Top 6 Procurement Risks to Avoid

We’re not here to state the obvious: procurement is inherently risky, everyone knows that.

However, we are here to dive into the most common obstacles within procurement, share some real-life examples of organizations grappling with these risks, and explain how they can detrimentally impact businesses as a whole.

Plus, we’ll provide some actionable tips on mitigating these risks.

So, consider this article your very first step towards a more agile, resilient, efficient, and, ultimately, successful procurement function.

Let’s begin.

Needs assessment is the very first phase of the procurement process.

Do a single misstep at this point, and you’ll be triggering a cascade of challenges down the line.

But, why do such missteps occur in the first place?

Put simply, they stem from answering some of the following questions inaccurately.

Source: Veridion

The risks associated with this are obvious: either you end up with insufficient stock, failing to meet customer demand or causing a drop in productivity, or you overstock, straining your cash flow and storage capacity.

In both scenarios, your bottom line, operational efficiency, and reputation are at stake.

That’s why effective inventory procurement planning must be prioritized more, warns Michael Tomchin, founder and CEO of apparel brand Cycology, particularly in the retail sector.

Illustration: Veridion / Quote: SDC Executive

Neglecting it, he says, can potentially spell ruin for entire businesses.

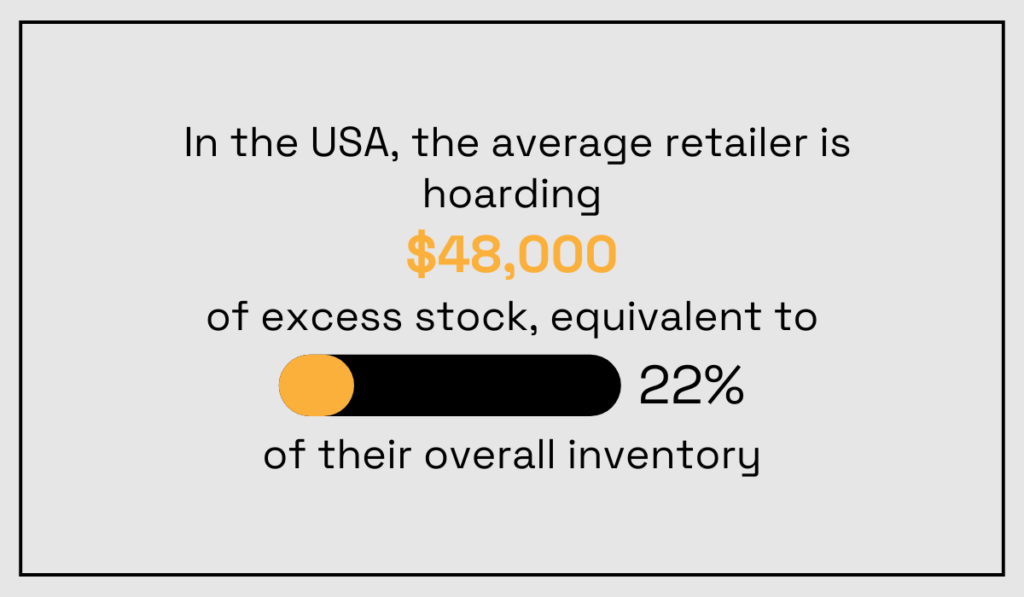

Overstocking seems to be a more common problem in this context, as it ties up company funds and then typically requires substantial discounts to clear.

And we’re talking about considerable sums of money here.

Inventory Planners’ research reveals that, on average, US retailers hold $48,000 worth of excess stock, equivalent to 22% of their total inventory.

Illustration: Veridion / Data: Inventory Planner

Let’s be honest: that’s a hefty chunk of change tied up in goods that aren’t bringing in any revenue.

However, the issue of inaccurate needs assessment isn’t confined to retail; various industries encounter similar challenges.

Take the Department of Health in Manila, Philippines, for instance.

In 2022, an audit uncovered millions of dollars worth of expired, damaged, and surplus medications in their inventory.

The culprit?

You guessed it: inadequate procurement planning.

So, how do you dodge this bullet?

Simple—step up your needs analysis game.

Sure, you can’t exactly predict future requirements and demand with pinpoint accuracy, but what you can do is keep a keen eye on your procurement data and market trends.

