a look at some estimates.

McKinsey’s 2020 research suggests that a prolonged disruption could erase 30–50% of a year’s EBITDA for companies across industries.

The calculations focused on production and didn’t take into account distribution channel disruptions.

In a climate where a single large-scale event can wreak havoc on your organization’s financial health, knowing the individual cost and value of each supplier becomes crucial.

And that’s where supply chain visibility comes in.

Eric Fullerton, VP of Product Marketing at project44, explains how ensuring sufficient supply chain visibility today requires more than understanding the movement of assets and inventory.

Illustration: Veridion / Quote: Transport Topics

In other words, organizations need to have an in-depth understanding of how individual suppliers fit the big picture.

Doing so goes beyond improving risk mitigation to ensure greater overall efficiency and sustainability of your business.

So, how can you understand the value of the entire supply chain?

You can start by visualizing it.

Despite all the data you’re collecting, mapping your supply chain can be challenging.

This is where technology can lend a helping hand.

As shown in the video below, solutions like Log-hub use data to generate quick supply chain models, making it easier to see who your key suppliers are and how they’re all connected.

Source: Log-hub on Youtube

This supply chain design and optimization software supports data import directly from Excel, so it will also work for organizations that are yet to undergo more profound digital transformation.

Still, the surest way to calculate suppliers’ impact and value in your unique context is to adopt a supplier segmentation model.

Some of the most popular supplier segmentation models include:

However, most businesses use customized versions of these models that fit their unique context.

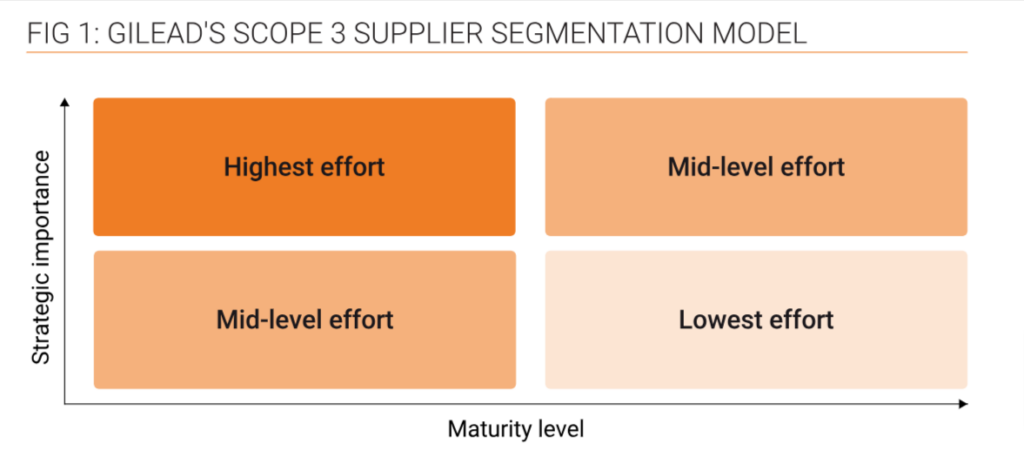

Take the pharmaceutical company Gilead as an example.

Gilead has a well-established supplier emissions-reduction program, but its effective implementation depends on understanding which suppliers are critical to their operations, as well as their Scope 3 maturity.

As such, the quadrant-style segmentation model resembles the Kraljic Matrix, but it replaces the risk axis with more relevant criteria.

Source: Procurement Leaders

Without the matrix, Gilead would be assessing its suppliers in a vacuum, and wouldn’t be able to focus its efforts on critical suppliers with low Scope 3 maturity.

Ultimately, understanding your supply chain in full is the first step towards better supplier management.

Selecting suppliers with values aligned to your own sets the stage for smooth, long-term collaboration.

When you and your suppliers share similar mindsets and work toward common goals, building trust and maintaining a strong partnership becomes much easier.

Plus, it’s less likely you’ll clash or face other issues later on.

Supplier relationships can become incompatible for many different reasons, from different communication styles to general attitude mismatches.

While some issues remain internal, others can escalate and become public, potentially harming your business reputation.

Jim Fleming, one of ISM’s chief experts and a former supply chain manager at Intel, notes that businesses need to keep in mind social responsibility and ethical business practices.

