Supplier Sourcing: What CPOs Need to Know

Finding the right suppliers is at the heart of successful procurement.

The suppliers you choose can significantly influence your bottom line—through competitive pricing, high-quality products, and reliable service.

Think about it like this: if you were building a house, you wouldn’t hire the first contractor you come across.

You’d compare prices, check their reputation, and make sure they could meet deadlines.

The same logic applies to supplier sourcing.

You want to make the most informed choice about who you will work with to get the best possible result.

Today, we’ll explore supplier sourcing a bit more, why it’s important to approach it thoughtfully, and some common challenges you might encounter along the way.

Let’s get started.

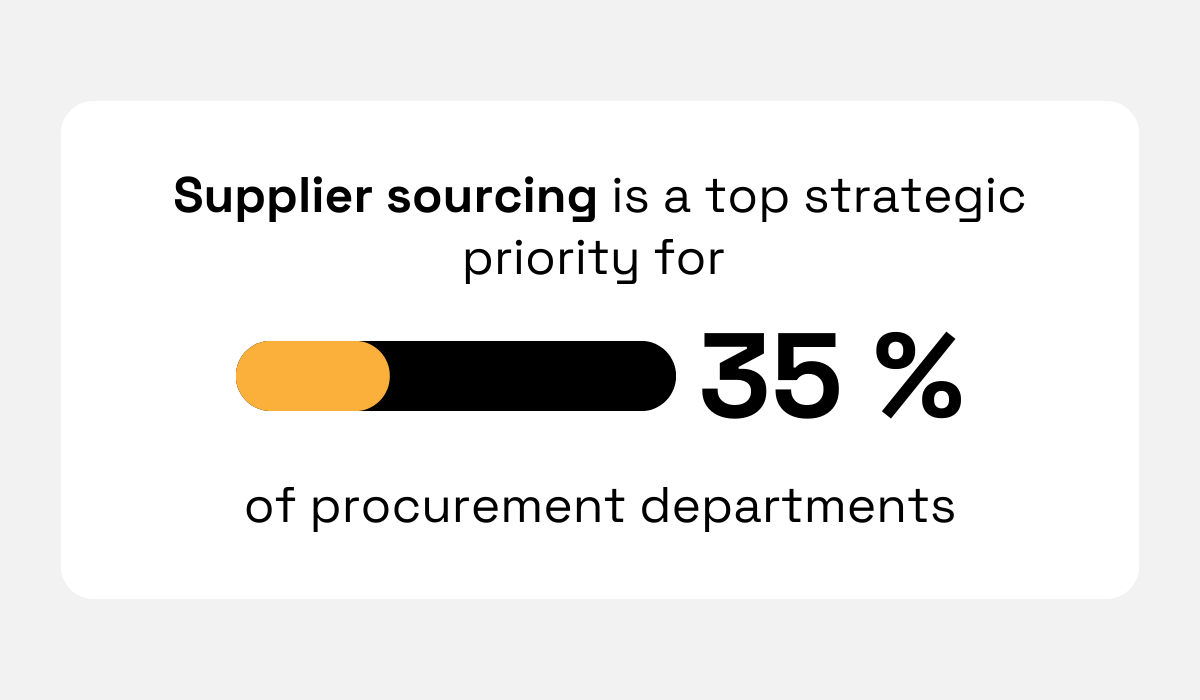

According to PwC’s 2024 Digital Procurement Survey, sourcing ranks as the top strategic priority for 35% of procurement departments.

Illustration: Veridion / Data: PwC

However, the landscape of supplier sourcing is evolving.

Today, it’s not solely about securing the lowest price from suppliers.

Instead, the focus has shifted significantly toward ethical sourcing.

