Supplier Relationship Management: 5 Mistakes to Avoid

Key Takeaways:

Do you think your supplier relationships are strong?

Your suppliers might not see it that way.

More than half say their biggest customers only care about cost, which often leads to strained partnerships, missed opportunities, and even supply chain disruptions.

And that’s just one of many mistakes companies make.

Let’s break down five supplier relationship management mistakes that could be costing you more than you realize.

Not segmenting suppliers makes supplier relationship management harder than it needs to be.

If you manage hundreds or even thousands of suppliers, you can’t build strong relationships with all of them.

Nor should you.

Some suppliers are critical to operations, while others simply fulfill routine orders.

So, if you treat all suppliers the same, you risk underinvesting in key partnerships while wasting time on suppliers that don’t need deep engagement.

This is something procurement professionals are increasingly recognizing, as one put in a Reddit discussion:

Source: Reddit

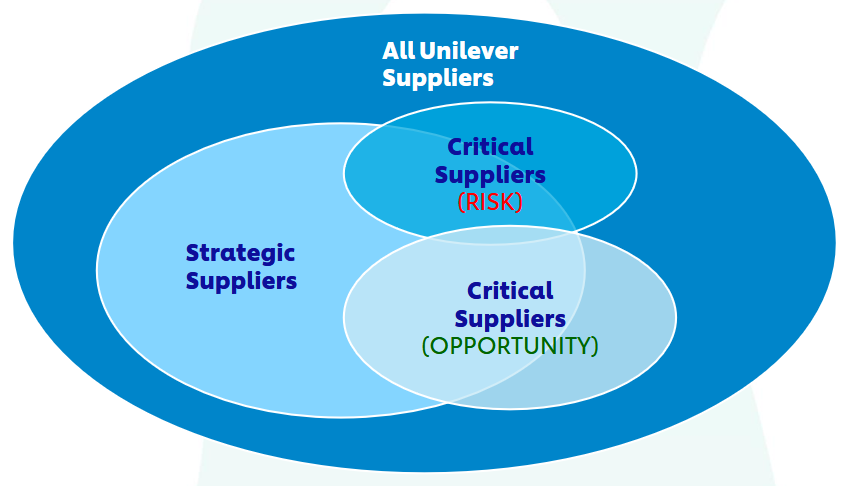

Take Unilever as an example.

In 2021, they worked with 56,300 suppliers.

Did they build the same strong relationships with all of them? Of course not.

If Unilever treated every supplier the same, their procurement team would be overwhelmed, unable to differentiate between those that drive business success and those that are purely transactional.

That’s why Unilever segments its suppliers.

They define strategic suppliers as those representing a significant proportion of spend or volume.

Within that, they further classify suppliers into two groups:

Below is a visual representation of Unilever’s supplier segmentation:

Source: Unilever

With this approach, Unilever doesn’t waste time micromanaging low-risk transactional suppliers.

Instead, they focus their SRM efforts where they have the most impact—minimizing risks with one group and driving innovation with the other.

So, to avoid this mistake, the solution is obvious—segment your suppliers.

There are several ways to do that.

Some companies use spend analysis, breaking suppliers down by total spend and category.

Some focus entirely on risks suppliers pose to their business, as this procurement professional explains in the Reddit thread mentioned above:

Source: Reddit

Others rely on supplier pyramids, where suppliers are ranked by strategic value, or the Kraljic Matrix, which categorizes suppliers based on risk and profitability.

If you want to explore these models in more detail, check out our article on supplier segmentation methods.

The key takeaway is to stop spreading resources too thin and, instead, manage suppliers based on what they bring to the table.

Strategic ones? Invest in those relationships.

Low-risk transactional ones? Keep things simple.

That’s how you make supplier relationship management work in the first place.

If your approach to supplier relationships is all about what you get out of it, you’re making a mistake—and suppliers notice.