And it’s not just due to regulations—nowadays, consumers simply place more value on them.

Illustration: Veridion / Quote: ISM

In other words, even if you’re doing everything to uphold standards, working with suppliers who don’t do the same puts your reputation at risk.

One notable example is the 2017 scandal when a major steel supplier, working with the likes of Boeing, Ford, and Toyota, admitted to fabricating their quality control data.

With the supplier’s misconduct directly endangering end users, the transportation giants had to deal with both disrupted supply chains and mounting safety concerns.

Kobe Steel’s internal report later revealed “deep-seated issues around corporate culture and compliance.”

And that’s hardly the only episode resulting in a serious breach of trust and ethics.

Last year, H&M dropped one of its Turkish suppliers after a shocking display of violence against its union leader.

Source: Just Style

While the attack itself was difficult to foresee, there were signs of mounting tensions—Akar Textile had allegedly filed for bankruptcy and was negotiating severance payments.

Both cases beg the question:

Was there any way to get wind of these problems before they escalated?

Assessing the supplier’s value system during initial sourcing or later risk management can be very challenging.

Even if their communication is on point, and due diligence reveals perfect ESG compliance, it’s no guarantee that the relationship won’t unravel down the line.

The key to effective supplier management is gathering as much information as possible—and that’s where Veridion’s expansive, global supplier database comes in handy.

Our AI-powered service scours the internet for qualitative business data, analyzing multiple sources to deliver essential supplier insights, as shown in the video below.

Source: Veridion on Youtube

The data goes well beyond supplier location or financial performance.

With over 80 data points and counting, you can effectively uncover risk factors and get a sense of the overall company culture.

Having a complete picture of either potential or existing suppliers is a key ingredient for confident decision-making and successful supplier management.

If your research reveals something troubling within an ongoing supplier relationship, prioritize open dialogue and communicate your expectations regarding their value system.

Suppliers may not be fully aware of the impact of their actions or policies, and an honest conversation can help clear the air.

Procurement consultant Olga Catena backs this advice.

Illustration: Veridion / Quote: LinkedIn

If the conversation leads to the decision to part ways, it’s ultimately for the best.

A shared value system is essential for strong supplier relationships, so the earlier you prioritize it, the better.

While much is said about supplier collaboration, it’s not always understood as a two-way street.

In a buyer-supplier relationship, the supplier is expected to meet the buyer’s needs and fulfill their expectations to the best of their ability.

This is the natural, universally accepted dynamic, but it still requires certain boundaries.

For example, supplier attentiveness and flexibility are highly valued.

However, maintaining a supplier relationship is difficult if you routinely set unrealistic deadlines or make last-minute changes to plans.

In other words, even the most important customer cannot expect to make demands without offering something in return.

Unfortunately, some buyers create an even greater imbalance by not honoring their commitments and making late payments.

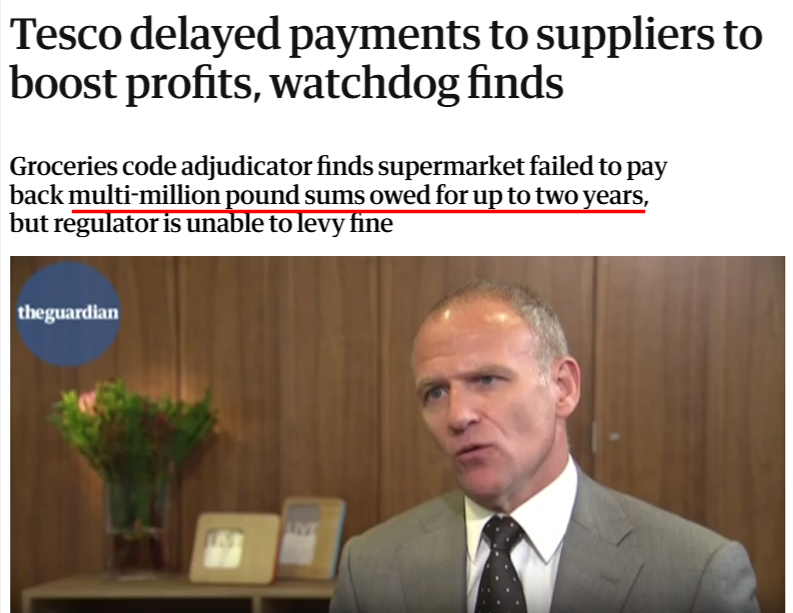

Back in 2016, UK retail giant Tesco made headlines for prioritizing its finances and intentionally delaying payments to suppliers over extended periods of time.