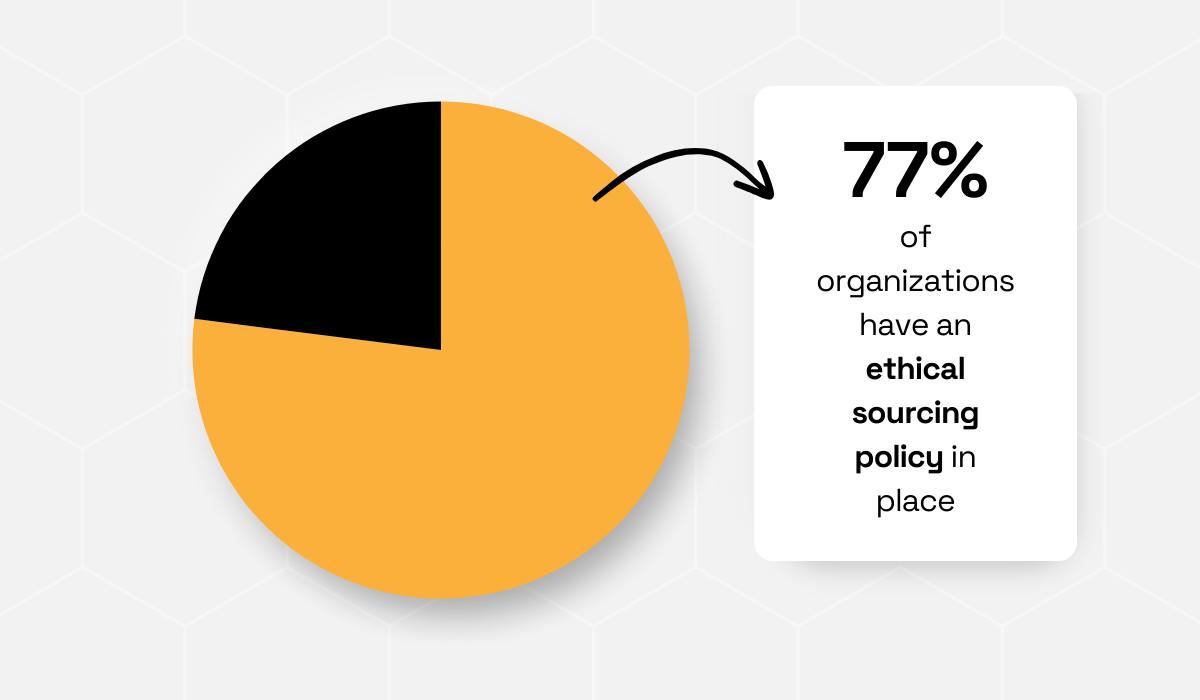

The Global Procurement & Supply Report by CIPS indicates that 77% of organizations have implemented an ethical sourcing policy, reflecting a growing awareness of the broader impacts of procurement decisions.

Illustration: Veridion / Data: CIPS

In other words, companies no longer focus on just finding the cheapest providers, but on finding those who prioritize sustainability, fair labor practices, and social responsibility.

As one procurement leader in the MENA region stated in the same report, procurement now holds significant power to influence these critical issues.

Illustration: Veridion / Quote: CIPS

So, it’s clear that ethical sourcing is becoming a key factor in supplier decisions.

Now, let’s shift gears and talk about the different types of suppliers.

After all, each business has unique needs and the type of supplier you source will depend on those needs.

Here’s a breakdown of the main supplier categories:

| Raw materials suppliers | Companies that provide the basic building blocks for your products, whether it’s steel, fabric, or any other raw material. |

| Product assemblers | If your business designs individual components but doesn’t assemble the final product, these suppliers bring it all together. |

| Service providers | Companies or freelancers offering consulting, design, or legal support—intellectual services that your business may need. |

| Technology suppliers | They provide the digital tools, like software and systems, that keep your operations running. |

Each type of supplier plays a distinct role, and sourcing the right one can make or break your efficiency and success.

There are also different types of supplier sourcing to consider, and this article provides in-depth information on the topic: 9 Types of Supplier Sourcing You Need to Know About

When you find the right suppliers, the benefits naturally follow.

A good sourcing strategy leads to better deals, supply chain resilience, and consistent quality.

Strategic sourcing doesn’t just help you find a supplier, but the best one for your business development.

For starters, the more suppliers you have access to, the more leverage you gain in negotiations.

Instead of being locked into a relationship with one supplier, you can compare and pit suppliers against each other to get the best terms.

Take it from Marijn Overvest, founder of Procurement Tactics.

When he worked as a Procurement Manager for a major retailer in the Netherlands and Belgium, he was tasked with negotiating a massive €50 million contract for a commodity product.

He didn’t settle for one or two suppliers—he negotiated with four.

Illustration: Veridion / Quote: Procurement Tactics

By meeting with their management teams, he worked hard to secure favorable terms.

