Procurement Cycle: The Full Guide

Understanding the procurement cycle is crucial for any business looking to streamline its operations and cut costs.

But if you’ve ever felt overwhelmed by the complexities of managing procurement, you know that having a structured process is key.

This article is for procurement professionals who are struggling with inefficient processes, high costs, and supplier management challenges.

We’ll break down the procurement cycle step-by-step, highlighting its benefits and addressing common hurdles you might face.

Plus, we’ll introduce you to tools that can simplify each stage, making your procurement cycle smoother and more efficient.

Let’s dive in!

First off, it’s important to clarify what exactly the procurement cycle is.

To put it very simply, we can borrow Pipefy’s definition of the term.

Illustration: Veridion / Quote: Pipefy

As they put it, the procurement cycle is all about identifying and meeting procurement needs.

However, to fully grasp the process, we need to expand this a bit further.

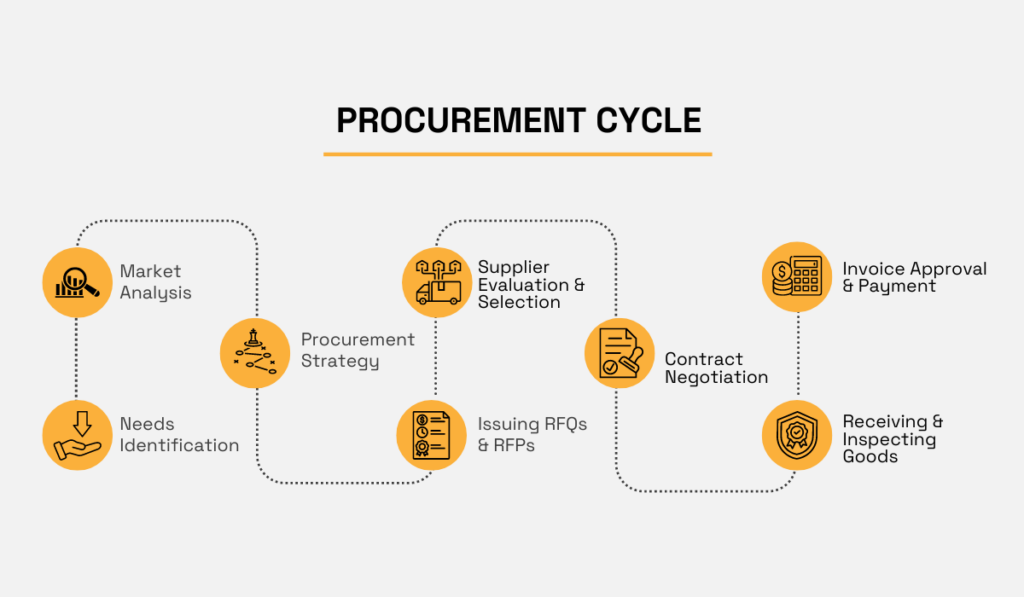

The procurement cycle consists of multiple steps that ensure a smooth and efficient procurement process, from initial needs identification to the final receipt and payment of goods or services.

Source: Veridion

Some procurement teams might haphazardly go through these steps without paying close attention to each step, but this can lead to various issues, such as:

Furthermore, we must consider evaluating supplier performance, supplier monitoring, and even relationship management as essential steps of the procurement cycle.

These steps illustrate that the procurement cycle goes beyond simply buying goods or services.

Instead, it also involves ongoing assessment and interaction with suppliers to ensure they continue to meet performance standards.

To summarize, we can divide the entire cycle into these three general stages:

| STAGE | MAIN GOAL | EXPLANATION |

|---|---|---|

| Planning and Preparation | Define specific requirements and procurement strategy | Identify specific goods or services needed. Conduct thorough market research to understand options and costs, then develop a strategic approach for procurement. |

| Selection and Contracting | Select suppliers and agree upon terms | Evaluate the received bids using set criteria to determine the best supplier in terms of cost, quality, and reliability. Engage in negotiations to finalize contracts. |

| Execution and Review | Execute orders and manage supplier relationships | Manage orders and suppliers, take care of invoicing, supplier monitoring, and relationship management. |

In essence, the procurement cycle is a comprehensive process that needs to be well-organized and followed-through to ensure that procurement needs are met.

Now that we have a clear understanding of what the procurement cycle is, it’s important to explore why having a well-run procurement cycle is so beneficial.

