6 Procurement Challenges to Overcome

As the role of procurement departments expanded over time, so did the challenges they faced in their daily operations.

Whether some procurement risks come to fruition, dark purchasing gets out of control, or inaccurate data leads to suboptimal sourcing decisions, such challenges can impede any company’s efficiency and bottom line.

Conversely, understanding and addressing these challenges head-on is crucial for maintaining a competitive edge and ensuring smooth operations.

In this article, we’ll explore six common procurement challenges and provide actionable tips on how to overcome them.

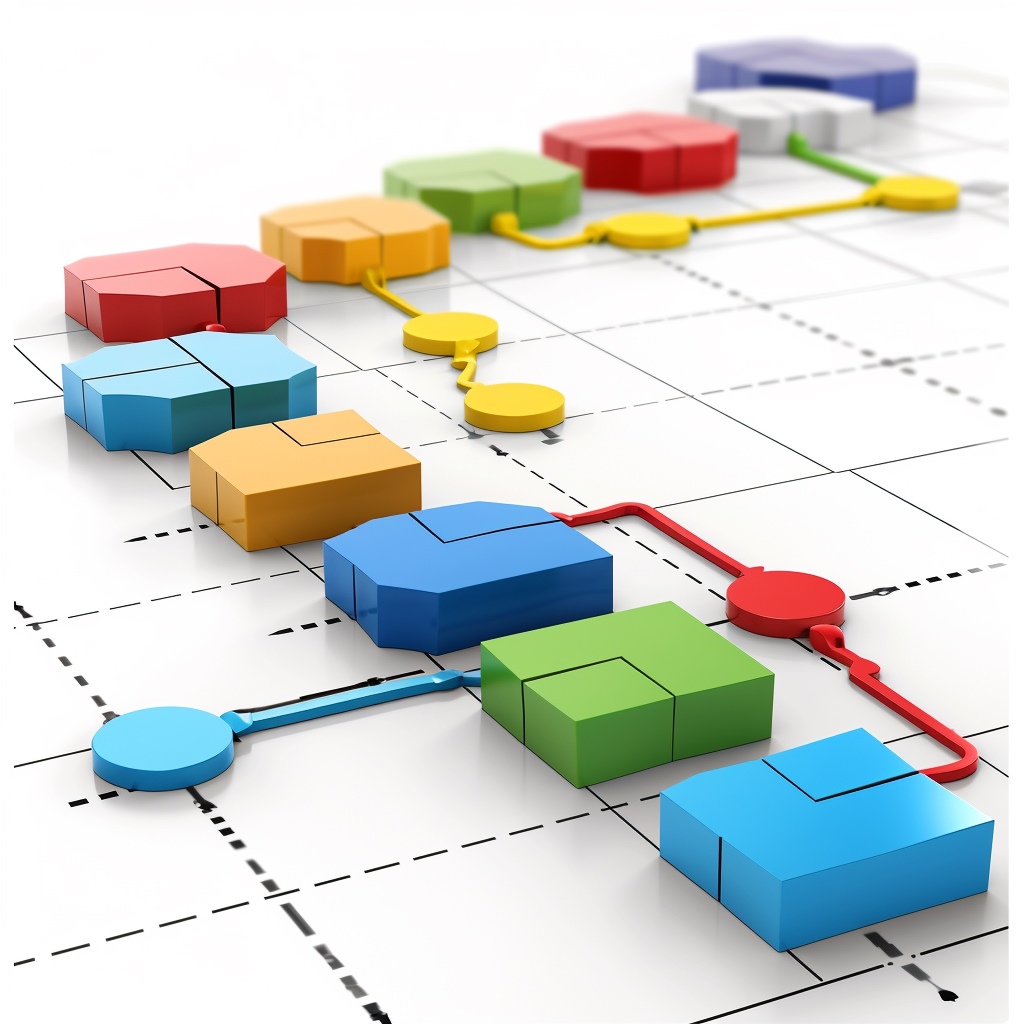

The process of procuring goods and services your company needs involves a series of inherent risks that can disrupt supply chains and affect procurement performance management.

