6 Ways to Successfully Mitigate Procurement Risk

If you’re leading a procurement team or part of it, chances are you’re interested in refreshing your expertise in procurement risk management.

And you certainly have many reasons to do so.

Inflation, geopolitical conflicts, health crises, natural disasters, economic fluctuations, regulatory/ESG compliance issues, supplier default or bankruptcy… should we go on?

Clearly, successfully mitigating these and a host of other procurement risks is paramount for companies seeking to protect their productivity, reputation, and bottom line.

Here are some of the best practices that can help.

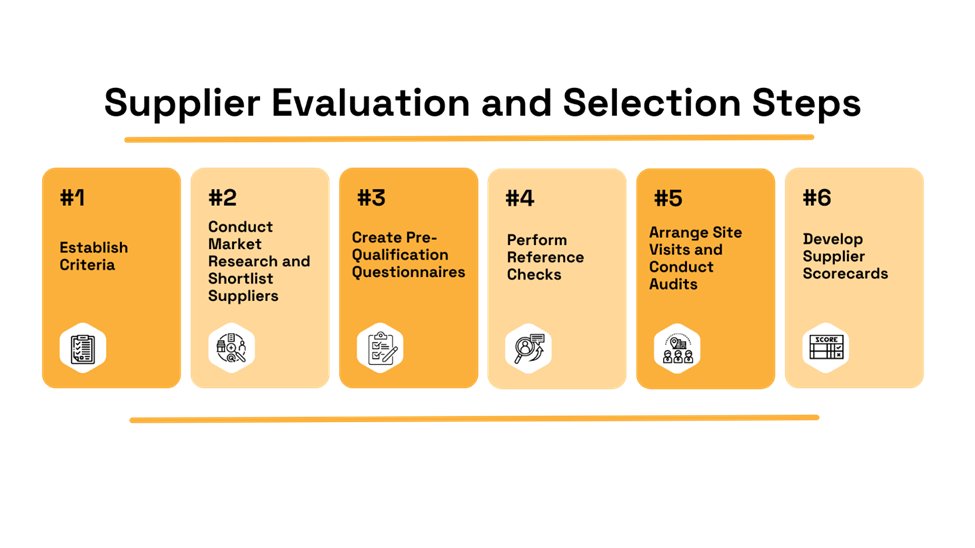

Carefully evaluating your suppliers is essential for mitigating a range of procurement risks and ensuring the smooth functioning of your supply chain.

While this principle extends to your existing suppliers through performance management and regular reviews, conducting a thorough initial evaluation of potential suppliers is the most effective way to ensure the long-term success of your procurement endeavors.

Through this process, your team can identify and select reliable partners who:

So, how can you effectively evaluate and select suppliers?

Here are the key steps to follow.

Source: Veridion

Of course, the exact order and specifics of these steps will vary depending on an individual company’s procurement policy, the nature of the goods or services being procured, and the data collection and analytics tools used.

For instance, preliminary reference checks can now be conducted earlier in the process by leveraging online search or big data platforms, allowing for an early assessment of a supplier’s track record and reliability.

However, the supplier evaluation process always starts with defining clear procurement criteria.

This includes product or service specifications, quality and delivery standards, and compliance requirements.

The second step—researching to find eligible suppliers that fit your criteria and shortlisting them—is typically a time-consuming and resource-intensive process if done through manual internet searches.

When we add issues involving outdated, missing, or incomplete supplier data, this process can take several months or even longer.