In the next sections, we’ll cover three main benefits: cost savings, increased efficiency, and better quality goods and services.

First off, a well-executed procurement cycle can bring significant cost savings to an organization.

Key cycle stages such as supplier selection, contract negotiation, and order management directly impact pricing and overall savings.

Some commonly used strategies within these stages that generate procurement savings are illustrated below.

Source: Veridion

Naturally, many of these strategies are directly related to suppliers.

For example, negotiating discounts for bulk purchases or securing lower prices through long-term contracts can result in substantial savings.

Competitive bidding strategies, where multiple suppliers compete to provide the best value and quality goods, are also effective.

Additionally, streamlining procurement processes through technology—something we will explore in depth later—can significantly reduce costs.

But these savings are not just theoretical, data shows.

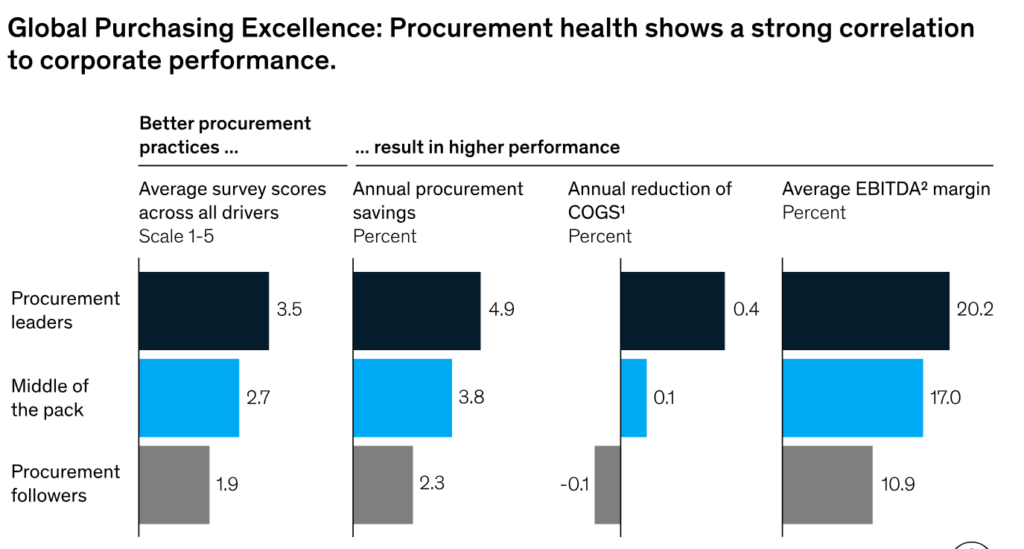

McKinsey’s research shows that companies that excel in their procurement functions achieve much greater performance compared to others, including a 4.9% annual savings and a 0.4% reduction in COGS.

Source: McKinsey

These figures highlight the substantial impact a well-run procurement cycle can have on an organization’s financial health.

Some of the cost savings brought on by a well-run procurement cycle come from increased process efficiency.

A well-managed procurement process streamlines operations, reduces redundancy, and minimizes delays.

By clearly defining each step and ensuring all stakeholders understand their roles, businesses can significantly cut down on wasted time and resources.