After multiple discussions, he managed to save the company €2 million.

But he didn’t stop there.

Overvest decided to take the negotiation further by running an e-auction with the same suppliers.

This competitive bidding process saved the company an additional €3 million, bringing the total savings to €5 million.

His case perfectly illustrates how a robust supplier sourcing process can provide the leverage needed to secure better deals and generate procurement cost savings.

More suppliers lead to more competition, which in turn drives down costs and improves profit margins.

Relying on a single supplier might seem convenient, but it’s risky.

What happens if that supplier can’t deliver due to unforeseen circumstances like a natural disaster, political instability, or financial trouble?

The result could be production delays, lost revenue, or worse.

Strategic supplier sourcing helps mitigate this risk by ensuring you have multiple suppliers in place.

This strategy keeps your operations running smoothly, even if one supplier is suddenly unavailable.

A clear example of the need for diversification happened during the 2011 earthquake in Japan, which disrupted the global electronics supply chain.

Car manufacturers like Toyota and Nissan quickly realized that depending too much on suppliers from a single region made them vulnerable.

Toyota responded by creating a diversified supplier strategy.

The company now sources parts from various suppliers and regions, maintaining backup systems so that, in the event of a disaster, they can continue production without major interruptions.

Illustration: Veridion / Quote: Automotive Logistics

Nissan took a similar approach, diversifying its suppliers to avoid over-reliance on Japanese sources.

They started sourcing certain parts from South Korea, which not only ensured supply continuity but also helped them avoid rising production costs in Japan.

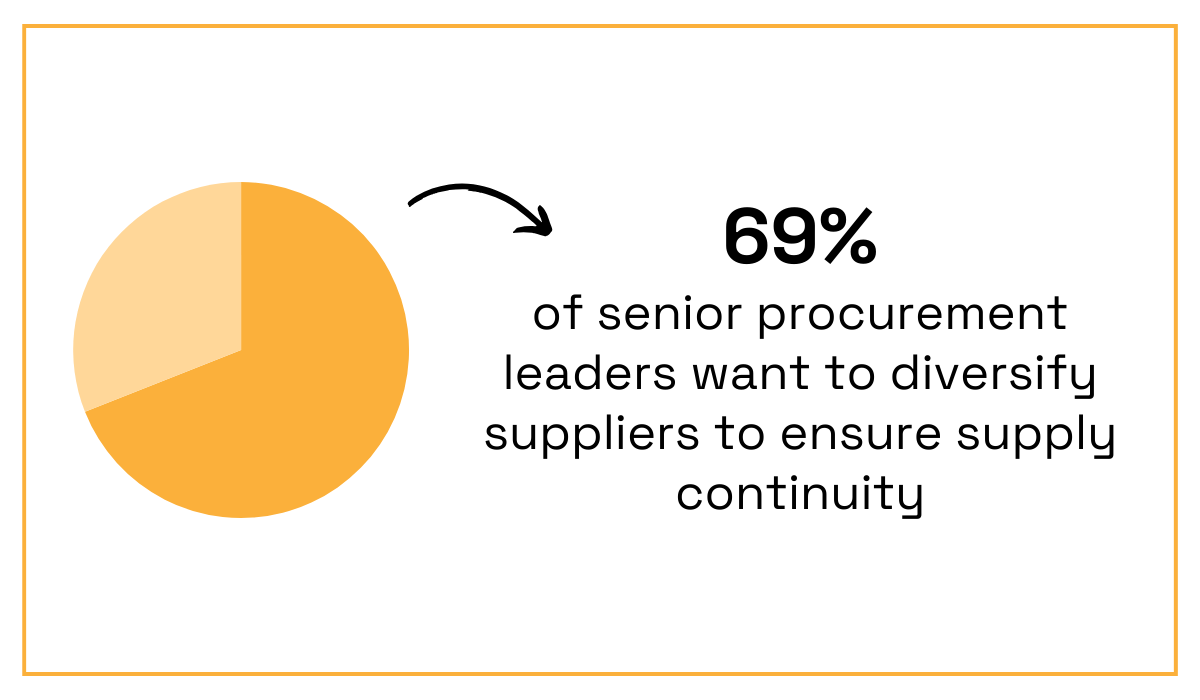

This approach is now common.