By vigilantly tracking, analyzing, and learning from your past spending and procurement activities, you’ll uncover insights that can steer you away from over or understocking and towards fulfilling company goals and needs with confidence.

Let’s face it, suppliers hold a lot of power in shaping the success of a business.

Partnering with the wrong ones can, therefore, lead to a plethora of problems, such as:

Obviously, this is something you’d definitely want to avoid.

As they say at Quandary Consulting Group, suppliers should be boosting your success, not dragging you down and causing you problems.

Illustration: Veridion / Quote: Procurement Magazine

Unfortunately, when the procurement teams don’t choose wisely, problems are exactly what you get.

Consider the 2023 scandal involving a prominent meat supplier to UK supermarkets, caught distributing chickens dosed with medicines potentially hazardous to consumers.

Remember, situations like these don’t tarnish only the supplier’s reputation but also that of the buyer, often resulting in substantial customer loss.

Not to mention that these stores end up with significant financial losses, too, due to their capital being tied up in unsellable products.

However, unreliable suppliers don’t just damage reputations and bottom lines; they disrupt project timelines as well.

Recently, Boeing had to stall the delivery of 50 planes because of a mistake their fuselage supplier found in some of their product.

Source: United Press International

While the issue was spotted on time and didn’t raise any safety concerns, this error still meant costly rework and frustrating delays for the aircraft manufacturer.

So, how do you mitigate this risk and ensure you have dependable suppliers from the start?

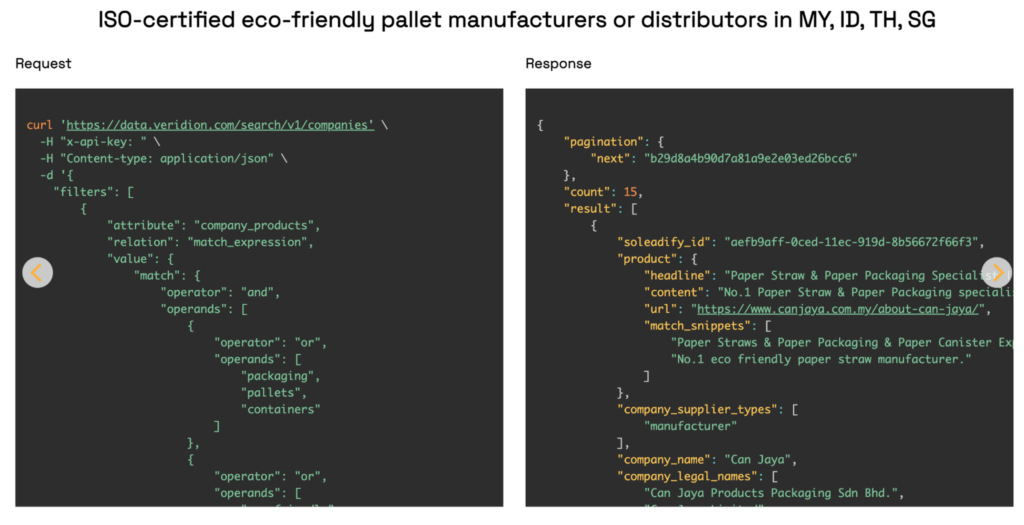

Well, finding reliable partners requires reliable tools.

Take our AI-powered supplier discovery platform, Veridion, for example.

With Veridion’s complex search API, you set your own supplier criteria, and the system scours through mountains of data until it finds ideal candidates for you.

Source: Veridion

The best part?

The whole thing takes just a couple of moments.

But, did you know that Veridion also enables users to search for suppliers based on ESG criteria such as diversified ownership, ESG policies, and ESG controversies?

That way you make sure, not only that you have the right suppliers by your side from the get-go, but also that they align with your environmental, social, and governance goals.

In any case, no matter how you choose to find your suppliers, be sure to do your due diligence to ensure they are the right fit.

If you do this step right, you’ll secure long-term partnerships with trustworthy allies.

If not, you just might expose the entire business to some serious consequences.

Most of the risks outlined in this article stem from a single source: the lack of transparency in procurement activities and procedures.

The primary culprit?

Manual processes.

Not only are they prone to human error, but they are also incredibly sluggish, time-consuming, and labor-intensive, resulting in inaccurate, incomplete, and untimely data.