Some of these risks are caused by external factors, such as natural disasters or geopolitical instabilities.

Others include a number of potential challenges that procurement professionals must navigate.

Despite some overlaps between these two groups, such risks include:

Source: Veridion

Failure to effectively manage these and other procurement risks can lead to operational interruptions, increased costs, reputational damage, and even legal liabilities.

For instance, consider a scenario where a key supplier unexpectedly goes bankrupt.

Without a robust risk management strategy in place, the sudden disruption to the supply chain could result in production delays, increased costs due to expedited shipping, and ultimately, dissatisfied customers.

Therefore, companies should adopt a proactive approach and implement strategic measures to effectively mitigate procurement risks.

One best practice is to diversify the supplier base.

In fact, 76% of US-based businesses surveyed by QIMA in 2023 said that they altered their supplier geography, i.e., diversified their supplier base in the last 12 months.

That’s because companies can, by engaging multiple suppliers for critical components or services, spread risk and minimize the impact of disruptions caused by the failure of a single supplier.

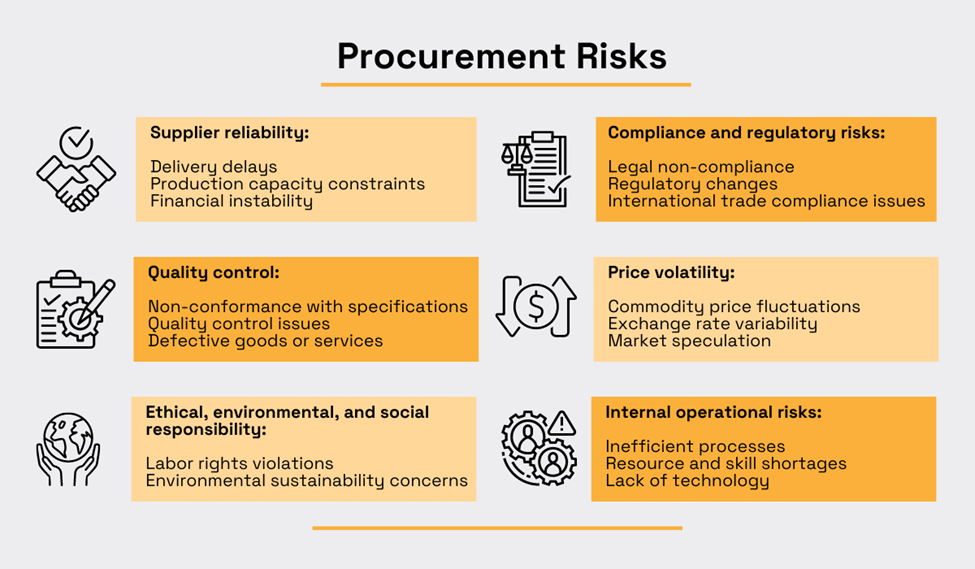

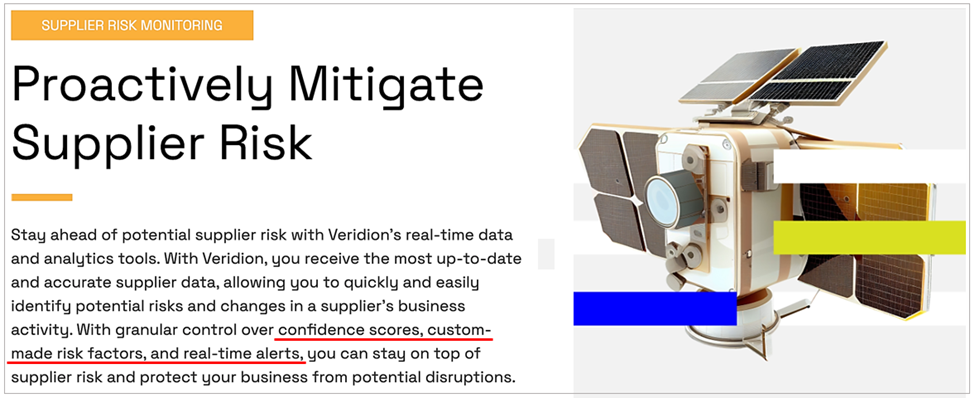

Additionally, leveraging advanced procurement management, analytics, and risk assessment tools can significantly enhance risk management capabilities.