In fact, 69% of procurement leaders want to diversify their suppliers in the next three to six months, according to the above-mentioned report by CIPS.

Illustration: Veridion / Data: CIPS

Sourcing from multiple suppliers reduces risk and ensures that, no matter what challenges arise, your operations continue uninterrupted or with minimum impact.

Supplier sourcing also plays a critical role in maintaining high-quality standards.

Careful vetting of suppliers allows businesses to choose those with solid quality control systems, consistent track records, and the capability to meet your requirements.

But how does this work in practice?

Companies often start by creating a list of key quality metrics, such as defect rates, on-time delivery performance, or adherence to industry standards.

They then assess potential suppliers against these metrics, allowing them to select those who can meet or exceed expectations.

Once onboarded, continuous monitoring of supplier performance helps ensure that quality remains consistent over time.

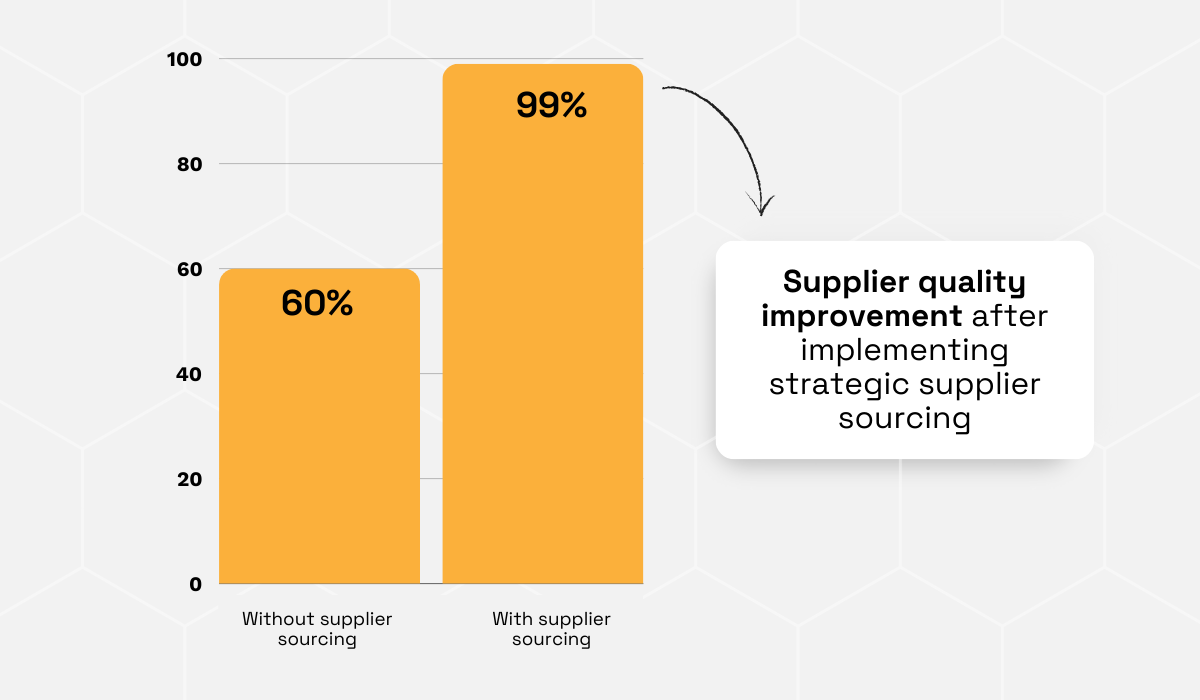

One notable example is a Colorado manufacturer that improved supplier quality by implementing a strategic supplier sourcing program.

Initially struggling with inconsistent lead times and frequent rework due to poor supplier quality, the company revamped its supplier selection process.

They prioritized local suppliers with robust quality control systems and emphasized long-term partnerships with mutually beneficial terms.

As a result, supplier on-time delivery improved from 50% to 95%, and quality jumped from 60% to over 99%.

Illustration: Veridion / Data: Linkedin

This led to a 30% boost in gross profit and a 50% reduction in inventory, freeing up $750,000 in cash.

As this case shows, diligent supplier sourcing not only improves quality but also enhances efficiency and brings more profit.

Despite the clear advantages, supplier sourcing comes with its challenges—especially when managed manually or when dealing with numerous suppliers from different regions.

