6 Strategies for Procurement Risk Management

As a procurement professional, you already know that your function is not without risks.

From financial and operational to market and supplier-related risks, there are so many aspects of your operations that you need to balance in order to make sure your organization keeps thriving.

That is why, in this article, we’re going to present you with 6 strategies you should consider implementing for the purpose of managing and mitigating procurement risks.

Without any further ado, let’s get started.

When it comes to financial risks in procurement, there are no two ways about it: you want to avoid them altogether.

Of course, there are specific types of financial risks that you can’t really control, such as those that come with currency exchange rate fluctuations.

But then, there are risks that stem from your organization’s spending patterns.

The good news is that those can be mitigated with the help of regular spend analysis.

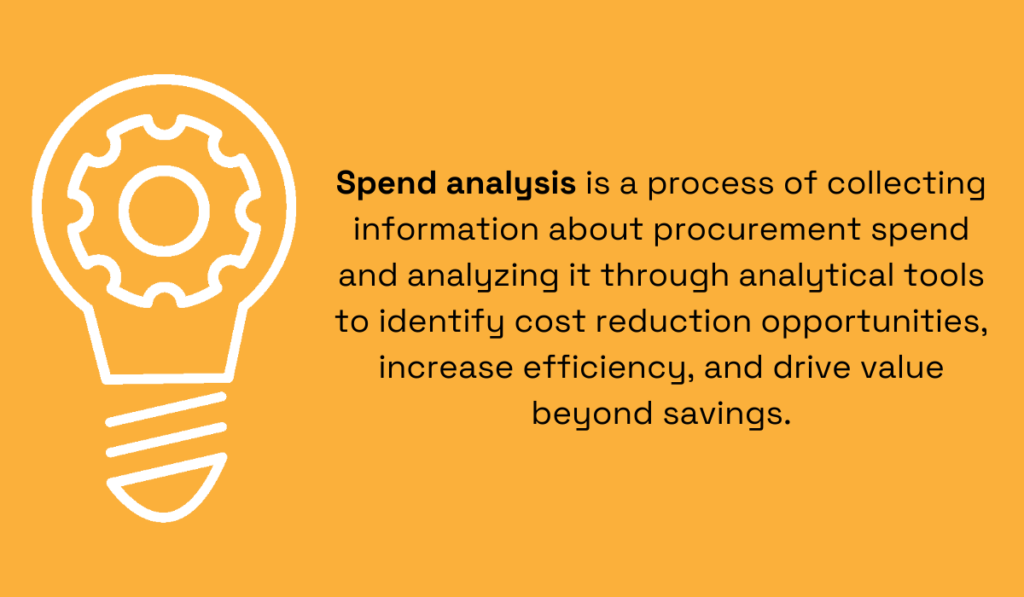

Illustration: Veridion / Data: Kissflow

Simply put, analyzing what you’re purchasing, who you’re purchasing from, and how much you pay for the goods can help uncover inefficiencies in your procurement process that can lead to financial risks.

Take maverick spend, for instance.

If employees make purchases that are outside of the established procurement spending policies, your organization is bound to experience significant financial losses.

And according to APQC’s Open Standards Benchmarking data, that can mean significant losses.

Illustration: Veridion / Data: Supply & Demand Chain Executive

For a company that realizes, say, $500 million in annual revenue, this amounts to $12.5 million in maverick purchases.

That is not a negligible amount.

On top of that, reports APQC, maverick spending translates to slower and more expensive procurement purchases:

“Despite the common belief that maverick buying enables employees to obtain materials faster, this purchasing method may result in slower order processing. At the median, organizations with higher levels of maverick purchasing need 16 hours more to issue a purchase order to a vendor.”