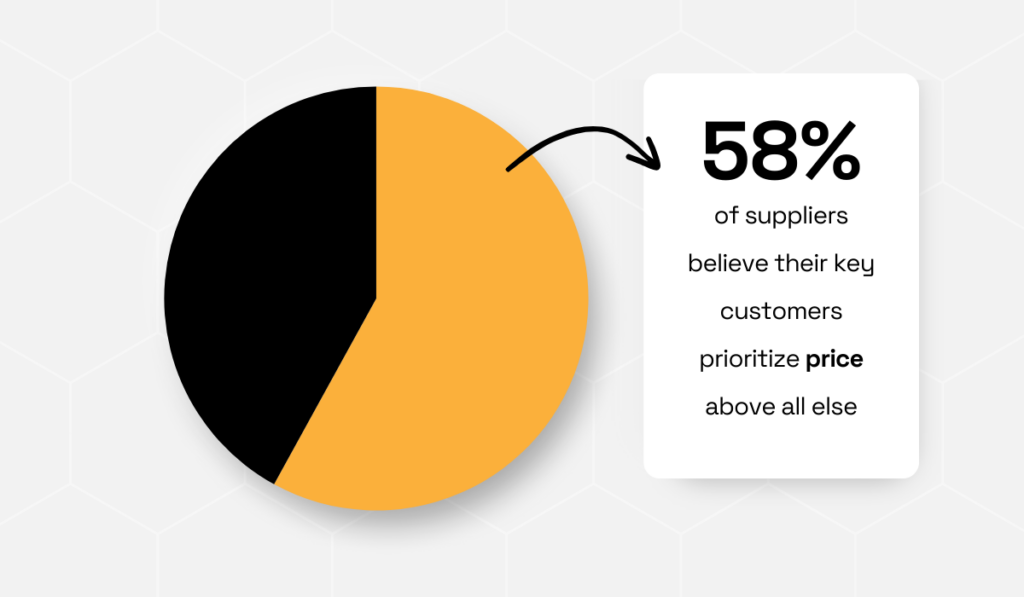

According to the 2024 Voice of the Supplier survey by HICX, 58% of suppliers feel their most important customers only care about cost.

Illustration: Veridion / Data: HICX

When that’s the main driver of the relationship, don’t expect suppliers to go the extra mile for you.

They’ll prioritize customers who offer more than just purchase orders.

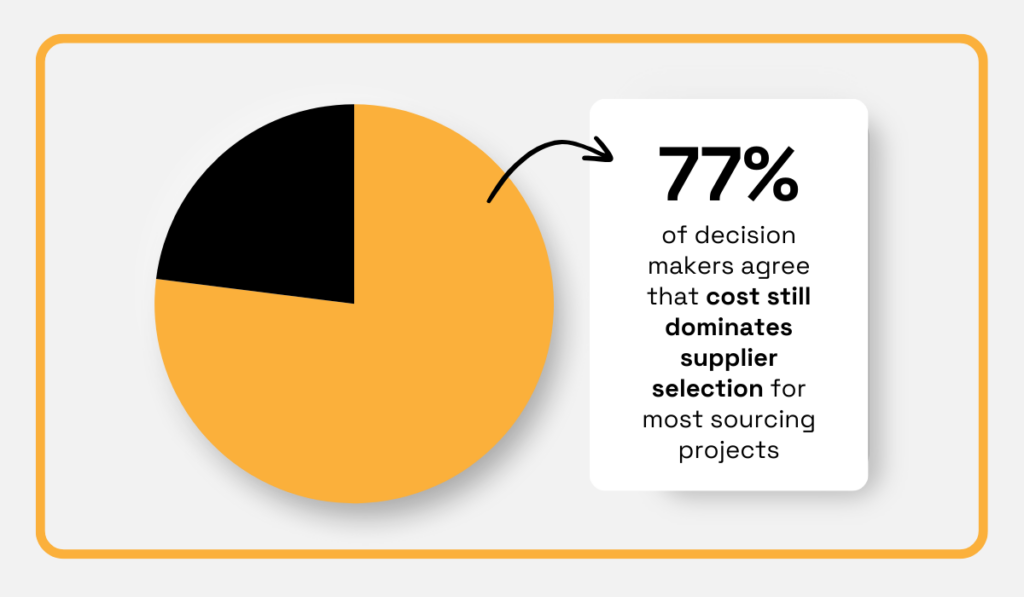

Unfortunately, many procurement professionals still make this mistake.

In a study by Ivalua and Forrester, 77% of them agreed that cost is still the primary factor in sourcing decisions.

Illustration: Veridion / Data: Ivalua

That makes true collaboration difficult.

If a supplier is chosen purely because they’re the cheapest, what incentive do they have to invest in a long-term partnership?