Below are some common issues and their potential solutions.

Finding suppliers that meet your specific standards can be tricky, especially when you require highly specialized products or services.

The more niche your needs are, the smaller the pool of potential suppliers becomes. In highly specialized industries, you may be left with just one or two viable suppliers.

Source: Veridion

This leaves your company vulnerable to supply chain disruptions and higher costs if something goes wrong.

So, how can you fix this?

For one, think bigger.

Expanding your search outside your usual supplier pool is critical.

Digital sourcing platforms can help you connect with suppliers globally, giving you more options for competitive pricing or a wider spectrum of products.

Our very own supplier discovery platform, Veridion, solves that problem.

Veridion enables you to quickly search through millions of suppliers across the globe using criteria that matter most to your business—whether that’s location, product type, company size, financial health, compliance standards, or ESG criteria.

Source: Veridion on YouTube

This level of detail allows you to find suppliers who check all your boxes in just minutes.

Rahul Kale, Head of Business Management at Enemtech Capitals India, suggests another thing you can do—adjust your requirements:

Illustration: Veridion / Quote: Linkedin

Simplifying your requirements and having access to the global supplier network at your fingertips will help you find good options in no time.

Let’s not forget—maintaining supplier relationships isn’t a walk in the park.

You need to build trust and keep communication channels open, which can be challenging, especially when dealing with global procurement.

This is where cultural differences, language barriers, and varying business practices can all complicate matters.

Even with local suppliers, handling multiple vendors can become overwhelming, leading to misunderstandings, misaligned expectations, and supply chain delays.

A breakdown in communication with one key supplier could affect your entire procurement cycle.

So, what’s the key to overcoming these challenges?

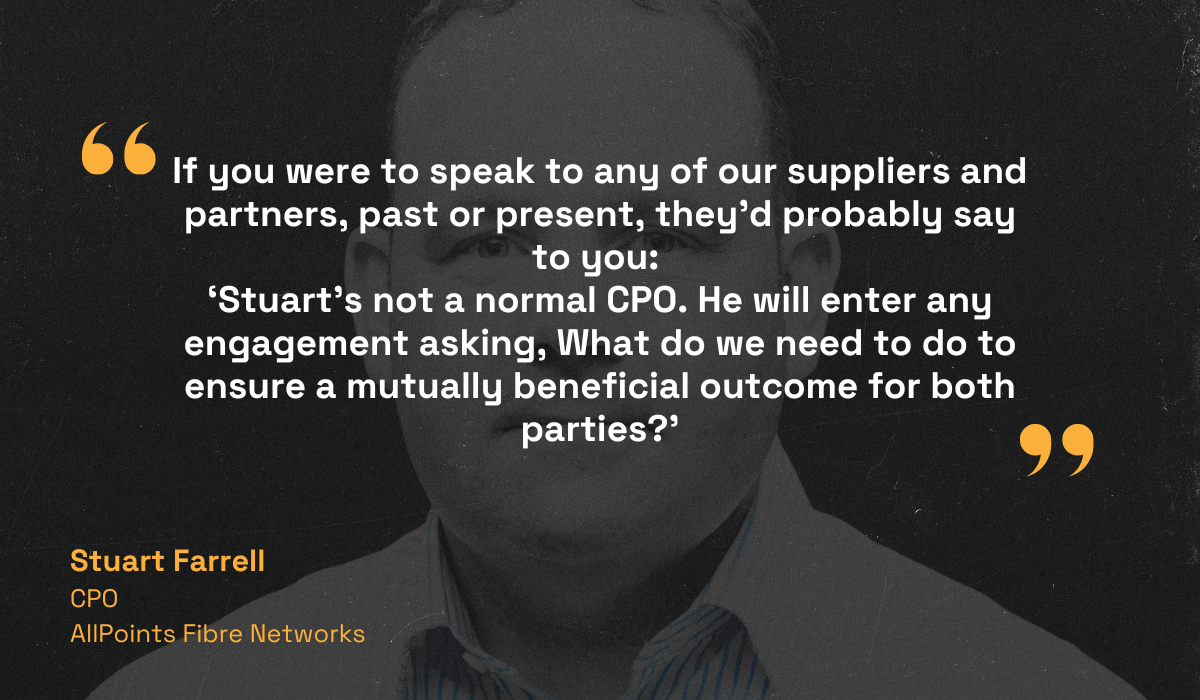

Trust, clear communication, and, as Stuart Farrell, CPO at AllPoints Fibre Networks (APFN), emphasizes, the importance of mutual benefit:

Illustration: Veridion / Quote: Procurement Magazine

When there is mutual benefit, both parties are satisfied and it is easier to maintain a strong relationship.

