Supplier Capability Assessment: Everything You Need to Know

Key Takeaways:

Have you ever wondered what Supplier Capability Assessment (SCA) is all about and why it is so important?

If so, you’re in the right place.

In this article, we’ll explore everything you need to know about this vital process that keeps your supply chain resilient and your business poised for long-term success.

From its benefits to the tools that help streamline the process, we’ll cover it all—empowering you to improve your own supplier evaluations and take your business to the next level.

Let’s start with the basics and explore the purpose of SCA.

The benefits you stand to unlock with this process just might surprise you.

You can think of supplier capability assessment as your first line of defense against supply chain risks.

It helps catch and address weaknesses in supplier processes early, preventing potential disruptions such as delivery delays, quality issues, or financial instability.

This is how you protect your reputation, your operations, and your bottom line.

The 2023 BCI survey proves that vendor-related risks are real—and occur quite frequently.

As it turns out, 37.3% of companies across industries report issues with tier 1 suppliers, while 19.7% experience problems at tier 2.

Plus, an additional 11.3% encounter challenges further down the supply chain (tiers 3 and 4).

Illustration: Veridion / Data: BCI

SCA plays a crucial role in mitigating these issues, detecting and fixing them before they escalate and start causing damage.

For example, your supplier might lack the resources to scale production during demand surges or fail to implement systematic testing, increasing the risk of defective products.

Without SCA, those problems might go unnoticed until they impact your final product, operations, and customers.

Take Boohoo, a British online fast-fashion retailer, as a cautionary tale.

Boohoo recently faced disputes with suppliers over poor quality, which ultimately harmed their sales.

Source: Retail Gazette

Namely, in May of 2024, the company reported widening losses, jumping from £90 million to £160 million in just a year.

Analysts point to high return rates as a significant contributor to their losses.

A Boohoo spokesperson told TheIndustry.fashion that they are working to resolve the issues with suppliers:

“We are currently talking with a very small number of supplier partners where, unfortunately, the product supplied was not of a high enough standard. We are working collaboratively with them to remedy the situation and ensure this does not happen again.”

However, with proactive and thorough SCA these problems could’ve probably been prevented altogether.

Overall, in today’s unpredictable and competitive market, you can’t afford to rely on vendors who fail to meet your standards or expose you to unnecessary risks.

That’s why SCA is a must.

It helps ensure your supply chain is resilient, your suppliers reliable, and your operations smooth.

SCAs help verify that suppliers meet all relevant regulatory, industry, and organizational standards, shielding your company from legal liabilities and reputational damage.

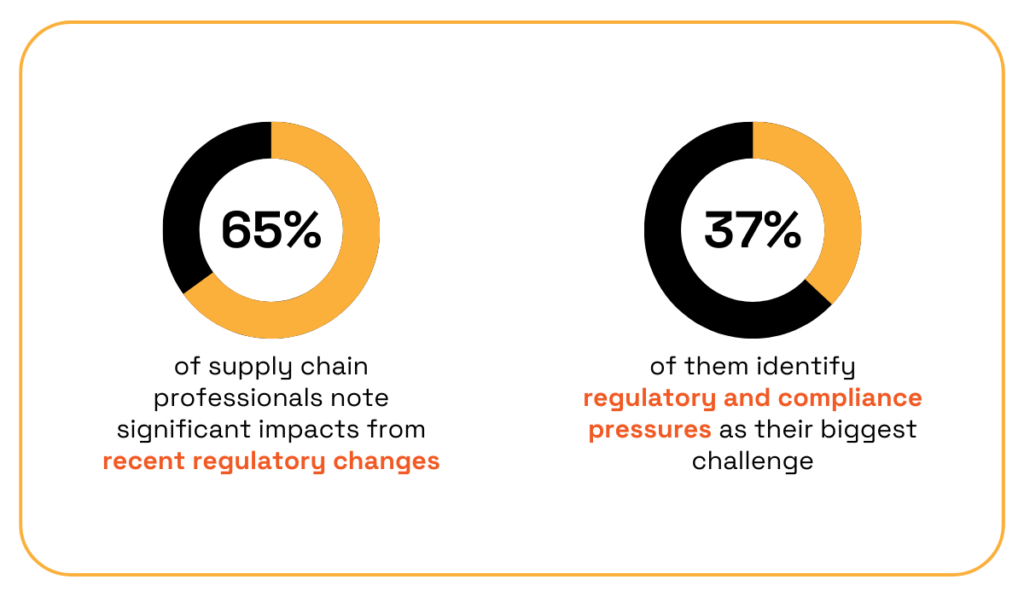

Recent studies indicate that procurement is facing increasing pressure to ensure compliance, demonstrating just how important SCAs are in today’s regulatory environment.

