Supplier Management: 6 Best Practices to Adopt

Key Takeaways:

Managing suppliers is no small task—especially when you’re responsible for overseeing complex, enterprise-level supply chains.

From ensuring timely deliveries to maintaining quality and cost efficiency, the stakes are high, and missteps can ripple across the organization.

This article is your guide to mastering supplier management.

You’ll discover six best practices, each to strengthen your supplier relationships, improve communication, and minimize supplier-related risks.

Let’s get started!

Managing suppliers isn’t just about placing orders and crossing your fingers.

You’ve got a lot on your plate—delivery timelines, quality control, cost management, and a million other moving parts that need to stay in sync.

Without clear communication, things can easily spiral out of control.

That’s why having reliable communication channels in place is step one in building efficient supplier management.

But how do you make this work in practice?

It starts with choosing the right communication tools that align with your needs and the needs of your suppliers.

Email is great for formal agreements or detailed updates that require documentation.

However, when speed is of the essence—like quick updates or urgent follow-ups—messaging platforms such as WhatsApp or WeChat can offer the responsiveness you need.

Many professionals have shared how these tools have helped them stay on top of supplier communications, including this one on Reddit:

Source: Reddit

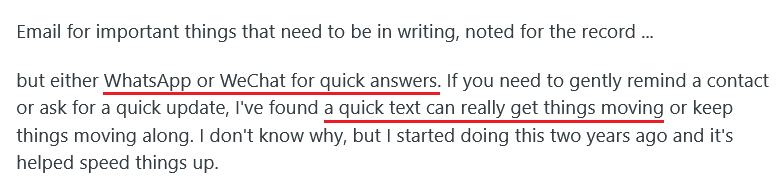

Beyond emails and chat apps, there’s a growing case for adopting more integrated communication tools like Slack.

And if your team, by any chance, already uses Slack internally, why not extend it to your suppliers?

Slack Connect allows you to create shared spaces where you and your suppliers can exchange updates, address issues, and collaborate in real-time.

Source: Inc

According to Slack, users report resolving problems 40% faster, and partners (like suppliers) respond twice as quickly.

Source: Slack

For supply chain management, where time-sensitive decisions are the norm, these numbers carry significant weight.

Take Saks, the premier digital platform for luxury fashion in North America, and the exclusive partner of Saks Fifth Avenue stores.

They’ve integrated Slack with their suppliers to handle everything from inventory to shipping issues, making communication quicker and more efficient.

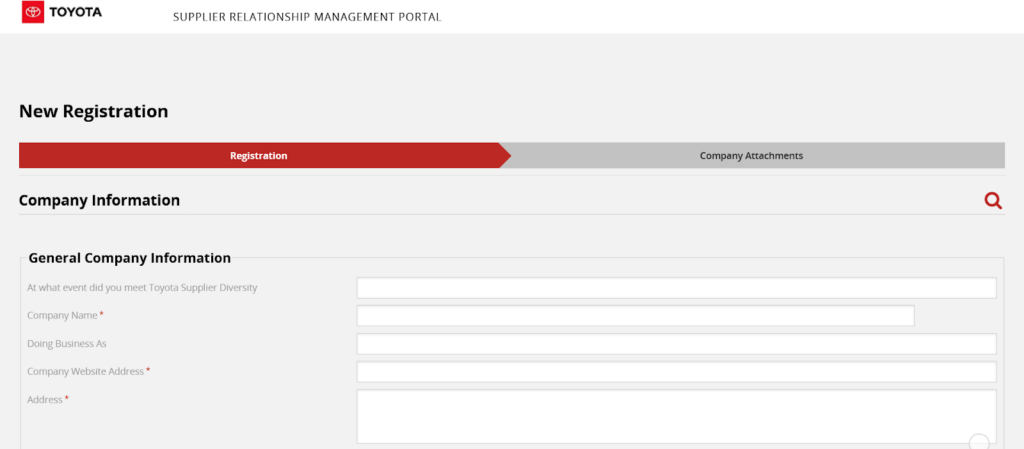

If off-the-shelf tools don’t quite fit your needs, you can take a page from Toyota’s playbook and develop a customized supplier portal.

Source: Toyota

In fact, this system is part of Toyota’s automated “kanban” lean manufacturing approach, which has transformed the way they manage inventory.

With just enough stock to meet demand and tightly coordinated production schedules, Toyota has turned communication into a competitive advantage.

Ultimately, the goal is simple: reduce the friction in communication.