What about language barriers?

When it comes to international suppliers, using technology can bridge the communication gap.

Translation tools, dedicated communication platforms, or hiring a multilingual team can significantly reduce misunderstandings.

It’s also essential to establish clear written agreements and ensure both parties fully understand the terms before moving forward.

All in all, with the right mindset and tools, this challenge is completely solvable.

The world doesn’t stay still, and neither do markets.

Procurement professionals constantly navigate shifts in consumer preferences, technological advancements, and supply chain trends.

Staying ahead of these changes is a challenge because what worked a year ago may not work today.

So, how can you keep up?

The key is agility.

Regularly reviewing your supplier base, performing market analysis, and being open to new partnerships can save you from scrambling when changes hit.

Among the solutions, Syed Faizan Jafar Abidi, Senior Procurement Manager at Abbott, advocates for giving newer suppliers a chance:

Illustration: Veridion / Quote: Linkedin

Smaller or newer suppliers can often offer more competitive pricing or quicker turnaround times, making them ideal partners when the market shifts.

Finally, by diversifying your supplier base, which is one key benefit of supplier sourcing, you can build a more resilient procurement strategy that withstands sudden changes in the market.

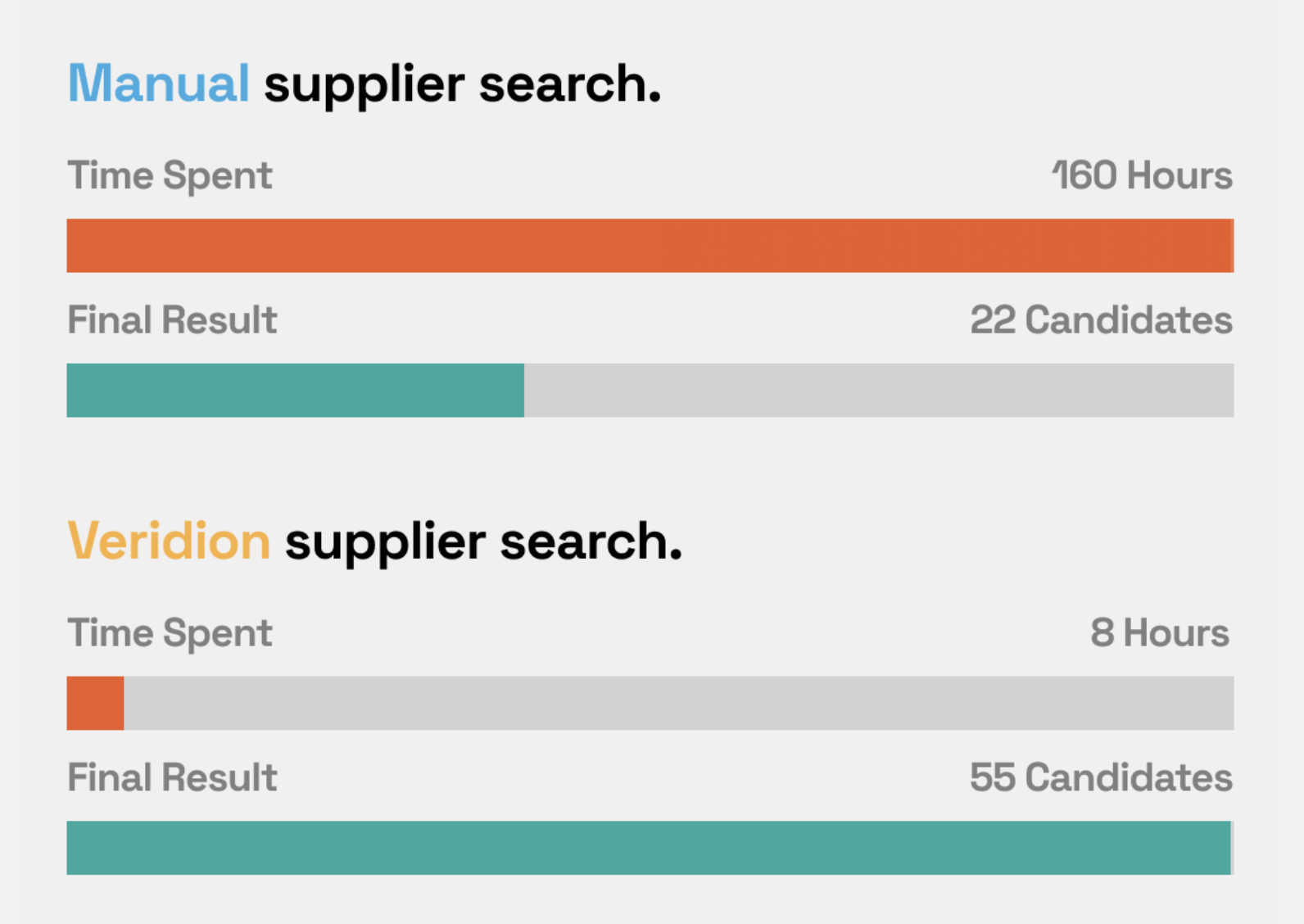

To speed up the process and find quality suppliers.

Sourcing new suppliers can be a time-consuming, complex, and sometimes risky process.

Manually searching for suppliers often involves:

McKinsey reveals that, on average, it takes about three months to complete a single supplier search.

Sourcing professionals are often logging over 40 hours of work to evaluate just a few dozen suppliers from a pool of thousands.

Illustration: Veridion / Data: McKinsey

And that’s just the beginning—the evaluation, negotiation, and onboarding processes add even more time and effort.

A supplier-sourcing solution streamlines this entire process, mitigates errors, and helps your procurement team work more efficiently.

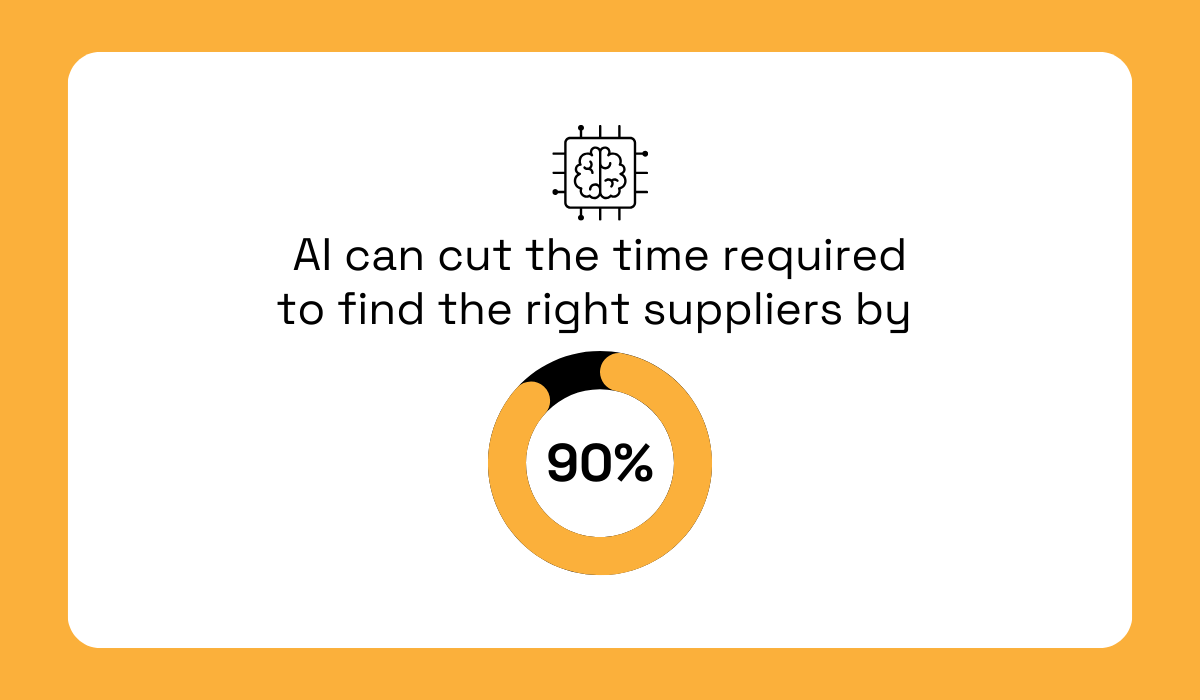

For starters, supplier sourcing solutions use automation, AI, and machine learning to cut down the time required to find suitable suppliers.