Eventually, this leads to a completely wrong picture of your procurement function as a whole.

This, in turn, fosters poor decision-making and places the entire business at a competitive disadvantage.

Essentially, with manual processes, you don’t just waste time but also leave money on the table.

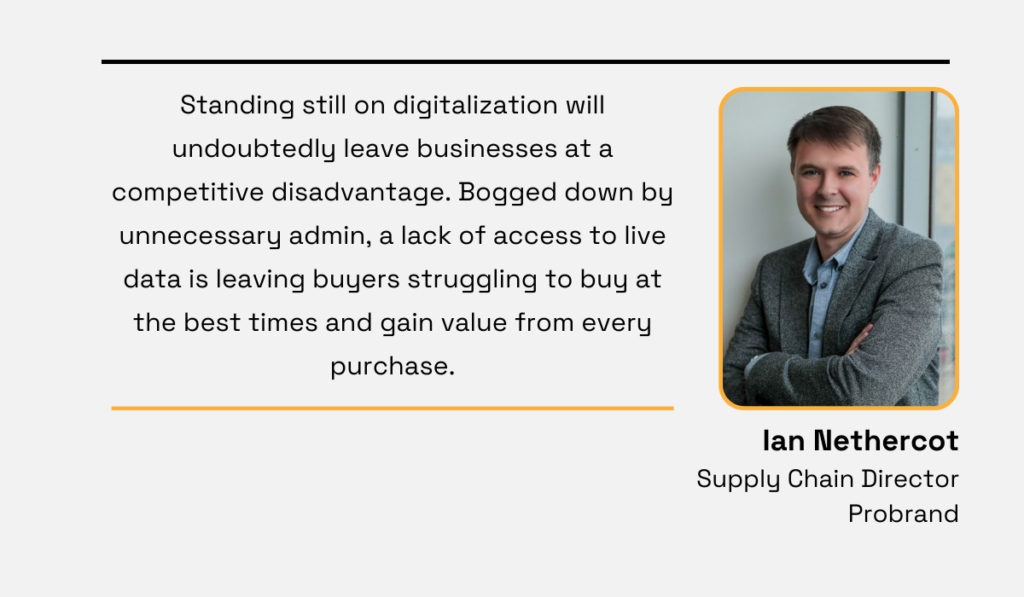

Ian Nethercot, a supply chain director at Probrand, an IT procurement company, seems to agree.

Illustration: Veridion / Quote: Technology Magazine

He explains that IT procurement suffers greatly due to a lack of automation, as it introduces a lot of unnecessary tasks and makes necessary ones much more difficult to carry out.

This results in many mistakes and missed cost-saving opportunities.

At the end of the day, no matter the industry or sector, no matter the company goals or size, and no matter a project’s scope, procurement is never an easy feat.

Doing it manually only makes things worse.

It’s perhaps no surprise, then, that we are witnessing a gradual but definite shift towards the digitalization of this important process through various procurement automation tools.

