Challenges in Implementing Cost Savings Initiatives in Procurement

After almost ten years, cost savings have again emerged as the top priority of Chief Procurement Officers (CPOs).

This doesn’t imply that reducing procurement costs without compromising quality hasn’t always been at the forefront of CPOs’ minds.

However, the road to achieving this has never been a walk in the park.

In this article, we’ll break down the complexities of the current procurement landscape, shining a light on the tough challenges that procurement executives face when trying to implement cost savings initiatives.

Join us to learn more about how to overcome these hurdles.

Since cost-saving initiatives most often require changes to established procurement processes, they can be met with resistance from stakeholders, be they managers, employees, or existing suppliers.

For instance, let’s say that a company decides to implement an automated procurement data management system to enhance efficiency and data-driven decision-making.

In such cases, more traditional procurement managers, who are adept at tasks like negotiating and relationship building with suppliers, may find it challenging to transition into roles that involve extensive data analysis.

Likewise, the introduction of procurement automation tools and related processes may raise concerns among other employees about their future roles, and whether their skills align with this evolving digital landscape.

Concurrently, some suppliers used to more manual and personalized interactions might be hesitant to adopt new technologies (such as automated order processing or invoicing).

These examples can block one’s efforts to digitally transform the procurement process.

They also illustrate nicely why, according to McKinsey, about 70% of all digital transformation initiatives fail.

Harry Robinson, Senior Partner at McKinsey, explains what’s behind such a high failure rate.

Illustration: Veridion Data: McKinsey

Bottom line, if you want to successfully transform your procurement department, you’ll need to implement strategic change management actions.

These actions include:

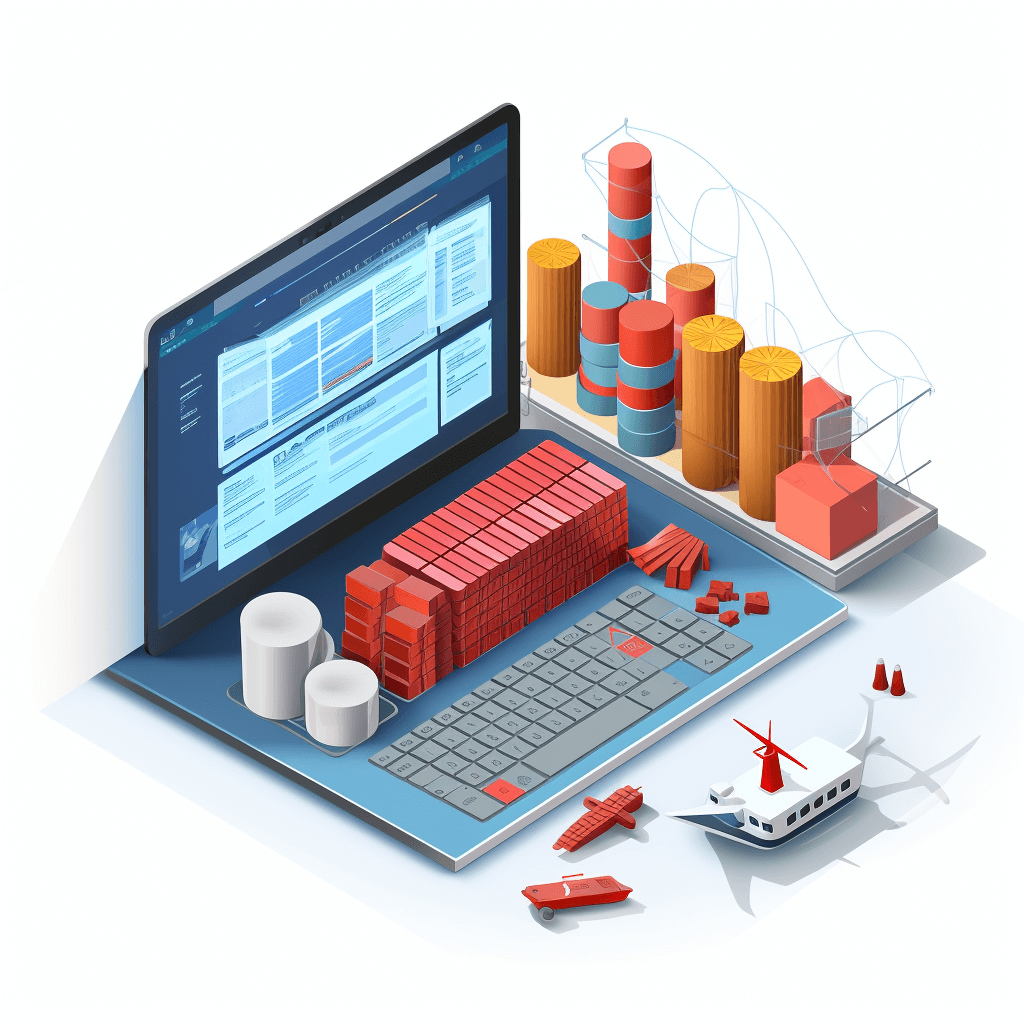

Since any cost-saving initiative involves changes, it should be preceded by a properly planned change management strategy.

As you can see below, the steps involved in creating an efficient strategy encompass all the above-suggested change management measures.

Illustration: Veridion Data: Walk Me

Any changes in procurement processes, such as introducing new technologies and workflows, should follow a predefined strategy predicated on open communication and involvement of all stakeholders.

This particularly refers to top managers with budgeting powers, whose support should match the expectations of proposed changes.

As for front-line employees and existing suppliers, a well-executed change management strategy can ensure that everyone:

Overall, resistance to change when implementing cost-saving initiatives in procurement is one of the biggest barriers to their success.

To overcome this challenge, procurement executives should use strategies to build a cooperative environment, and create a culture that is open to change, enabling the implementation of cost-saving initiatives.

The success of cost-saving initiatives in procurement depends on real-time information exchange between procurement and other departments, such as finance, production, IT, and operations.

When departments keep their data siloed and lack transparent communication channels, this can seriously hinder the procurement process, leading to inefficiencies and missed opportunities for cost savings.

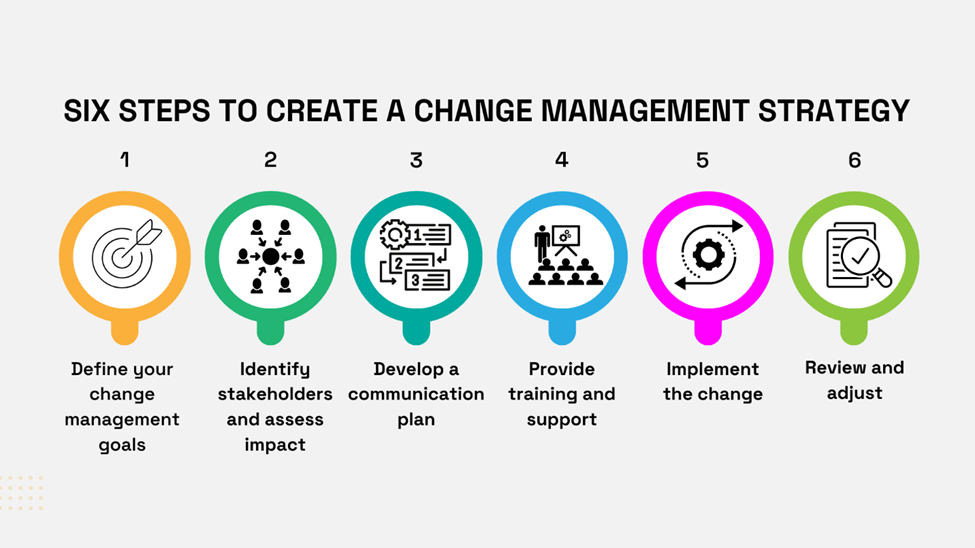

Data silos are information controlled by one department, and isolated from others.