McKinsey notes that these tools can reduce the time needed to identify the right suppliers by up to 90%.

Illustration: Veridion / Data: McKinsey

What would typically take months can now be done in days, if not hours.

Just take our Veridion as an example:

Source: Veridion

With such solutions in place, your procurement team can focus on strategic decisions rather than tedious manual searches.

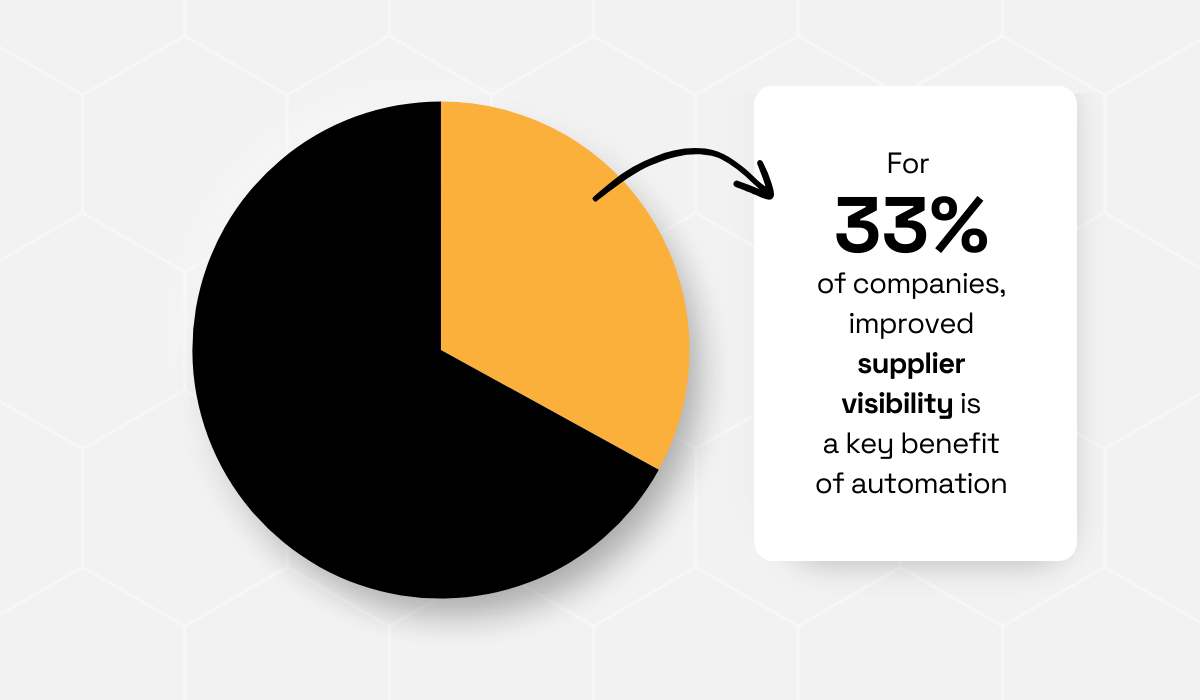

Another advantage of using automated sourcing tools is enhanced supplier visibility.

And, according to Keelvar’s report on sourcing automation, 33% of business leaders cite improved supplier visibility as a key benefit of automation.

Illustration: Veridion / Data: Keelvar

When you have a clearer picture of who you will potentially work with, you can better manage risks associated with supplier reliability, compliance, and financial stability.

And, ultimately, make a better choice.

Mastering supplier sourcing is about more than just finding the suppliers who offer the lowest price.

It’s about building long-term partnerships that align with your business goals and values.

By carefully selecting, diversifying, and nurturing supplier relationships, you can secure better deals, ensure consistent quality, and even uphold ethical standards.

While the process comes with challenges, using the right strategies and tools can help you overcome them and boost your business’s success.

So, if you’re ready to take your sourcing game to the next level, evaluate your approach today and make sure you only work with suppliers that further drive your success.