Top 5 Benefits of Supplier Evaluation

Key Takeaways:

Your supply chain is moving smoothly, and then, out of nowhere, a supplier hits financial trouble or fails to meet compliance standards.

Suddenly, your operations are at risk.

This is a scenario you want to avoid at all costs, right?

Enter supplier evaluations.

In this article, we want to show you how just evaluating suppliers can give your organization a real advantage and protect you from unwelcome surprises.

Let’s get started.

Supplier risks can evolve quickly and unpredictably—one day it’s financial instability, the next it’s a compliance issue or delivery delays.

Without regular supplier evaluations, these risks can catch you by surprise, potentially disrupting your entire supply chain.

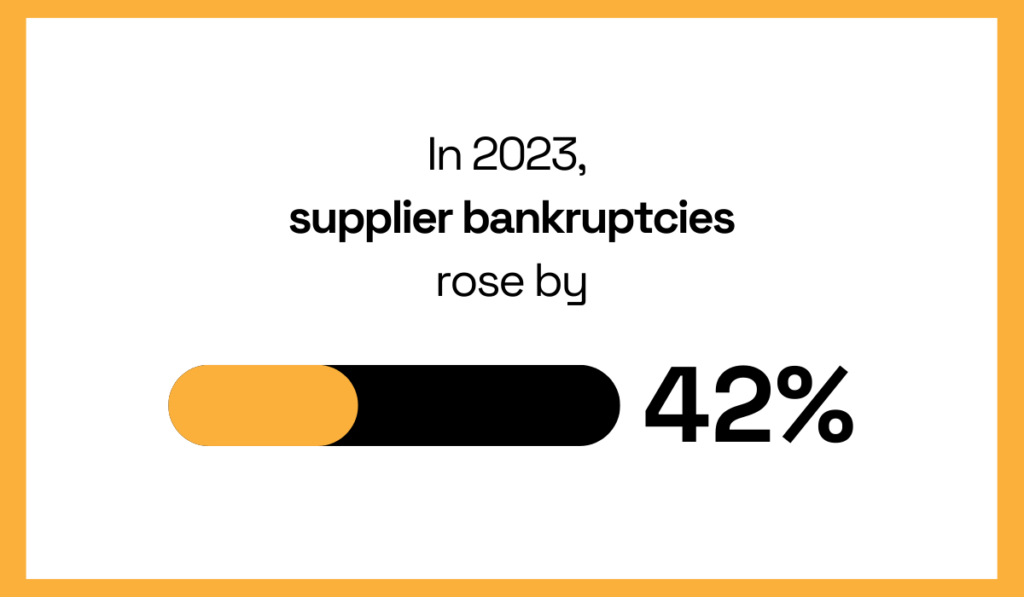

For example, a 2024 Sphera survey reports a 42% increase in supplier bankruptcies, highlighting how quickly a supplier’s financial health can deteriorate.

Illustration: Veridion / Data: Sphera

Now, imagine working with a supplier that looks stable on paper, but their financial situation is declining.

They’re falling behind on payments, and their production is slowing down.

If you don’t conduct regular evaluations, you might not catch these signs until the supplier’s problems start impacting your orders.

However, by reviewing their financial health and performance as part of an ongoing evaluation process, you can identify the warning signs early.

This gives you the chance to take some measures—such as diversifying your supplier base or renegotiating terms—to mitigate potential disruptions.

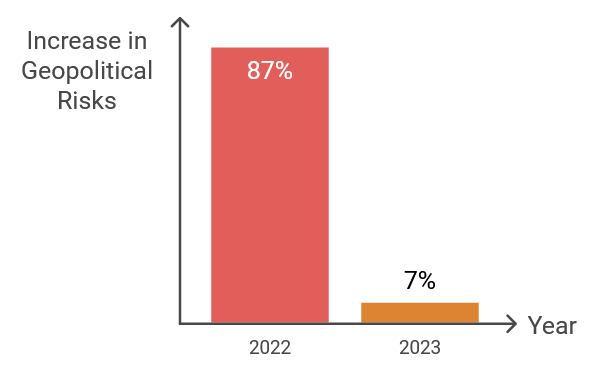

The same Sphera report reveals that geopolitical risks increased by 87% in 2022, with a further 7% rise in 2023.

Illustration: Veridion / Data: Sphera

Tracking these risks manually can be overwhelming, especially with the complexity and scale of today’s global supply chains.

This is where advanced technologies like Veridion come in.