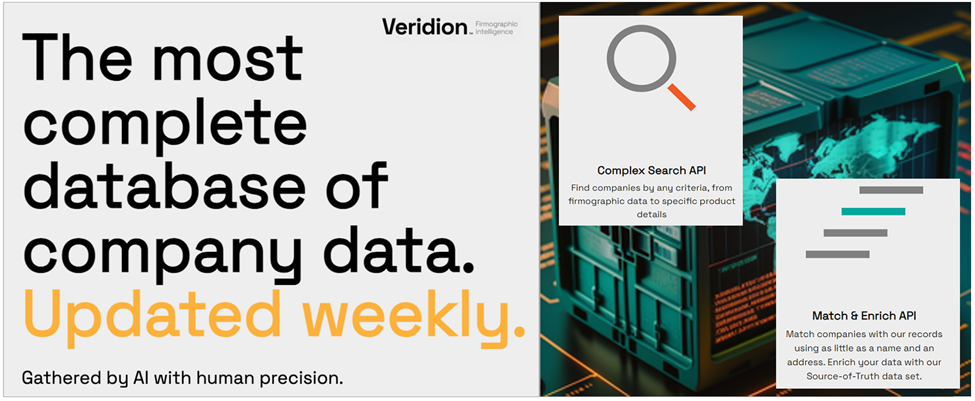

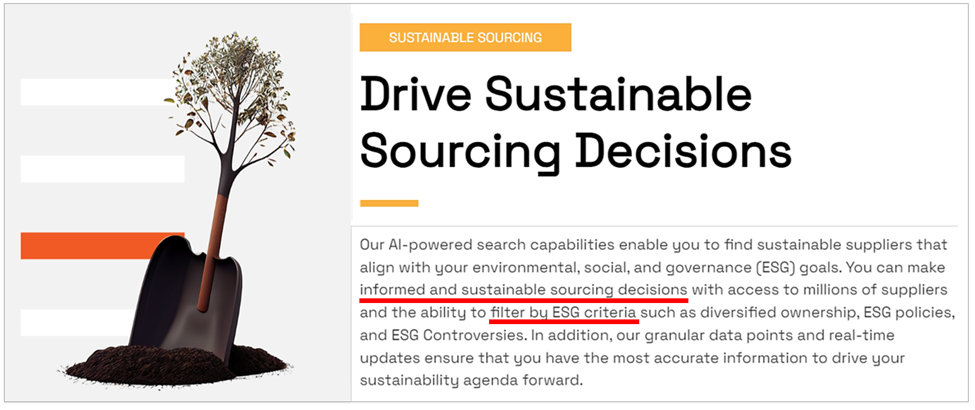

Fortunately, supplier discovery and evaluation, as well as risk assessment, can now be done much faster and easier with the help of supplier sourcing tools like our Veridion.

Source: Veridion

With Veridion, you get a regularly updated, AI-powered global database of suppliers and advanced search APIs that seamlessly integrate with your other procurement automation tools.

Veridion’s proprietary machine-learning algorithms constantly scour the internet and check all sources to provide you with the most accurate and up-to-date supplier data.

This data accuracy and freshness are crucial for careful supplier evaluation and successful risk mitigation, particularly when considering possible supplier scams and frequent supplier data changes.

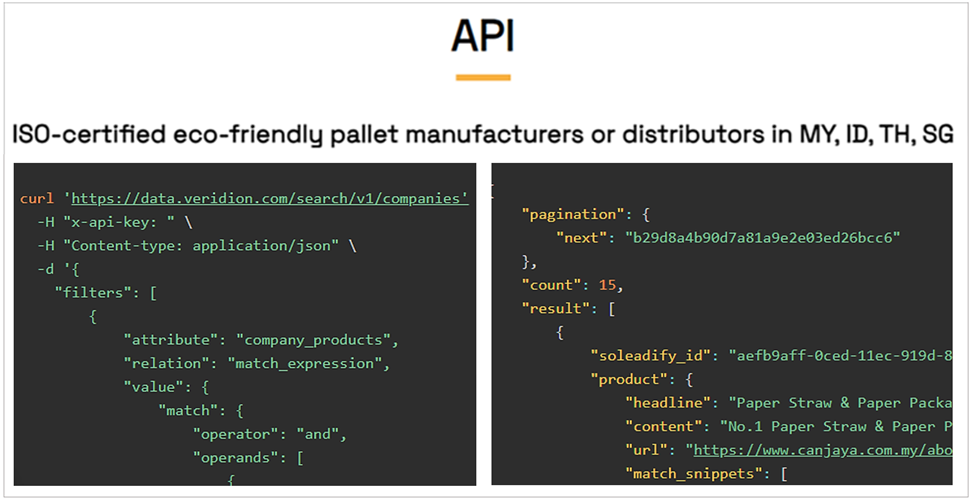

Source: Veridion

Moreover, the initial search for suppliers is simplified by allowing you to define procurement criteria in a natural language.

Source: Veridion

Once the search parameters are set, the list of all potential suppliers that fit your criteria is generated in seconds.

This aligns with McKinsey’s estimates that big data analytics tools can cut the time needed for supplier sourcing by as much as 90%.

Additionally, your team can utilize Veridion’s database for market intelligence, empowering them to assess various factors:

From the supplier’s financial stability, labor practices, and ESG policies, to the economic and political landscape in their country and region.

