6 Key Steps of the Supplier Evaluation Process

Whether you’re vetting new suppliers or assessing existing ones, one thing is certain: you can’t take chances.

A weak link in your supply chain can slow down or completely stop operations, drive up costs, hurt your reputation, and seriously impact your bottom line.

That’s why supplier evaluation is non-negotiable.

But how do you do it right?

We’ll walk you through 6 key steps of the effective supplier evaluation process.

Every step is designed to help procurement teams like yours build a stronger, more resilient supply chain, improve supplier performance, and optimize costs.

Ready? Let’s get started.

You can’t evaluate anything if there are no criteria set.

So, the first, and arguably the hardest, step is to establish evaluation criteria.

Why the hardest?

Because there are countless factors to consider, both qualitative and quantitative, and there’s no universal benchmark.

Every company is unique, and the factors that matter most will vary depending on your industry, priorities, and goals.

For example:

This makes defining your evaluation criteria as complex as it is important.

Here’s a quick breakdown of some of the most common criteria used in supplier evaluations:

| Cost | Cost is usually the first thing organizations look at, but remember, it isn’t just the price on the invoice. It’s the total cost of ownership, including initial price, ongoing costs, and long-term value. |

| Quality | No matter how affordable a product is, if it doesn’t meet quality standards, it’s not worth it. |

| Reliability | Can the supplier deliver what they promise, when they promise? Reliability impacts timelines, customer satisfaction, and your bottom line. |

| Compliance | Especially important in regulated industries. Does the supplier meet all legal, ethical, and industry-specific requirements? |

These are just a few examples. There are many more you could consider, from innovation potential to geographical proximity.

But ultimately, it all comes down to what matters most for your organization.