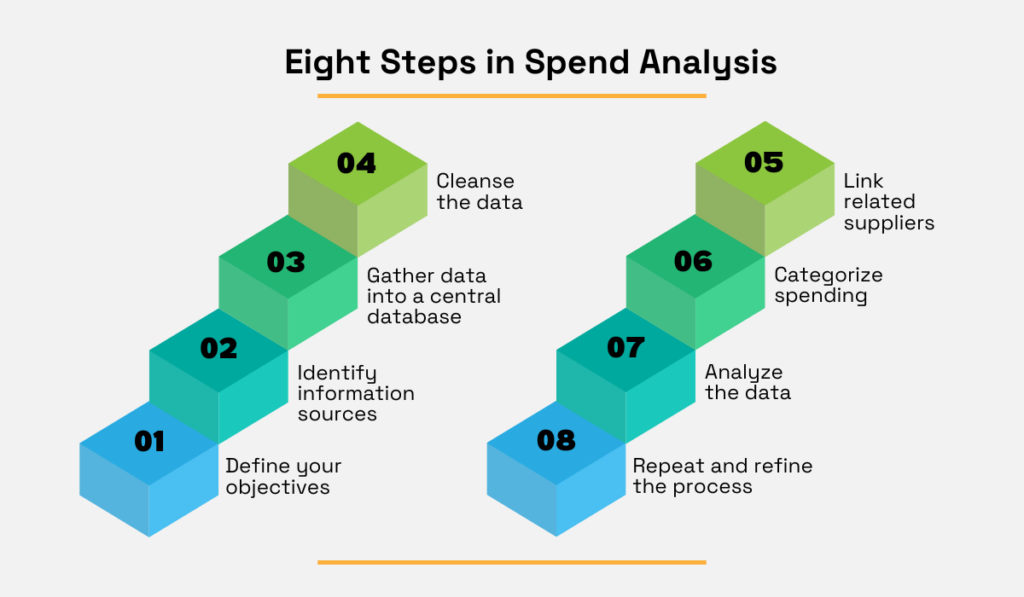

Regularly conducting spend analyses can help you nip such issues and inefficiencies in the bud.

Source: Veridion

Let’s explain how, using an example.

Let’s say that you’re interested in analyzing how your procurement department spends money on individual suppliers.

You can start by collecting and organizing supplier data from sources like purchase orders, supplier contracts, and invoices.

Then, you can further enrich your findings with qualitative data:

Having a holistic view of all of your suppliers, their service levels, and cost-effectiveness will allow you to identify any inefficiencies, but also instances where your organization can prevent overspending.

Nicolas Olague, General Manager at Amazon Business US, explains that “many companies only look at their top 30% of spend which means they don’t control the other 70%. That means they will be buying products at rates that have not been negotiated.”

However, he continues, if you choose to leverage data, you can create policies to mitigate rogue spending and realize cost savings.

Illustration: Veridion / Quote: The Independent

All of this, in turn, helps you mitigate potential financial risks.

Overall, by analyzing your organization’s spending patterns and being diligent about it, you can do much more than just identify cost-saving opportunities.

You can also develop policies that will help you prevent risks before they have the chance to happen.

While giving your business to a small number of top-performing suppliers is a good way to realize cost savings and streamline your processes, it is not risk-free.

Sure, they may be delivering high-quality goods at a competitive price and within agreed-upon timelines now.

But what if the region they’re in suddenly faces a natural disaster, geopolitical dispute, or a pandemic?

