6 Reasons Why Procurement Performance Management Is Important

Procurement performance management can be the superhero of your procurement department—it sets goals, tracks progress, and swoops in to save the day by boosting procurement efficiency.

Whether it’s choosing the best suppliers, championing sustainability, or dodging supply chain risks, this powerhouse does it all.

Today, we’re unveiling six reasons why giving procurement performance management the spotlight it deserves can be a game-changer for your procurement—and the rest of the organization.

Buckle up, and let’s dive in.

It goes without saying that, when you measure, analyze, and report your procurement performance, you can significantly increase and optimize your procurement.

In other words, when you understand how your procurement is performing across different areas, such as cost management, supplier management, and procurement process efficiency, you can improve in these areas.

Consequently, the entire organization benefits from gaining more value in terms of cost reduction, risk mitigation, and competitive advantage.

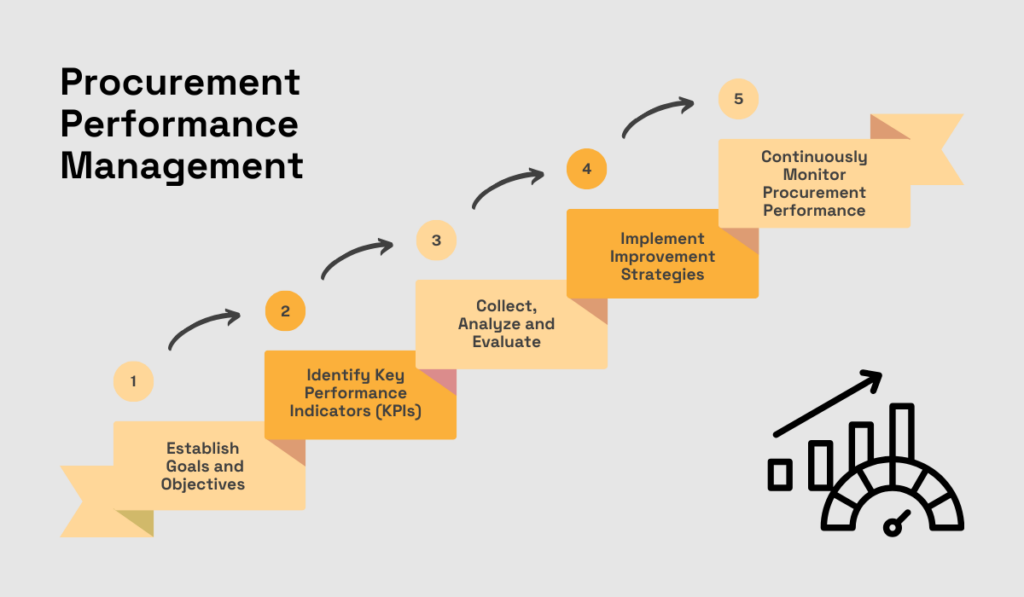

Of course, to measure procurement performance effectively, you must first establish which key performance indicators (KPIs) you will track and analyze.

The next crucial step is sharing the insights gained within the department and using them collaboratively to enhance procurement performance.

Source: Veridion

Let’s see how this looks in practice.

For instance, if you monitor process efficiency KPIs such as inventory turnover, you can analyze turnover rates and identify slow-moving inventory items.

Based on this data, you can adjust procurement strategies to reduce carrying costs and improve cash flow.

IKEA, for example, separates high- and low-flow goods in separate facilities to optimize storage and retrieval processes, minimizing costs and enhancing efficiency.

Similarly, if, by analyzing procurement cycle time, you notice that your procurement cycle times are too long, you can be encouraged to implement procurement automation tools.

As a result, you achieve faster order processing, minimize bottlenecks, and enhance the overall procurement cycle.

How you perform in cost management is another essential metric to track that can point out how to increase procurement performance further.

For example, tracking unit costs and total procurement spend can help you identify areas where costs are higher than expected.

You may discover opportunities to negotiate better deals with suppliers or streamline procurement processes to reduce expenses and improve efficiency.

Simply put, tracking cost management metrics enables you to pinpoint areas for improvement and take actions to drive cost savings and operational efficiency.

So when you measure, analyze, and report procurement performance, you not only improve procurement performance but also showcase that procurement is a key factor that can benefit the entire organization.

In today’s fast-paced business environment, data has become a critical asset for informed decision-making, and procurement is no exception.

Procurement performance management is the backbone for enabling data-driven strategies that optimize processes, reduce costs, and enhance overall efficiency.