Moving forward, the subsequent steps typically entail issuing RFXs or administering pre-qualification questionnaires to shortlisted suppliers.

As mentioned, this can be followed by (further) supplier reference checks by contacting the clients they cited (or you discovered).

Then, for those suppliers who require on-site visits and audits, these activities are arranged and conducted.

Again, technological advancements have enabled these steps to be done virtually with the help of video conferencing and video immersion tools, and even augmented reality (AR) headsets.

Source: Swagelok

Depending on the technology used and your preferences, such visits and audits can be:

Each of these setups offers flexibility, cost-efficiency, and accessibility during supplier evaluation and selection.

Finally, supplier scorecards are developed to objectively evaluate and compare different suppliers based on predetermined criteria.

This facilitates informed decision-making in supplier selection.

Again, although we focused on a thorough initial supplier evaluation as the best way to ensure that the selected suppliers are reliable, high-performing, and low-risk, the principle of careful evaluation applies throughout the procurement lifecycle.

Equally, a comprehensive risk assessment is an integral part of the risk mitigation process that precedes final supplier selection and also extends for the duration of your supplier relationships.

Any risk assessment aims to proactively identify supply chain vulnerabilities and develop risk management strategies to mitigate these risks effectively.

In procurement, a comprehensive risk assessment covers both internal and external factors that could impact your procurement process and supply chain operations.

An assessment of your organization’s internal procurement risks involves analyzing factors such as procurement policy and process inefficiencies, overreliance on a single supplier or geographic region, and compliance issues within your operations.

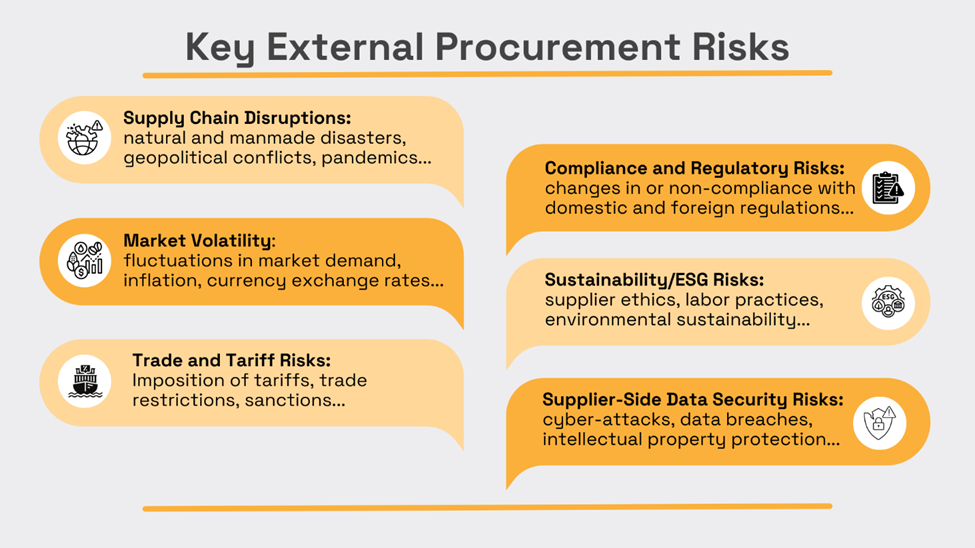

However, we’ll focus on external risk factors.

Associated with suppliers, logistics, and market factors, these risks are often interconnected and pose significant challenges to procurement professionals.

Of course, there is always the risk of suppliers not consistently meeting delivery deadlines and quality standards, which is minimized through supplier evaluation and selection, as well as ongoing performance monitoring and contract/relationship management.

In addition, such external procurement risks to assess include:

Source: Veridion

For instance, Amazon Business’s annual study in the “2024 State of Procurement Report” showed that 85% of companies have difficulties in finding suppliers whose sustainable practices fit their procurement sustainability goals.

In other words, they can’t properly identify or address sustainability/ESG risks.

This is another area where big data platforms like Veridion can help.

Source: Veridion

Moving on, let’s cover the process of comprehensive risk assessment.

First, potential internal and external risks relevant to your procurement process and supply chain are identified.

Then, the likelihood and potential impact of each identified risk is assessed, and risks are prioritized based on their severity of consequences and likelihood of occurrence.

After that, contingency plans and mitigation strategies for high-priority risks are developed.