Other departments cannot access or use the data. Naturally, that causes operational inefficiencies.

Here are just some of the issues caused by data silos:

Illustration: Veridion Data: Astera

As you can see, one of the biggest issues with data silos is that they prevent efficient data exchange and communication between departments.

Thanks to siloed information, procurement may lack crucial insights into the company’s financial aspects, production schedules, or IT requirements, limiting their ability to make well-informed cost-saving decisions.

For instance, if the procurement team is not aware of specifics about upcoming projects in production that will require special materials or components, they might miss potential cost savings that could be realized by bulk purchasing or strategic sourcing.

It’s important to note that company culture, management styles, and interpersonal relationships are often the causes of individual data silos.

That’s why the issue of poor cross-departmental collaboration has to be tackled on two levels: technical and organizational, as illustrated below.

Source: QuestionPro

On the technical side, the first step is to create centralized access to data.

That can be done by implementing integrated software solutions, such as enterprise resource planning (ERP) systems that allow seamless data sharing across departments.

Using such a centralized platform creates a single source of up-to-date information and ensures all teams have real-time access to the same information, fostering better collaboration.

Concurrently, to tackle the organizational aspect, executives need to ensure that open communication and free information-sharing between relevant stakeholders become a part of the work culture.

To sum up, a lack of data integration and close collaboration between procurement and other departments is the downfall of many cost-saving initiatives.

To overcome this challenge, companies should invest in integrated data management systems, utilize collaboration tools and methods, and establish a collaborative, data-driven procurement culture.

This challenge is closely related to the previous one as data silos and poor collaboration lead to limited spend visibility, meaning that procurement teams don’t have a holistic view of the company’s overall spending.

And, when there’s no clear understanding of where money is being spent, it can be difficult to identify cost-saving opportunities and formulate appropriate initiatives.

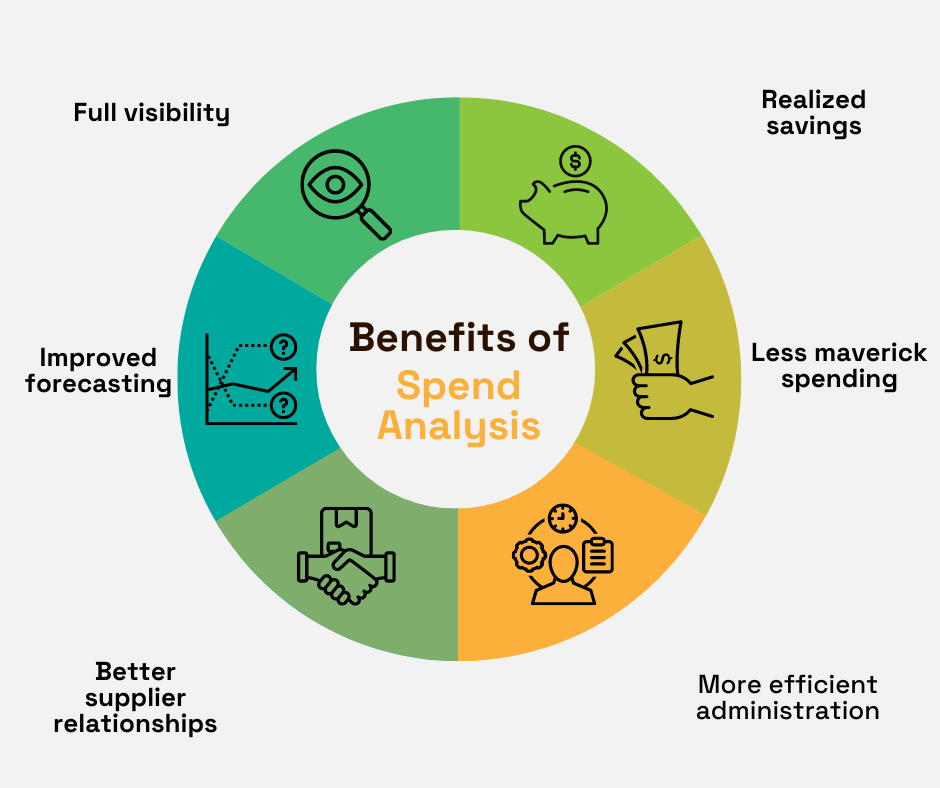

Simply put, you need to be able to perform a complete spend analysis in order to implement cost-saving initiatives.