Source: Guardian

Missing a single invoice is one thing, but repeated delays or intentional tardiness erode trust and breed discontent.

Even though some of the suppliers in question agreed to be paid at a later date, many more were put in the difficult position of having their cash flow reduced, resulting in:

On the other side, Tesco’s CEO at the time, Dave Lewis, admitted that both the company’s reputation and supplier relationships took a hit.

Illustration: Veridion / Quote: Guardian

Lewis pledged that Tesco would change its approach completely and invest in stronger supplier relationships.

Fast forward a few years, and the company became one of the bright examples of businesses supporting suppliers during the COVID-19 pandemic.

For instance, Tesco prioritized payments to all small suppliers while actively collaborating with strategic partners to meet changing demand.

The positive trend continued in 2024 when Tesco expanded its Good Faith Receiving (GFR) auditing system which prioritizes strong supplier relationships.

GFR system ensures that payments are made on time while any discrepancies in volume or stock condition are addressed later.

Now, what are some practical steps that you can take?

For starters, you don’t need a dedicated system to prioritize timely payments.

Be as prompt with payments as possible, and if a delay is inevitable, be upfront about it.

Inform your supplier as soon as possible and give an estimate on when they can expect the money.

Open communication about invoice status fosters understanding and reduces frustration for your supplier.

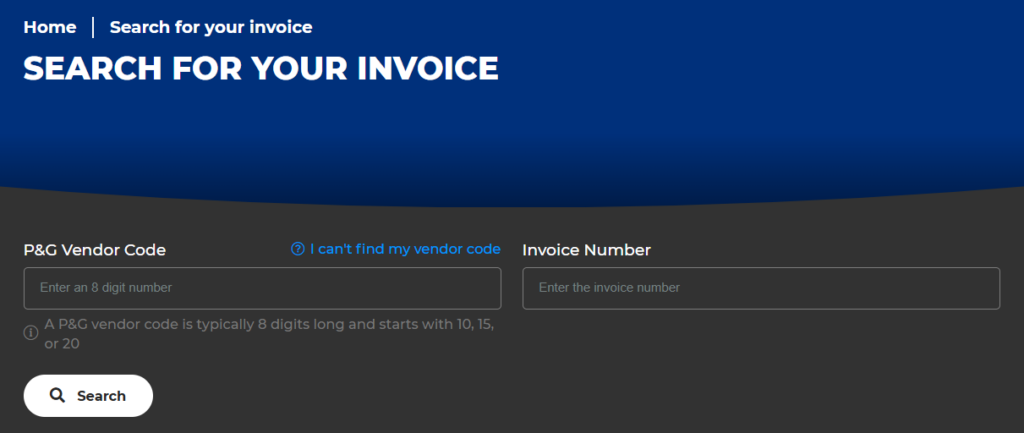

Another option is to ensure easy, self-service access to invoice payment status.

Even a simple search bar like the one below will help reduce uncertainty.

Source: P&G

Regardless of your approach, it’s vital to recognize that collaboration is a two-way effort.

Sticking to agreed-upon payment terms is the bare minimum, but it goes a long way toward building goodwill and introducing future improvements.

Establishing service-level agreements and penalties is important, but don’t overlook rewarding your suppliers for their consistency and excellence.

There’s no room for hesitation when suppliers fail to meet their obligations.

An unaddressed issue is bound to repeat sooner or later, which is why feedback is critical for both organizations and suppliers.