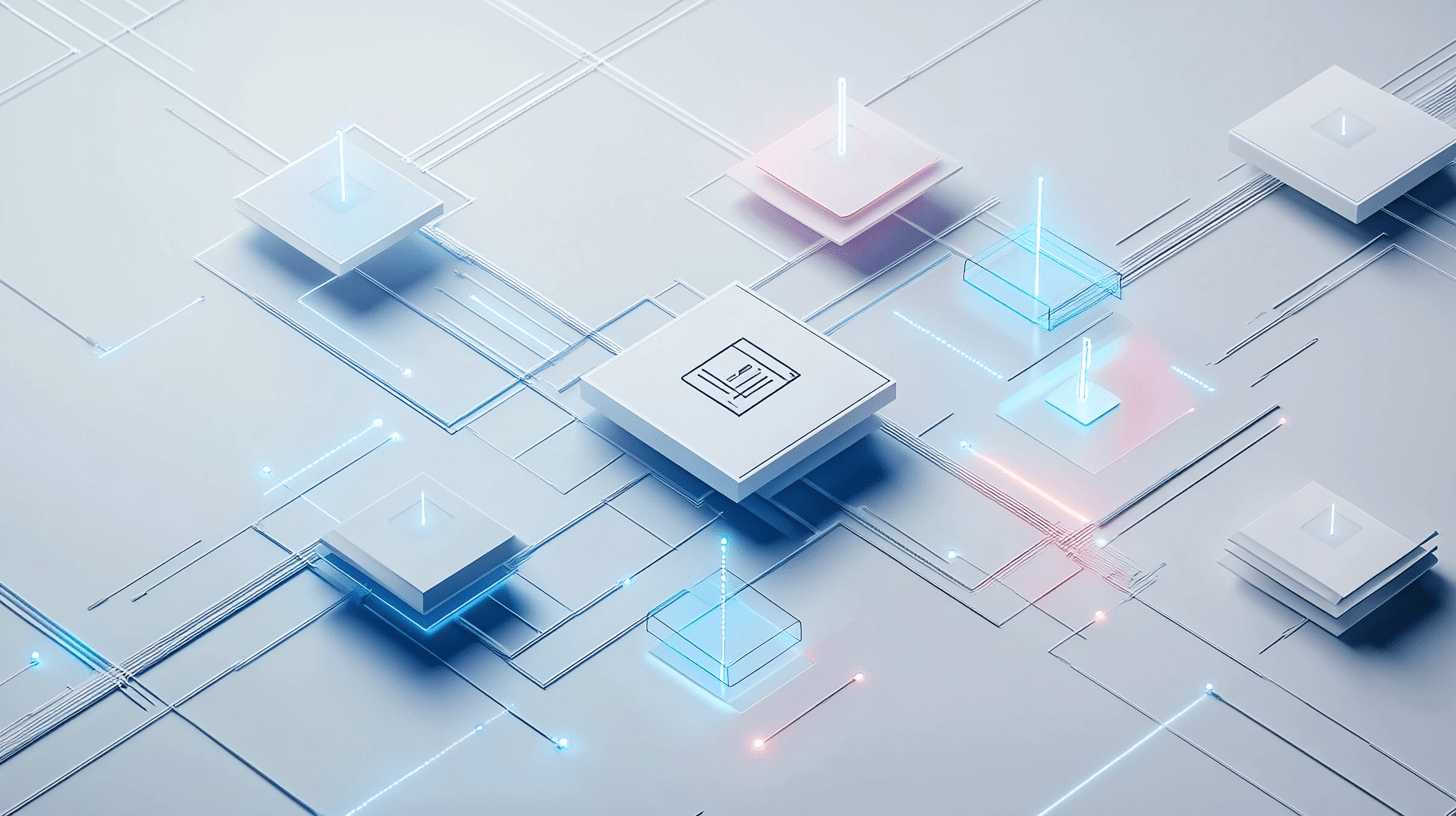

If you’re struggling to define criteria, Carter’s 10C framework is a great place to start.

Source: Veridion

It’s not gospel, but it provides a solid foundation for evaluating suppliers comprehensively.

You can learn more about it in our other article on the topic.

Now, as much as we’d love to hand you a perfect list of criteria, you already know that’s simply not possible.

But what we can do is share something that will make a day-and-night difference in the quality of your evaluations.

It’s the advice to involve your team.

Procurement isn’t a solo game.

So, you’ll want to get input from stakeholders across departments to ensure the criteria truly reflect what your organization really needs.

The production team, finance, compliance, and even customer service might all have different priorities, and combining their input will give you a more complete picture.

Once your list is locked in, make it your North Star.

It’ll guide every evaluation, helping you compare suppliers objectively and avoid gut-driven decisions that can backfire later.

This step isn’t particularly glamorous, but it’s foundational.

Not all suppliers are created equal, and treating them like they are is a surefire way to waste time, resources, and opportunities.

That’s why the next step in the supplier evaluation process is segmenting them.

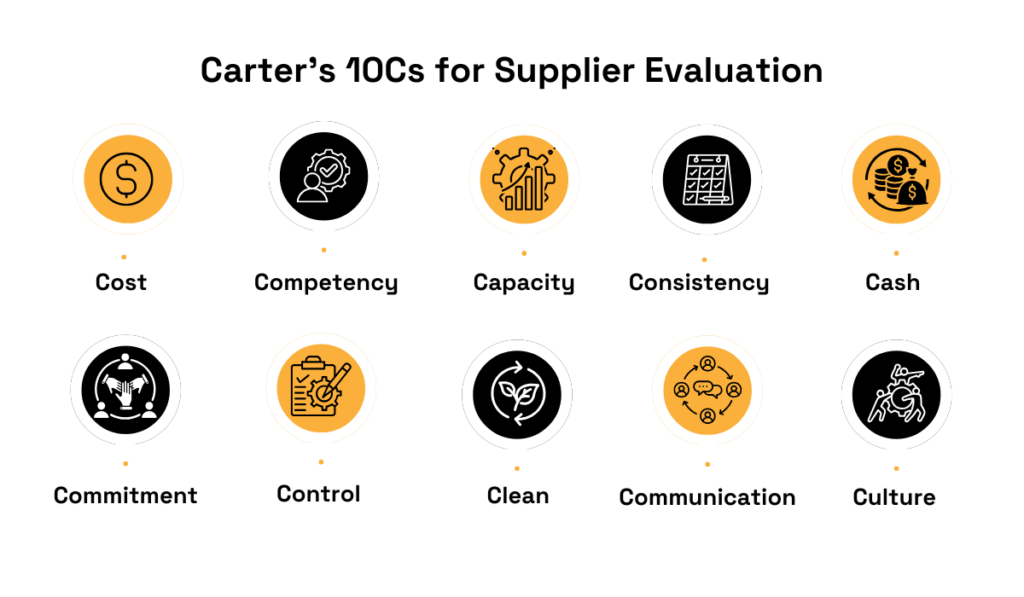

Supplier segmentation is the process of categorizing suppliers into distinct groups based on specific criteria.

Source: Graphite Connect

This helps you focus your time and resources on the most critical supplier relationships, which leads to better management, reduced risk, and increased supply chain efficiency.

When it comes to segmentation, you have plenty of options to choose from.

You can segment suppliers based on strategic importance, categorize them by spend volume, or sort them by risk level.

