6 Key Procurement Goals You Should Aim to Achieve

The days when procurement was all about getting the best price, quality, and delivery are long gone.

That’s not to say that these traditional procurement goals have changed.

Rather, they’ve evolved to include broader, more strategic objectives that drive operational efficiency, supply chain resilience, sustainability, and long-term value creation.

Against this background, we’ll explore six key procurement goals that every procurement team should aim to achieve.

We’ll also provide insights and practical examples to help you enhance your company’s procurement strategy, so let’s get into it.

In a world where the latest technological advancements and unprecedented supply chain disruptions intersect, leveraging new procurement technologies is vital for any company that wants to stay competitive.

Of course, it’s likely that your company already utilizes some procurement or procurement-adjacent software solutions, such as e-procurement platforms, enterprise resource management (ERP) and accounting systems, and supplier relationship management (SRM) software.

Even so, there still might be many procurement processes that rely on manual methods, utilizing spreadsheets and legacy systems with limited process automation and data analysis capabilities.

This manual approach can result in inefficiencies, errors, and challenges in comprehensively tracking and analyzing procurement data.

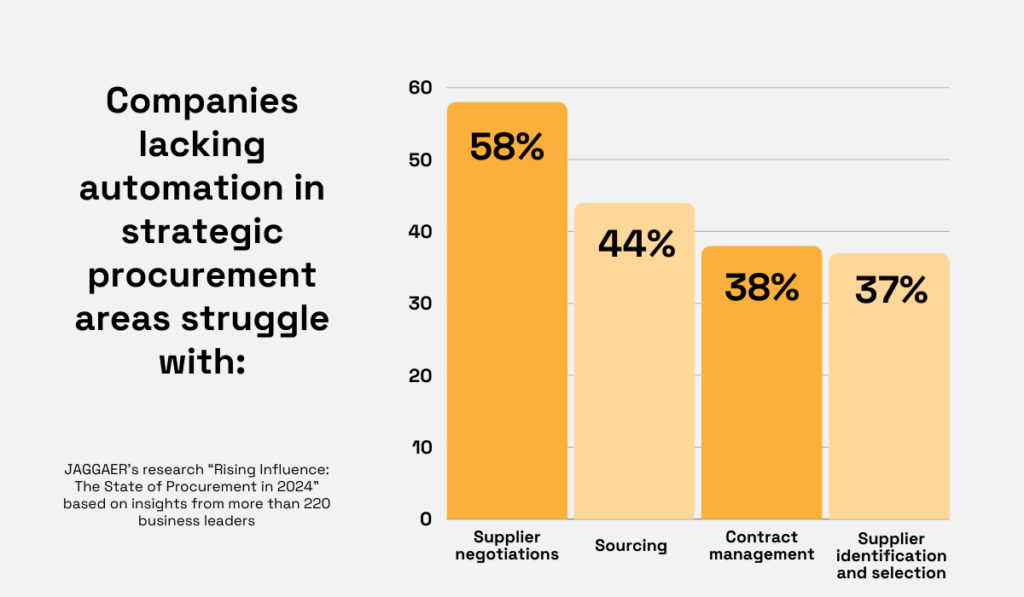

As highlighted in a recent global research survey by Jaggaer, many companies face these difficulties because they lack automation in strategic procurement areas, as shown below.

Illustration: Veridion / Data: JAGGAER

As illustrated, 58% of companies—presuming they overlap with 38% lacking automation in contract management—would profit from introducing supplier contract management software into their operations.

When such a system is populated with comprehensive contract details, performance metrics, and historical data, and integrated with other procurement tools and business systems, it can provide valuable insights for supplier negotiations.

For example, data from supplier contracts can highlight trends in pricing, delivery performance, and compliance.

This can, in turn, inform negotiations with both new and current suppliers.

Of course, the efficiency gains and cost savings arising from automated contract workflows, approvals, and supplier compliance monitoring provided by contract management software shouldn’t be neglected.