As the below image shows, spend analysis aims to answer crucial questions about spending patterns across different categories, suppliers, and periods on a company-wide scale.

Source: Veridion

When the data related to any of these elements is outdated, incomplete, or hard to access and analyze, the procurement team lacks a unified view of the company’s spending, which can lead to suboptimal decision-making.

For instance, without access to real-time financial data from the finance department, you might make purchasing decisions without accounting for the company’s current financial health and budget constraints.

You might finalize contracts with suppliers based on outdated budget information, unintentionally committing to expenditures that surpass the company’s current financial limits.

This issue can be addressed by establishing a centralized data management system to consolidate procurement data from various internal and external sources.

Various spend analytics tools can be used to gain full visibility into the company’s expenditure. Then, you can leverage insights to optimize procurement processes and achieve those cost savings.

Here’s a full spectrum of benefits when spend analytics are based on integrated, accessible, and regularly updated datasets.

Source: Veridion

As you can see, cost savings directly result from enhanced visibility brought by spend analysis.

Naturally, when spending is tracked and analyzed, this also reduces rogue spending and saves money through that aspect.

It’s also worth noting that analytics tools enable spend analysis to be an ongoing process, which allows procurement teams to analyze data in real time and respond swiftly to changing business conditions.

The bottom line, overcoming the challenge of limited spend visibility requires the creation of a complete spend analysis. Only then will you be able to identify cost-saving opportunities, and implement related initiatives.

One frequent cost-saving method in procurement involves finding new suppliers that offer high-quality goods at a lower price than the current suppliers.

However, identifying suppliers that strike the right balance between price, quality, and delivery time can be quite challenging.

Consider a scenario where a manufacturing company seeks to reduce production costs by identifying new suppliers for a critical component.

The current supplier, although providing high-quality materials, is relatively expensive and has extended delivery lead times.

However, when the procurement team decides to explore alternative suppliers, they find that their supplier databases are outdated and lack comprehensive information about potential candidates.

Consequently, the team invests valuable time and resources in manually researching and vetting potential suppliers, slowing down the process and delaying the realization of potential cost savings.

This time-consuming and resource-intensive nature of supplier sourcing is backed by a McKinsey article, stating that it takes about 3 months to find a new supplier and that AI-based tools can cut that time down by 90% or even more.

Illustration: Veridion / Data: McKinsey

In light of these numbers, it’s clear that identifying the right suppliers can significantly hamper both the speed and quality of decision-making in procurement.

But as the article mentioned above has shown us, AI tools are here for the rescue.