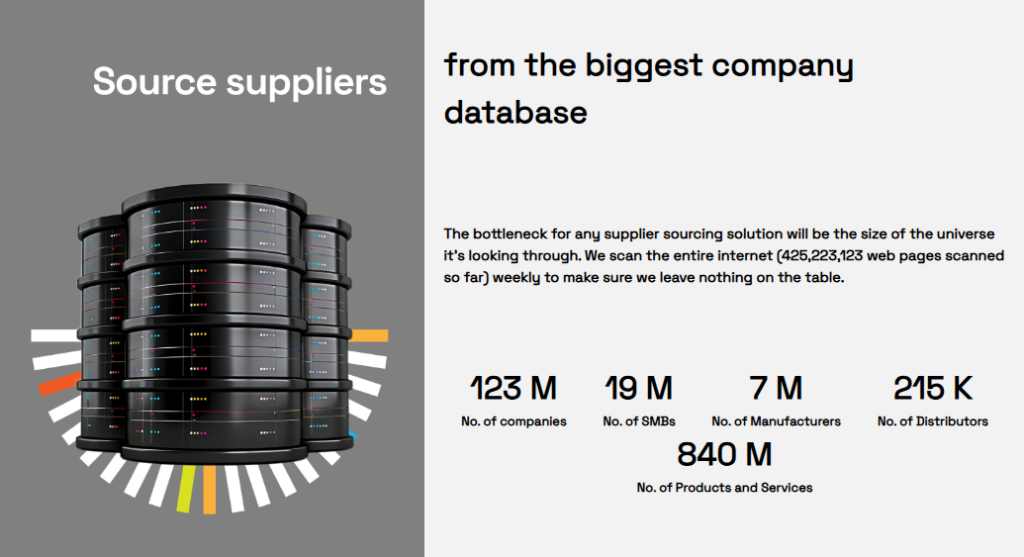

Veridion is one of the largest supplier data platforms, providing comprehensive information on over 120 million companies worldwide—from firmographic data to financial stability information and suppliers’ ESG compliance.

Source: Veridion

Veridion continuously monitors vast amounts of data, weekly updating supplier profiles and alerting you to potential risks, such as financial instability, compliance issues, or even environmental concerns.

Source: Veridion

For example, if a supplier starts falling short of ESG targets or gets flagged for legal disputes, Veridion can alert you immediately.

This will enable you to stay proactive and avoid being caught off guard.

The bottom line is, supplier evaluations do more than just help you respond to risks.

They help you identify and prevent them from affecting your supply chain in the first place.

Wouldn’t you agree this deserves more attention?

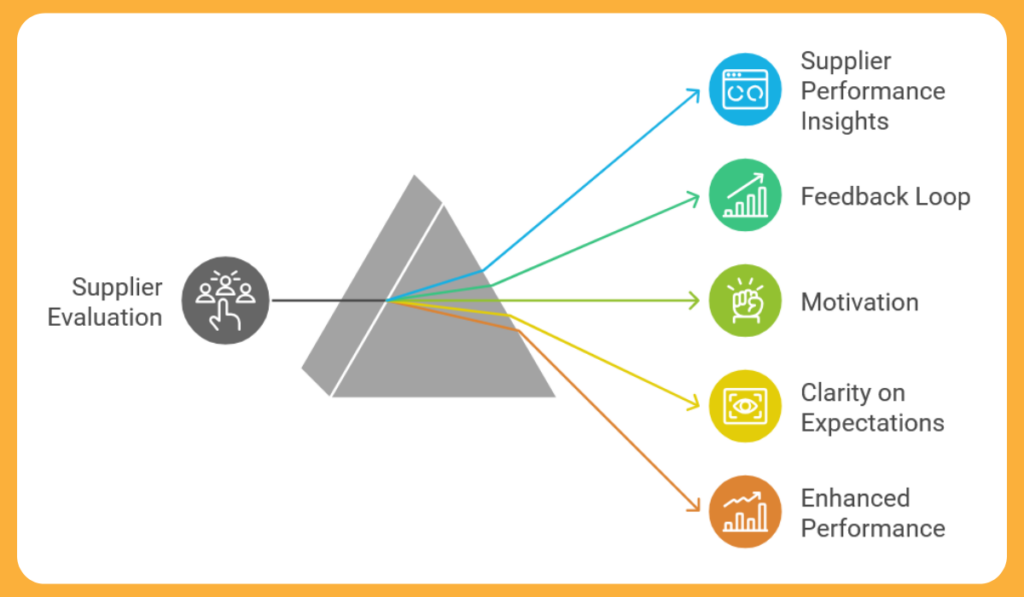

When done strategically, supplier evaluation isn’t just a tool for supplier risk management.