On the other hand, companies that think beyond cost and focus on mutual benefit become their suppliers’ customers of choice.

That’s when the real advantages start:

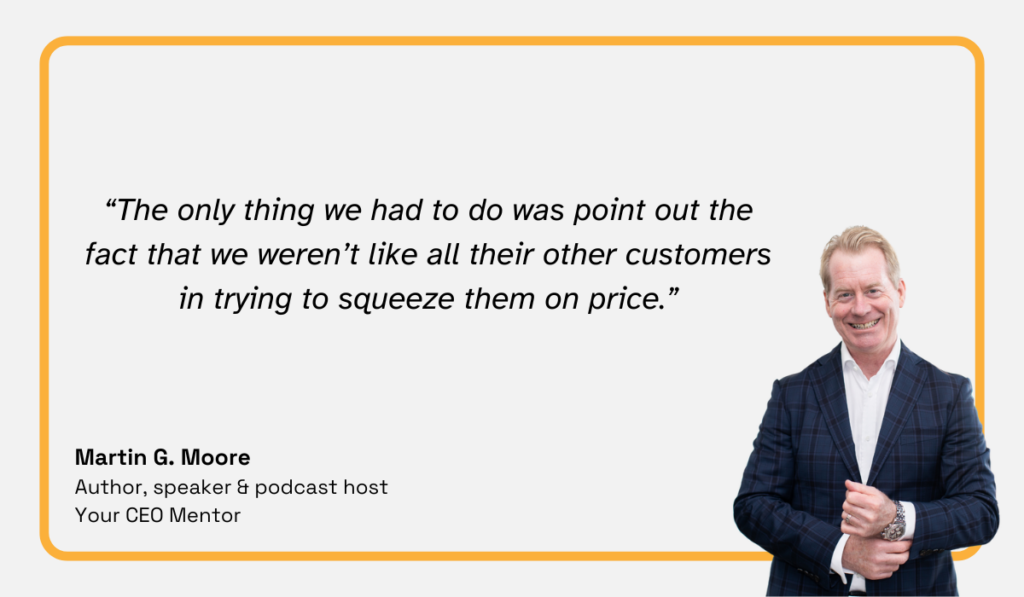

Martin G. Moore, former CEO of CS Energy and the host of the Your CEO Mentor podcast, explains how his company secured top-tier treatment from suppliers simply by recognizing their challenges.

Source: Your CEO Mentor on YouTube

If you watched the video above, you saw that instead of constantly pushing for lower prices, Moore sometimes agreed to hold prices steady when suppliers were under pressure.

In return, he negotiated priority service, access to the best resources, and faster response times.

That simple shift made suppliers more willing to go the extra mile.

Illustration: Veridion / Quote: Your CEO Mentor on YouTube

This kind of supplier-first thinking isn’t just theoretical—it’s a strategy some major companies have actively adopted.

Tesco, for example, has worked to rebuild supplier trust after past missteps.

In 2016, this retailer faced backlash for delaying supplier payments to improve its own financial position.

But in recent years, it has taken steps to repair relationships and foster long-term collaboration.

In 2024, Tesco and NatWest, a major retail and commercial bank in the UK, launched a sustainable finance initiative to support 1,500 farmers in Tesco’s supply chain.

Source: Tesco

This program offers preferential loan rates to help them transition to sustainable farming methods—including installing solar panels, wind turbines, and heat pumps to reduce energy costs and carbon emissions.

Farmers in Tesco’s supply chain also gain access to preferred suppliers and volume discounts on renewable energy assets.

So, instead of demanding lower prices from suppliers, Tesco is actively helping them invest in cost-saving, green technology that will benefit both sides.

Of course, not every company has the resources to launch a large-scale finance program with a bank.

But meaningful change doesn’t always require a massive initiative.

If you want suppliers to see you as a valued partner rather than just another cost-driven customer, small changes can go a long way.

Paying on time, or even just having open, honest discussions about mutual goals can strengthen relationships.

And the companies that recognize this? They’re the ones suppliers go the extra mile for.

Another common mistake in supplier relationship management is a lack of clear communication.