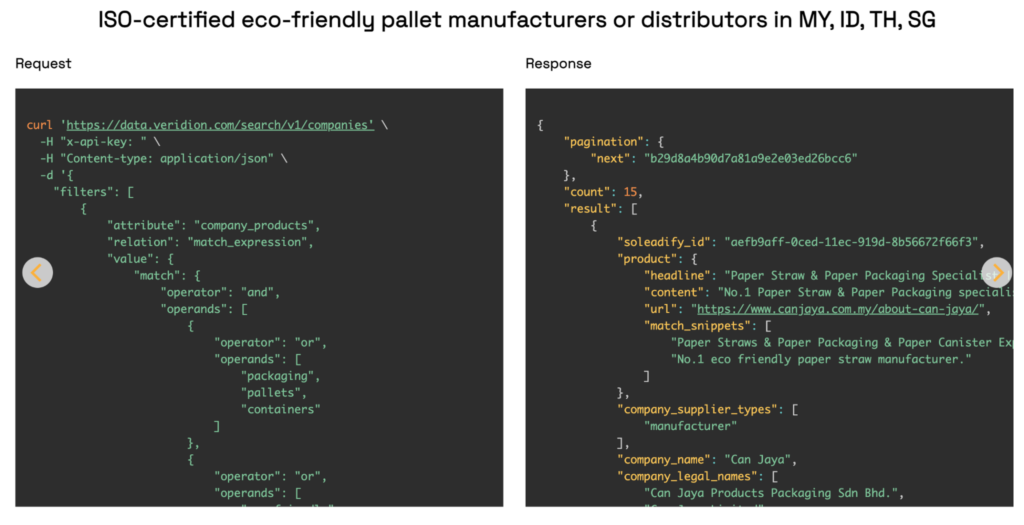

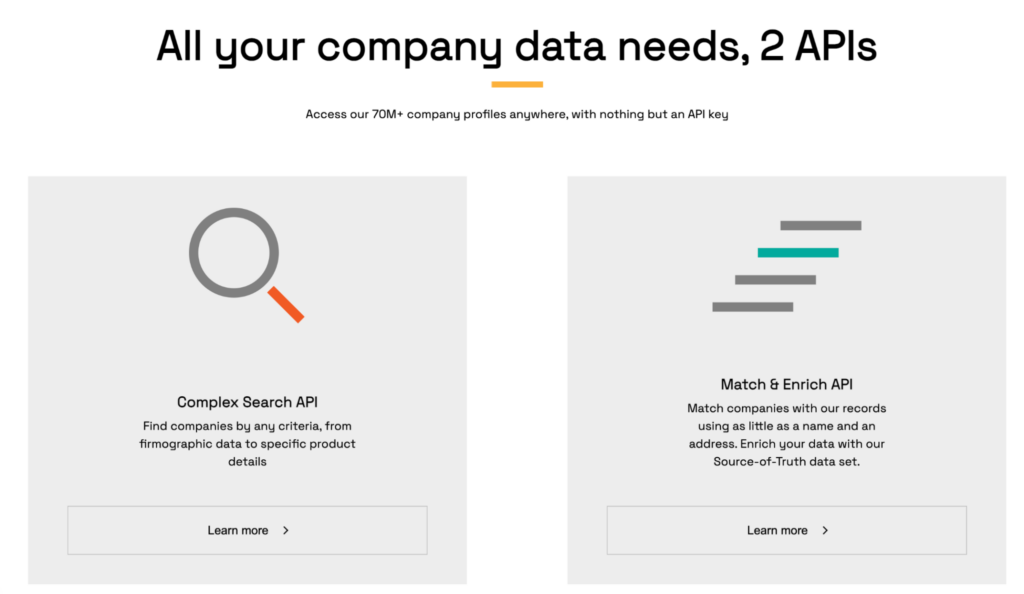

Our own AI-powered tool, Veridion is a prime example of that.

It’s a supplier sourcing enabler providing users with a global, constantly refreshed supplier database.

Source: Veridion

In a nutshell, Veridion’s AI-based machine learning models scour billions of web pages every week to provide clients with the most current information on over 80 million companies around the world.

Clients can use the Complex Search API to find suppliers according to any criteria, from specific product details to firmographic data such as a company’s industry categorization, size, region, certifications, and sustainability criteria.

For example:

Source: Veridion

With access to a vast amount of supplier data and an efficient way to search them using natural language input, it becomes much easier for procurement professionals to identify suppliers that meet the required quality standards at a more affordable price.

At the same time, procurement teams can use Veridion’s Match & Enrich API to keep the company’s supplier database regularly updated with relevant information about supplier performance, financial stability, history, and ownership structure.

Source: Veridion

This accelerates supplier risk assessments, enhances performance and compliance monitoring, and helps companies adapt to changing market conditions (covered next).

To recap, while identifying the right suppliers can be challenging, employing the right supplier-sourcing tools can revolutionize this process and generate significant efficiency gains and cost savings.