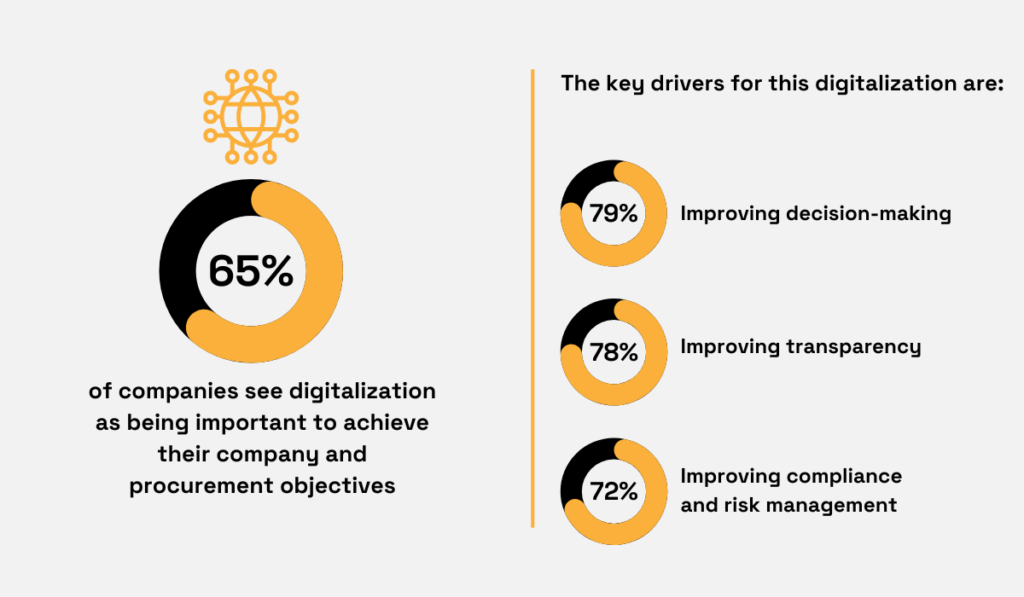

The Globality and ProcureTech survey reveals that 65% of companies now view technology as indispensable for achieving their procurement and, consequently, their business goals.

Illustration: Veridion / Data: ProcureTech

What’s more, improving decision-making, increasing transparency, and mitigating risk are the top three drivers for digitalization, according to the survey respondents.

Ultimately, it’s safe to conclude that relying on manual processes is no longer just a risk, but a guaranteed path to decreased efficiency, increased costs, and potentially catastrophic consequences for entire businesses.

And the only way out of this predicament is through the automation of procurement processes.

Supply chains are inherently versatile in terms of the risks they pose.

These risks can manifest in various forms: from political unrest, economic challenges, and technological advancements to labor or material shortages, and even natural disasters.

For instance, in April 2024, an earthquake struck Taiwan, which impacted the Taiwan Semiconductor Manufacturing Co, the world’s largest chipmaker and supplier to Apple and Nvidia, damaging some of their equipment and forcing them to halt certain operations.

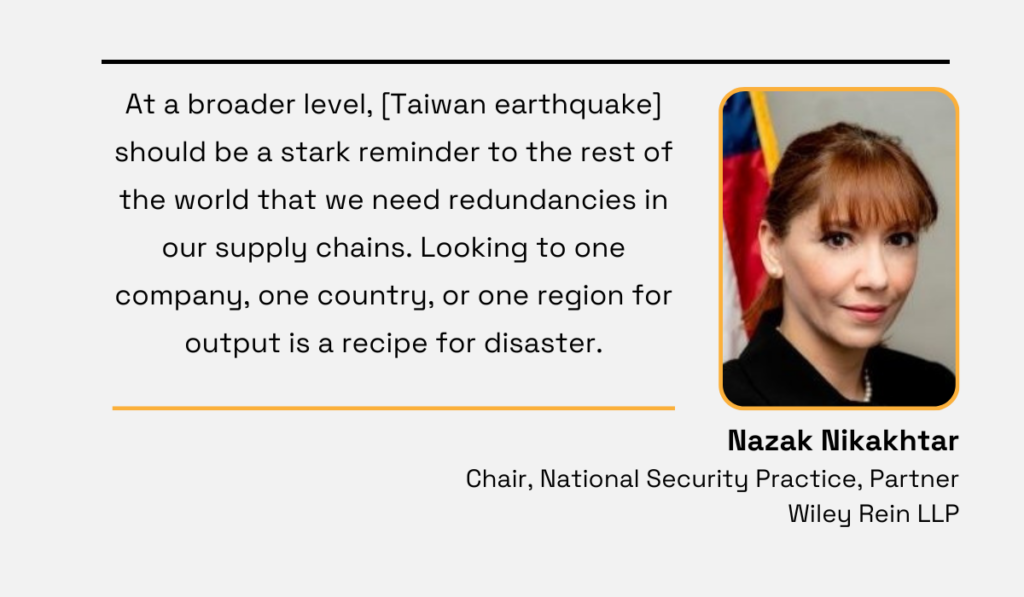

While the damage ultimately wasn’t catastrophic, it served as a significant lesson in the importance of sturdy supply chain risk management, as noted by Nazak Nikakhtar, a partner at Wiley Rein LLP.

Illustration: Veridion / Quote: Fox Business

After all, in today’s hyper-connected world, even a momentary interruption can send shockwaves through the entire supply chain, harming suppliers and buyers alike.