Chris Anchondo, Category Manager at FleetPride, points that out when asked about the difficulties of working with suppliers:

Illustration: Veridion / Quote: Fleet Equipment

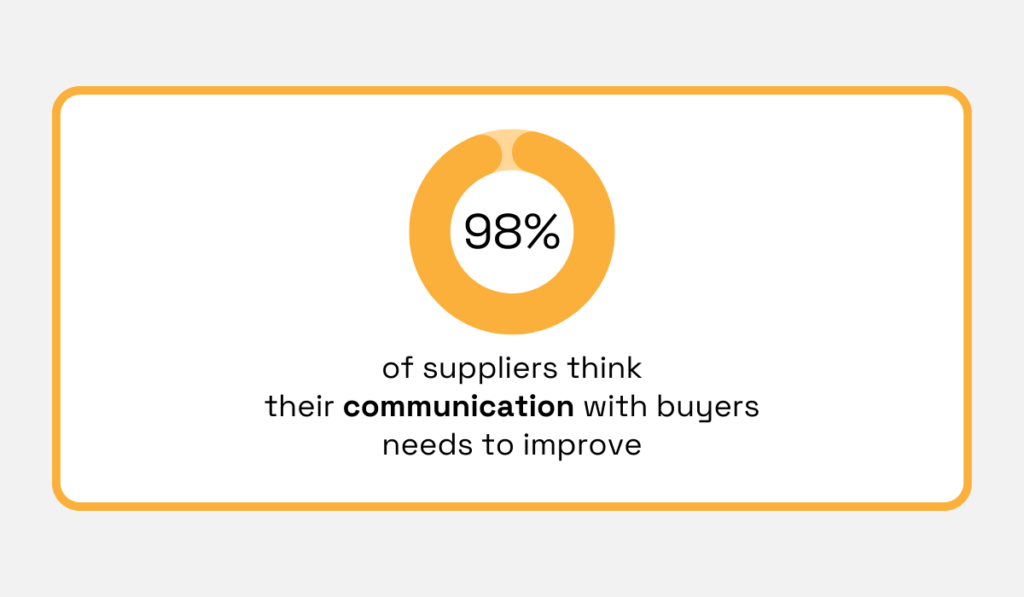

Suppliers agree as well.

In the HICX research mentioned earlier, nearly all suppliers indicated that better customer communication is needed.

Illustration: Veridion / Data: HICX

When communication breaks down, it leads to costly delays, misunderstandings, and inefficiencies—for both sides.

Just consider how wrong orders, inaccurate product specifications, or misaligned expectations can waste time and money.

But when companies prioritize communication, the results speak for themselves.

Suppliers are more willing to open up and collaborate when they feel they’re in the loop.

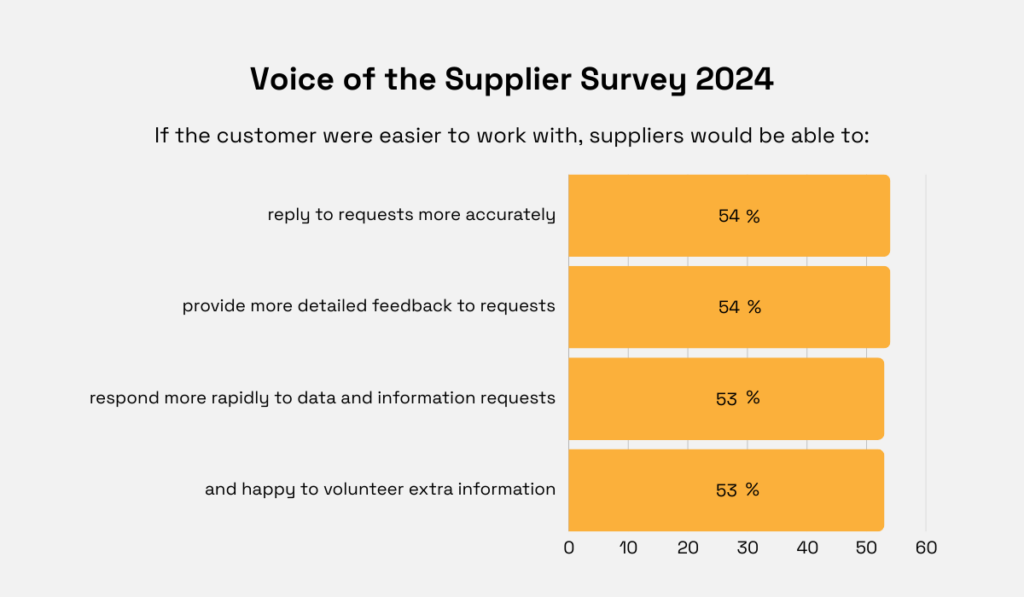

For example, the research also revealed that 54% of suppliers believe improving communication would enable them to respond to requests more accurately and provide more detailed feedback.