Depending on the identified risks, this could involve diversifying your supplier base, implementing robust contract clauses, or investing in procurement automation tools.

Finally, processes for ongoing monitoring and review of risk factors are established, the effectiveness of mitigation measures is regularly assessed, and strategies are adjusted as needed to address emerging risks or changing market conditions.

Therefore, a comprehensive risk assessment inevitably leads to a robust risk management strategy, which is essential for safeguarding your procurement operations against disruptions and mitigating their impact on your business continuity.

Demand forecasting is a strategic process that involves predicting future customer demand for products or services based on historical data, market trends, and other relevant factors.

By accurately anticipating demand, companies can optimize their procurement processes, minimize risks, and ensure efficient inventory management.

Moreover, they can share demand forecasts with their suppliers, enabling better planning and management on both sides of the company-supplier relationship.

In the table below are the benefits of accurate demand forecasts for companies, but also the benefits of demand forecast sharing for suppliers.

| Company-Side Benefits | Supplier-Side Benefits |

|---|---|

| Negotiating favorable terms based on demand predictions | Better preparing for your upcoming orders, improving lead times |

| Identifying potential supply chain disruptions or bottlenecks | Adjusting production schedules to meet demand fluctuations |

| Optimizing production schedules and inventory levels, reducing stock-holding costs | Improving inventory management, minimizing shortages/excess |

| Improving customer satisfaction through product availability and timely delivery | Engaging in collaborative planning sessions, providing specific insights, and refining own demand forecasting |

Given these and other benefits, what does it take to generate accurate demand forecasts?

In short, technology.

Demand forecasting involves analyzing vast amounts of data, including historical sales data, market trends, seasonal variations, and other factors.

Manual analysis of such data would be incredibly time-consuming and error-prone.

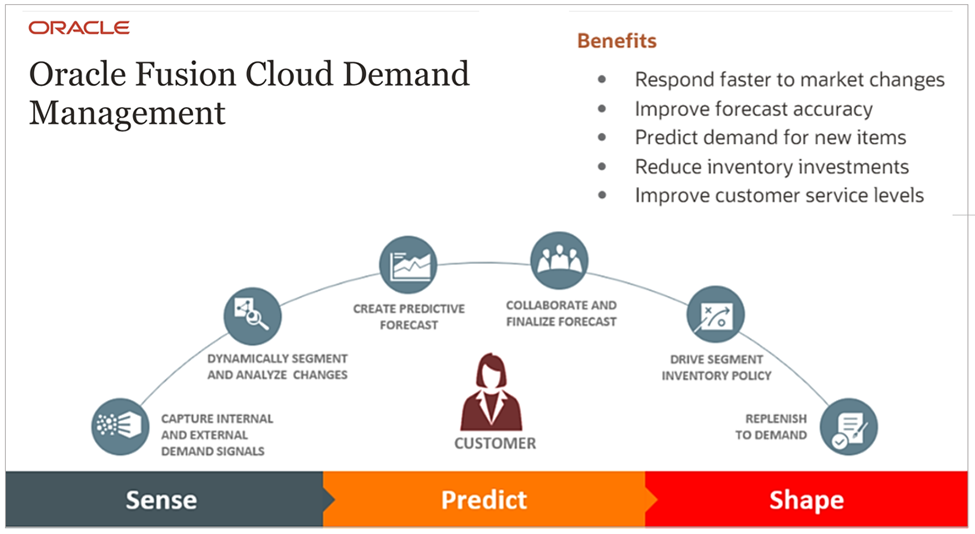

Fortunately, modern demand management tools utilize advanced algorithms and machine learning techniques to process large datasets efficiently and derive actionable insights.

These tools can automatically analyze historical data, identify patterns, and forecast future demand with a high degree of accuracy.

Here’s one example:

Source: Oracle

Oracle Demand Management Cloud helps companies create accurate demand forecasts by blending field-tested forecasting algorithms with adaptable analytics.

This demand planning software also provides real-time insights into demand and supply dynamics, enabling faster response to market changes.

In short, such tools allow you to integrate accurate demand forecasts into your risk management processes and share them with your suppliers, ensuring a proactive approach to identifying and mitigating potential supply chain disruptions.