However, what you’ll often see companies do is rely on one of the two most popular, time-tested segmentation methods:

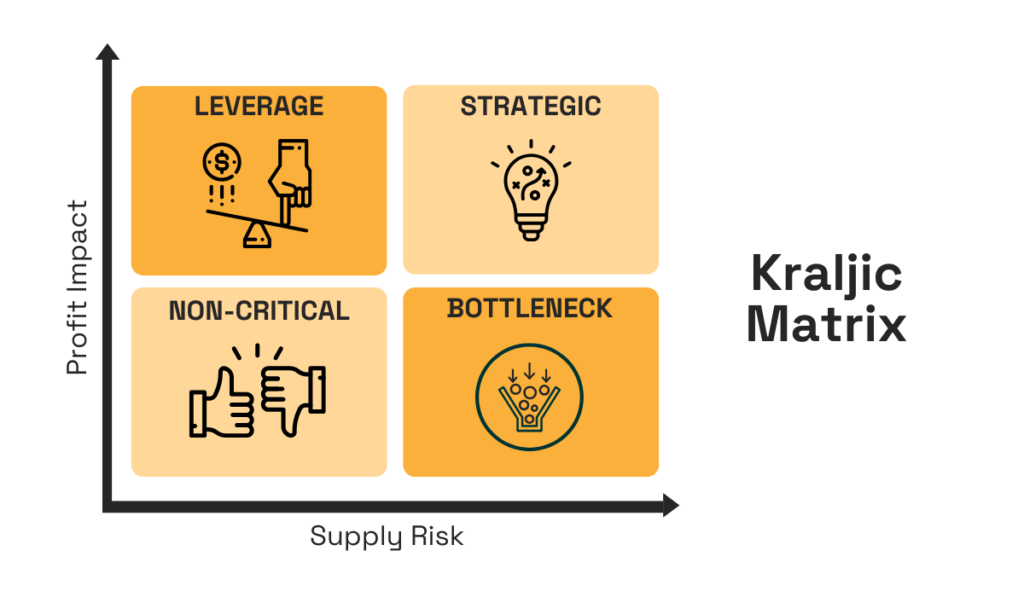

Let’s start with the Kraljic Matrix, also known as the supplier segmentation matrix.

Developed by Peter Kraljic, this method categorizes suppliers into four quadrants based on two dimensions: supply risk and profit impact.

Source: Veridion

Using this matrix, you can quickly sort suppliers and develop tailored strategies for each group.

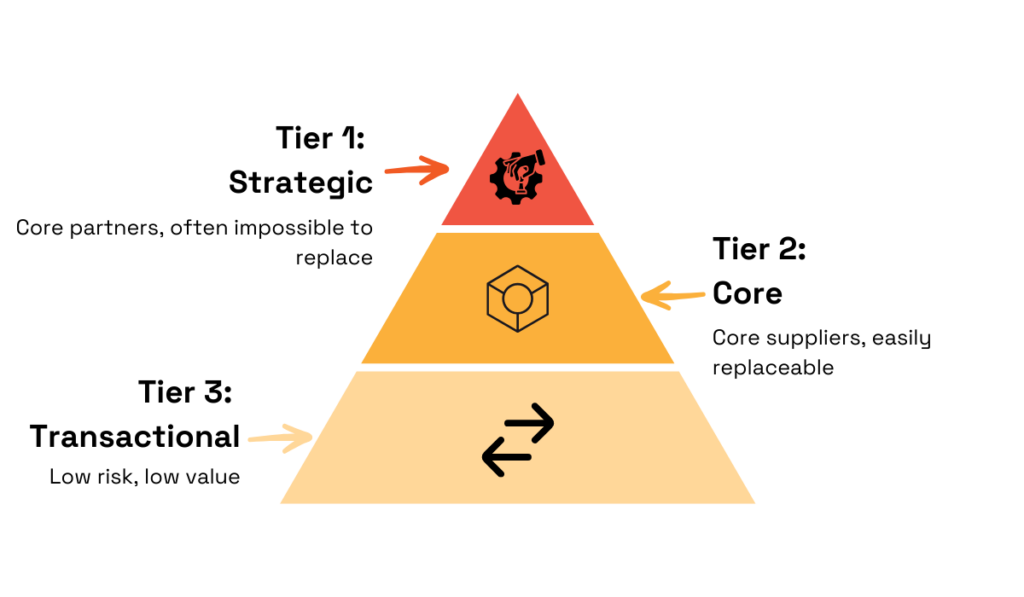

The Pyramid Approach is another widely used method for supplier segmentation and it’s particularly effective for medium and smaller-sized companies where you aren’t managing thousands of suppliers and don’t need complex segmentation.

It’s simple, clear, and easy to implement, making it a great option for teams looking to prioritize without overcomplicating the process.

This method organizes suppliers into tiers, usually three or four, based on their importance, the company’s needs, and supply chain complexity.

Here’s a quick breakdown of the tiers:

Source: Veridion

Ultimately, it doesn’t matter whether you choose the Kraljic Matrix, the Pyramid Approach, or any other segmentation method, the goal is always the same: to categorize your suppliers in a way that maximizes efficiency, minimizes risk, and fosters stronger, more reliable relationships.

And while supplier segmentation is most often discussed in the context of evaluating existing suppliers, it can also play a key role when vetting new ones.