For example, such tools can help you identify risks during supplier discovery and evaluation and monitor risks throughout your supplier relationship, as illustrated below.

Source: Veridion

As highlighted, some tools, like our Veridion, include:

This enables your procurement team to identify and assess potential threats proactively, allowing for timely intervention and risk mitigation strategies.

For example, if a risk monitoring tool informs you that a supplier is going through financial distress, you can establish a backup plan, including finding alternative suppliers if yours is forced to declare bankruptcy.

By embracing these best practices and adopting a proactive risk management approach, companies can fortify their procurement processes, safeguard against disruptions, and drive sustainable growth despite an increasingly volatile business landscape.

Another procurement challenge refers to dark purchasing, also known as tail, rouge, or maverick spending.

These terms are used to describe unauthorized or untracked procurement outside established processes, such as company departments getting their office supplies through small, uncontrolled purchases from multiple vendors.

As such, dark purchasing can lead to:

Addressing this challenge starts with analyzing what categories of procured goods and services are not controlled—or at least not fully controlled—by your procurement department.

These categories can significantly vary from company to company depending on its industry, size, and other factors.

Despite this, here are some common cost categories that typically have higher rates of dark purchasing:

Source: Veridion

The classification of spend categories where most dark purchasing occurs should be done as part of a comprehensive spend analysis aimed at identifying which costs can be grouped and placed under the control of your procurement department.

For example, travel arrangements are often decentralized, with department managers or employees booking flights, accommodations, and other travel-related services independently, bypassing established procurement channels.

If these expenses are centralized and managed by the procurement team, this can lead to opportunities for supplier consolidation, stronger negotiation leverage, and cost savings.

To effectively minimize dark purchasing, companies should establish clear policies and procedures governing procurement processes.

This emphasizes the importance of centralized purchasing and compliance with established protocols.

Of course, tools like e-procurement platforms or spend management software can:

Overall, by leveraging technology-driven solutions to analyze your company spend and identify categories exposed to dark purchasing, you can mitigate the associated risks, optimize procurement efficiency, and achieve cost savings.

One major challenge in procurement is related to inaccurate or outdated data that hampers informed decision-making, thereby leading to suboptimal supplier selection, lost opportunities, and unidentified risks.

This is underlined by The Data Warehousing Institute (TDWI), estimating that U.S. companies lose over $600 billion a year due to inaccurate or missing data.

At the same time, that’s not surprising, considering the amount of data that companies need to analyze to make data-driven procurement decisions.

For instance, when looking for new suppliers, relying on outdated data can result in misinformed assessments of supplier capabilities, performance history, and financial stability.

Consequently, procurement teams may overlook more suitable suppliers or engage with high-risk vendors without being aware of it.

To overcome this issue and get the most accurate and up-to-date information about potential suppliers, you can leverage our supplier-sourcing and risk management tool, Veridion.

Veridion provides businesses with a global, AI-powered database of suppliers containing over 80 million companies, each followed through more than 60 data points.

Best of all, our database is updated on a weekly basis.