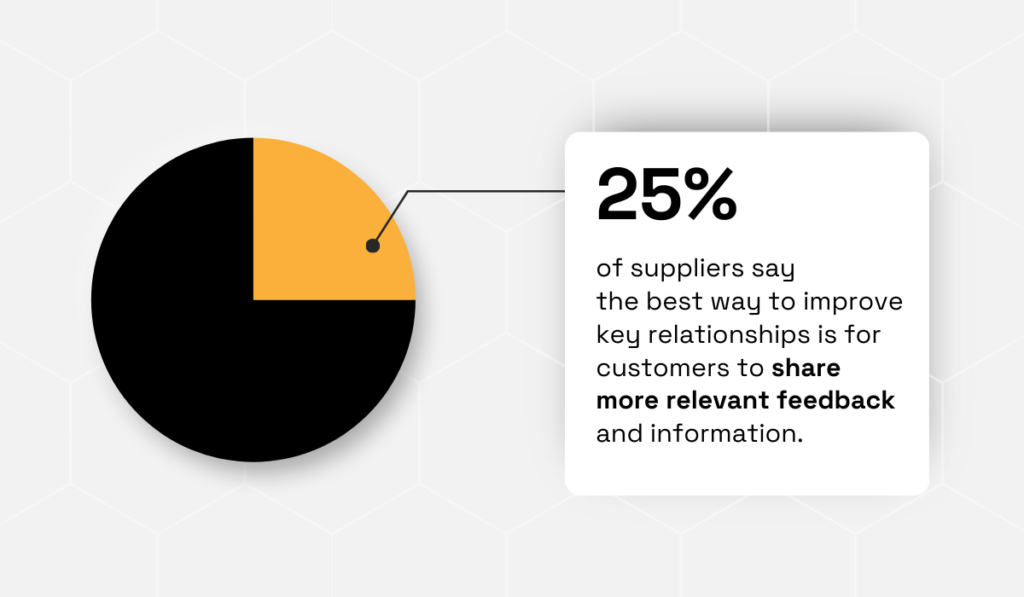

In fact, HICX’s survey shows that a quarter of surveyed suppliers believe that getting relevant feedback helps build stronger relationships.

Illustration: Veridion / Data: HICX

However, feedback should be aimed at encouraging improvement.

Focusing solely on the negative and imposing financial penalties or rating downgrades for minor issues can push your suppliers away.

One way of avoiding this is by balancing penalties with incentives and rewards.

Just like penalties discourage repeat violations, positive reinforcement encourages continuous effort and high standards.

This approach is something we see implemented regularly in the business world, where rewarding good performance leads to stronger, more sustainable relationships.

For instance, suppliers that constantly meet or exceed KPI targets often receive public recognition through various supplier awards.

And the more high-profile the buyer, the more likely it is that industry-relevant outlets will share the news.

Airbus’ supplier Mankiewicz Coatings recently won both supplier awards in their designated category, instantly putting them on the map of companies with similar needs.

Source: Coatingsworld

And the promotion works both ways.

Top-performing suppliers are likelier to get approval to mention their main clients by name or get direct quotes for case studies.

An instant credibility boost can make a big difference when marketing their products or services.

Finally, there are significant co-development and innovation opportunities.

As long as they have a suitable platform for collaboration, innovative suppliers can help you improve your products, processes, and services.

For instance, a 35-year-long partnership between Airbus and one of its key suppliers, Honeywell Aerospace, resulted in a new Flight Management System (FMS) that incorporates external connectivity and enhances fuel savings.

Source: Flyingmag

Airbus gets a new FMS that’s fully tailored to its aircraft models and Honeywell affirms its industry position.

Meanwhile, both are looking at higher margins.

To make the most of these incentives and reward systems, be sure to revise them regularly and base them on measurable results.

Logistics Coordinator for the Finnish Valmet Automotive, Anastasiya Diadichenko, clarifies the latter:

Illustration: Veridion / Quote: LinkedIn

Ultimately, maintaining strong supplier relationships requires constructive criticism, but it needs to be carefully balanced with prompt recognition of positive supplier contributions.

Supplier evaluations need to be rooted in hard data.

While effective supplier management requires clear communication and soft skills, organizations must also ensure compliance and measure performance against defined benchmarks and KPIs.

Broadly speaking, this means collecting data on critical metrics like quality, cost, delivery time, and compliance.