Understanding where a potential supplier might fit into the supplier category can help you make better decisions upfront, ensuring you focus on building strong relationships with the right partners from the start.

Supplier evaluations are only as good as the data they’re based on and even small gaps in data can lead to biased or incomplete assessments.

Having the right data is everything.

Without it, you’re relying on assumptions, and assumptions are a dangerous game in procurement.

Gathering supplier data means collecting information about whether a supplier can meet your standards and expectations.

This includes past performance metrics, certifications, financial stability, and anything else that clearly shows their capabilities.

The goal is to build a complete, unbiased picture of each supplier so you can evaluate them with confidence.

Why is this so important?

Imagine deciding on a supplier without knowing their financial history, only to discover later they’re on shaky ground, or missing critical compliance issues that could lead to regulatory fines.

These oversights could put your entire supply chain at risk.

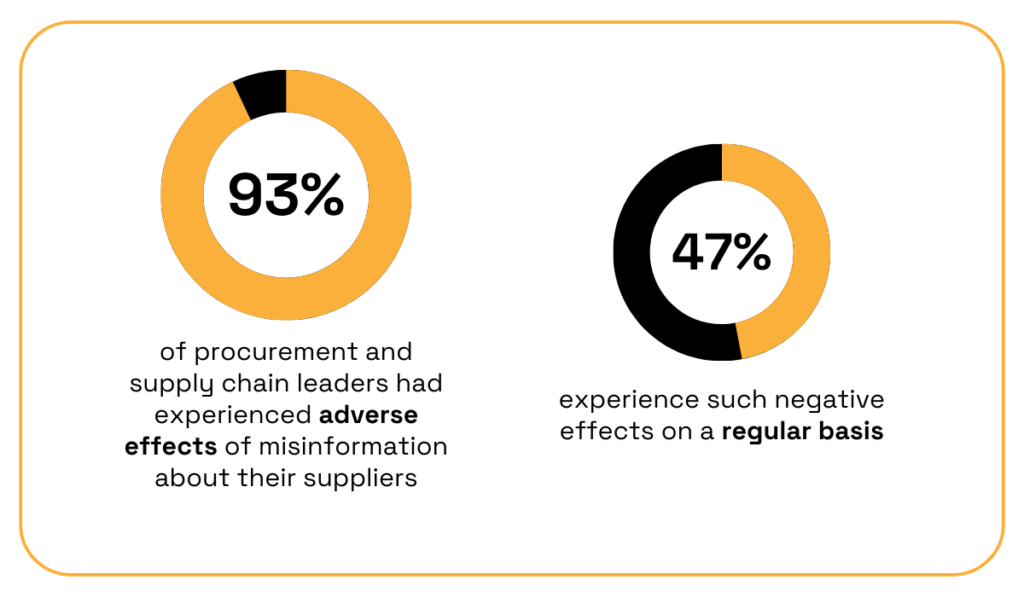

According to a 2020 Supplier Information Study, 93% of procurement leaders reported adverse effects from misinformation about suppliers, and nearly half said they experienced these issues regularly.

Illustration: Veridion / Data: TealBook

But here’s the challenge: Gathering this data is often a slow, costly, and frustrating process for most companies.

This happens because they either:

Fortunately, it doesn’t have to be this way.