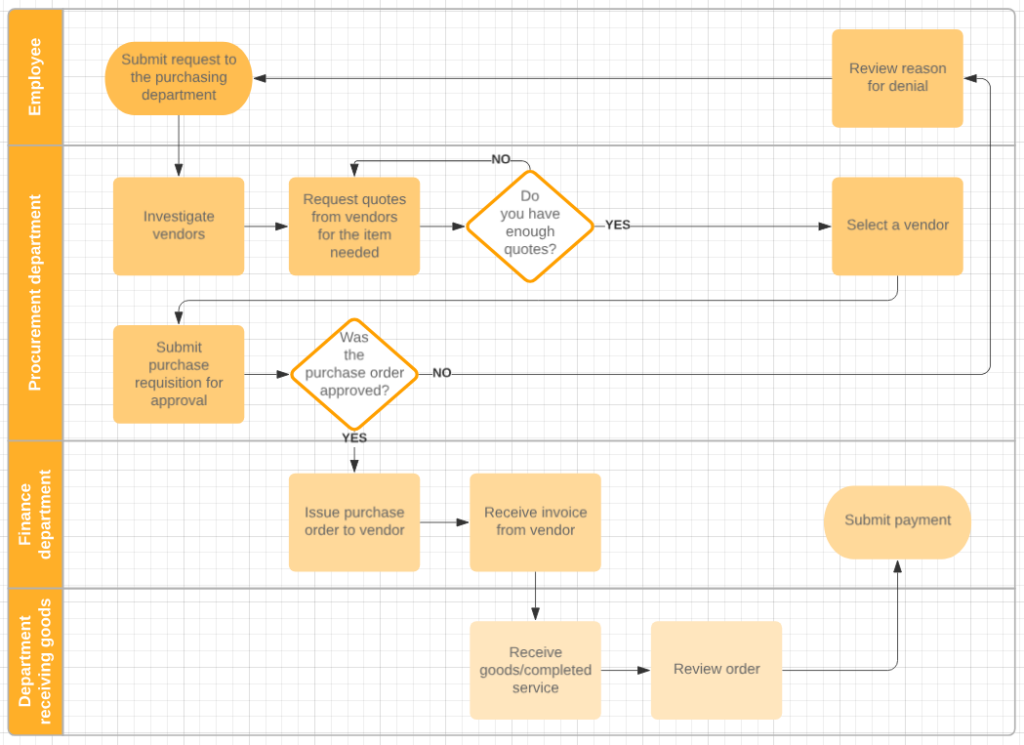

Another way to achieve efficiency is to establish a defined flow in the procurement process, such as the one shown below.

Source: Lucidchart

As you can see, this process is divided by department.

It illustrates how smoothly operations can run between procurement, finance, goods inspection teams, and individual procurement employees.

With specific rules and workflows in place, most issues are accounted for and handled efficiently.

Furthermore, research conducted by The Hackett Group shows that technology enablement plays a critical role in enhancing procurement efficiency.

Illustration: Veridion / Quote: The Hackett Group

They looked at Digital World Class procurement teams, which The Hackett Group defines as leaders in digital transformation.

They found that, despite year-on-year increases in operating costs, procurement operations working at the highest level were able to operate at 21% lower cost than their peers.

On top of this, they are reported to have top-quartile performance in business value, digital enablement, and operational excellence.

This demonstrates that leveraging technology both saves costs and ensures smoother and more efficient operations.

Another key aspect to consider in the procurement cycle is the quality of goods and services.

High-quality goods are crucial for maintaining customer satisfaction and reducing returns and complaints.

The procurement cycle directly affects this by implementing quality checks and standards at various stages.