Source: Veridion

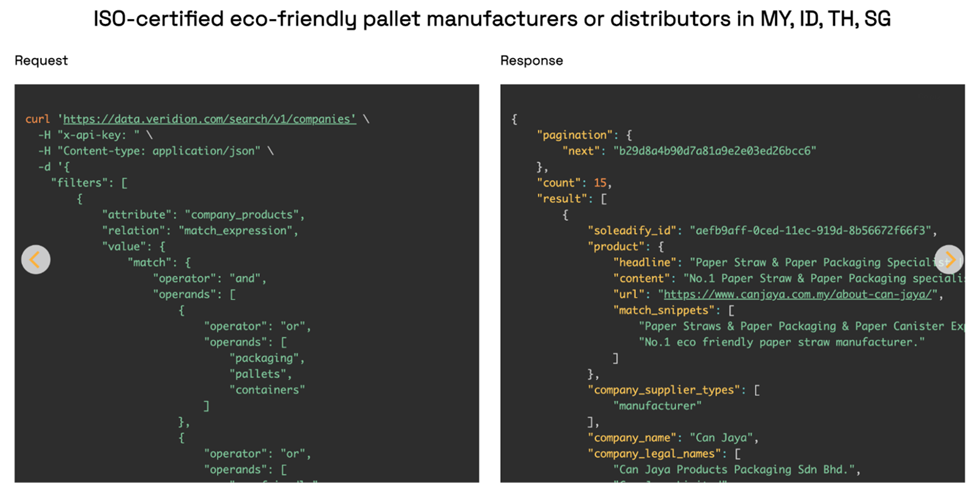

By accessing this database and searching for suppliers with the help of advanced search APIs, you can find prospective suppliers that meet your specific procurement criteria in any part of the world.

Moreover, you can do so in seconds or minutes instead of weeks or months.

All you need to do is use Veridion’s natural language input to set your criteria, like in this example.

Source: Veridion

Your search results will provide the freshest data about all suppliers that fit the set criteria.

As mentioned, you can also use Veridion for supplier risk monitoring and for gathering procurement market intelligence.

Combined, these features allow you to leverage accurate data to:

Moreover, you can utilize Veridion’s Match & Enrich API to update your current supplier records and enrich them with the latest data.

This can help revamp your company’s supplier database and allow you to regularly audit and cleanse procurement data to ensure accuracy and reliability.

To recap, the challenge of inaccurate internal and external supplier data can be overcome by leveraging the right tools that provide accurate and up-to-date data on a regular basis.

The next procurement challenge on our list refers to the essence of any smoothly functioning organization—good internal communication, collaboration, and coordination.

More precisely, siloed communication among departments results in the misalignment of procurement goals with overall business objectives, leading to duplication of efforts, missed opportunities, and suboptimal outcomes.

Conversely, companies with effective communication in procurement realize, on average, 53% higher savings than their less communication-savvy counterparts.

To drive our argument home, here’s a quote from Michael Schanker, SVP of Strategic Marketing at Coupa Software:

Illustration: Veridion / Data: Procurement Magazine

So, how does one go about breaking down internal information silos and improving interdepartmental communication?

The first thing to do is establish clear and efficient communication channels, which can include team collaboration platforms like Slack or integrated software solutions like Enterprise Resource Planning (ERP).

Aside from technology-driven solutions, effective internal communication should also include clear data-sharing protocols to facilitate data transfers between departments.

Additionally, it’s essential to define the roles and duties each department has with regard to communicating and data-sharing with the procurement team.

Naturally, regular department-level meetings focused on future procurement needs can help streamline communication between, for example, your company’s finance or production departments and your procurement function.

Source: Zipdo

Another information silo-breaking measure is to establish cross-functional teams for specific procurement initiatives.

This will allow representatives from different departments to collaborate, align goals, and share insights.

Of course, fostering a culture of open communication and knowledge sharing can further enhance interdepartmental collaboration.

To recap, a lack of internal communication can be addressed by implementing tools and methods aimed at facilitating company-wide communication, which is paramount for maximizing procurement efficiency and achieving organizational success.

In today’s globalized supply chains, any disruption caused by events such as pandemics, natural disasters, or geopolitical conflicts presents a major risk for companies.

Moreover, the effects of such disruptions in the last four years were felt around the world, and ongoing geopolitical and economic tensions are still causing problems.

The consequences of these disruptions can be far-reaching, impacting production schedules, inventory management, and ultimately, customer satisfaction.

Companies may face delays in receiving raw materials, transportation bottlenecks, and increased costs associated with rerouting supply chains or sourcing alternative suppliers.

Furthermore, the interconnected nature of global supply networks means that disruptions in one region can have ripple effects across the entire supply chain, exacerbating challenges for businesses.

On that note, here is what DHL underlined as the top 5 supply chain risks in 2024:

Illustration: Veridion / Data: DHL

Against this background, let’s see what your procurement department can do to mitigate these risks.