Modern procurement software captures vast amounts of data, from supplier performance metrics to spend analysis data, providing real-time visibility into your procurement operations.

With such comprehensive data at your disposal, you can make decisions based on quantifiable insights across various procurement processes:

Let’s focus for a moment on supplier discovery and selection.

When it comes to sourcing suppliers, it’s even more crucial to rely on accurate, fresh, and objective data.

Therefore, combining performance data with external supplier market intelligence is essential.

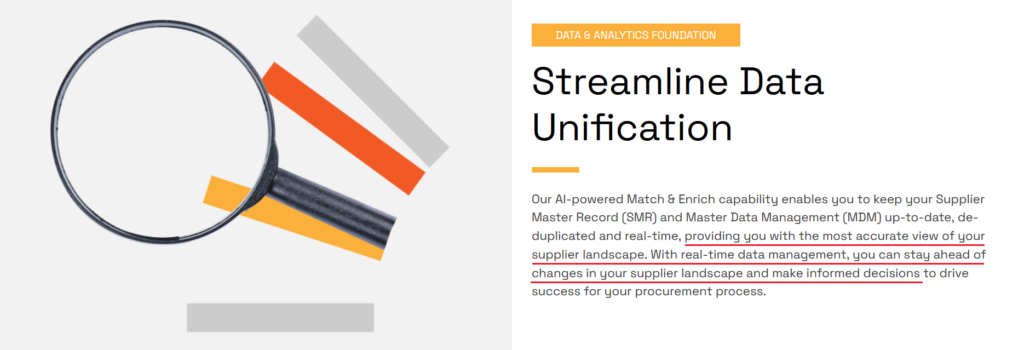

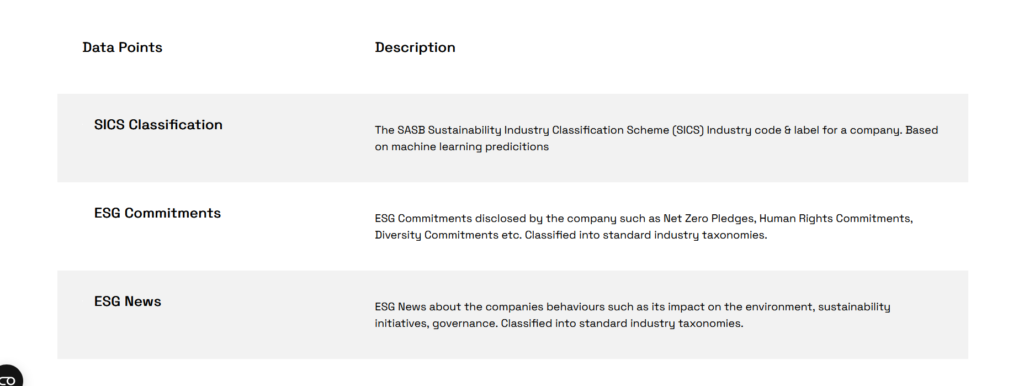

One solution that excels in providing near-real-time insights on suppliers is our supplier sourcing enabler, Veridion.

Veridion aggregates data from diverse sources and employs AI-powered analytics to provide you with comprehensive insights into your supplier landscape, from firmographic information to sustainability metrics.

What’s more, with Veridion, you’re always in the know about what is happening with suppliers, so you can make timely decisions.

For example, if a supplier loses a certificate, Veridion alerts you, and you can make decisions based on data rather than intuition.

Source: Veridion

To conclude, effective procurement performance management, supported by robust data analytics capabilities, is essential for making more informed decisions.

Procurement performance management not only aids in sourcing suppliers but also in selecting the best partners for your organization—repeatedly.

When you consistently track and analyze supplier performance metrics, you ensure collaboration with the most suitable and dependable suppliers.

This naturally enhances procurement performance and cultivates stronger partnerships.

The key performance indicators (KPIs) pertinent here include:

For instance, assessing supplier availability determines how much you can rely on them, while evaluating the supplier defect rate (the number of products you had to return due to poor quality) gauges the quality of their products.

Additionally, the supplier compliance rate—which encompasses on-time delivery, adherence to specifications, and compliance with regulations—reflects the supplier’s commitment to contractual agreements, industry standards, and ethical practices.

Regular monitoring of these KPIs enables you to identify suppliers that consistently deliver quality products on time and ensure reliability in your supply chain operations.

Simultaneously, it allows you to recognize suppliers who fail to meet your standards, thereby posing higher risks to your operations.