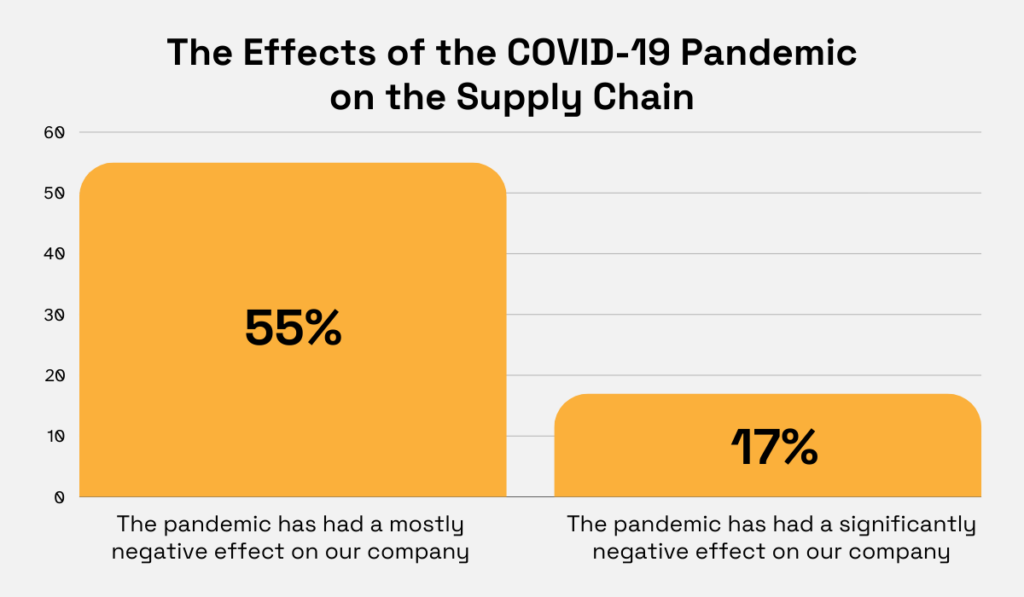

In that case, you might have the same experience as the respondents of Ernst & Young’s survey on how COVID-19 impacted global supply chains.

According to their findings, only 2% of the surveyed companies felt prepared for the pandemic.

The majority, as you can see below, have reported experiencing serious disruptions.

Illustration: Veridion / Data: Ernst & Young LLP

So, to prevent unexpected supply chain disruptions from having an adverse effect on your organization, you need to stay prepared.

And the best way to do that is to diversify your supplier network.

This is going to reduce your reliance on a single supplier, making it easier for you to mitigate the risks that come with potential supply chain disruptions.

That way, even if your supplier suddenly experiences unforeseen events, quality issues, or delays in production, your organization is going to remain resilient and adapt more easily to these new circumstances.

More and more organizations are recognizing the benefits of having a diverse supplier network.

One such example is the fiber product manufacturer Clearfield.

Their COO Johnny Hill explains that diversification of the supply chain allowed them to handle market uncertainties better.

Illustration: Veridion / Quote: Cabling Installation & Maintenance

By now, you’re probably wondering how you can diversify your own supplier network, without spending months and months on research.

The answer is simple: Veridion.

Veridion is a supplier sourcing enabler that leverages the powers of AI and machine learning to provide you with quick access to a vast global database of suppliers.

Our data is refreshed on a weekly basis, providing you with reliable information about tens of millions of suppliers and 200 million products and services in mere minutes.

With our company search service, you can set specific criteria and easily identify the suppliers that precisely match your sourcing needs.

Source: Veridion

In short, Veridion makes the task of diversifying your supplier network quick, easy, and stress-free.

Relying on such a tool for supplier diversification will not only allow you to save time and resources, but also help you remain stable in the face of supply chain disruptions.

As much as you may try to completely mitigate procurement risks, the reality is that sometimes, things will simply be out of your control.

After all, you cannot stop earthquakes, political instabilities, or financial crises.

However, what you can do is stay prepared for them by developing robust contingency plans.

Contingency planning means you’ll systematically develop preventive and recovery measures to deal with potential threats.

Having a contingency plan and sticking to it will help you minimize the impact of disruptions and allow you to remain stable.

Think about it: if you develop standardized procedures, outline communication protocols, and define exactly how to proceed if matters escalate, there will be no room for panic.

But to be fully prepared for any scenario, consider starting with a thorough risk assessment.