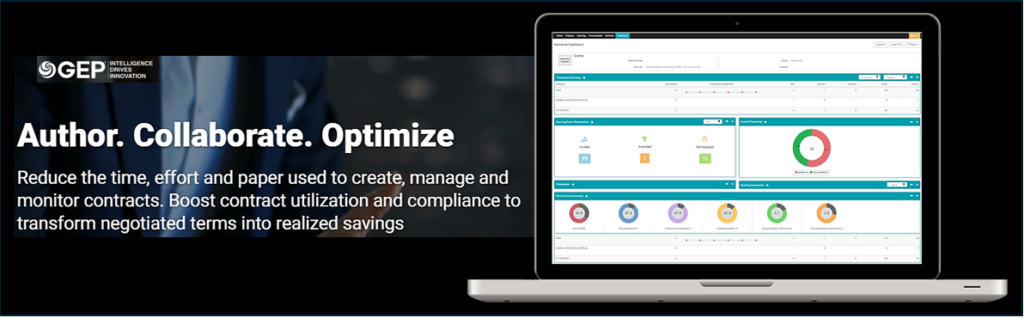

For instance, GEP Smart eContract management software gives you complete control over contract search, collaborative authoring, and monitoring while measuring performance, sending non-compliance alerts and renewal notifications, and providing contract intelligence.

Source: GEP

This is only one example of how a single software solution can help companies improve the efficiency of their procurement processes and gain actionable strategic insights.

But there is a range of comprehensive or specialized e-procurement solutions that can address other automation and data analytics issues.

For example, supplier data platforms and e-sourcing tools can accelerate and streamline supplier identification and selection processes.

Moreover, many of these solutions are powered by machine learning (ML) algorithms and artificial intelligence (AI) features, enabling robotic process automation (RPA) and predictive analytics.

The bottom line is that the benefits of these and other procurement technologies are too substantial to ignore, so making the most of them should be one of your company’s main goals.

In fact, according to Amazon’s 2024 State of Procurement Report, 98% of decision-makers indicated they’re planning investments in automation, AI, and data insights tools.

So, why not join them?

Lastly, keep in mind that these technologies can significantly improve the realization of all other key procurement goals outlined here, starting with data consolidation.

Today, data relevant to procurement is everywhere, with its volume and speed of generation growing exponentially.

This data comes from various internal and external sources.

Think everything from purchase orders, invoices, and logistics to supplier databases, market intelligence, and industry reports.

In practice, this means that procurement teams often encounter duplicated, outdated, siloed, and fragmented data, which makes meaningful data analysis and insight extraction much harder.

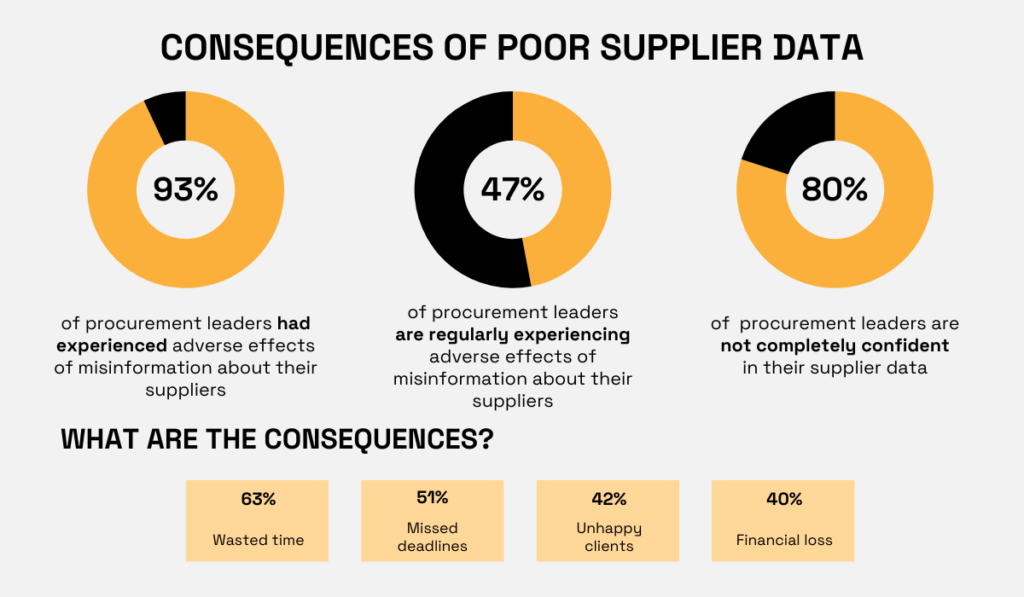

Moreover, the consequences of bad data can be immense:

They can range from missed opportunities, unhappy clients, and broken deadlines to wasted time and even financial loss.