For example, the 2024 Inspectorio survey reveals that 65% of supply chain professionals regard recent regulatory changes as significant, seriously affecting their operational and compliance strategies.

On top of that, 37% of them identify regulatory and compliance pressures as their biggest challenge.

Illustration: Veridion / Data: Inspectorio

After all, ignoring compliance risks—even if they originate from a vendor and not you directly—can spell disaster for the entire organization.

Take Boeing, for instance.

Currently, one of their key suppliers is facing a lawsuit over an “excessive amount of defects” at its Kansas plant.

Source: NPR

Although Boeing itself is not named in the lawsuit, news headlines like “Boeing Supplier Regularly Shipped Parts with Defects” dominate the coverage.

In other words, Boeing’s name at the center of the controversy is, in a way, overshadowing the supplier’s role.

To make matters worse, the Federal Aviation Administration (FAA) has also pointed fingers at Boeing for failing to verify supplier compliance, further tarnishing the company’s reputation.

This is what the FAA wrote in their letter to Boening:

“The above-described circumstances indicate that Boeing may have failed to ensure its completed products conformed to its approved design and were in a condition for safe operation in accordance with quality system inspection and test procedures.”

The lesson?

Your suppliers’ compliance is your compliance.

Any problems on their end can put your business at significant risk—especially in high-stakes industries like aviation, where safety and regulatory adherence are paramount.

So, don’t wait for a crisis to act.

Instead, be proactive and implement SCAs to make sure all applicable standards and regulations are met.

Remember, it’s not just about following the rules but about protecting your workforce, your customers, and the future of your business.

SCAs also play a role in identifying hidden inefficiencies that could increase costs and erode your profitability.

For instance, they assess whether a supplier has effective quality assurance practices, minimizing the risk of defects and reducing expenses related to returns, rework, or warranty claims.

After all, these issues are notoriously expensive.

A 2024 Hexagon survey serves as proof, revealing that product recalls can cost between $8 million and $50 million.

Illustration: Veridion / Data: ETQ

That’s a steep price to pay for neglecting supplier evaluations, wouldn’t you agree?

Similarly, SCAs evaluate the reliability of suppliers’ delivery schedules and their capacity planning.

This helps prevent costs associated with delays, emergency shipments, or stockouts.

In 2018, KFC discovered just how costly such disruptions can be.

Their new logistics provider at the time wasn’t operationally ready to handle the job, leading to a chicken shortage and forcing about 600 KFC outlets in the UK and Ireland to close.

Source: The Guardian

While KFC did not disclose the financial impact, media estimates suggested losses of approximately £1 million per day.

Various experts immediately began dissecting the incident, attributing the fiasco to the logistics partner’s inadequate planning and operational readiness.

Samir Dani, who was a logistics and supply chain management professor at the University of Huddersfield’s Business School at the time, was one of these experts:

“It’s a complex scenario, but it largely stems from network planning. To deliver perishable products to stores, you need to carefully plan your network, determining how many distribution centres are required.“

This is precisely the type of risk SCAs are designed to mitigate.

They answer the big question: is your supplier truly capable of delivering what you need, when you need it?

That way, you proactively identify weaknesses and avoid any expensive surprises.

When SCA reveals gaps, try not to just point them out.

Instead, help your supplier solve the issue, whether it’s through training, sharing technology, or improving processes.

Supporting your vendors in such a way not only boosts their performance but also builds collaborative, long-term partnerships.

In other words, if you help your suppliers succeed now, they’ll have your back when it counts.