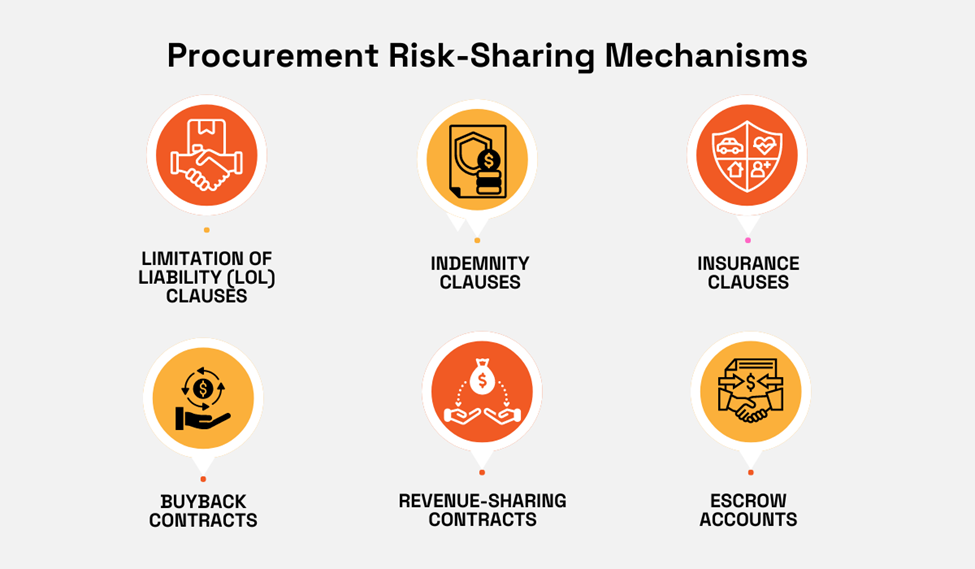

In procurement, different risk-sharing clauses and contract types are essential tools utilized to distribute potential risks between contracting parties.

These mechanisms play an important role in mitigating procurement risks by outlining the responsibilities and liabilities of your company (the buyer) and any supplier (the seller).

By clearly defining who bears the risk under various circumstances, risk-sharing clauses help safeguard both parties against unforeseen events and losses.

For example, a limitation of liability clause can mitigate significant financial losses in the event of supplier default, thereby transferring a portion of the risk to the supplier.

Of course, risk-sharing works both ways, i.e., it depends on what can be negotiated.

Let’s present six risk-sharing clauses/contract types, and then we’ll explain them and provide examples.

Illustration: Veridion / Data: The Procurement School / Academic

As promised, let’s start with the limitation of liability (LOL).

These contract clauses aim to limit liability for damages by excluding indirect or consequential losses and setting a cap on the liable amount.

Example: A supplier seeking to limit liability for damages resulting from late deliveries.

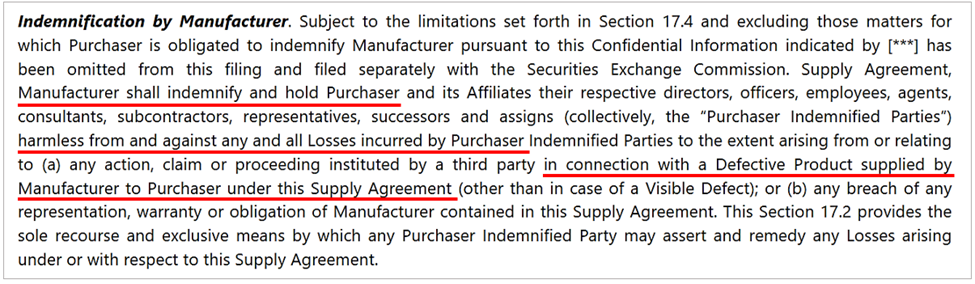

Next, indemnity clauses function as a built-in insurance policy between contracting parties, providing compensation for all losses and expenses incurred.

Example: A supplier required to indemnify a manufacturer against claims arising from delivering defective components.

Source: Law Insider

Moving on, insurance clauses require one or both parties to maintain insurance coverage to cover potential losses or liabilities arising from the contract.

Example: A manufacturer requiring its component suppliers to maintain product liability insurance to cover potential damages or defects caused by the components supplied.

In buyback contracts, the supplier agrees to repurchase unsold inventory from the buyer, sharing the risk of supply-demand imbalances.

Example: A car manufacturer agrees to buy back unsold vehicles from a dealership, or a vendor agrees to repurchase unsold seasonal goods from a retailer.

In revenue-sharing contracts, on the other hand, both parties agree to share revenue from sales, distributing the risk of fluctuating demand.

