Top Supplier Management Challenges and How to Solve Them

Key Takeaways:

Effective supplier management is essential for ensuring your company’s smooth operations, cost savings, and sustainable business growth.

However, like many business processes, managing suppliers comes with its share of challenges.

From scalability issues to outdated supplier data and limited visibility into supplier processes, these hurdles can significantly impact your procurement efficiency.

Is your organization ready to tackle these and other obstacles?

In this article, we’ll explore some of the top supplier management challenges and share actionable strategies to overcome them.

During periods of rapid business growth, procurement teams face immense pressure to scale supplier networks quickly without compromising quality or performance.

However, identifying, selecting, and onboarding multiple suitable suppliers at scale is often a daunting task.

Why?

Because the vetting process requires thorough due diligence.

This includes evaluating capabilities, assessing financial stability, and ensuring compliance with regulatory standards.

When multiple new suppliers are urgently needed to support growth, inefficiencies in the supplier selection process usually become more apparent.

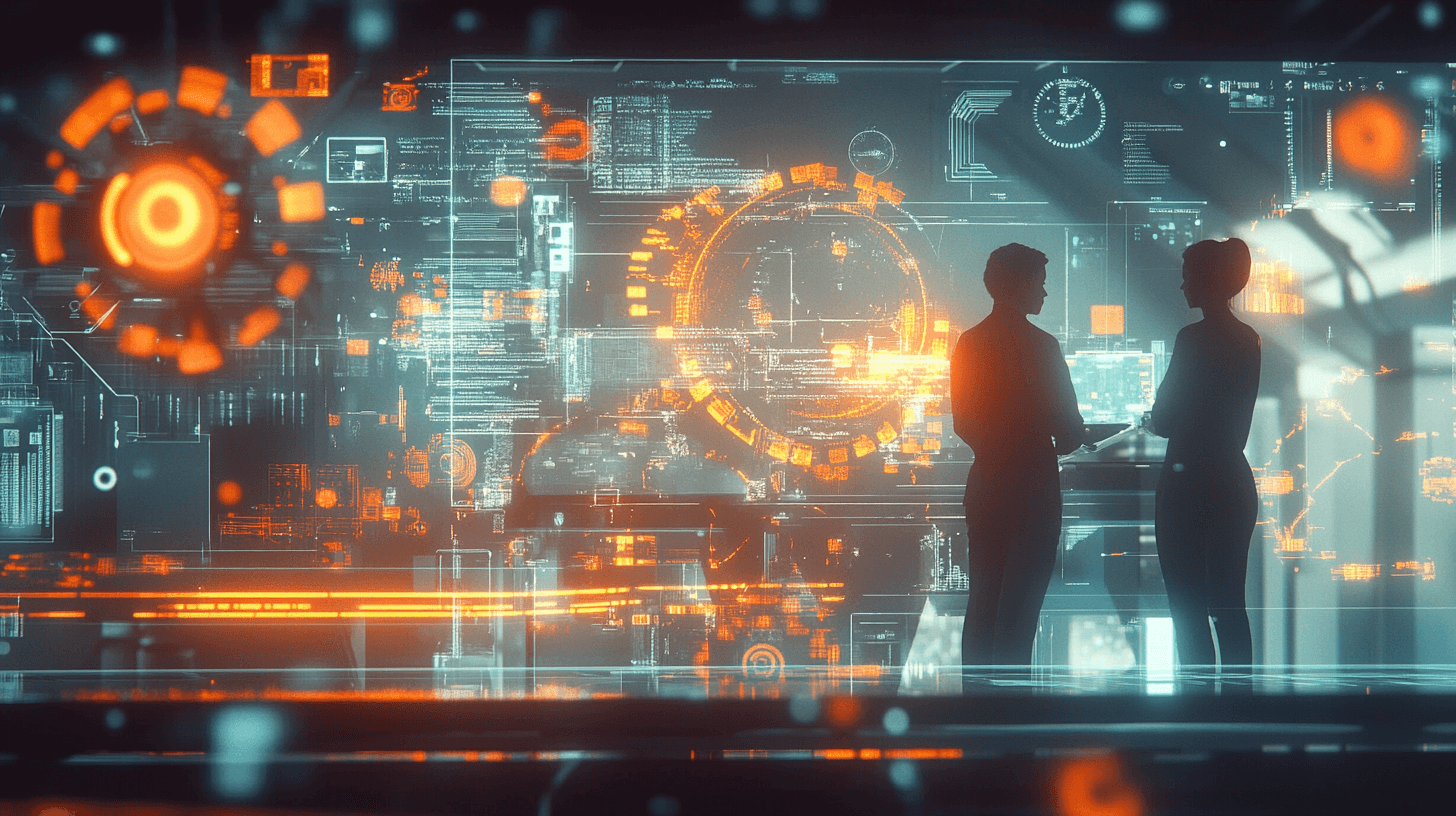

For instance, your organization may prioritize not only price, quality, and delivery, but also suppliers with sustainable practices.

Yet, finding such suppliers can be very challenging.

According to Amazon Business’s 2024 State of Procurement Report, almost nine out of ten companies face this issue.

Illustration: Veridion / Data: Amazon