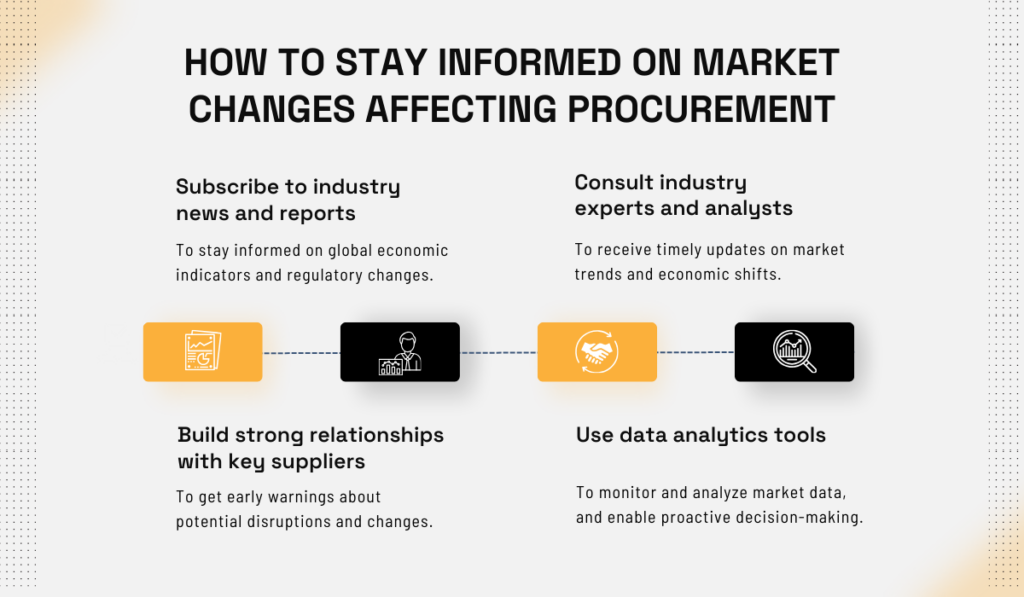

Another significant hurdle that can put your cost savings plans to a halt is the unpredictable nature of economic and market conditions.

Fluctuations in prices, currency exchange rates, regulatory changes, and geopolitical events are often hard to avoid.

But such events can significantly impact procurement costs, making it difficult to achieve stable and consistent savings.

To navigate this uncertainty, procurement teams must remain vigilant and well-informed about changes that could influence procurement costs.

Here’s an overview of what you can do to stay informed:

Source: Veridion

Regardless of how it’s achieved, staying abreast of market shifts, geopolitical developments, and changes in supplier’s business activity is crucial for adapting procurement strategies to the evolving landscape based on real-time information.

Another strategic move that companies can make to counter the risks associated with market fluctuations is diversifying their supplier base.

The supplier diversification approaches can include:

Both of these methods help procurement departments mitigate risks associated with supply chain disruptions caused by unexpected events such as natural disasters or geopolitical conflicts.

Companies across many industries have already started changing their sourcing practices and distribution networks to exploit differences in labor and material costs across different regions.

So for example, Mazda has replaced some Chinese auto parts suppliers with those in Mexico.

Overall, staying informed and having multiple suppliers for key goods enables companies to proactively address the challenges associated with the dynamic nature of market conditions, giving them the information and flexibility needed to sustain cost-saving initiatives.

In the world of procurement, achieving cost savings is like embarking on a journey of transformation.

Overcoming resistance to change requires strategic actions while dismantling data silos demands tech integration and cultural shifts. But the challenges we discussed today are hardly uncommon.

They just weren’t a top priority to tackle.

But now cost-savings are back as the CPOs’ main priority, so it’s time to think about what your company can do to address these issues.

Which tools and methods could you use to overcome the challenges?

Armed with resilience, you can not only achieve the desired cost savings but bring about a new era of excellence.

So go ahead and turn obstacles into stepping stones for lasting success.