However, armed with data, you are better equipped to make informed decisions regarding whether to replace underperforming suppliers or implement corrective measures to enhance their performance.

Such supplier assessments must be conducted regularly to derive numerous benefits not only for the procurement department but also for the entire organization, as highlighted by Marco Antonio Dias, Head of South America Logistics at Bosch Rexroth.

Source: Linkedin

To recap, procurement performance management significantly contributes to selecting the right suppliers.

By consistently monitoring, measuring, and sharing performance metrics with suppliers, you can attain extensive benefits, ranging from ensuring product quality to mitigating supply chain risks.

Procurement performance management is essential for identifying and mitigating risks within your supply chain, safeguarding your business from potential disruptions and losses.

These risks manifest in various forms:

Now, let’s delve into how procurement performance management can help you avoid such risks.

First, by regularly evaluating supplier metrics, like the ones depicted in the image below, you can identify and address potential supplier-related risks.

Source: Veridion

This ensures engagement with reputable and reliable suppliers, reducing the likelihood of disruptions in your supply chain.

Also, since procurement performance management facilitates compliance monitoring and enforcement, you can make sure that you work only with suppliers that adhere to laws, regulations, and ethical standards.

This protects your company from legal penalties and reputational damage.

Second, through data analysis and trend monitoring, procurement performance management enables proactive mitigation of market risks.

By staying ahead of market fluctuations, adjusting procurement strategies accordingly, and minimizing the impact of volatility, you can maintain operational stability and profitability.

On top of that, when you measure your operational performance, you can identify inefficiencies and enhance transparency within your operations.

In turn, you can take action and mitigate potential operational risks.

The bottom line is this: this vast amount of data on your procurement performance combined with market intelligence is a way to risk mitigation.

As Nicolas Walden, Associate Principal and UK & Europe Practice Leader, Procurement Advisory for The Hackett Group, emphasizes, the future of risk management is data-driven.

Procurement performance management provides the necessary framework and tools to achieve this, enabling you to make informed decisions and effectively manage risks across your supply chain based on performance data.

By now, we have seen that procurement performance management establishes clear performance expectations and metrics.

This is crucial for fostering a culture of accountability among procurement team members and promoting transparency and responsibility in procurement activities.

Let’s explain this in more detail through an example.

For instance, consider a retail company aiming to optimize its supply chain efficiency to meet customer demands effectively.

As part of its procurement strategy, the company sets specific performance targets and KPIs for its procurement team.

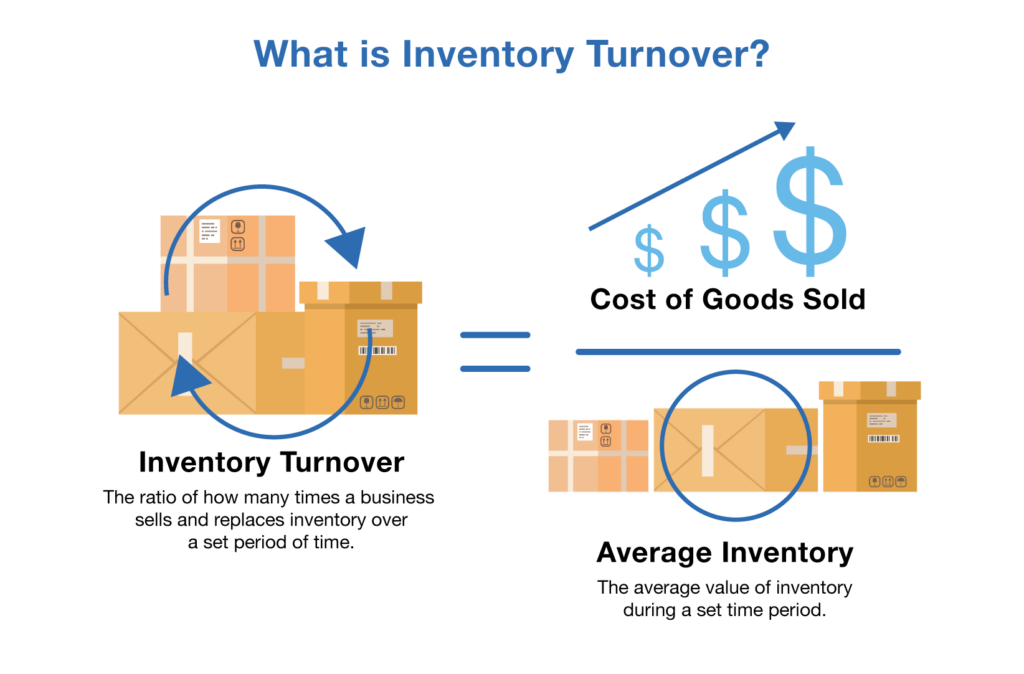

One key performance indicator is the inventory turnover rate, measuring how quickly inventory is sold and replaced within a given period.