First of all, it’s crucial to stay informed on emerging geopolitical crises, new protectionism measures (trade bans, import tariffs, export controls), or more stringent environmental regulations (in your home country as well as your suppliers’ countries).

Source: Veridion

That way, your procurement team can proactively look for alternative sourcing options or implement other risk management strategies.

For instance, you can consider sourcing materials or components from two or more suppliers (dual sourcing), thus creating contingencies in case of any supply chain disruption.

Alternatively, you can discuss backup options with your existing supplier of critical goods or services, such as using their production capacities in other countries unaffected by a disruption.

The bottom line is, to manage the risks associated with supply chain disruptions, companies need to anticipate potential issues and have contingency plans in place to mitigate their impact on operations and enhance the resilience of their supply chain.

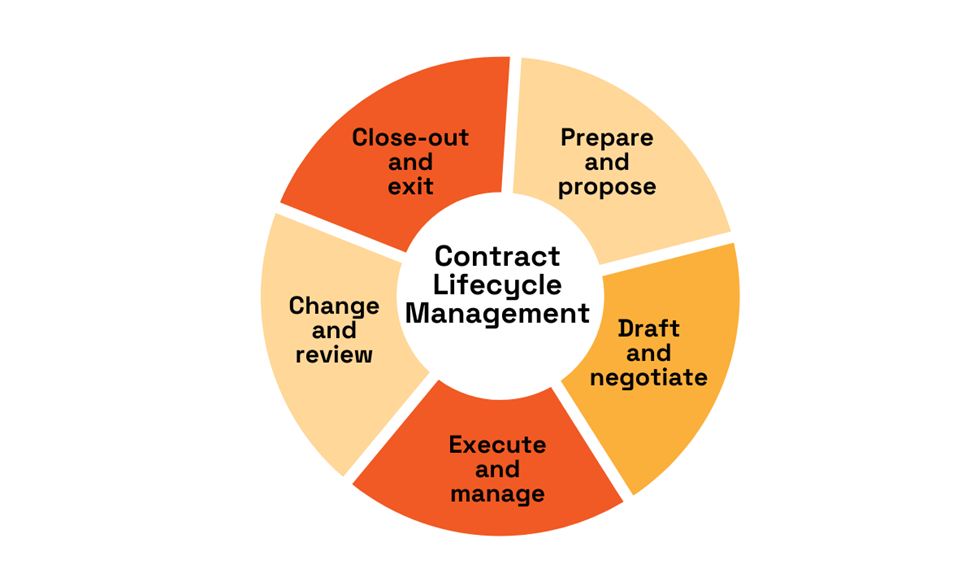

Contract management poses several challenges for companies, primarily due to the complexity of managing various contracts across different suppliers, departments, and regions.

Since each contract comes with its own terms, conditions, and renewal dates, managing this volume and variety of supplier contracts can be overwhelming without a centralized system in place.

Moreover, contracts typically contain complex legal and commercial terms, which may vary depending on the type of goods or services being procured.

Therefore, poor contract management increases the risk of non-compliance with contractual obligations, potentially resulting in

Given the above, one of the best ways to tackle this challenge is to implement contract lifecycle management (CLM) software.

This will allow you to automate contract creation, streamline approval workflows, and ensure compliance with contractual terms, i.e., more efficiently manage all stages of a contract lifecycle illustrated below.

Illustration: Veridion / Data: Contract Exec

By leveraging CLM software features, your procurement team will be able to avoid or minimize issues like missed contract renewals, overpayment, non-compliance penalties, and supplier disputes.

Another tip that can help address this challenge is to establish a contract governance framework.

In essence, this framework consists of policies, procedures, and tools used to:

To recap, by forming a strong contract management structure and utilizing CLM solutions, you can mitigate potential risks associated with ineffective contract management practices.

With procurement challenges behind us, it’s clear that overcoming them requires a strategic approach, proactive risk management, and alignment with organizational goals.

By implementing the suggested best practices, leveraging technology, and fostering collaboration, your company can optimize its procurement processes, mitigate risks, and maintain a competitive edge in today’s complex procurement landscape.