Such difficulties in finding suitable suppliers are often further aggravated by:

These factors slow down procurement teams and—especially when time is critical—lead to suboptimal supplier sourcing decisions.

In fact, McKinsey reports that a single supplier search can take months, with full-time sourcing professionals evaluating only a few dozen potential suppliers.

Now, imagine the added pressure when multiple suppliers are urgently needed.

So, how can these scalability challenges be addressed?

By leveraging procurement tools and platforms that can scale with your business.

An example of one such solution?

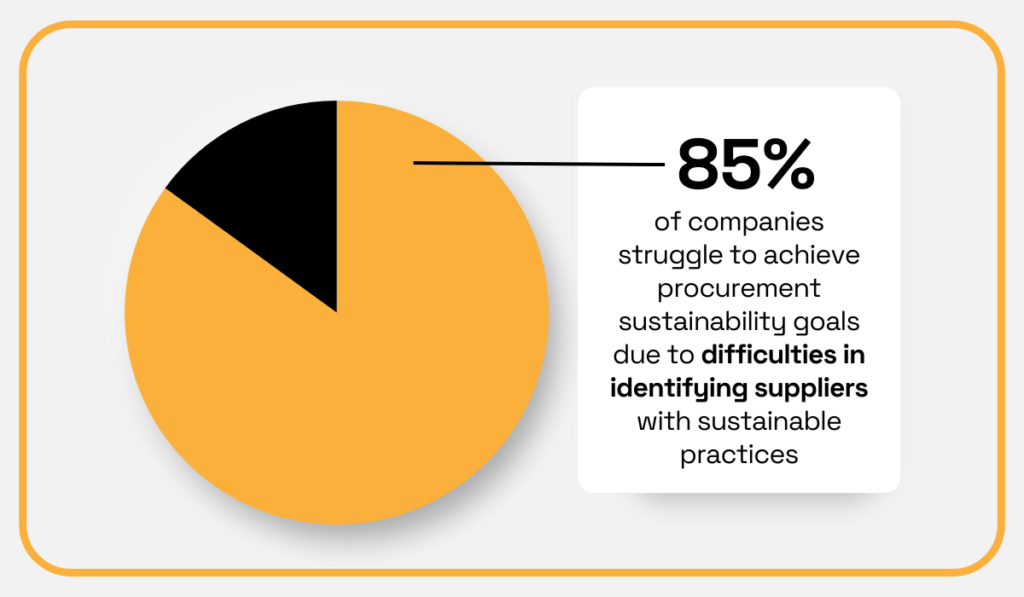

AI-powered supplier discovery platforms like our Veridion.

Source: Veridion

Since Veridion’s data universe encompasses all companies with an active web presence worldwide, it significantly streamlines the supplier discovery process.

How significantly?

According to the McKinsey findings we mentioned earlier, by more than 90%.

By now, you must be wondering how Veridion achieves this.

Our AI-driven bots continuously scour the internet, ensuring that no supplier data is more than two weeks old.

This means that your procurement team can easily conduct multiple searches, confident that the results are accurate and up to date.

Using natural language input, they can enter specific search criteria and receive a shortlist of eligible suppliers within seconds.

To see this process in action, watch this short video:

Source: Veridion on YouTube

This quick, comprehensive global search is invaluable when scaling your operations.

It not only saves time and resources but also ensures that no potential suppliers are overlooked.