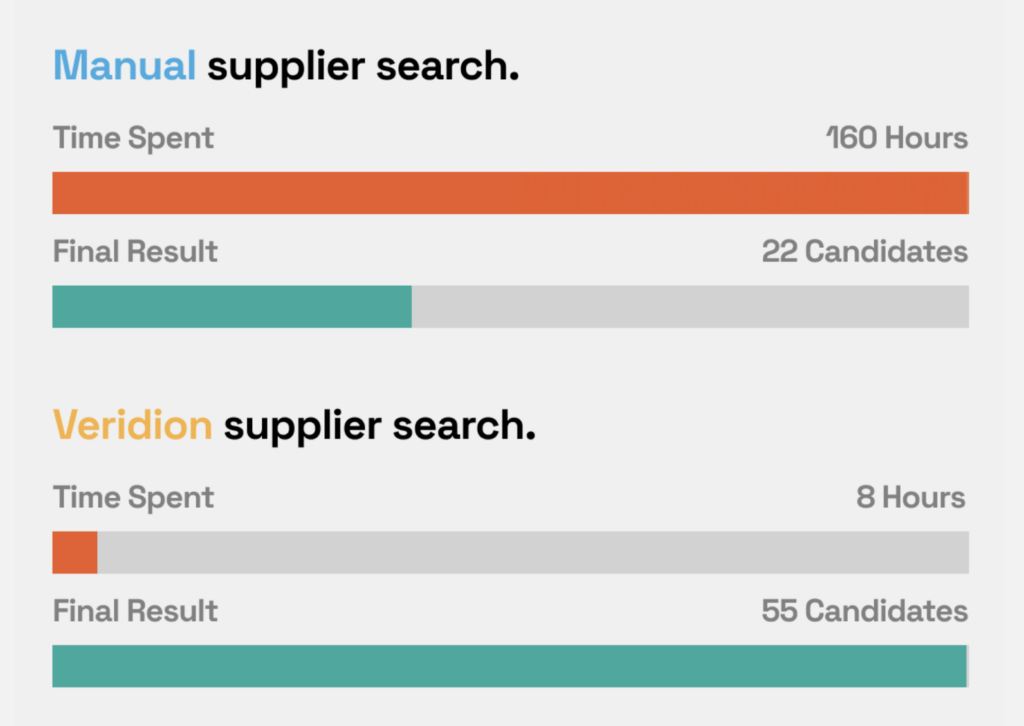

With Veridion, what used to take months now takes minutes.

Source: Veridion

Veridion is an AI-powered data platform that scans billions of websites weekly, collecting fresh, reliable supplier information from around the globe to provide comprehensive, accurate, and up-to-date supplier profiles.

Source: Veridion

Realizing the challenges procurement teams face with fragmented, slow, and often unreliable data, we built Veridion to serve as a single source of truth and a supplier sourcing enabler.

Our platform profiles over 123 million suppliers across 246 countries, covering more than 750 million products and services.

By combining digital and legal data, we deliver unmatched precision and reliability, offering over 80 critical data points (and counting), from financial health and regulatory compliance to corporate structures and ESG practices.

Source: Veridion

What does this mean for you?

Well, imagine vetting a new supplier.

With Veridion, you can quickly access detailed profiles that include financial stability, compliance records, corporate structures, and even ESG practices.

Instead of spending weeks piecing this information together manually, you gain real-time insights in minutes.

Source: Veridiondata on YouTube

And it’s not just about new suppliers.

Veridion also helps you enrich existing supplier profiles with the latest data, ensuring your decisions are based on complete and accurate information.

All in all, whether you choose to use Veridion or rely on other methods, make sure your data is as complete and unbiased as possible.

Accurate data isn’t just the foundation of supplier evaluations, it’s the backbone of every decision that impacts your business.

Get it right, and you’ll set the stage for partnerships that drive value for years to come.

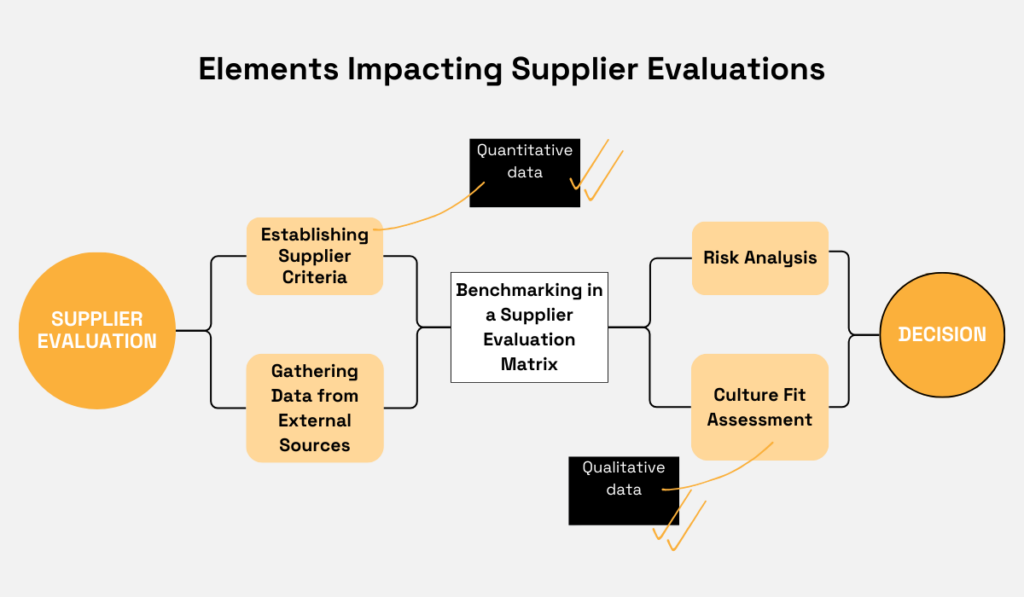

Now that you’ve established your criteria, segmented and prioritized suppliers, and gathered the data you need, it’s time to compare suppliers.

The best way to do that?

By using a supplier evaluation matrix.

It’s a practical tool that allows you to compare suppliers side by side in a clear, structured format.

The matrix consists of two axes: one lists the criteria you’ve established, and the other lists the suppliers you’re evaluating.

Source: Veridion

Each supplier is scored against the criteria, giving you a comprehensive overview of how they stack up against one another.