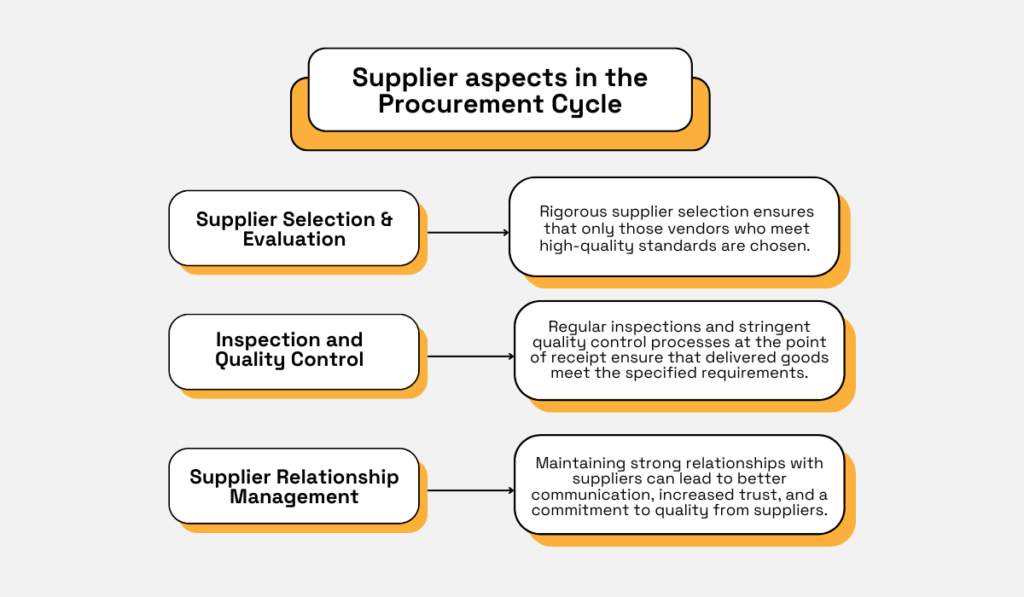

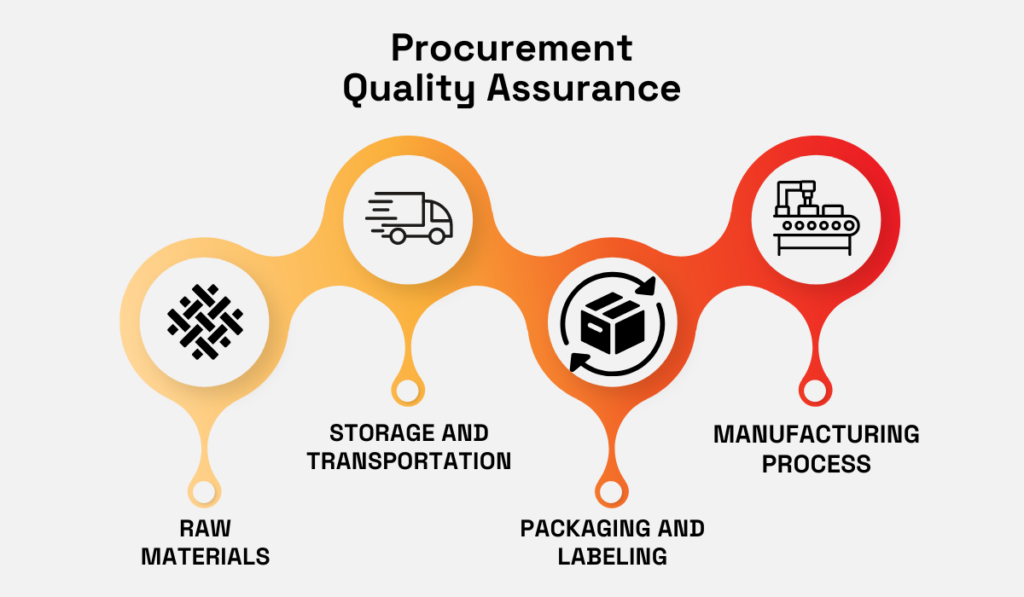

The most critical steps revolve around suppliers and the goods they deliver, as illustrated below.

Source: Veridion

Ensuring that goods are of the highest quality and value should begin with the supplier selection process.

Therefore, choosing reliable and reputable suppliers who meet your quality standards is essential.

Establishing strong relationships and effective supplier management practices helps maintain these standards over time.

When it comes to quality checks themselves—during the inspection phase of the procurement cycle—teams focus on several key aspects of the quality of goods.

You can see the breakdown of these aspects in the illustration below.

Source: Veridion

Quality assurance in procurement involves monitoring the manufacturing process to ensure consistency, as well as verifying proper packaging, labeling, storage, and transportation to maintain product integrity.

It also evaluates whether raw materials meet the specified standards and whether suppliers adhere to the agreed-upon quality measures.

Lastly, the inspection of final goods involves a thorough check to ensure they meet all required specifications and standards before acceptance and payment.

This comprehensive approach to quality assurance ensures that every aspect of the product lifecycle is monitored and managed.

While a well-run procurement cycle offers numerous benefits, it’s not without its challenges.

Procurement professionals face many hurdles, such as supplier risk, fluctuating market prices, and maintaining compliance with regulations.

In the upcoming sections, we will explore three of these challenges in detail and discuss some strategies to overcome them.

Let’s begin.

Firstly, one challenge you can face is relying on outdated procurement cycle processes.