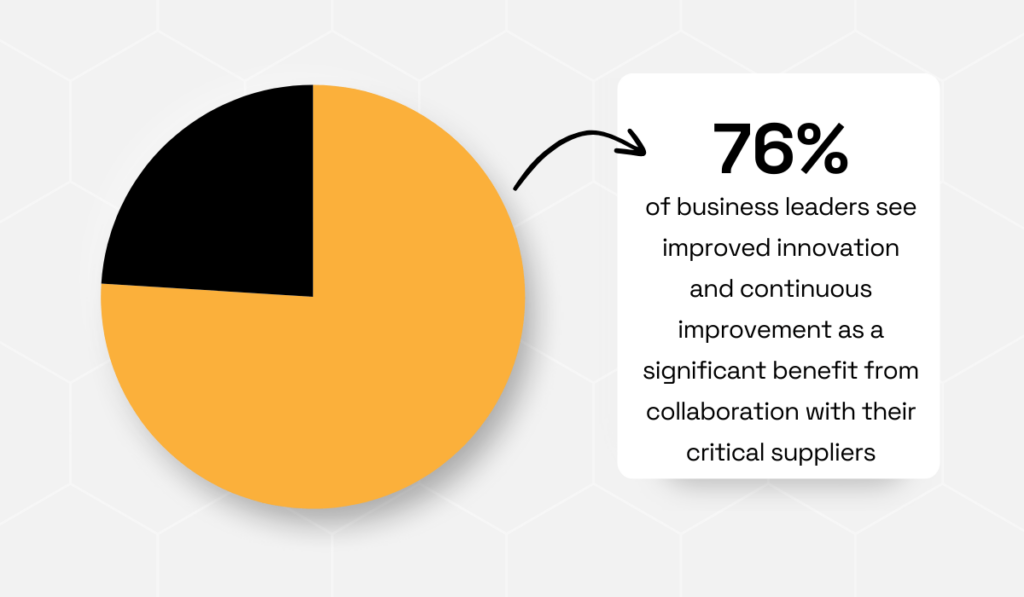

In fact, research confirms that strong supplier relationships unlock incredible perks.

For instance, the 2024 State of Flux survey shows that 76% of business leaders say collaborating with critical suppliers leads to better innovation and continuous improvement.

Illustration: Veridion / Data: State of Flux

This just goes to show that the purpose of SCAs isn’t only quality assurance.

They can also open doors to strategic improvements that positively impact the entire business in the long run.

Krystal Suffling, Branch Manager at Aspire2, a leading New Zealand training provider, understands this very well.

She always looks for opportunities to help suppliers improve:

Illustration: Veridion / Quote: Shopify

According to her, these efforts lead to genuine, mutually beneficial relationships that stand the test of time:

“[…] if you can help to streamline processes that the supplier currently works with you on, then they know you’re not just trying to get on their good side, and they’re usually very appreciative of their feedback.”

And such partnerships can be game-changers.

Suppliers who feel supported by you might share insider tips, offer better pricing, or help you out during tough times when certain products are scarce.

In short, SCAs strengthen both the buyers and suppliers alike.

They ensure you grow together, face challenges as a team, and build resilience that keeps both parties competitive.

Predetermining which KPIs will be assessed during an SCA benefits everyone involved.

For buyers like you, it ensures the evaluation process is consistent and unified, while suppliers get a clear understanding of what you value and expect.

That way, you build a foundation for more transparent and fair assessments.

So, to get you started, here are some essential KPIs to consider:

| Quality KPIs | Defect rate, First pass yield |

| Delivery KPIs | On-time delivery rate, Lead time adherence, Order fulfillment accuracy |

| Cost KPIs | Price competitiveness, Cost variance, Value for money |

| Capacity KPIs | The supplier’s ability to handle current and additional workloads, as well as scalability and adaptability |

The key here is relevance. It’s best to focus on the KPIs that align with your needs and objectives.

For example, if your customers expect fast delivery from you, your suppliers need to support this priority.

Therefore, tracking metrics like lead times or order fulfillment accuracy becomes crucial.