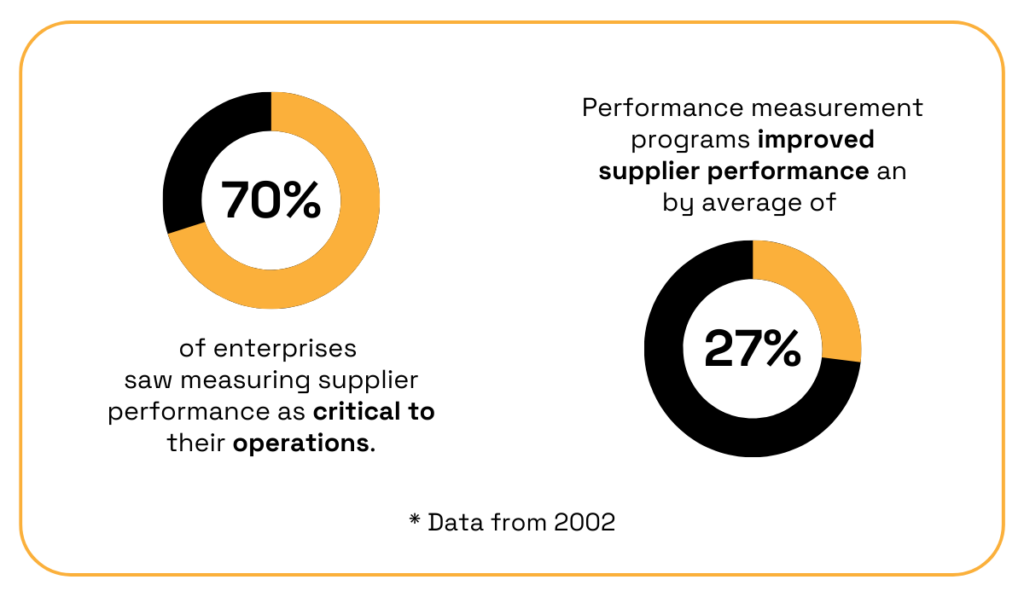

The importance of formal performance measurement programs was recognized decades ago, with one 2002 study foregrounding both their benefits and priority status.

Aberdeen Group’s research showed that performance measurement programs resulted in a performance improvement of roughly 27% among the surveyed suppliers.

Illustration: Veridion / Data: Aberdeen Group

More recent studies confirmed that supplier performance evaluations have a positive impact on future performance.

They also deliver other substantial benefits such as reduced costs and improved supplier-buyer relationships.

Source: Veridion

Nowadays, systematic performance tracking is even more widespread and advanced, which makes capturing key supplier performance metrics easier.

Many organizations rely on different versions of the supplier evaluation matrix, but there are limitations to this method.

Namely, matrices are a valuable assessment tool, but since they’re based on human input, they’re often subjective and prone to inconsistencies.

Some categories like “supplier responsiveness” or “cultural fit” are inherently rooted in subjective evaluations which is why it’s important to complement them with quantifiable metrics.

This is where software can help.

Dedicated supplier performance management systems collect hard data from diverse sources at a fraction of the time and enable real-time performance monitoring.