Both sides of the partnership should be able to communicate quickly and easily, ensuring that everyone stays in sync and problems get solved faster.

Messaging platforms or advanced tools like Slack and supplier portals make this happen.

And that’s the first step to better supplier management!

Once you’ve established clear communication, you’re in a stronger position to assess supplier performance and provide constructive feedback.

But for evaluating supplier performance, you first have to set performance metrics.

Why is this so important?

Without KPIs, it’s nearly impossible to evaluate how well suppliers are delivering.

This could lead to misunderstandings, missed deadlines, or a plethora of other costly inefficiencies.

And let’s be honest: it’s hard to fix a problem if you can’t measure it.

KPIs, however, turn vague goals into concrete, trackable targets. They give you the data you need to make informed decisions and hold suppliers accountable.

But—how do you decide what to measure?

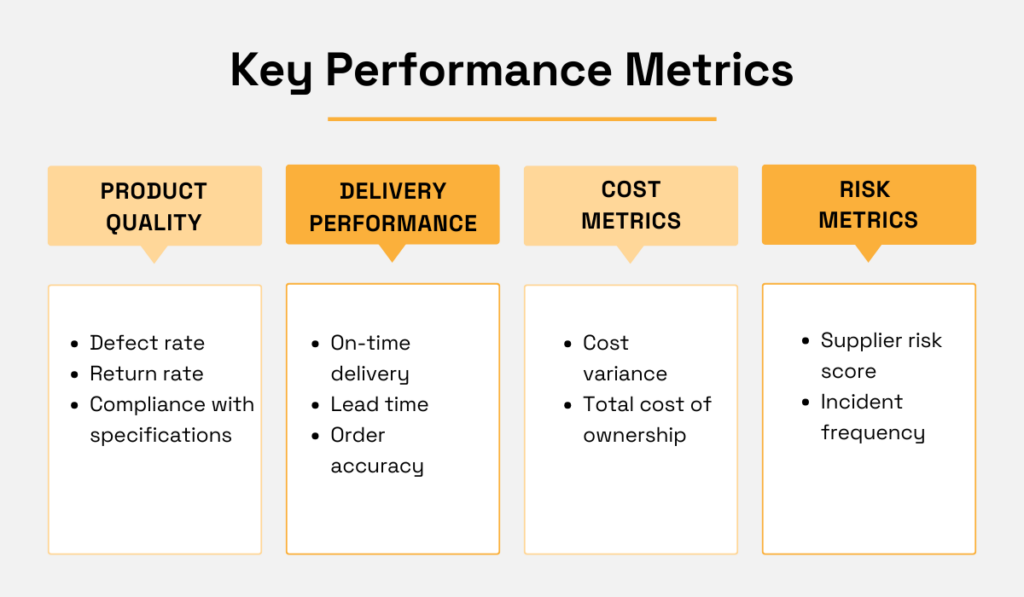

It’s always good to start by looking at the things that are critical to your business, be it product quality, cost savings, or how much risk a supplier brings to your organization.

According to that, here are some key KPI areas to consider:

Source: Veridion

We dive deep into these and more key metrics for assessing supplier performance in another article, so feel free to take a look.

Let’s now focus on one example to better explain why you should set up KPIs, and, most importantly, what to do with them.