And these adverse effects are widespread, as the below findings from a 2020 survey of procurement leaders show.

Illustration: Veridion / Data: TealBook

As these numbers show, poor supplier data expose procurement teams to inefficiencies, increased costs, and missed opportunities for optimization and innovation.

And that’s why cleaning up your data should be one of your key procurement goals.

For example, consolidated, unduplicated, and clean internal data sources enable procurement teams to accurately track spending, manage inventory efficiently, and forecast demand with greater precision.

On the other hand, clean external data sources help procurement teams benchmark performance, identify market trends, and make informed supplier selection decisions.

Moreover, external sources that provide clean, accurate, and up-to-date data—such as supplier data platforms—can cut the time needed to find new suppliers by 90% or more, according to McKinsey.

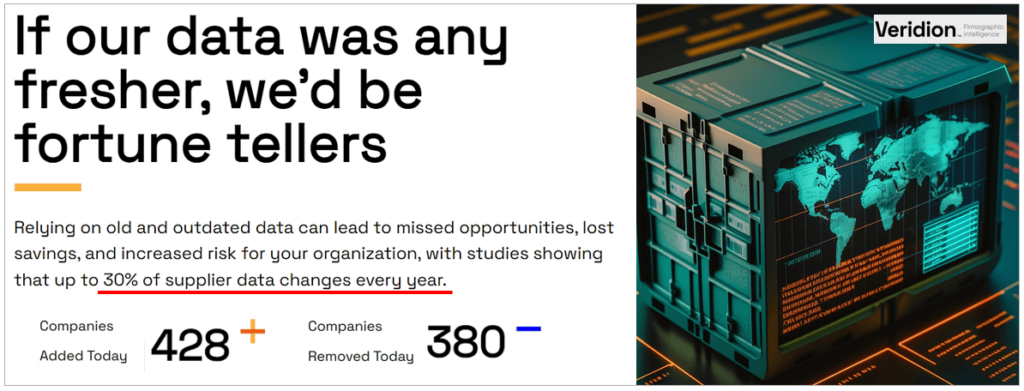

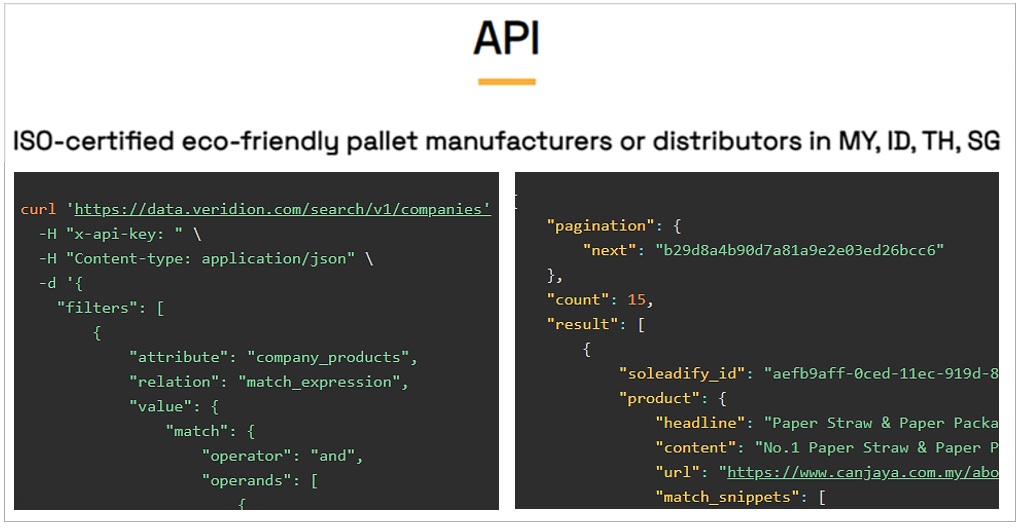

One such platform is our own Veridion.

Source: Veridion

With Veridion, procurement teams get access to the most complete, weekly updated, global database of suppliers curated by our AI-powered, proprietary machine-learning algorithms.

This is crucial not only because it makes supplier discovery quick and easy, but also because teams can be sure that the provided data is fresh and accurate.

Along with database access, you get Veridion’s Complex Search API, which enables you to set search parameters using natural language.