Illustration: Veridion / Data: HICX

These improvements lead to a significant boost in both productivity and responsiveness—an advantage your company can gain simply by making communication a priority.

How can you make that a reality for your company?

For starters, you should establish clear communication channels.

And the right technology can help you here.

Tools like Slack, for example, offer real-time messaging with external organizations through Slack Connect.

Source: Veridion

Saks, the premier digital platform for luxury fashion, uses it to communicate with suppliers to discuss inventory, product availability, and shipping in real time.

This allows both sides to collaborate more effectively, reduces the risk of errors and improves their operational efficiency.

Another way to streamline communication is by using more advanced technology, like supplier portals or SRM software.

These platforms centralize all communication, allowing for a smoother exchange of information and the ability to track updates across purchase orders, invoices, payments, contracts, and more.

Below you can see what P&G’s suppliers can access through their supplier portal:

Source: P&G

And if you wonder if suppliers actually see value in such tools, the answer is—yes.

The aforementioned Voice of the Supplier survey found that 63% of suppliers believe technology that supports better information sharing significantly enhances collaboration.

Additionally, 56% said it helps manage communication and planning more effectively.

This shows that suppliers are definitively ready to use the technology you choose and work together on better communication.

Building strong supplier relationships is important, but relationships alone won’t guarantee results.

A major mistake companies make is assuming everything is fine without actively tracking supplier performance.

If you’re not monitoring key metrics, you could be relying on underperforming or high-risk suppliers without realizing it—until a missed deadline, quality issue, or cost overrun disrupts your business.

A supplier might be consistently late on deliveries, but without a system in place, you may not see the pattern until it’s already costing you.

Financial instability, declining quality, or non-compliance with standards are all risks that regular reviews can help you catch early.

Source: Veridion

Another common mistake is focusing too much on activity rather than actual results.

Just because a supplier attends meetings and communicates well doesn’t mean they’re delivering value.

Instead of measuring effort, track tangible outcomes—like how quickly a supplier develops new products or whether their quality standards are improving.

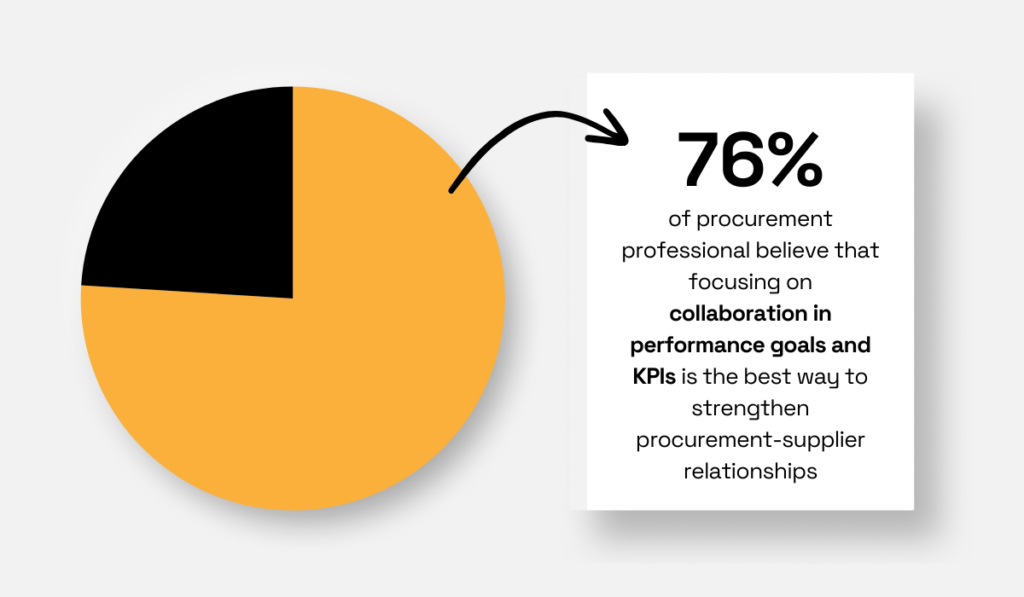

Research from Ivalua and Forrester we cited above has also found that 76% of decision-makers believe placing more emphasis on collaboration within performance goals and KPIs is the most effective way to improve supplier collaboration.