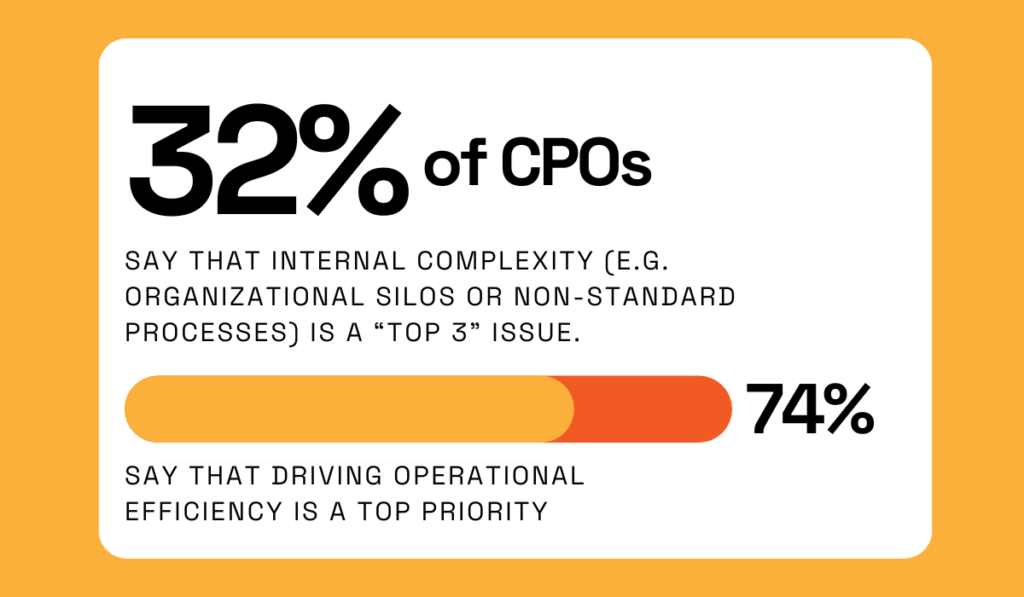

Consider the findings from Deloitte’s 2023 global CPO survey.

While the majority of organizations value operational efficiency, one-third of them struggle with rising internal complexity, such as silos and non-standard processes.

Illustration: Veridion / Data: Deloitte

Silos occur when departments work in isolation rather than collaboratively, leading to inefficiencies and communication breakdowns.

Non-standard processes, on the other hand, refer to the lack of a unified, streamlined approach to the procurement cycle.

One tell-tale sign of these inefficiencies is that procurement teams spend most of their time on data management, creating reports, checking for compliance issues, and managing risks.

And, according to KPMG, these tasks can account for 80% of procurement efforts.

Illustration: Veridion / Data: KPMG

If this is the case in your organization, you can start by standardizing procedures across departments, ensuring consistent workflows that are easy to follow and manage.

Regular training and cross-departmental communication can really help break down silos and promote a more integrated approach to procurement.

Also, take a look if you’re following some of the best practices for efficient data management and procurement efficiency— these can really help alleviate some bottlenecks.

Overall, with constant monitoring and a strong focus on continuous improvement, you can ensure processes are up-to-date and efficient.

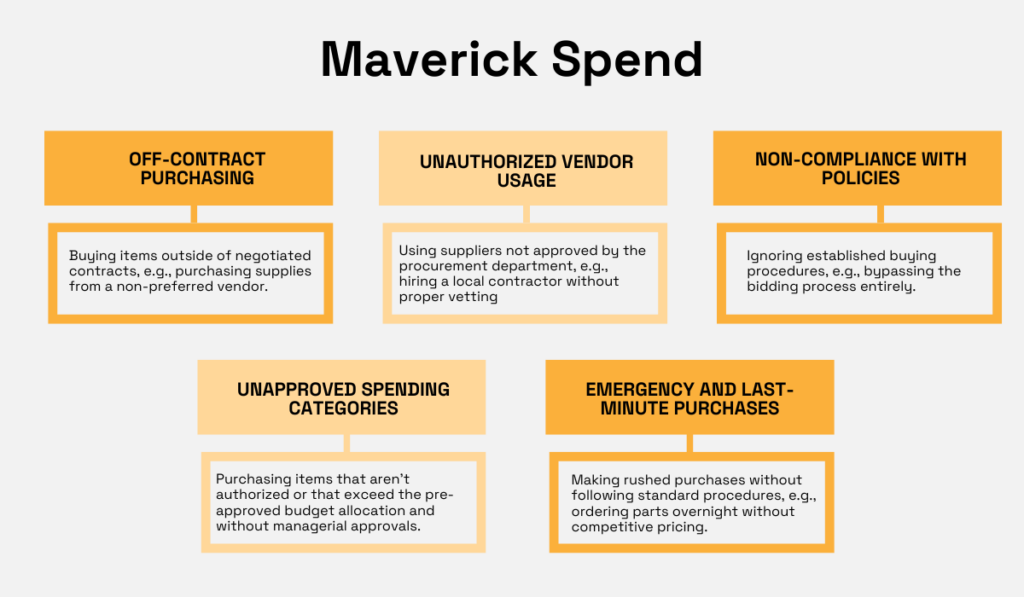

Lack of direction and clearly defined processes can also give rise to another challenge—maverick spend.