It’s also an opportunity for both the company and suppliers to grow together.

This is because regular evaluations provide businesses with deep insights into how their suppliers perform and help create pathways for improvement.

But why is this such a crucial benefit?

Because suppliers often don’t know where they stand unless you provide them with clear feedback.

Source: Veridion

Supplier evaluations highlight both strengths and areas where they need to improve, giving suppliers the knowledge they need to enhance their performance.

This feedback loop not only motivates suppliers, though.

It also helps them understand what’s important to your company—whether that’s improving quality, meeting deadlines, or adapting to new market needs.

And when suppliers have clarity on these expectations, they are better equipped to meet them, which leads to higher performance over time.

For example, Unilever, which places a strong emphasis on sustainability, works closely with its suppliers to meet ambitious goals like reducing environmental impact and waste.

To support this, Unilever partnered with TELUS Agriculture & Consumer Goods to implement a supplier self-assessment tool based on their Sustainable Agriculture Code.

This tool allows suppliers to measure their own performance against Unilever’s sustainability goals, highlighting both successes and areas for improvement.

Andrea Granier, Global Sustainability Procurement Manager at Unilever, says it best:

Illustration: Veridion / Quote: TELUS

What’s the outcome?

With data from over 230 key suppliers, Unilever is able to track performance trends and identify opportunities to collaborate with suppliers on solving challenges.

Suppliers benefit from clearer expectations, which drives their own improvements in operations and sustainability practices.

This creates a win-win situation: suppliers grow stronger, more capable, and more aligned with Unilever’s goals, while Unilever builds a more resilient, efficient, and sustainable supply chain.

In short, supplier evaluations do much more than just weeding out bad apples.

Rather, they empower every supplier to perform at their best.

At its core, supplier evaluation is essential for ensuring that suppliers meet the quality standards your company expects.

These standards help prevent costly mistakes, such as product defects, returns, or even damaged customer trust.

When evaluating suppliers, companies aren’t just reviewing the suppliers themselves—they’re also assessing the quality of the products they provide.

This can include steps like inspecting goods to ensure they align with agreed-upon quality and commercial parameters.

As Bronwyn Julie, QA Specialist at Cape Bio Pharms (Pty) Ltd, explains, sometimes evaluations require inspections directly at the supplier’s site to verify product quality in person.

Illustration: Veridion / Quote: LinkedIn

But what happens when companies neglect to evaluate suppliers’ quality consistently?

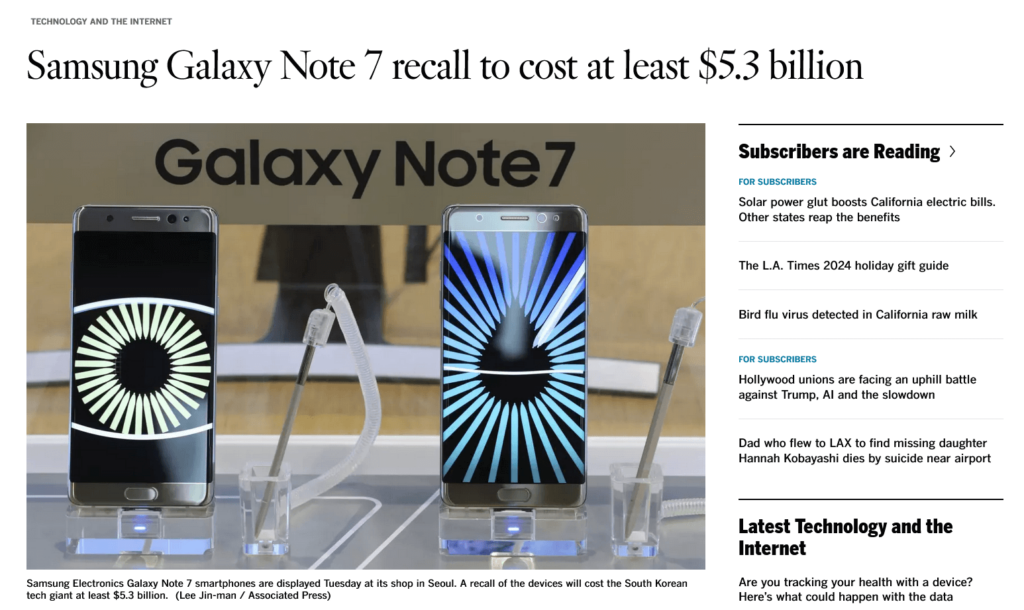

Remember the 2016 Samsung Galaxy Note 7 incident.