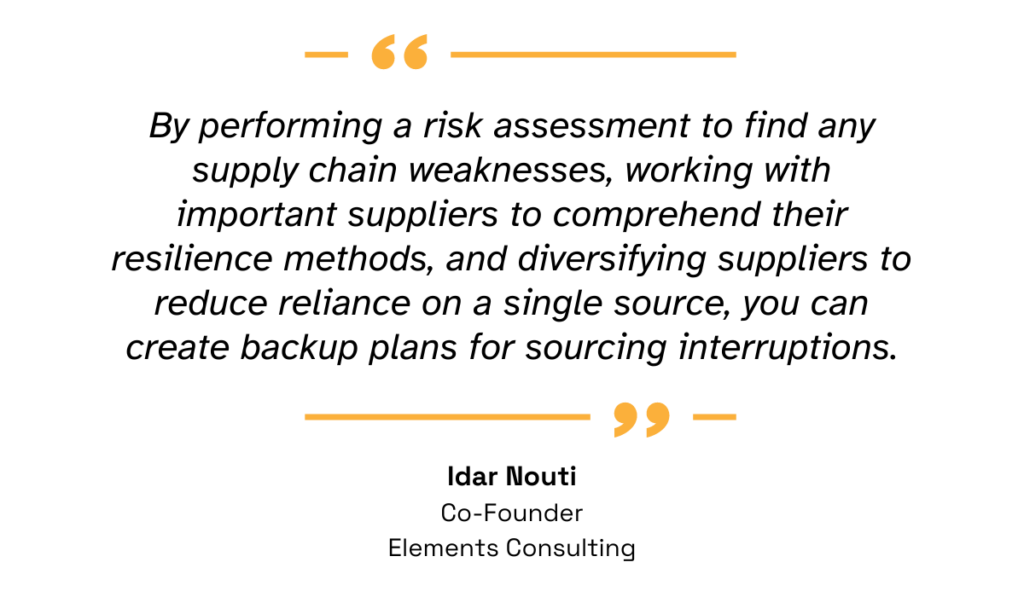

Idar Nouti, an expert in strategic sourcing and procurement, elaborates:

Illustration: Veridion / Quote: LinkedIn

A thorough risk assessment will allow you to identify potential areas for concern and make contingency planning easier.

But Nouti brings up another important point—the fact that good suppliers should have contingency plans of their own.

So, talk to your suppliers about how they intend to respond to potential disruptions.

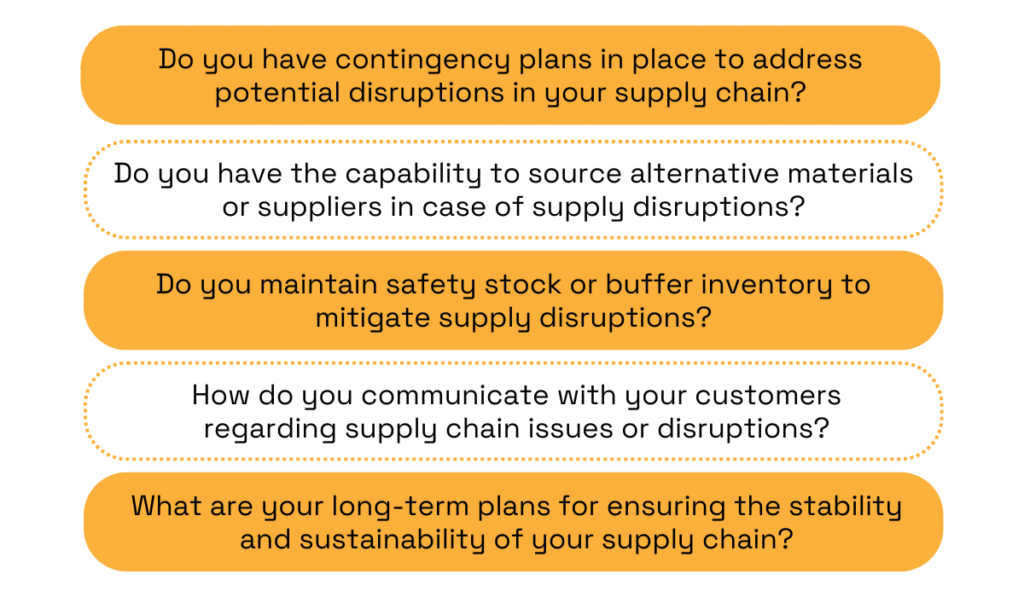

Consider asking them some of the following questions:

Source: Veridion

Their answers to these questions will not only tell you what kind of support you can expect in case of unfavorable circumstances but also reveal how serious and reliable a supplier they truly are.