Maverick spending refers to purchases made outside of established procurement procedures and guidelines.

This type of spend can manifest itself in several ways, some of which are illustrated below.

Source: Veridion

The significant issues that can arise from maverick spend include increased costs due to missed opportunities for bulk purchasing discounts, higher transaction costs, and a lack of visibility into overall spending.

It can also lead to compliance risks and difficulties in managing supplier relationships effectively.

Luckily, steps can be taken to mitigate this issue.

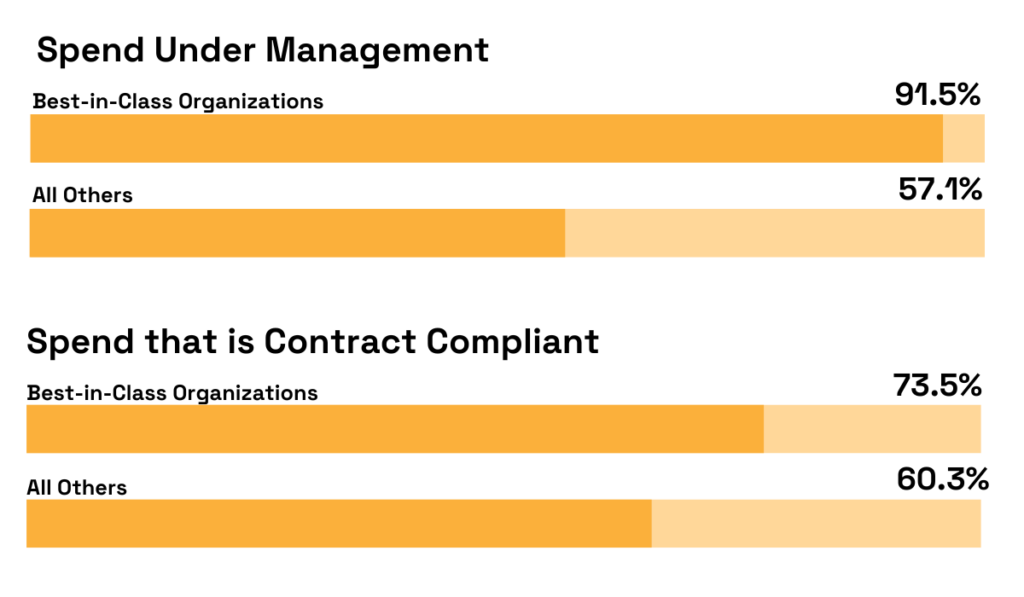

According to a report by Ardent Partners, organizations that are best-in-class in terms of procurement performance have significantly higher spend under management and spend that is contract-compliant.

Illustration: Veridion / Data: SpendHQ

The key characteristics of these organizations include:

In your organization, you should ensure that procurement processes are well-defined and communicated, leveraging technology to monitor and enforce compliance.

Also, training employees on the importance of following procurement policies and providing them with easy-to-use procurement tools can help minimize maverick spend.

Ultimately, addressing maverick spend through strong leadership, clear processes, and effective use of technology can lead to significant cost savings and an overall better procurement cycle.

A closely related challenge is poor procurement visibility.

This refers to the inability to track and monitor the procurement process from end to end, including sourcing, purchasing, and supplier performance.

Frank Kenney, Director of Market Strategy at B2B integration solution Cleo, highlights the importance of visibility:

“Visibility and the ability to see things that are happening – both in a real-time way and being able to go back and take a look at trends – becomes incredibly important, especially when you are thinking about all of the little pieces of the puzzle.”

To combat poor procurement visibility, you should centralize your procurement data by using robust procurement software or dedicated platforms.

This will allow you to create a single source of truth for all procurement data, enabling real-time tracking and reporting, as well as offering insights into spending patterns, supplier performance, and potential bottlenecks.

Also, by integrating with ERP or inventory management tools, this centralized data hub becomes even more powerful, providing a holistic view of the entire supply chain.

You should also keep a close eye on automation and emerging AI technologies.