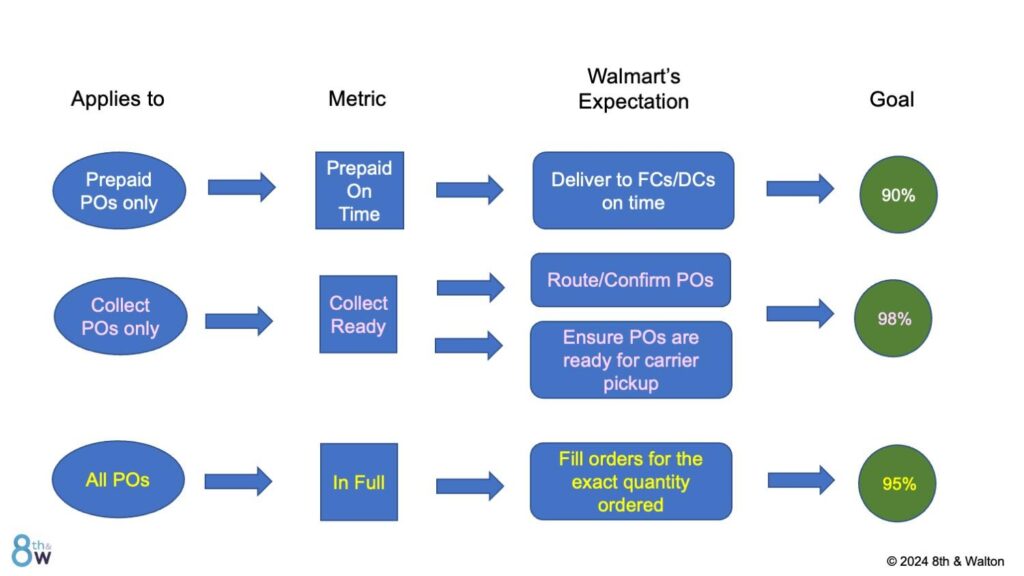

Walmart, for example, requires its suppliers to meet strict on-time and in-full (OTIF) delivery standards.

Ryan Petty, Senior Product Manager at SupplyPike, explains what exactly the OTIF program is in Walmart:

Illustration: Veridion / Quote: Conversations on Retail on YouTube

The reason for that is, of course, to keep their shelves stocked, and consequentially, their customers satisfied.

So, as of March 2024, Walmart’s goals are:

By setting this KPI—and tracking it—Walmart makes it clear that on-time delivery is non-negotiable for both prepaid and collect suppliers.

Source: 8th & Walton

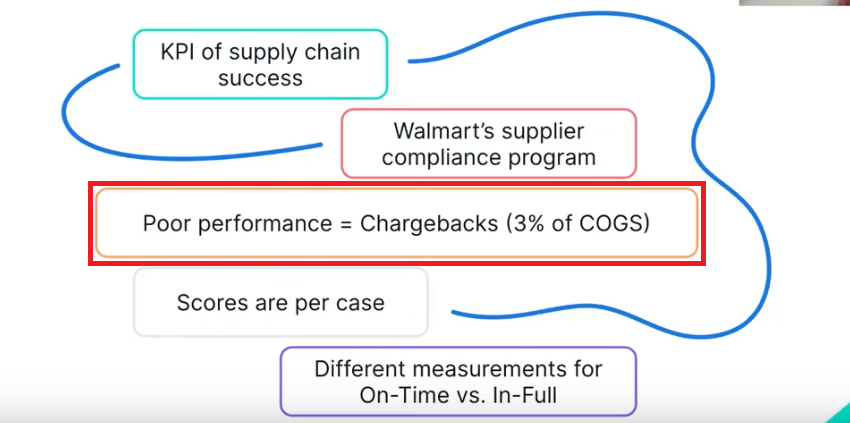

But it’s not enough to just track performance.

You also need to build KPIs into your contracts.

This means making the KPIs official, with clear penalties if suppliers fail to meet them.

That’s precisely what Walmart does.

They included penalties in contracts for suppliers who miss their OTIF targets.

More specifically, if a supplier fails to meet the OTIF guidelines on a delivery, they are fined 3% cost of goods on all cases that did not meet the goal.

Source: Conversations on Retail on YouTube

This kind of accountability ensures that suppliers take their commitments seriously and helps maintain a smooth flow of goods.

So, it’s obvious that KPIs aren’t just for tracking supplier performance but also a tool for driving performance.

When suppliers know they’re being measured, they take ownership of their work, which leads to continuous supplier performance improvement.

Just make sure to set the KPIs that matter most to your organization—and include them in contracts!

Building long-term partnerships with suppliers is one of the most effective practices for creating a stable, efficient, and innovative supply chain.

When suppliers become more than just vendors and instead act as strategic partners, the benefits extend far beyond cost savings.

They can help you:

Take McDonald’s and Coca-Cola, for example.

If you’ve ever enjoyed a Coke alongside your McDonald’s meal, you’re experiencing the result of one of the most enduring supplier partnerships in history.

For decades, these companies have worked hand-in-hand, creating a mutually beneficial relationship that continues to thrive.

Source: Pinterest

Of course, relationships like this don’t develop overnight.

Building strategic partnerships requires these three things:

But the real key is demonstrating to your suppliers that their success is intertwined with yours.

How can you do that?

Offering long-term contracts, for instance, can provide suppliers with the stability they need to innovate and scale.

Volume guarantees are another way to show commitment, incentivizing suppliers to prioritize your business and even share cost savings.