Illustration: Veridion / Data: Ivalua

In other words, by aligning expectations and tracking results transparently, both you and your suppliers can work toward continuous improvement.

So, to avoid this mistake, monitor and review supplier performance, and share the feedback with suppliers.

And the best way to ensure supplier accountability is by using clear, measurable performance indicators.

Here are some KPIs to include:

| On-time delivery rate | Are suppliers consistently meeting deadlines? |

| Quality performance | What’s the defect or return rate? |

| Lead times | How fast are suppliers delivering? |

| Cost adherence | Are suppliers respecting agreed pricing? |

| Innovation | Are suppliers bringing new ideas or process improvements? |

Using scorecards, dashboards, or automated tracking tools will make it easier to monitor these KPIs and share insights with suppliers.

But while tracking performance in these areas is vital, there’s one crucial metric many companies overlook: supplier sustainability practices.

It’s easy to get caught up in the operational side of things when managing supplier relationships—timely deliveries, quality products, and smooth communication.

These are all crucial factors in ensuring a healthy, efficient supply chain.

However, overlooking suppliers’ sustainability practices can be one of the most significant risks to your business, even if everything seems fine on the surface.

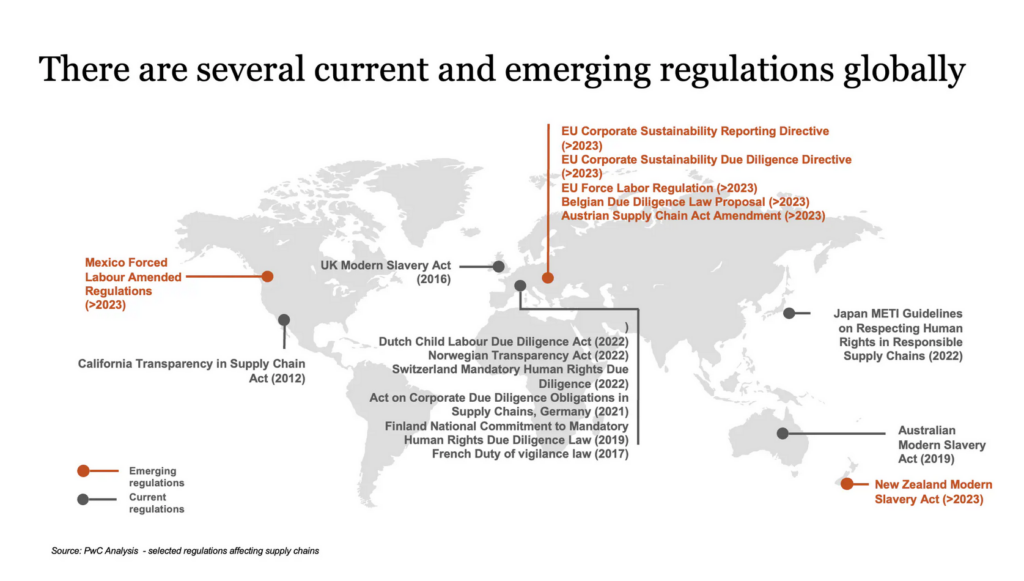

These risks can lead to major headaches down the road, starting with regulatory non-compliance now that governments around the world are tightening regulations surrounding sustainability.

Source: PwC

On the other hand, ethical and sustainable business practices have become a significant consideration for buyers, investors, and partners.

If your suppliers engage in unethical practices, such as human rights violations or environmental damage, your company could bear the brunt of the backlash.