From there, your team can refine the results for further evaluation and risk assessment.

Platforms like Veridion are particularly effective when multiple suppliers are needed simultaneously, such as during market expansion or entry into new industries.

Additionally, other scalable procurement tools—such as those automating e-sourcing and RFx processes—can further streamline supplier selection.

Together, these solutions directly address the challenges of scalability in supplier selection.

Ultimately, this empowers your team to meet growth demands without compromising quality or efficiency.

This challenge mostly affects smaller organizations that often lack the personnel or budget to manage supplier relationships effectively.

Tight budgets and small procurement teams mean that tasks like supplier performance tracking, compliance monitoring, and risk management often fall by the wayside.

Additionally, smaller businesses are more likely to use manual processes for supplier management activities.

While these methods may work initially, they consume valuable time, are prone to errors, and become increasingly inefficient as supplier networks expand.

However, this issue isn’t exclusive to small businesses.

Manual processes remain surprisingly widespread across the industry.

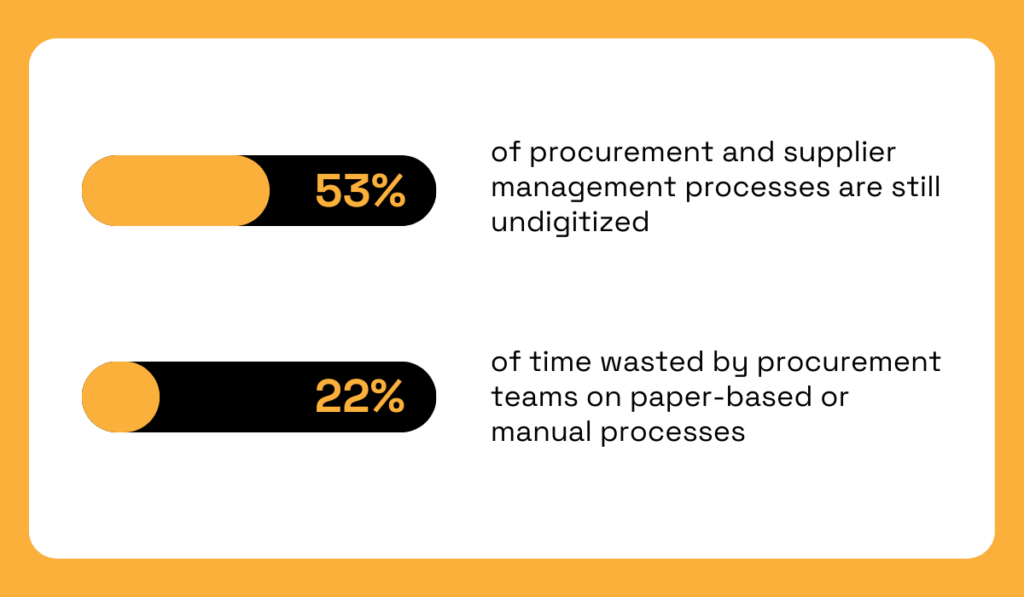

A 2023 Ivalua research showed that more than half of procurement and supplier management processes have yet to be digitized.

This inefficiency comes at a cost, with procurement teams estimating they waste over a fifth of their time each year handling paper-based or manual tasks.

Illustration: Veridion / Data: Ivalua

Clearly, this reliance on manual processes creates a significant drag on productivity, especially for procurement teams with limited resources.

Tasks like tracking supplier performance or ensuring compliance often involve tedious data entry and time-consuming follow-ups.

These inefficiencies not only strain teams but also increase the risk of errors and missed opportunities.