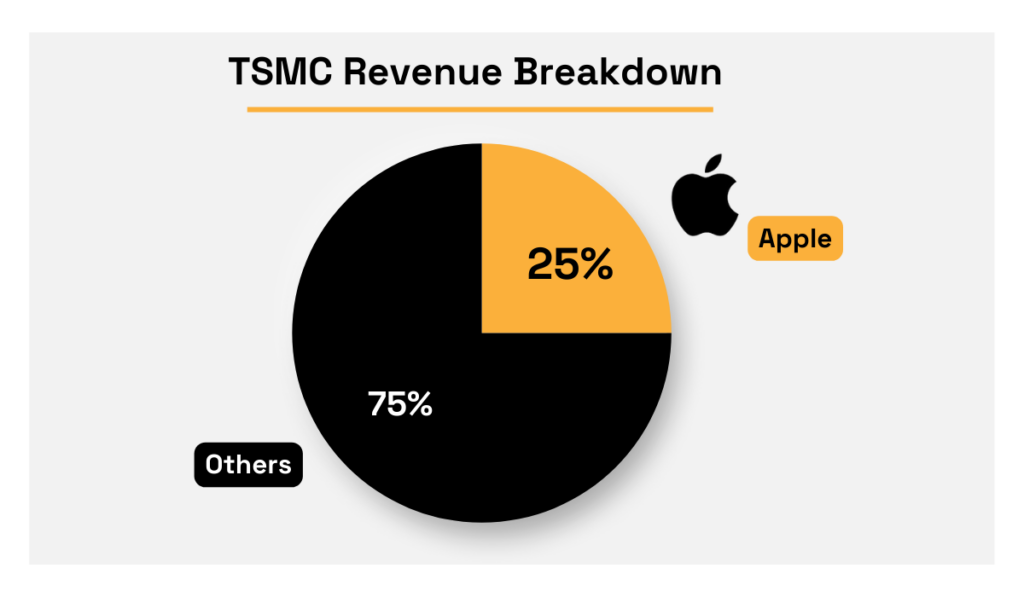

Take Apple and TSMC, for example.

Apple is TSMC’s largest customer, accounting for approximately 25.2 % of its semiconductor manufacturer’s annual revenue.

Illustration: Veridion / Data: Wccftech

In return, Apple enjoys preferential treatment, such as dedicated engineers for custom chip designs and early access to cutting-edge manufacturing technologies.

This partnership allows both companies to excel—Apple gets chips optimized for its products, and TSMC secures a reliable revenue stream.

Moreover, this close collaboration helped Apple weather the global semiconductor crisis better than many of its competitors, ensuring continuity in production during a time of widespread supply chain disruptions.

Source: Reuters

However, not all suppliers are candidates for this kind of partnership.

That’s why you have to segment your suppliers.

This process is important to identify which relationships warrant this level of investment.

So, you should categorize suppliers into different segments, from high-risk and bottleneck suppliers to strategic and preferred suppliers.

Then, focus on supplier groups who play a critical role in your operations or who have the potential to drive innovation.

With them, work on building long-term relationships by offering long-term contracts or guaranteeing high volumes.

At the same time, you should be actively engaging with these suppliers on things like:

All in all, these types of relationships will make your business more agile, responsive, and better equipped to handle changes in the market.

So, make sure to turn some of your suppliers into strategic ones.

On the surface, relying on a single supplier may seem efficient—simpler communication, reduced administrative work, and streamlined operations.

But what happens when that single supplier is disrupted by a natural disaster, political turmoil, or logistical delays?

Your entire operation could come to a grinding halt.

This is the critical lesson diversification teaches: depending too heavily on one supplier or region is a risky game.

The COVID-19 pandemic highlighted this risk.

Companies like Gap Inc., which relied heavily on Vietnam for 30% of its production, faced weeks-long factory closures due to a coronavirus outbreak.

Source: CNN

Similarly, the global semiconductor shortage exposed the vulnerabilities of over-concentrated supply chains.

Access to key raw materials, such as neon and palladium, became increasingly difficult due to geopolitical tensions, climate change, and conflict, prompting companies to rethink their sourcing strategies.