The beauty of this tool lies in its flexibility. It can be as simple or as complex as your situation requires, allowing you to add as many criteria and suppliers as needed.

There are 3 common matrix types:

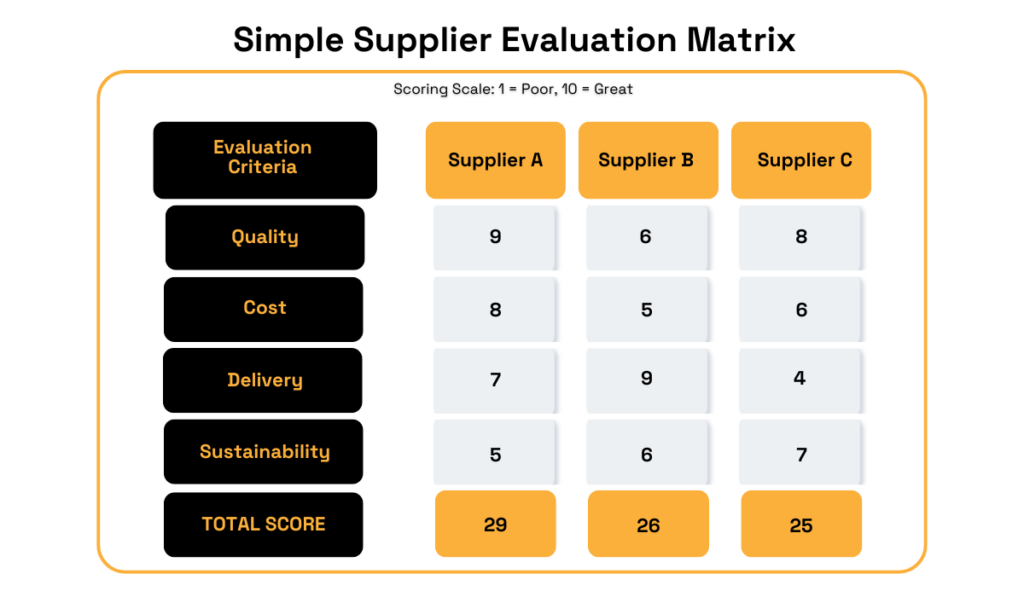

Let’s start with the simplest one.

This is the most straightforward version, designed for quick and easy comparisons.

It typically includes a handful of standard criteria like cost, quality, delivery, and sustainability, and assigns each supplier a score on a scale of 1-5 or 1-10.

These scores are then totaled to provide a clear comparison.

Source: Veridion

However, this simplicity is also its limitation. The simple matrix treats all criteria as equally important, which isn’t always the case.

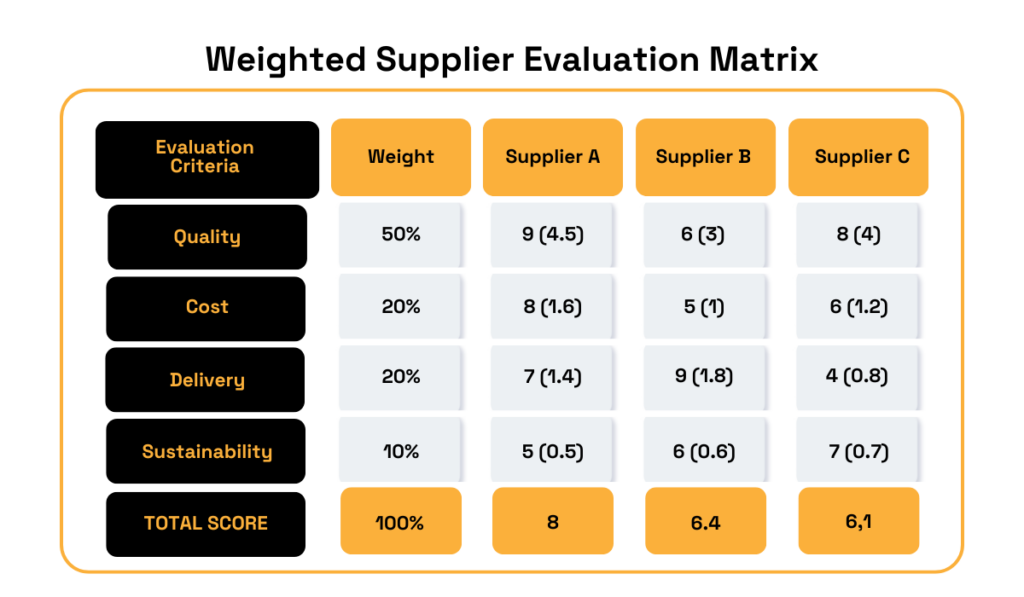

This is where the weighted matrix comes in.

The weighted matrix builds on the simple version by assigning different levels of importance to each criterion.

For instance, sustainability might carry a weight of 10%, quality 50%, and cost 20%.