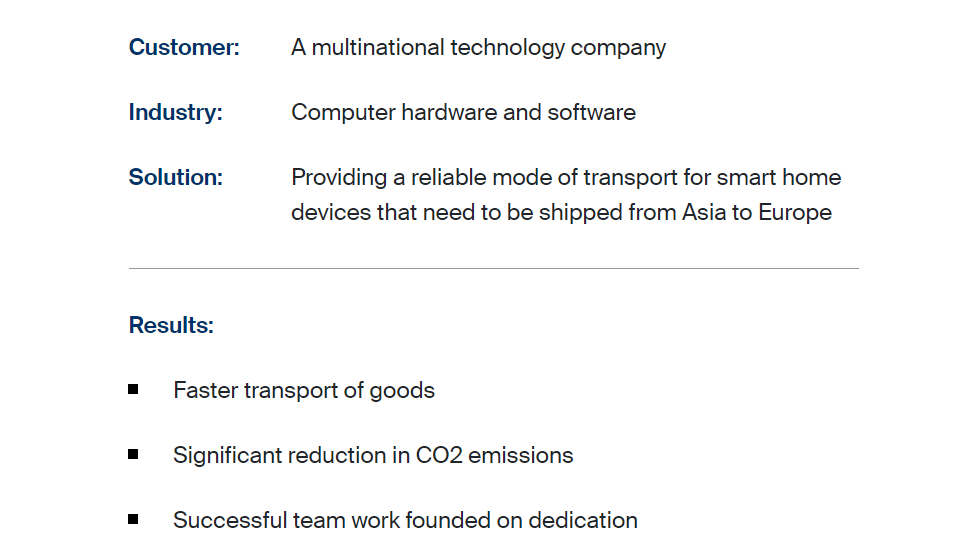

Kuehne+Nagel, one of the world’s leading logistics companies, sets a positive example.

They decided to implement alternate modes of transport to ensure that their customers receive their goods on time, no matter the circumstances.

Source: Kuehne+Nagel

For their customers, this means one less thing to worry about and more time and resources for mitigating other risks that could impact their operations.

The bottom line is: contingency planning is a key part of managing procurement risks.

It involves developing clear protocols, working with top-tier suppliers, and securing alternative sourcing options, in turn letting you remain calm even if a storm hits.

Another big part of risk management in procurement is the cultivation of strong relationships with your suppliers.

Yes, both you and your suppliers have your own business goals you need to meet, but purely transactional relationships can make this harder for you.

However, if your partnership is built on trust and collaboration, your organization is bound to experience benefits that go beyond just better resilience to procurement risk.

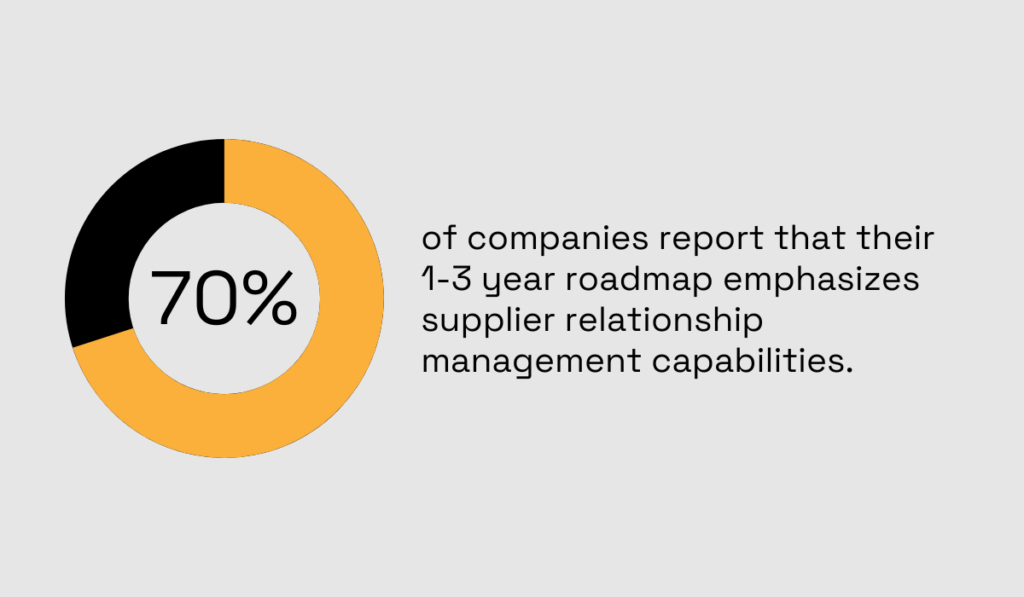

And, according to the KPMG 2023 Global Procurement Survey, an increasing number of companies are becoming aware of this.

Illustration: Veridion / Data: KPMG

So, let’s explore why investing in your supplier relationships is so important for successful risk management.

For starters, putting in an effort to treat your suppliers as partners gives them the opportunity to gain a deeper understanding of your business objectives, effectively turning them into strategic allies.