Source: BlueCart

The procurement team is tasked with ensuring optimal inventory levels to prevent stockouts while minimizing excess inventory costs.

Another KPI is supplier lead time, tracking the time from placing an order to receiving goods.

The team focuses on negotiating shorter lead times with suppliers to reduce order fulfillment cycles and improve responsiveness to customer needs.

With these performance targets in place, each member of the procurement team understands their role in contributing to reaching objectives.

Also, regular performance monitoring and reporting mechanisms allow the team to track progress and identify areas for improvement.

During monthly reviews, the team can assess performance, discuss challenges, and implement corrective actions if needed.

For example, if the inventory turnover rate falls below the target, the procurement team may analyze demand patterns and adjust ordering strategies accordingly.

Similarly, if supplier lead times exceed expectations, negotiations may be initiated to address inefficiencies in the supply chain.

Overall, procurement performance management is all about setting clear objectives, measuring performance against predefined metrics, and enabling continuous improvement in procurement practices—to ultimately reach those procurement goals.

And not to forget—fostering accountability along the way.

Procurement holds significant influence within organizations due to its relationships with suppliers and pivotal role in supply chains.

By integrating sustainability criteria into your operations, you can harness this influence to drive ethical and sustainable business practices.

This entails directing more spending toward suppliers committed to reducing social and environmental impact, upholding human rights, ensuring safe working conditions, and striving for net-zero emissions.

And procurement performance management can help you achieve this.

Namely, assessing your procurement from a sustainability standpoint helps you pinpoint suppliers adhering to sustainable practices.

By integrating sustainability and social responsibility into your procurement metrics, you can champion sustainable business practices, bolster local communities, and mitigate environmental harm across the supply chain.

However, as Pierre Laprée, Chief Product Officer of SpendHQ, points out, many times, procurement teams don’t know where to begin:

“Procurement teams play a pivotal role in driving sustainable and ethical practices, but they face notable challenges, particularly in the realm of data. Managing and measuring ESG initiatives is new to many, and people are unsure where to begin.”

Luckily, leveraging big data solutions, such as Veridion, which provide intelligence on supplier ESG criteria, can serve as a valuable starting point for addressing these challenges.

Source: Veridion

It’s simple: when you have access to ESG metrics on suppliers to rely on, you can more easily select suppliers that share the same sustainability values as you.

Before we conclude, let’s examine one great example of leveraging procurement performance management to promote ethical and sustainable practices.

Decathlon, a global sports retailer, places a strong emphasis on working with suppliers that share its commitment to sustainability.

The company integrates sustainability criteria into its supplier selection process and conducts regular audits to assess supplier compliance with environmental and social responsibility standards.

Nuno Tinoco, Head of Footwear, explains their approach to measuring supplier performance through sustainability criteria:

“For many years now, we have had our own requirements to assess the level of our suppliers. These requirements are more demanding than local laws and aligned with best international standards. These assessments are done regularly through official audits but critical points are checked daily by our compliance team with suppliers in the field. We are able to do this by having offices inside our factories with a daily Decathlon presence and by building close relationships with our suppliers’ teams.”

Decathlon’s rigorous approach to supplier performance management has enabled it to achieve significant progress towards its sustainability goals.

This includes the transition to 100% renewably sourced electricity for all of its distribution and logistics activities by 2026 and the reduction of CO2 emissions across its supply chain.

Additionally, 82% of its suppliers are receiving A, B, or C ratings for working conditions, up 28% from 2017.

In summary, procurement performance management is vital in driving ethical and sustainable business practices by providing you with the tools and insights needed to evaluate and improve supplier sustainability performance.

Through strategic procurement practices and effective supplier performance management, you can create positive social and environmental impact while also enhancing your reputation and long-term sustainability.

And that wraps up our six reasons why procurement performance management can be your organization’s superhero.

Measuring procurement performance offers invaluable insights for informed decision-making, from enhancing procurement efficiency to mitigating risks and promoting sustainability.

As businesses navigate increasingly complex markets, the importance of procurement performance management will undoubtedly continue to rise.

So, embrace it wholeheartedly.

Doing so will empower you to seize new opportunities for growth and success while effectively navigating the challenges of the modern business landscape.