Parisa Sadrzadeh, VP of DoorDash, explains delivery speed is often the deciding factor when customers choose between brands:

Illustration: Veridion / Quote: Shopify

And suppliers have a vital role in your ability to deliver on time and meet your customers’ expectations.

Additionally, your targets and definitions of success within these metrics may also vary depending on your industry.

Rob Ruffin, Expert Vice President at Bain & Company, a top management consulting firm, gives an example:

“For instance, success on the speed dimension in retail might be same-day delivery where an industrial manufacturer might outperform peers with lead-times measured in days.”

The key takeaway?

Take the time to thoroughly think through your goals, needs, and measures of success before you outline specific KPIs.

By doing so, you can tailor your supplier assessments to focus on the metrics that truly matter, ensuring relevant, actionable results.

Despite its many benefits, supplier capability assessment comes with several challenges.

Let’s break down some of the most common ones.

One significant obstacle is the potential for subjectivity and bias.

Some evaluation metrics may rely on an auditor’s subjective judgment, which can inadvertently introduce favoritism toward certain suppliers.

This undermines the integrity of the process, increasing the likelihood of selecting less qualified vendors.

And the potential consequences?

Serious quality issues.

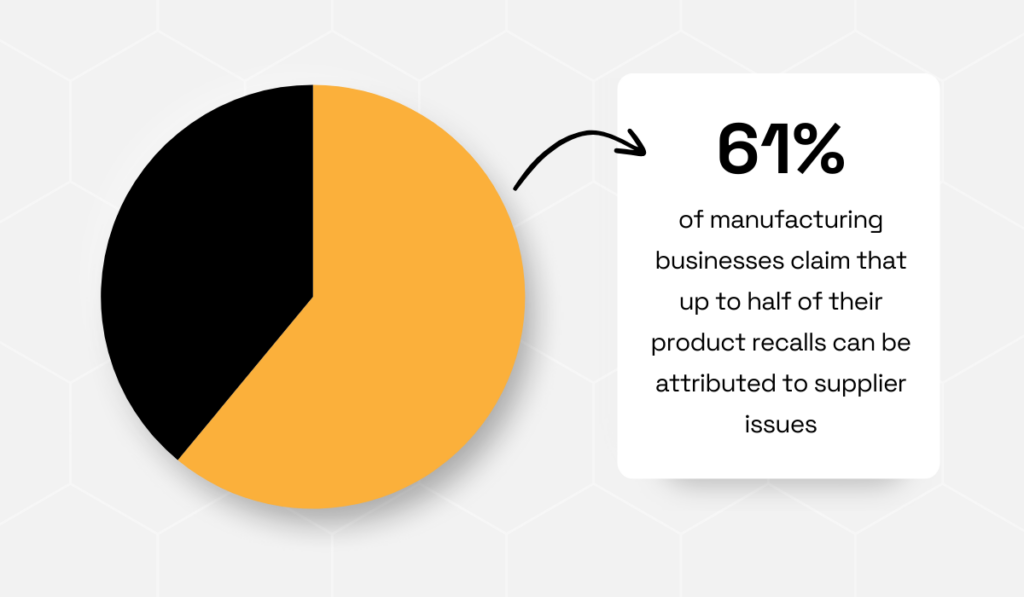

Remember those costly product recalls we mentioned earlier?

The same Hexagon survey reveals that supplier issues are responsible for up to half of them, according to 61% of manufacturing businesses.

Illustration: Veridion / Data: ETQ

So, essentially, if your SCAs aren’t as objective as possible, you’re gambling with your product quality—and your reputation.