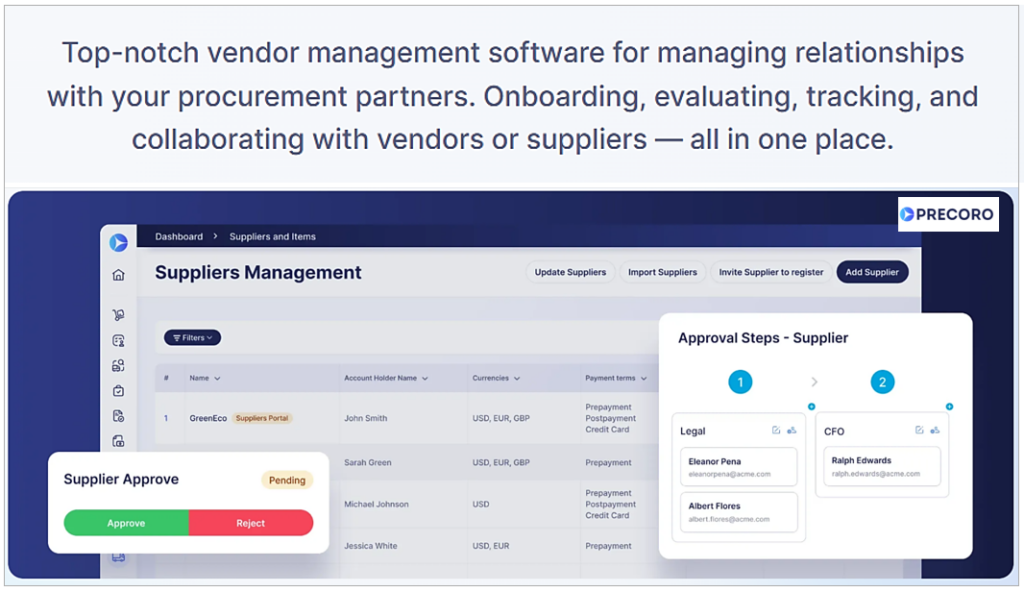

To overcome these challenges, smaller organizations can turn to affordable, scalable technology solutions.

For instance, cloud-based supplier management platforms enable teams to centralize supplier information, automate repetitive tasks, and access real-time performance data.

One such platform tailored for small and medium-sized businesses is Precoro.

Source: Precoro

These platforms significantly reduce the time spent on manual processes, allowing your procurement team to focus more on strategic priorities.

Such procurement management tools provide an excellent starting point.

However, technology isn’t the only solution smaller organizations can leverage to improve supplier management.

Building strong supplier relationships is another critical strategy.

By fostering open communication and transparency with key suppliers, you can encourage close collaboration and mutual growth.

For example, regular performance reviews and joint planning sessions can help align supplier goals with your company’s objectives.

Additionally, streamlining internal processes can go a long way in maximizing efficiency.

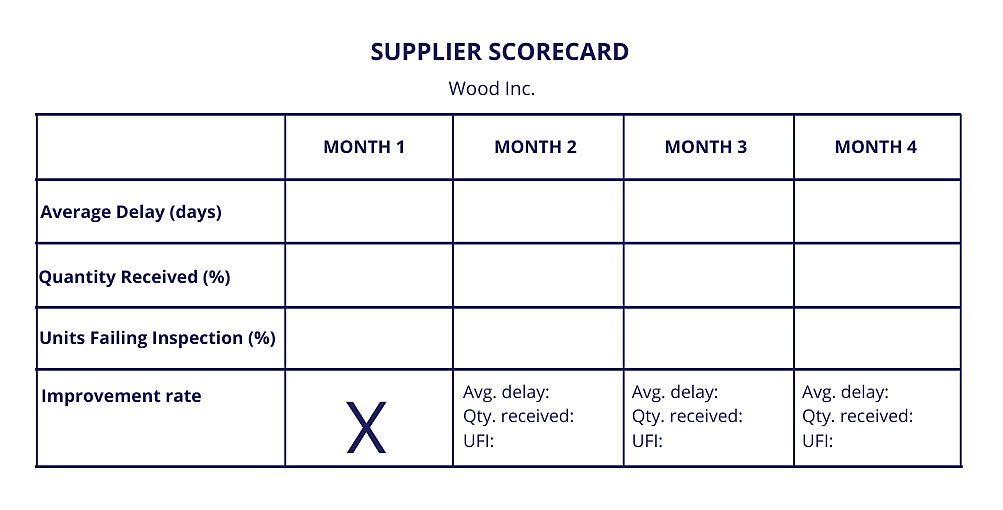

Standardizing workflows, such as creating clear onboarding procedures and using supplier scorecards, ensures consistency and reduces the burden on your team.

Here’s an example of a supplier scorecard focused on performance monitoring.

Source: MRP easy

Supplier scorecards are particularly valuable as they provide a structured, data-driven way to monitor and improve supplier performance over time.

Moreover, outsourcing certain procurement tasks—such as supplier audits or compliance checks—to third-party experts can free up internal resources while ensuring compliance with industry standards.