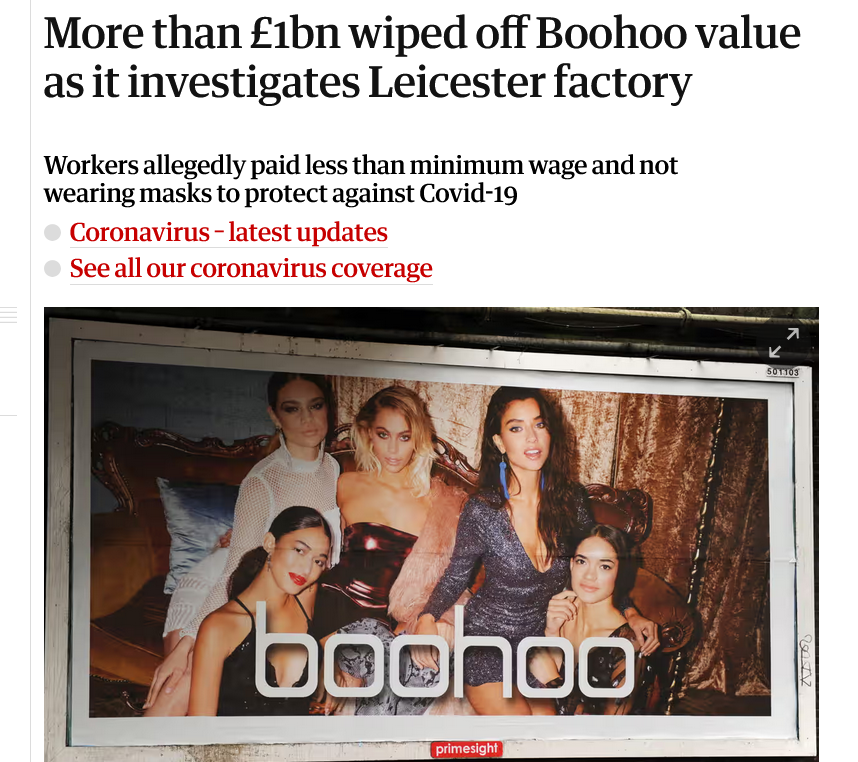

A glaring example of this happened in 2021 with Boohoo, a well-known fast-fashion retailer.

Source: Business & Human Rights Resource Centre

An investigation uncovered that workers at the Leicester-based Jaswal Fashions factory, a supplier to Boohoo’s Nasty Gal brand, were paid as little as £3.50 per hour and were subjected to poor working conditions.

The scandal quickly made headlines, and as a result, several major retailers, including Next, Zalando, Amazon, and ASOS, severed ties with Boohoo.

The financial fallout was swift and severe, with the company’s market value dropping by £1.5 billion in just two days.

Source: The Guardian

This incident highlighted how ignoring sustainability practices—specifically labor rights and ethical sourcing—can have a devastating effect on a brand’s reputation and bottom line.

Even if your suppliers are not directly involved in something as severe as forced labor, overlooking sustainability can still open you up to reputational damage if your company’s association with questionable suppliers is uncovered.

So, how do you stop making this mistake?

By regularly evaluating supplier sustainability practices.

Start by integrating sustainability criteria into your supplier discovery and selection processes.

Data platforms like our Veridion, which provides up-to-date information on over 120 million suppliers globally, can help you from the start.

Veridion’s database offers a comprehensive look at suppliers’ ESG practices, and allows you to search for suppliers based on the exhaustive criteria seen below:

Source: Veridion

Veridion’s data is gathered weekly from global and local news sources, as well as companies’ digital presence.

This ensures you’re always aware of the latest suppliers’ ESG practices.

Another approach is to collaborate with your suppliers to improve sustainability.

Offer guidance, incentives, or resources to help them meet higher standards.

Take a cue from General Motors, which created the Supplier Sustainability Council in 2020.

This initiative brought key suppliers together to focus on sustainability, fostering collaboration and knowledge-sharing.

As Marc Winterhalter, Vice President of Purchasing & Sustainability at Nemak (a GM supplier), put it:

“There is value for us because we are learning from others. We are committed to bringing value to the group by sharing our knowledge in areas where we might be advanced.”

So, to avoid making the same mistake again, always track and follow your suppliers’ sustainability practices!

How many of these mistakes are you making in your supplier relationship management?

Are you failing to segment your suppliers or overlooking their sustainability practices?

These missteps might seem small now, but they can snowball into missed opportunities, supply chain disruptions, and reputational damage.

Take a step back, assess your approach, and use the strategies we mentioned throughout the article to avoid these five mistakes.