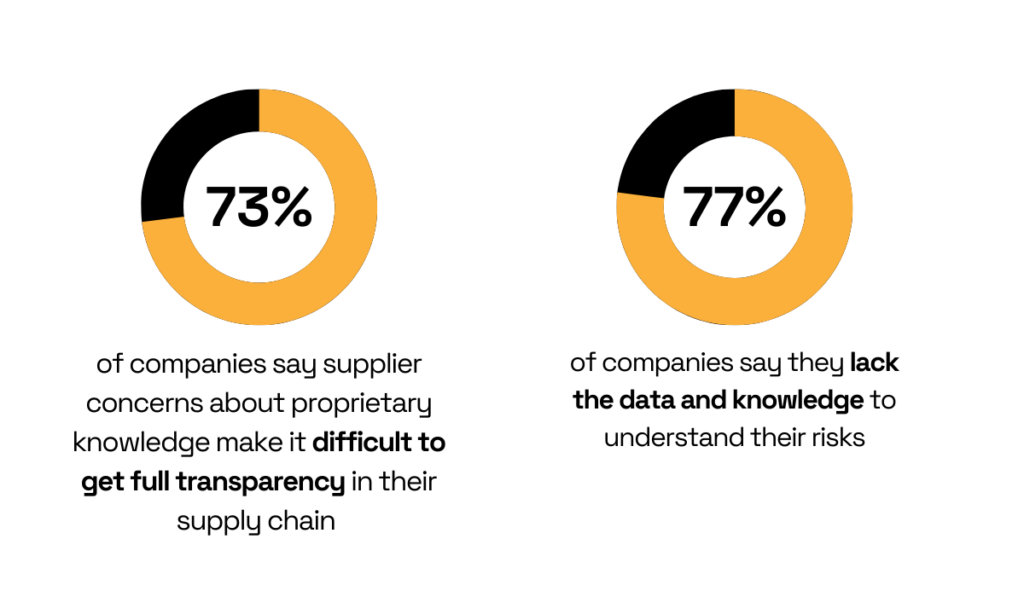

Another big problem is the availability of accurate supplier data.

Sometimes, suppliers may withhold information due to concerns about proprietary knowledge or intellectual property, in turn hindering the entire evaluation process.

In fact, the WTW 2023 survey reports that 73% of procurement professionals face supply chain transparency issues for these very reasons.

This lack of visibility likely contributes to the 77% who admit they lack the data and insights needed to fully understand their risks.

Illustration: Veridion / Data: WTW

After all, without reliable data, how can you make informed decisions?

You can’t. And that’s a problem.

Finally, when conducting SCAs, you have to consider the dynamic nature of businesses.

As Tom Thimot, CEO of Supply Wisdom, a risk intelligence platform, says, businesses are constantly evolving:

Illustration: Veridion / Quote: Supply & Demand Chain Executive

Suppliers are also in a constant state of flux, and their capability profile can change practically overnight.

This means that an SCA conducted today may quickly become outdated, rendering the entire process ineffective.

The bottom line is this:

Yes, SCAs can be tricky but they’re still essential for ensuring business continuity and long-term success.

Luckily, there are services that can help you overcome these challenges, making the assessment process much more efficient and reliable.

Veridion is our AI-powered supplier data platform that provides access to detailed information about millions upon millions of global suppliers and their products.

By using this service, overcoming common challenges in supplier capability assessment becomes a breeze.

For instance, thanks to our robust data manufacturing process, you don’t have to worry about bias or data inaccuracy anymore.

Source: Veridion

This process prioritizes trustworthy sources and ensures every data attribute undergoes rigorous validation for the highest level of accuracy and reliability.

As such, it completely eliminates the need to rely on anecdotal or incomplete information, reducing subjectivity in your evaluations.

Moreover, Veridion ensures its database stays current, with weekly updates capturing the latest developments in the supplier landscape.

Source: Veridion

As a result, you always have access to the freshest data, enabling you to make well-informed decisions based on real-time insights, no matter how turbulent the market gets.

So, don’t let SCA challenges hold you back.

With Veridion, you can tackle this crucial task with ease, gaining actionable insights that keep your supplier base accountable and performing at its peak.

Hopefully, you now recognize the importance of supplier capability assessments and their role in ensuring disruption-free, compliant, and cost-effective operations.

However, here’s another thing to keep in mind: this process should never be treated solely as an opportunity to scrutinize your suppliers or highlight all their shortcomings.

That’ll only drive a wedge between you, and you’ll likely get little in return, let alone the improvements you’re hoping for.

Instead, focus on collaborating with your suppliers to help them enhance their capabilities through advice, constructive feedback, or by sharing best practices.

That’s a sign of a strong buyer-supplier relationship—one that will pay dividends for years to come.