By combining these approaches, you can ensure that suppliers are managed effectively, even with limited resources.

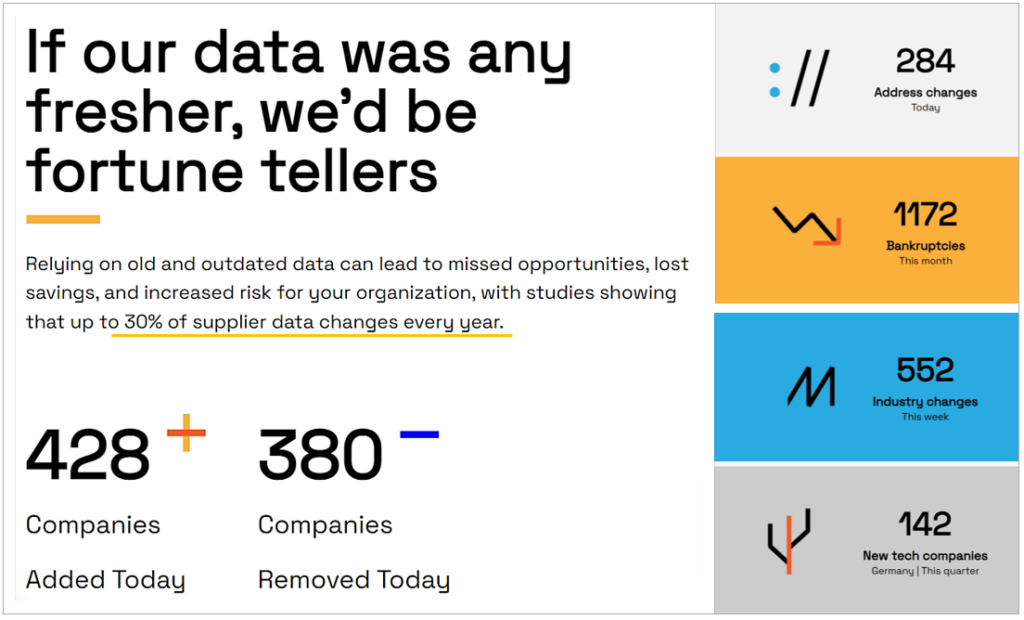

Maintaining accurate, up-to-date supplier information is a persistent challenge for most procurement teams.

Supplier details—such as contact information, certifications, and compliance status—can change frequently, making it difficult to ensure records are current.

Unfortunately, relying on outdated or incomplete supplier data can lead to significant issues.

Think delays in communication, compliance problems, and poor decision-making.

Don’t believe us?

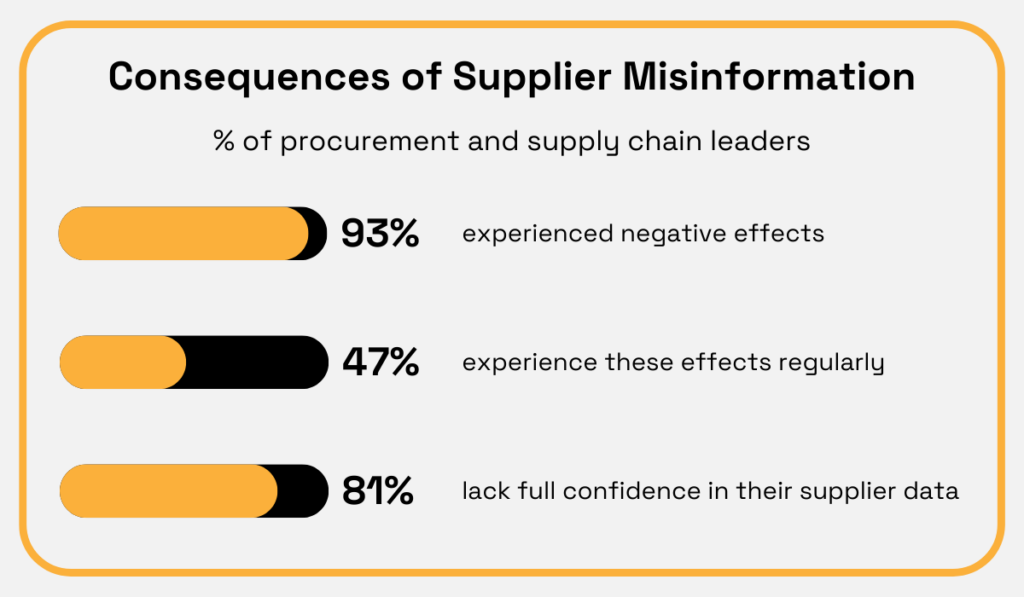

Take a look at the findings of a Tealbook survey, highlighting just how widespread these challenges are.