The device—which was meant to be a cutting-edge smartphone—instead became infamous for battery failures that led to overheating and even fires.

Investigations revealed that Samsung sourced batteries from two suppliers, one of which provided batteries that were too large, leading to short-circuiting, while the other rushed production, resulting in critical defects.

The consequences were bad: Samsung had to recall millions of devices, costing the company over $5 billion.

Source: LA Times

Beyond the financial impact, it damaged Samsung’s brand reputation and consumer trust.

This crisis could have been avoided with stricter supplier evaluation and quality assurance measures.

It’s a powerful reminder of what’s at stake when suppliers aren’t held to the highest standards.

On the other hand, Jaguar Land Rover (JLR) provides a positive example of how supplier evaluation can ensure quality assurance.

JLR doesn’t only evaluate its direct suppliers.

It also requires them to evaluate their own suppliers to ensure that every link in the supply chain maintains high-quality standards.

According to JLR’s Global Supplier Manual, part of which you can see below, suppliers are expected to have robust quality management systems and actively monitor their sub-suppliers’ performance.

Source: SMR Automotive

So, if issues do arise, suppliers are required to work with their sub-suppliers to resolve them, minimizing risk further down the line.

By insisting on this level of accountability, JLR prevents defects from creeping into their supply chain.

Their commitment to quality has translated into solid financial performance, as highlighted by Richard Molyneux, Chief Financial Officer, who reported a record £2.3 billion free cash flow in 2024.

“The financial year ending 31 March 2024 saw many of the challenges we faced in previous years ease. Improved production and sustained global demand for our products led to us achieving our highest ever annual revenue and highest profit since FY14/15. Our record free cash flow of £2.3 billion allowed us to reduce our debt by repaying maturing debt and the completion of a $400 million tender for three of our bonds.”

The takeaway?

Supplier evaluation is essential for quality assurance.

It safeguards your products from defects, maintains customer trust, and reinforces your brand’s reliability in the market.

Neglecting this process can lead to disastrous consequences, like Samsung’s Galaxy Note 7 debacle, while adopting best practices can set your company up for long-term success and stability.

Which example would you follow?

Supplier evaluations are an effective way to cut unnecessary costs in your supply chain.

Just think about the $5 billion Samsung lost because they didn’t properly evaluate their supplier’s product!

That was undoubtedly an unnecessary cost for them.

However, if you thoroughly assess your suppliers, you can identify those who offer the best balance of cost, quality, and service.

An essential part of this process is evaluating the total cost of ownership (TCO).

This includes not only the purchase price but also hidden costs like delivery, maintenance, and potential risks from delayed or defective products.

As Ts. Saw Chang Long, National Sales Manager at Sika, points out, many companies often disregard TCO—despite it being a key factor for reducing costs:

Illustration: Veridion / Quote: LinkedIn

To put this into perspective, imagine a manufacturing company evaluating two suppliers for a key raw material.

Supplier A offers a lower upfront price but has inconsistent delivery times, which causes production delays and leads to overtime costs.

Supplier B, on the other hand, charges slightly more but delivers reliably on time and provides higher-quality materials.

By evaluating both options and calculating the TCO, the company can see that Supplier B is ultimately more cost-effective.

The quality factor is self-explanatory.

Plus, fewer delays mean fewer operational disruptions, which lead to significant savings over time.

Supplier evaluations also reveal opportunities for negotiation, as Elizabeth Mesa, Global Real Estate Advisor at ONE Sotheby’s International Realty, summarizes.

Illustration: Veridion / Quote: LinkedIn

When evaluations show that a supplier consistently meets or exceeds performance expectations, you might be able to negotiate better terms, such as volume discounts or extended payment terms.

On the other hand, if an evaluation discovers inefficiencies or quality issues, you can switch to more efficient suppliers, reducing long-term costs.

Finally, supplier evaluations help uncover wasteful practices.

Whether it’s excessive packaging, inefficient logistics, or outdated processes, identifying these issues can lead to cost-saving opportunities.