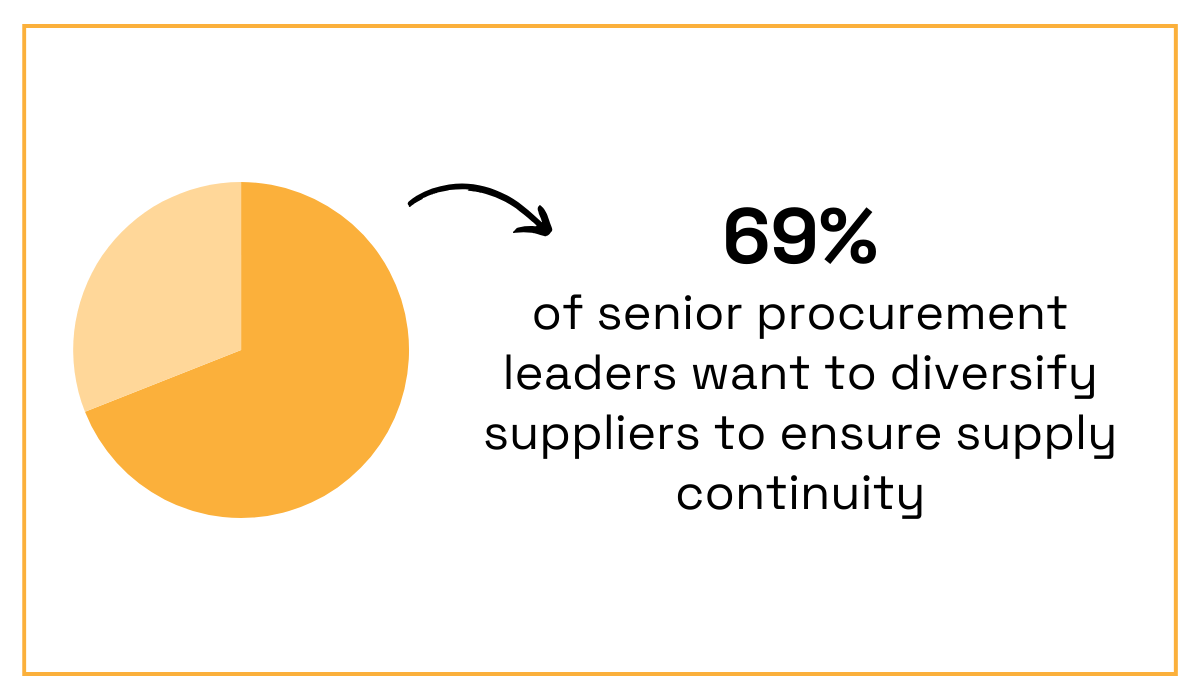

In response, businesses are pivoting toward diversification.

According to CIPS, 69% of procurement leaders plan to diversify their suppliers within six months.

Illustration: Veridion / Data: CIPS

Intel, an American multinational corporation and technology company, exemplifies this approach.

CFO David Zinsner emphasizes the importance of building a globally diversified supply chain to combat regional shortages:

Illustration: Veridion / Quote: CFO Dive

Intel is heavily investing in facilities across the U.S. and Europe to ensure continuity when disruptions occur.

Tesla has also embraced this strategy.

The company sources vital materials like lithium and nickel from suppliers across Australia, Canada, and China to ensure a steady supply of components, even in turbulent times.

However, diversification isn’t just about adding more suppliers.

It can mean nearshoring operations closer to home markets or adopting multi-shoring strategies to mitigate reliance on a single region.

For example, many North American companies follow the “China + One” strategy, complementing their Chinese suppliers with partners from countries like Mexico or India.

Source: Business Standard on YouTube

Another method involves diversifying logistics, such as using multimodal transport.

By spreading risk across multiple supply chain layers, companies enhance their resilience and flexibility.

Beyond mitigating risk, diversification fosters competition among suppliers, leading to better pricing, higher quality, and more favorable terms.

In short, a diversified supply chain isn’t just resilient—it’s also a driver of long-term success.

The question is: is your supplier base diversified?

If not, now is the time to think about supplier diversification options.

When we talk about supplier management, the focus often leans toward finding the best suppliers.

But what if the key to success lies in helping your suppliers become the best?

Supplier development is a strategy that helps you achieve that.

At its core, supplier development is about collaboration.

It involves working closely with your suppliers, offering training, resources, and support to help them meet your business’s quality, efficiency, and sustainability standards.

This approach comes with a wealth of benefits, including:

One standout example is Walmart’s Supplier Academy, which provides tailored training programs, webinars, and resources to help suppliers develop and align with Walmart’s expectations.

By equipping suppliers with the tools they need to succeed, Walmart not only strengthens its partnerships but also ensures a smoother, more efficient supply chain.

If you’re interested in what suppliers say about working with Walmart, check the video below:

Source: Walmart on YouTube

Another great case is Knorr, a Unilever division, which established the Knorr Partnership Fund in 2011.