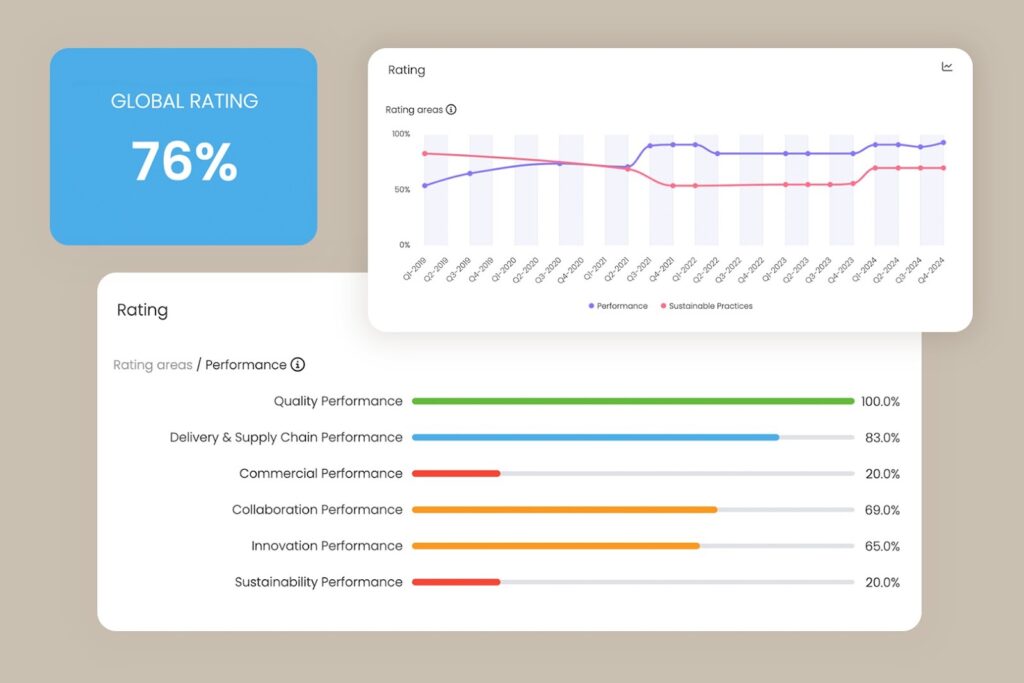

Here’s an example of Kodak Hub’s different rating areas and the solution’s timeline view:

Source: Kodiak Hub

Not only are these metrics quantifiable, but the system immediately moves to suggest corrective action and predict future risks.

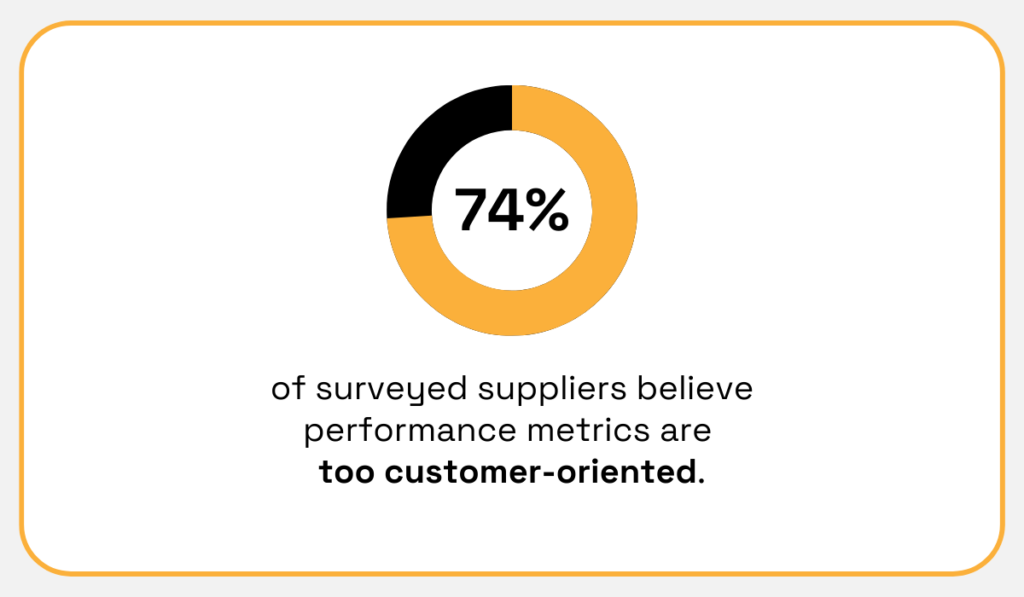

Once you’ve adopted a reliable system for collecting and analyzing performance insights, it’s essential to consider which metrics benefit your suppliers as well.

HICX’s research shows that suppliers are invested in improvement and value performance data, but only if it captures both customer and supplier perspectives.

In fact, nearly three-quarters of respondents believe performance metrics are overly customer-focused.

Illustration: Veridion / Data: HICX

Much like with overall collaboration, buyers must treat supplier performance management as a two-way street.

That way, you’ll have hard data that fosters collaboration and mutual recognition.

Approaching supplier management the right way can turn a challenge into a competitive advantage.

Choosing value-driven partners, fostering two-way communication, and recognizing your suppliers’ contributions accelerate this process.

Successful supplier management also means adopting a holistic view of your supply chain and grounding your decisions in data.

But remember, it’s not just about following these five tips—the point is to overhaul your approach to supplier management as a whole.

With these principles at the heart of your strategy, you’ll build a supplier network that drives both stability and growth, bringing long-term value to your organization.