In a nutshell, supplier evaluations bring many opportunities for cost savings that simply aren’t visible without evaluating suppliers and their performance.

In addition to assessing suppliers and their risks, regular evaluations force you to revisit your own business needs.

As market conditions, technologies, and priorities evolve, supplier evaluations ensure your supply chain remains aligned with your company’s goals.

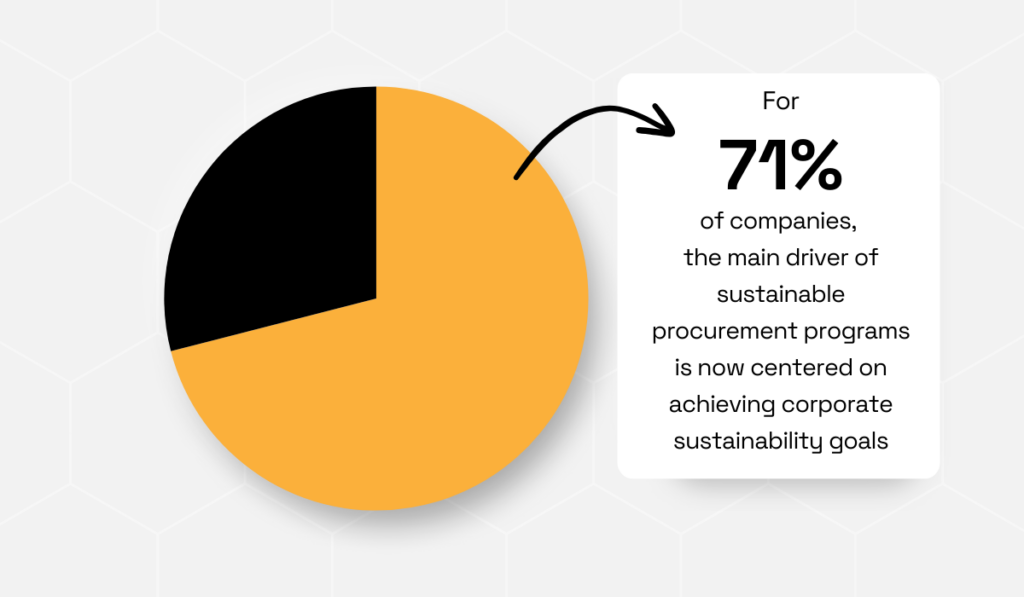

This is especially crucial for businesses transitioning to new operational models or focusing on sustainability—a priority for more than 70% of companies today.

Illustration: Veridion / Data: EcoVadis

Let’s say your company also decides to shift toward sustainable manufacturing practices.

Tom Raftery, host of Sustainability and Climate Talks, captures the importance of aligning suppliers with your new sustainability goals in his conversation with Anders Lillevik, CEO and founder of Focal Point:

Illustration: Veridion / Quote: Tom Raftery: Sustainability & Climate Talks on YouTube

Supplier evaluations provide the data to answer this question.

By assessing supplier capabilities, a company can identify vendors that not only meet cost criteria but also align with sustainability objectives—like reducing carbon footprints or using eco-friendly materials.

However, supplier evaluations do more than just ensure sustainability alignment.

They also help ensure that your supply chain is in sync with other business needs, such as innovation, cost-efficiency, and new product development.

This broader focus ensures your business remains competitive as market conditions shift.

Source: Veridion

Moreover, regular supplier reviews are essential for preparing your business for growth.

For instance, if your company anticipates a 30% increase in demand over the next year, supplier evaluations can show you which suppliers can scale production without sacrificing quality or delivery timelines.

At the same time, these evaluations will identify suppliers who might struggle with this increased demand, giving you time to find alternatives in time.

Ultimately, supplier evaluations allow your business to stay agile.

They help ensure that your supply chain evolves alongside your company—whether by adapting to sustainability goals, driving innovation, or scaling for growth.

This ongoing alignment ensures that your operations remain efficient, forward-thinking, and responsive to market shifts.

Supplier evaluation is a powerful tool that helps protect quality, reduce costs, and keep your business aligned with changing goals.

By ensuring your suppliers consistently meet your standards, it helps you avoid costly mistakes and disruptions.

It also opens up opportunities for cost savings by identifying suppliers who deliver the best overall value, not just the lowest price.

Most importantly, regular evaluations keep your supply chain flexible, so you can adapt to new priorities—whether that’s sustainability goals or other market shifts.

So, why wait any longer to reap these benefits?