It found that an overwhelming percentage of procurement and supply chain leaders have experienced negative effects due to inaccurate supplier information.

Illustration: Veridion / Data: Tealbook

The survey further revealed that these consequences have tangible impacts, including:

While these findings are troubling, they’re not surprising.

Procurement teams need to handle vast amounts of data daily to make informed, data-driven sourcing decisions.

When supplier data is outdated, it can lead to flawed assessments of key factors like supplier capacities, financial stability, or ESG/sustainability risks.

These errors ultimately result in missed opportunities and increased organizational risk.

On the other hand, having access to the freshest supplier data and automating updates with tools like Veridion can dramatically improve accuracy and reduce errors.

Source: Veridion

Veridion’s database, with its global coverage and weekly updates, ensures that you’re always accessing the most reliable supplier information.

Another feature that enables you to address the challenge of maintaining accurate supplier information is Veridion’s data enrichment service.

You can use this tool to seamlessly enhance your company’s existing supplier profiles by integrating comprehensive, up-to-date data.

If you’re curious how this works, check out this short video:

Source: Veridion on YouTube

By automating this process, you not only save time but also ensure your team has access to accurate, enriched data for supplier management purposes.

Ultimately, the challenge of outdated supplier information is best tackled by leveraging the right tools that deliver fresh, precise, and actionable data.

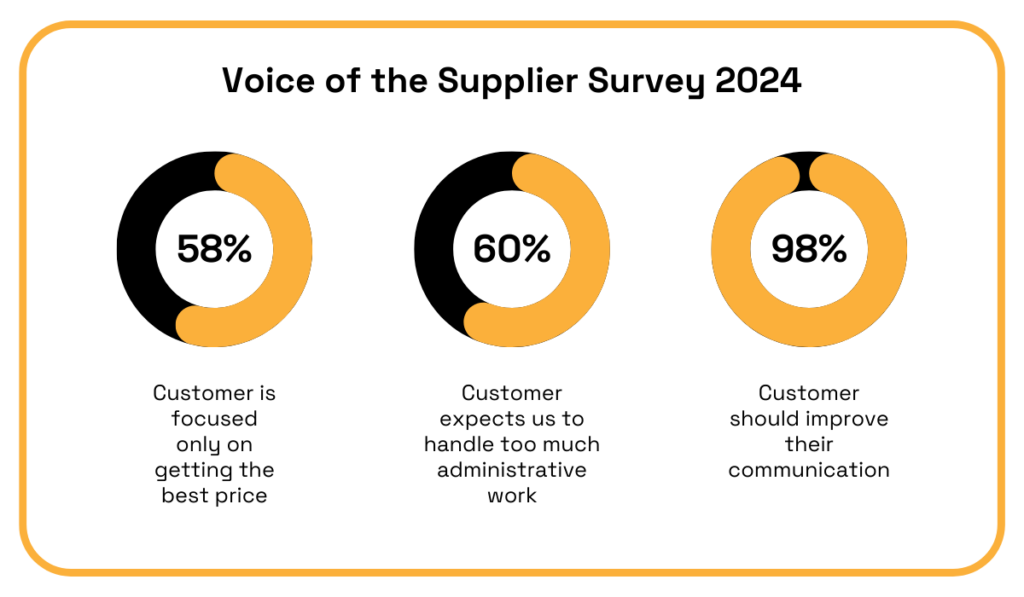

Securing supplier buy-in for performance management remains an ongoing challenge for many organizations.

Why?

Because suppliers often perceive these initiatives as micromanagement or unnecessary administrative burdens, which can lead to resistance.

This is particularly true when performance management programs require extensive administrative work or appear to prioritize customer demands over collaboration.

Such disconnects can result in suppliers being reluctant to engage fully, making it difficult to align on key performance indicators (KPIs) or improvement plans.