And while we can’t predict events like pandemics, material shortages, or natural disasters, we can arm ourselves with proactive strategies.

That means establishing contingency plans, diversifying our supplier networks, nurturing stronger relationships with them, and honing our ability to foresee potential scenarios through data analysis.

Many companies, such as Siemens, leverage modern technologies like AI to aid in these efforts.

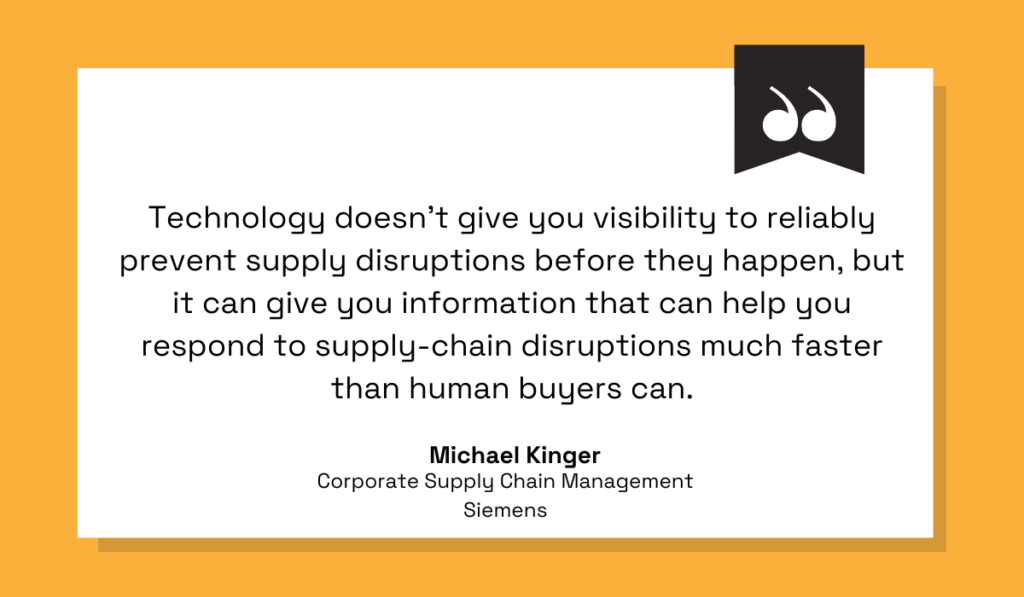

According to Michael Kinger, Siemens’ corporate supply chain manager, such technology isn’t a crystal ball by any means, but can definitely help lessen the blow of unforeseen events.

Illustration: Veridion / Quote: Harvard Business Review

Yes, the reality is that supply chain risk is unavoidable, unpredictable, and, at times, unnerving.

However, armed with resilient mitigation strategies, any obstacle can be transformed into an opportunity for growth, innovation, and getting ahead of the competition.

The role of contract management in procurement is to ensure everyone delivers on their promises.

For procurement teams, that means the delivery of the right product at the right time and for the right price.

For suppliers, it translates to timely payments, legal protection, and clarity of expectations.

However, if there are issues, such as inadequate record-keeping, limited visibility into contract terms, and the absence of robust contract management systems, that can lead to serious complications.

Think:

Let’s be realistic: nobody wants to become entangled in a legal dispute due to a contract breach, whether they’re buyers or suppliers.

Because, ultimately, regardless of who is deemed at fault in such disputes, a lot of money, time, and energy is sure to be wasted in the process.

Just ask Amazon and their warehouse equipment supplier, Gilimex Inc.

In 2022, they ended up in a legal battle over a substantial order cancellation on Amazon’s end despite an agreement they signed, with Gilimex seeking about $280 million in damages.

Source: The Wall Street Journal

And let’s not forget about Walmart, who had to fork over a whopping $20 million to their hand sanitizer supplier, K2 Distribution Co., all because of a—yet again—breach of contract.

So, to avoid being another cautionary tale, stop neglecting your contract management.