Each supplier is scored as before, but the final totals are adjusted based on the assigned weights.

Source: Veridion

This ensures that your most critical criteria have the biggest impact on the evaluation.

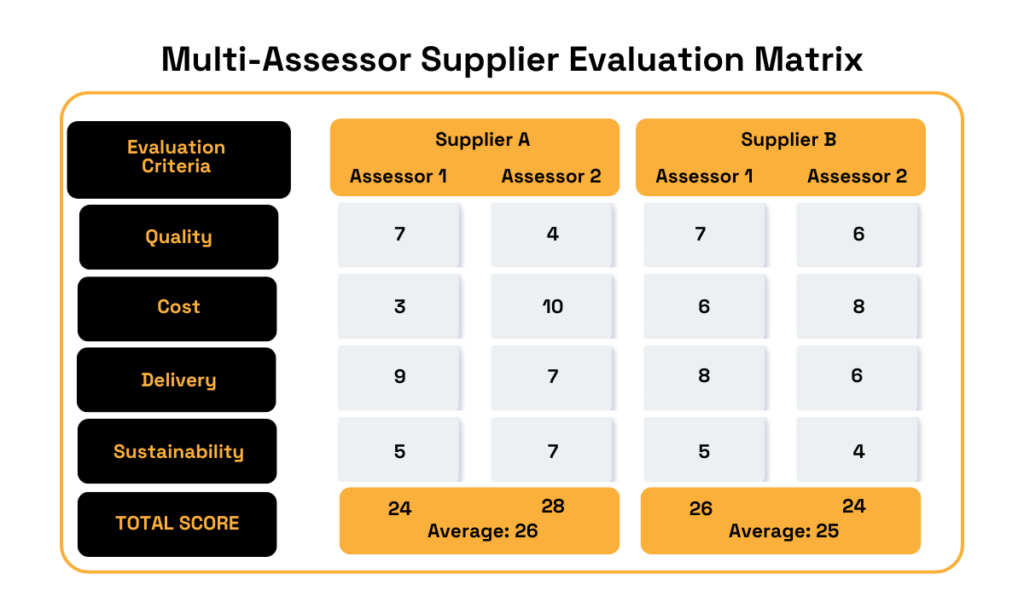

Lastly, there’s the multi-assessor matrix.

This approach involves multiple stakeholders scoring suppliers individually, and their scores are then combined for a more balanced evaluation.

It’s especially useful for large teams or organizations where input from various departments is necessary.

Source: Veridion

By breaking down complex decisions into simple, quantifiable steps, the matrix helps you make informed choices that align with your business goals.

It also provides a record of your evaluation process, which can be useful for justifying decisions or refining your strategy in the future.

You’ve crunched the numbers, compared the results, and are ready to choose your supplier.

Before you grab that shortlist and make a call, hold on for a moment.

The numbers might look neat and convincing, but as any seasoned procurement professional will tell you, there’s more to the story.

While the matrix is a fantastic tool for simplifying comparisons, it’s not the whole picture.

Numbers provide clarity, but to truly understand a supplier’s value, you need to consider the qualitative factors that don’t show up in a score.

Two factors that might not come to mind immediately but are critical to your decision-making process are cultural fit and risk mitigation.

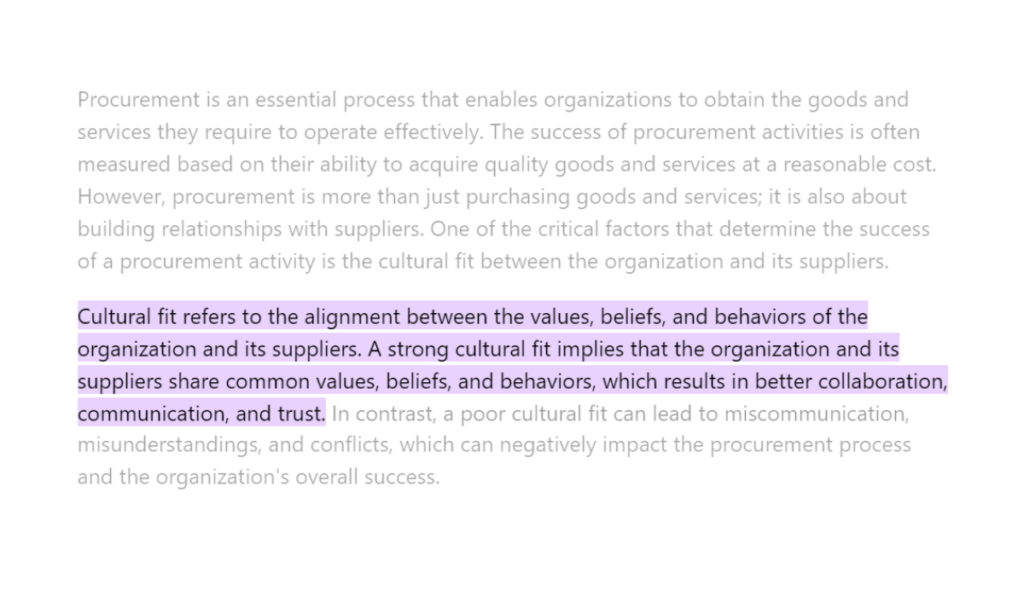

Cultural fit is about alignment, not just on paper but in practice.