Source: Veridion

Moreover, when it comes to cleaning data within your internal sources, Veridion’s Match & Enrich API can ensure your supplier master records and master data management (MDM) system are deduplicated and up to date.

This gives your company the most accurate view of its supplier landscape.

Other data-cleaning methods include:

With data being the main lever for informed decision-making, there is no doubt that your organization should use appropriate tools to keep your data clean.

Traditionally, procurement focused primarily on cost reduction, efficient transaction processing, and ensuring timely delivery of goods and services.

And while these goals remain valid and important, companies now go beyond them.

Nowadays, they strive to align procurement activities with their broader strategic objectives, such as sustainability, risk management, innovation, and long-term value creation.

There are many reasons for this strategic shift—from meeting customer demand for sustainable and ethical supply chain practices to increasingly complex global supply chains that require robust risk management.

Since we’ll discuss both sustainability and risk management later on, let’s focus on other examples of aligning procurement with broader organizational goals.

For instance, a company’s strategic goal may be to develop long-term partnerships with existing and new suppliers to drive innovation and cost-savings.

Procter & Gamble (P&G) are leaders in such open innovation trends, with more than 35% of their innovations coming from external partners.

Source: P&G

For example, when they wanted to launch a new line of Pringles chips with pop culture images printed on each crisp, instead of developing an internal printing solution, they created a technology brief and distributed it across their vast network of suppliers and partners.

Lo and behold, an Italian bakery has already invented how to print edible images on cakes and cookies, and this technology needed only a few tweaks to address P&G’s needs.

That way, they cut the required time to market from an estimated two or three years to less than a year at a fraction of initially envisaged costs.

There are many other examples of how procurement can help meet a company’s strategic procurement goals.

For instance, if a company wants to expand into new markets, the procurement team can strategically engage suppliers from those markets to build a robust supplier network before the planned market expansion.

In short, aligning procurement with broader organizational goals allows companies to reap strategic benefits beyond price, quality, and delivery.

Given the significant global events in recent years, from pandemics to geopolitical conflicts, improving procurement risk mitigation should be a top priority for any organization.

Simply put, risks are omnipresent in procurement, and while some are unavoidable, they can be better understood and mitigated through strategic measures.

Of course, supply chain disruptions are only one of many procurement risks that can lower your company’s operational efficiency, increase costs, and expose it to financial and reputational damage.

You can see some of them in the image below.

Source: Veridion

For instance, poor supplier selection usually involves ending up with suppliers that provide substandard product quality, are late with deliveries, or don’t comply with regulations and industry standards.

These supplier issues—and countless others—can lead to operational disruptions or, even worse, spill over into the public domain and cause your company substantial reputational damage and customer loss.

So, how can your team achieve the goal of improved risk management?

In essence, by leveraging a combination of risk management tools and methodologies.

Such tools include risk management software, supplier sourcing tools, and contract management solutions.

As for methodologies, they encompass risk assessment matrixes, scenario planning techniques, and continuous risk monitoring practices.

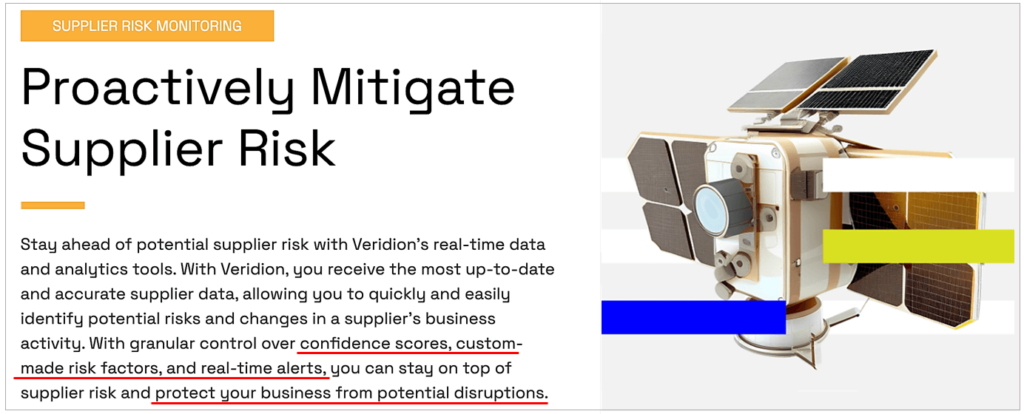

Here’s how our supplier sourcing tool, Veridion, enables procurement teams to automate and streamline some aspects of monitoring supplier risk.