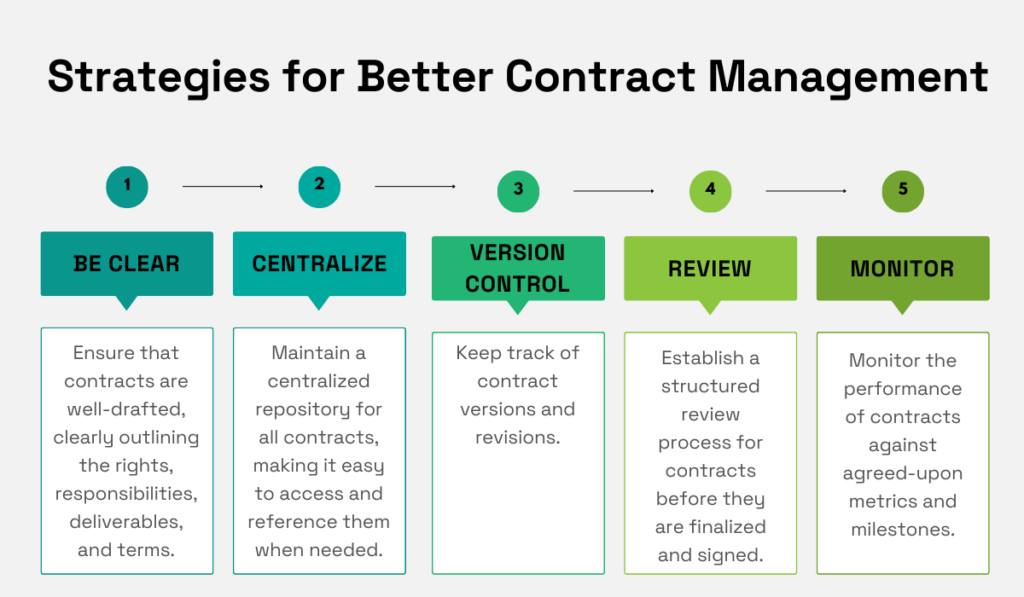

Instead, consider implementing the following measures.

Source: Veridion

This will make sure that all your contracts are managed with the utmost care, vigilance, and meticulousness.

In turn, not only will you be minimizing the risk of litigation, but you’ll actually maximize the value derived from your supplier partnerships.

Talk about a win-win situation.

Overspending is undeniably a significant issue, infiltrating every nook and cranny of procurement operations.

It sneaks in through inaccurate needs assessments, lax compliance checks, inadequate supplier management, and flawed market forecasting.

Before you know it, you’re grappling with overstocking, missed opportunities for cost savings, or suppliers inflating their prices, ultimately causing budget overruns and eroding the company’s bottom line.

Pierre Laprée, chief product officer at SpendHQ, puts it bluntly: procurement’s main job is to generate cost savings, not flush money down the drain.

Illustration: Veridion / Quote: SpendHQ

When it fails to do so, it’s not just a small oversight, but a colossal mistake—the kind that affects entire businesses.

The lack of transparency surrounding company spending and procurement activities is usually the main culprit behind this serious problem.

US hospitals and health systems serve as prime examples, with their total expenses ballooning by 18% in 2022, partially fueled by a staggering 258% surge in service procurement expenses.

Lindsay Maxwell, senior vice president of client services at RightSourcing, Inc., pins the blame on a lack of insight into where organizations’ money is really going.

Illustration: Veridion / Quote: Forbes

And to add fuel to the fire, these organizations, in their haste to get things done, often sidestep crucial procurement processes like competitive bidding, Maxwell explains.

Guess who benefits from such shortcuts? That’s right—the suppliers, who seize this chance to increase their prices.

So, the solution to overspending is pretty clear: improving your data transparency and procedural clarity.

This can be easily achieved through, for instance, e-procurement platforms.

They consolidate all procurement activities and spending onto a single platform, so you can better manage and track your processes.

This allows you to see what you’ve spent with suppliers in the past, contrast that with current market rates, and then take the necessary steps to trim costs where possible.

The reality is, you can’t completely dodge every procurement pitfall out there.

And you don’t need to. Each hurdle you tackle leaves you more agile, resilient, wiser, and ready for the next challenge.

Still, the good news is that most risks discussed in this article can be addressed head-on.

All it takes is a pinch of patience, the right tools, and a solid strategy.

So keep your eye on the market trends, automate tasks where possible, collaborate with reliable suppliers, establish contingency plans, and closely monitor every procurement activity.

Once you nail these steps, there’ll be no stopping you.