Giving them an insight into your goals and operations makes it easier for them to understand what matters to you.

This, in turn, helps them identify potential risks early on and communicate them to you, thereby making it easier for you to mitigate them.

Similarly, when you make an effort to understand your suppliers’ side of things—such as their vulnerabilities—you can work together on addressing them proactively.

On top of that, if your suppliers see you as a partner, they’re more likely to prioritize your needs in turbulent times.

Jon Willescroft, International Procurement Director at the integrated security company G4S, explains:

Illustration: Veridion / Quote: Economist Impact

The verdict is clear: prioritizing strong supplier relationships is key to successful procurement risk management.

So, make sure to foster open communication, build trust by honoring the commitments you make, and work collaboratively with your suppliers.

That way, you will develop mutually beneficial relationships that will not only protect you from risks, but also propel your business forward.

Now that you have an understanding of what building relationships can do for your organization in terms of risk mitigation, let’s discuss what data can do.

We have touched on the power of data in terms of supplier selection earlier in this article, explaining how it can help you diversify your supplier network by making it easy to pinpoint the suppliers that match your procurement needs perfectly.

But did you know that data can also help you negotiate better terms with suppliers, save you money, and reduce risks?

Scott Macfee, Chief Executive Officer of SpendHQ talks about this point in a supply chain magazine:

Illustration: Veridion / Quote: Supply Chain Brain

When you have accurate, up-to-date data at your fingertips, you can leverage it to, for instance, work out better rates with your suppliers.

Let’s say that your organization consistently orders a large volume of specific material from a supplier.

But upon gathering market data, you notice that the market price for this material has dropped significantly.

You can now approach your supplier and negotiate a lower price, using data and your history with them as a leverage point.

That way, you can reduce procurement costs and avoid the risk of cost overruns, ultimately contributing to your organization’s larger objectives.

But with data coming at you from various sources—both internal and external—it can be difficult to not only consolidate it all but also discern what truly matters.

This is where data analytics platforms come in.

Source: Sievo

They automate the tasks of analyzing and interpreting large amounts of data, allowing you to quickly identify high-risk suppliers, predict potential supply chain disruptions, and pinpoint inefficiencies and overspending.

Simply put, with the help of current and relevant data, you can always stay one step ahead of procurement risks and enhance your resilience going forward.

So, consider enhancing your procurement processes by investing in tools that will help you leverage valuable data and improve the way you handle procurement risks.

The final strategy on our list today is an easily overlooked one—but if you implement it the right way, you can save yourself a lot of trouble.

We are, of course, talking about developing clear supplier contracts.

An unambiguous contract has the power to protect you in case of contract non-compliance, one of the biggest pitfalls you can encounter in procurement.

As the name suggests, contract non-compliance happens when one of the parties fails to stick to the terms and conditions outlined in the contract.

And the consequences can be serious.

Source: Veridion

Using language open to interpretation or not displaying enough clarity when outlining the rights and obligations of both parties, can lead to disagreements, delays, and mistakes in fulfilling contractual obligations.

And if the situation escalates, it can easily result in serious, time-consuming, and costly legal disputes.

So, what can you do to protect yourself from such scenarios?

Patrick Gahagan, Director at SC&H Group who specializes in contract compliance audits and supply chain consulting, recommends investing in a third-party contract audit:

Illustration: Veridion / Quote: LinkedIn

Having professionals review your contracts can protect you from the many risks that come with contract non-compliance, so we believe it is an investment worth considering.

At the end of the day, creating clear, unambiguous contracts means that everybody wins:

Both you and your supplier have a complete understanding of your rights, but also your obligations to one another.

This makes it easier for both to hold up your end of the deal, thereby creating a positive environment where all the expectations get fulfilled, and forging a strong, thriving relationship in the process.

And there you have it:

Six strategies that are bound to help you and your organization minimize, if not completely eliminate the many risks that come with procurement.

Hopefully, you now have a deeper understanding of why it is important to regularly conduct spend analysis, develop thorough contingency plans, rely on fresh and accurate data, and build strong relationships with a diverse supplier base.

Although introducing some of these strategies might take time and some getting used to, we firmly believe that implementing them will change the way you manage procurement risk for the better.

So, give it a try!