Source: Veridion

As highlighted above, you can establish custom risk factors for specific suppliers and get real-time alerts if those risks are detected together with data confidence scores.

This enables you to identify potential risks ahead of time, making it easier to achieve this important procurement objective.

This goal is simply a strategic imperative.

Why?

Because the efficiency of most companies largely depends on how effectively their suppliers provide the raw materials, components, products, or services needed for everyday operations.

Therefore, the stronger your relationships with suppliers are, the more resilient your supply chain will be.

Building stronger relationships involves establishing a collaborative (rather than just transactional) partnership with suppliers based on trust, open communication, and mutual benefit.

This includes monitoring suppliers’ key performance indicators (KPIs) and giving them feedback on any identified shortcomings or providing support in addressing them.

Beyond that, many companies have long-term supplier development programs aimed at improving the performance and capacities of key suppliers.

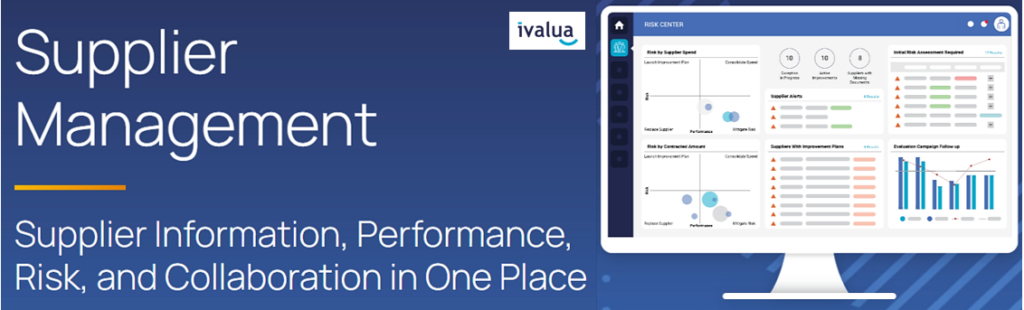

Of course, all these activities require and generate a lot of data, which is best managed with supplier relationship management (SRM) tools.

Source: Ivalua

As illustrated, SRM solutions centralize all supplier information, enable monitoring of supplier KPIs and regular performance reviews, and provide collaboration tools.

All these are prerequisites for building stronger supplier relationships.

With the right tools and sincere efforts to achieve closer, more efficient, and mutually beneficial relationships, the generated advantages can be significant.

They include:

The bottom line is, companies with advanced supplier collaboration practices are bound to outperform their competitors in terms of profitability and growth.

So, make sure to add this goal to your own list.

As we mentioned earlier, ensuring compliance with sustainability standards is an integral part of aligning your procurement with broader organizational goals.

Broadly speaking, these standards cover both your company’s and your suppliers’ environmental, social, and governance (ESG) aspects of operations, including ethical and sustainable sourcing practices.

But why is this procurement goal so important?

Essentially, it boils down to the increasing pressure exerted by regulators and, more importantly, consumers demanding more environmentally friendly and ethically sourced products.

Source: Fortune

So, how can you ensure your suppliers comply with your company’s sustainability standards?

Considering the range and complexity of the topics that need to be addressed, this requires an array of planned strategic procurement measures, such as:

Again, supplier data platforms like Veridion can help you select suppliers that align with your company’s ESG goals.

Source: Veridion

As shown, you can filter potential candidates according to sustainability criteria arising from their ESG policies and any related controversies.

In essence, this allows your team to make better-informed and sustainable sourcing decisions.

Moreover, this directly addresses the issue that 85% of companies surveyed for Amazon’s 2024 State of Procurement Report stated they have, citing difficulties in finding suppliers with sustainable practices.

To recap, compliance with sustainability standards helps your company meet growing regulatory and consumer demands and build a more, eco-friendly and resilient supply chain.

So, what general conclusions can we draw about these six key procurement goals your company and your procurement team should aim to achieve?

Firstly, note that these goals are never actually fully achieved; rather, they should be treated as ongoing, perpetual objectives that drive continuous improvement.

Secondly, by striving towards these goals, your organization can enhance operational efficiency, build a more resilient supply chain, and foster sustainable, strategic growth.