Source: CPO Strategy

As discussed in this CPO Strategy article, AI can significantly increase visibility by analyzing vast amounts of procurement data, identifying patterns and trends, and providing valuable insights.

By leveraging certain processes and cutting-edge tools, businesses can gain a comprehensive understanding of their procurement cycle and make data-driven decisions that improve efficiency, reduce costs, and drive sustainable growth.

Throughout this article, you might have noticed we’ve mentioned various tools and software for managing certain aspects of procurement.

This isn’t by chance.

Tools are essential for unlocking the benefits of the procurement cycle and managing most of the challenges present in this process.

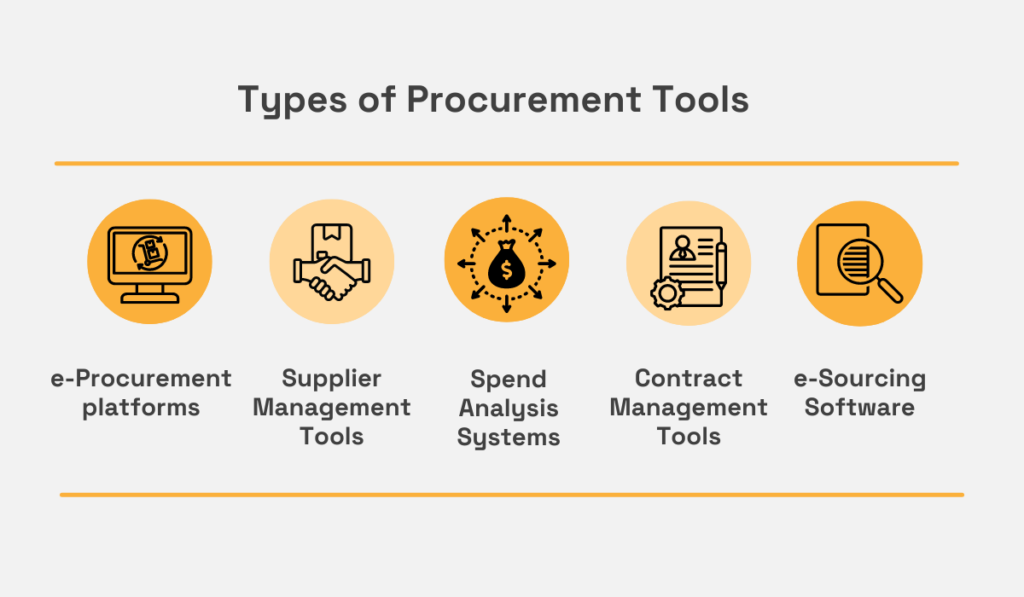

Some of the types of tools that are used throughout the procurement cycle include the ones shown below.

Source: Veridion

E-procurement tools automate the purchase order process, from requisition to payment, reducing manual work and errors.

On the other hand, e-sourcing tools help organizations solicit bids from suppliers, manage RFQs, and conduct auctions, ensuring competitive pricing and better supplier selection.

Contract management tools are another key category. They help manage the lifecycle of contracts from creation to renewal, ensuring compliance and reducing risk.

Also worth considering are supplier management tools, which can track supplier performance, manage relationships, and help you ensure suppliers meet company standards and requirements.

And then, there’s Veridion, our supplier sourcing enabler which takes supplier discovery to the next level.

Our powerful Search API helps procurement teams find and evaluate suppliers efficiently by providing access to a vast, up-to-date database of over 70 million companies worldwide.

Source: Veridion

Veridion can significantly aid the early stages of the procurement cycle.

By offering detailed supplier profiles and real-time data, our tool can ensure you make informed sourcing and evaluation decisions from the start, leading to reduced risks and better procurement efficiency later on.

Overall, utilizing the right procurement tools can greatly enhance your procurement cycle, making processes more efficient, reducing costs, and ensuring better quality and compliance.

We’ve covered a lot in this guide, walking you through every step of the procurement cycle from planning to evaluation.

We hope you now have a solid grasp of each phase and understand how they interconnect to form a seamless process.

With this knowledge, you can streamline your operations, cut costs, and foster stronger supplier relationships.

The practical tips and tools discussed here are designed to help you tackle procurement challenges head-on, ensuring your business runs more smoothly and efficiently.

So, take what you’ve learned and start optimizing your procurement cycle today. It’s time to turn those headaches into strategic advantages!