Kjell Olander, ITSM Lead at Rexel, defined it perfectly:

Source: LinkedIn

So, does the supplier’s way of doing business align with your organization’s values, priorities, and working style?

A supplier with an impressive score might still struggle to collaborate effectively if their company culture clashes with yours.

Risk mitigation is another key consideration.

Source: Veridion

Examine potential risks associated with each supplier, such as financial stability, geopolitical issues, or reliance on single-source components.

Even a top-performing supplier on paper might pose risks that outweigh their benefits.

Some of them will be accounted for during the data-gathering phase, but now it’s a good time to dig deeper into the matter.

Assessing these risks and planning for contingencies is vital to making a sound decision.

Once you’ve combined the quantitative results from your matrix with qualitative insights, you’re ready to make a well-rounded decision.

This dual approach not only helps you choose the right supplier but also builds confidence in your decision, knowing it’s rooted in both hard data and strategic foresight.

Selecting the right supplier is a big win, but it’s not the end of the story.

Many view supplier evaluation as a one-time task, something to check off the list before signing a contract.

However, that’s a mistake that can cost you dearly down the road.

Because things change.

Suppliers that were reliable yesterday might face new challenges today, from delayed shipments, quality issues, to even financial instability.

Without regular monitoring, you risk discovering these problems too late, when the damage has already been done.

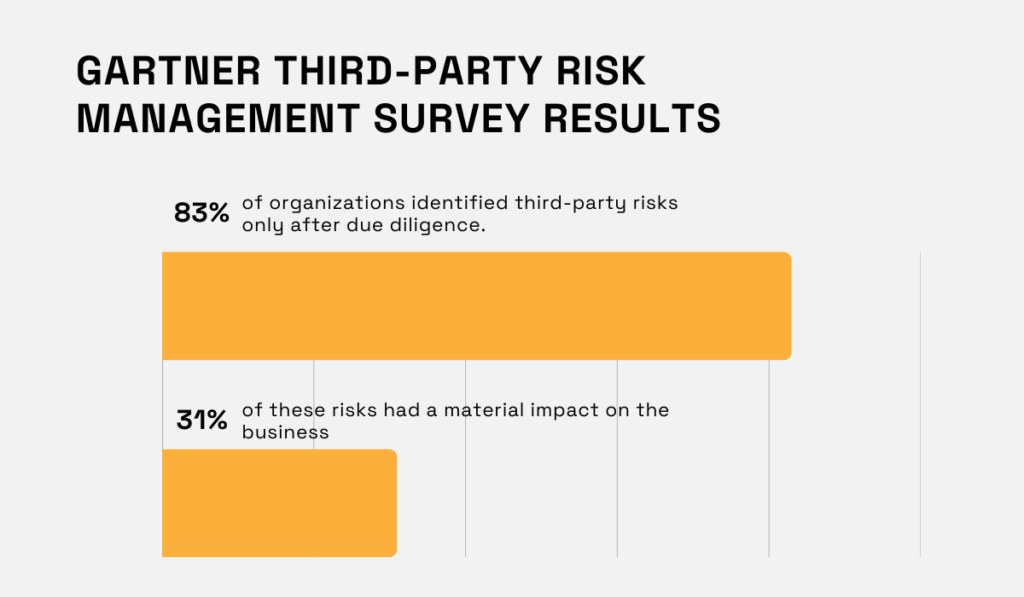

In fact, a Gartner survey found that 83% of organizations identified third-party risks only after conducting due diligence, with 31% of these risks having a material impact on the business.

Illustration: Veridion / Data: Gartner

The key to avoiding such surprises is continuous performance tracking.

This involves setting clear KPIs that align with your priorities and scheduling regular performance reviews to assess how well suppliers are meeting expectations.

These reviews create opportunities to address issues early, recognize successes, and strengthen partnerships.

In a world where things change faster than ever, staying proactive isn’t just a best practice. It’s the only way to ensure your supplier relationships remain a competitive advantage.

There you have it: the supplier evaluation process decoded.

No magic wand is needed, just some clear steps, sharp thinking, and a bit of work.

Now take what you’ve learned, put it into action, and start transforming your supplier relationships.

With the right approach, you’ll not only avoid costly mistakes but also build a supply chain that’s reliable, efficient, and ready for whatever challenges come your way.