HICX’s 2024 Voice of the Supplier Survey underscores this strain, revealing key pain points suppliers face:

Illustration. Veridion / Data: HICX

These findings highlight why suppliers may hesitate to embrace performance monitoring.

As illustrated, common concerns include:

Addressing these issues requires a shift toward building trust, enhancing transparency, and fostering a partnership-focused approach.

Additionally, it’s important to share the benefits of performance management for your suppliers, such as:

Building strong supplier relationships requires a combination of clear communication, trust, and collaboration.

According to Lucy Pickett, Sustainability Director at Roche, this starts with setting your vision and highlighting tangible benefits for your suppliers:

Illustration: Veridion / Quote: Verco Global

This quote underscores the importance of fostering a shared sense of purpose to secure supplier buy-in.

So, make sure to involve suppliers in setting KPIs and clearly communicate how achieving them will benefit both parties.

Providing training, resources, or tools to simplify compliance—especially for smaller suppliers—can further facilitate their engagement.

Additionally, regular feedback sessions help build trust and pinpoint opportunities for mutual improvement.

Ultimately, creating a collaborative environment where your suppliers feel valued and supported will encourage their active participation in performance initiatives.

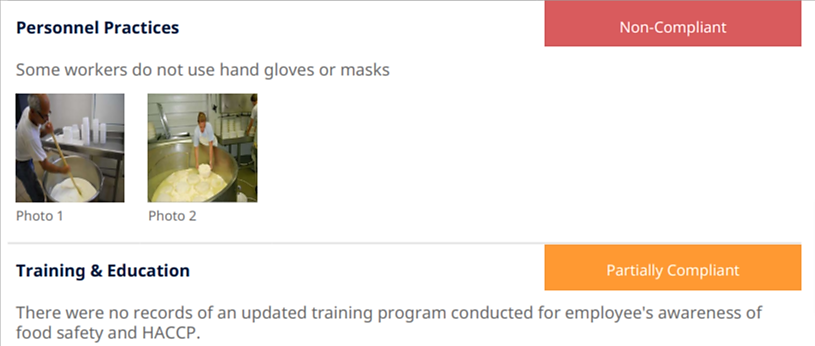

Companies often lack insight into suppliers’ production timelines, inventory levels, or compliance with industry standards.

These blind spots can lead to delays, quality issues, and hidden risks.

In turn, this can disrupt your operations, erode customer trust, and increase costs due to unforeseen complications.

For instance, without visibility into a supplier’s inventory levels, unexpected stock shortages can cause significant delays.

Similarly, a supplier’s failure to meet regulatory standards—and your inability to detect this—can expose your company to reputational damage or legal liability.

There are many examples of such cases in the news.

Source: Fast Company

If the above-cited company had visibility into its supplier’s operations, it could have likely prevented significant financial losses and public scrutiny.

Non-transparent supplier processes also make it harder to identify areas for improvement, such as optimizing lead times or reducing waste within the supply chain.

To tackle these challenges, prioritizing transparency and investing in tools that enhance supplier visibility is essential.

Technologies like supplier management software, blockchain for traceability, and IoT devices for real-time monitoring can offer valuable insights into supplier operations.

These tools allow you to, respectively:

In addition to technology, conducting regular or surprise audits can also be a highly effective strategy.

Audits provide firsthand insights into supplier performance and compliance, revealing non-conformances before they escalate into more serious issues.

Source: Safety Culture

While audits require resources, they are invaluable for gaining transparency, uncovering risks, and fostering accountability.

Equally important are open communication channels, which play a crucial role in increasing visibility.

Encouraging suppliers to share updates and challenges transparently promotes collaborative problem-solving and drives performance improvement.

By integrating technology, conducting audits, and maintaining open communication, you can significantly enhance visibility into your suppliers’ processes.

This reduces disruptions and helps you build stronger, more resilient supplier relationships.

Having explored these supplier management challenges, it’s clear they play a critical role in your company’s operational efficiency, cost control, and risk mitigation.

The difference between a positive and negative impact lies in how you address these challenges.

By leveraging advanced tools, fostering collaboration, and implementing strategic processes, you can turn potential hurdles into opportunities.

A proactive approach not only simplifies your supplier management but also drives long-term business growth, resilience, and competitive advantage.