This initiative invests €1 million annually into co-funded projects with suppliers to help farmers meet, and even exceed, Unilever’s Sustainable Agriculture Code.

Source: Unilever

But what happens if suppliers aren’t immediately willing to embrace development?

This is where incentives can be very helpful.

For example, Aldar Properties, a real estate development company from UAE, recently introduced a sustainability incentive program that rewards contractors who align with its green goals.

Incentives include financial bonuses, training opportunities, expedited payments, and public recognition, motivating suppliers to adopt sustainable practices and improve overall performance.

Faisal Falaknaz, Chief Financial and Sustainability Officer at Aldar, explained their approach:

Illustration: Veridion / Quote: Gulf Business

Even giants like Toyota emphasize rewarding supplier development and innovation.

As Jean-Christophe Deville, Toyota Motor Europe’s VP of Supply Chain, explains:

“The intention is to reward both the supplier, for offering innovative solutions, as well as to reward Toyota. If a supplier does not find it attractive to work with Toyota, we believe their motivation in the long run will reduce.”

This win-win mindset fosters trust and drives suppliers to continuously improve.

And the best thing about supplier development is that it’s universally applicable—whether you’re in retail, manufacturing, real estate, or any other industry.

By nurturing supplier growth and rewarding their efforts, you won’t only improve your supply chain but build stronger partnerships that benefit your entire organization.

And we saw how important that can be.

Supplier management is challenging, no two ways about it.

Especially when you have to juggle multiple vendors, compliance requirements, and risk evaluations.

That’s where technology shines.

Leveraging the right tools can streamline processes, reduce risks, and provide powerful insights to build a resilient supply chain.

So, what kind of tools are we talking about?

Supplier management software is a great place to start.

It automates time-consuming tasks like documentation, performance tracking, and compliance checks while consolidating all your supplier data in one centralized system.

These solutions often include additional features like:

Let’s now look at some examples of how such a platform helps with supplier management.

First, we go to Norway.

Norway’s largest beauty and wellness retailer, VITA, tackled its complex network of 1,000 suppliers and 14,000 product lines by partnering with Ignite.

Source: Ignite

This platform helped VITA consolidate all supplier data in one place, assess risks systematically using trusted indexes like Transparency International, and prioritize suppliers requiring further analysis.

By doing so, they ensured compliance with Norway’s Transparency Act while maintaining an ethical and future-proof supply chain.

Katrine Norman Johansen, Head of Procurement at VITA, sums it up:

Illustration: Veridion / Data: Ignite

Similarly, Britvic, the largest supplier of branded soft drinks in Great Britain, used SAP Ariba solutions to completely transform its procurement and supplier management processes.

Simon Mays, Procurement Transformation Director at Britvic, described the challenges they faced:

“Many of our employees were frustrated with outdated procurement processes and a lack of data availability. Users often did not know which supplier to contact, and overall sourcing governance and pipeline management was difficult.”

With SAP Ariba, Britvic gained a unified source-to-pay solution.

This allowed the company to digitize supplier contract management, standardize workflows, and improve sourcing governance.

These improvements enhanced supplier collaboration, aligned procurement with business goals, and delivered significant results:

Source: SAP

But, of course, supplier management doesn’t stop at organization—it’s about continuously staying ahead of challenges and opportunities.

This is where big data platforms like our Veridion stand out.

Veridion is a powerful service that has access to data on over 120 million companies across the globe, offering unmatched supplier insights.

Source: Veridion

Whether you’re searching for new suppliers or assessing existing ones, Veridion’s capabilities make it seamless.

Veridion allows you to:

Check out this video to see how Veridion matches and enriches supplier data:

Source: Veridion on YouTube

Ultimately, leveraging technologies like these will transform your supplier management into a proactive and data-driven process.

Whether you’re streamlining operations with management software or using platforms like Veridion for deep insights and real-time alerts, technology will ensure your supply chain remains agile, transparent, and resilient.

And that’s necessary in today’s complex supply chains.

Managing suppliers is no small feat, but it’s entirely manageable with these best practices.

Each of these practices is a step toward reducing risk, improving efficiency, and driving mutual success for you and your suppliers.

When you achieve that, you will build a supply chain that supports your business goals and gives you a competitive edge—ensuring stability, agility, and innovation even in the face of challenges.

So, if you haven’t yet, start by adopting at least one of these practices today.

Starting with the right technology could be a smart first step, as it can streamline your efforts and make implementing the other practices much easier.

Best of luck with your supplier management!