Example: A manufacturer and a distributor share profits from a jointly marketed product.

As for escrow accounts—typically managed by a neutral third party—they’re used for holding funds until specified conditions are met, providing security and mitigating financial risks for both parties.

Illustration: Veridion / Definition: Investopedia

Example: In a software development contract, the client deposits payment into an escrow account managed by a third party. Funds are released to the developer upon completion, reducing the risk of non-payment and ensuring satisfaction for both parties.

In summary, leveraging risk-sharing clauses and contracts can enable your company to mitigate various financial, operational, and reputational risks inherent in procurement processes.

As previously discussed, accurate demand forecasting is the foundation upon which optimized inventory management is built and numerous procurement risks are mitigated.

What risks, specifically?

Let’s start with the risk of supply chain disruptions.

More precisely, having the right amount of inventory on hand can buffer against various disruptions by providing a safety cushion.

A typical example is when the supplier’s lead time changes or their delivery is delayed for any reason, such as the recent pandemic.

Source: The Guardian

We’ll comment more on the above article’s claim when we introduce solutions for optimizing inventory management.

Another risk that is reduced is the occurrence of stockouts, which can lead to lost sales opportunities and dissatisfied customers.

These can occur due to various factors, such as the above supply chain disruptions, but also inaccurate inventory data, poor demand forecasting, or sudden spikes in demand.

Furthermore, optimal inventory levels also help mitigate your company’s financial risk by:

Now, let’s turn to what practices you can apply for successful inventory optimization.

Source: Veridion

Lastly, we should mention the two seemingly opposing, but actually complementary inventory management strategies—safety stocks and just-in-time (JIT) delivery.

Safety stock involves maintaining a reserve of inventory to buffer against unexpected fluctuations in demand or supply chain disruptions.

Conversely, JIT delivery emphasizes minimizing inventory levels by synchronizing production with demand, aiming to reduce carrying costs and increase efficiency.

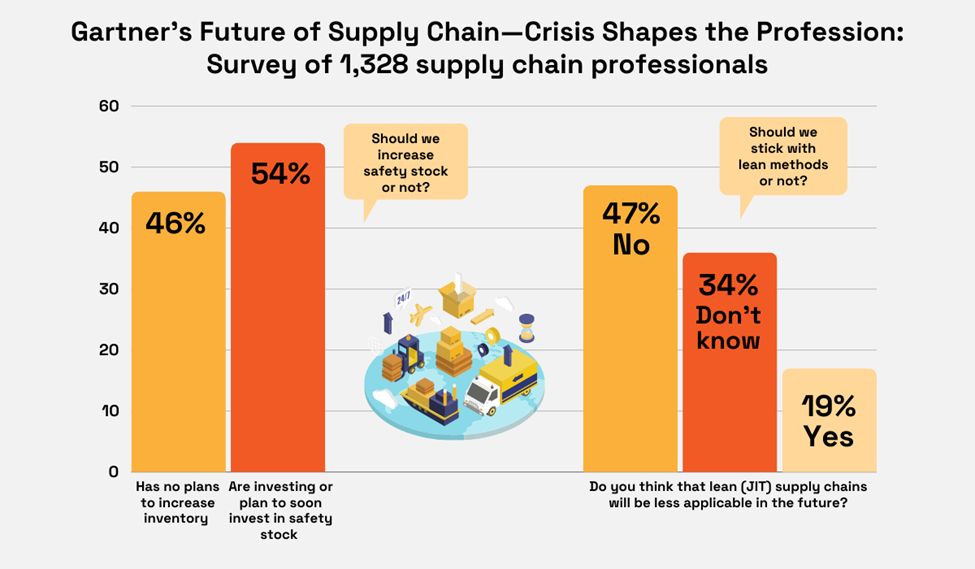

Although researchers in the above-referenced article suggest that the JIT inventory management model will be less applicable in the future due to past and present supply chain disruptions, some surveys, like the one from Gartner, indicate an industry divide.

Illustration: Veridion / Data: Gartner

As illustrated, Gartner’s 2021 survey found that 47% of respondents feel that lean supply chains will still have utility, 34% don’t know, and only 19% think that lean methods are a thing of the past.

Despite divided opinions, balancing these two strategies can help companies strike the right equilibrium between inventory costs and operational resilience.

In conjunction with applying the suggested inventory optimization practices, you can successfully mitigate a number of procurement risks.

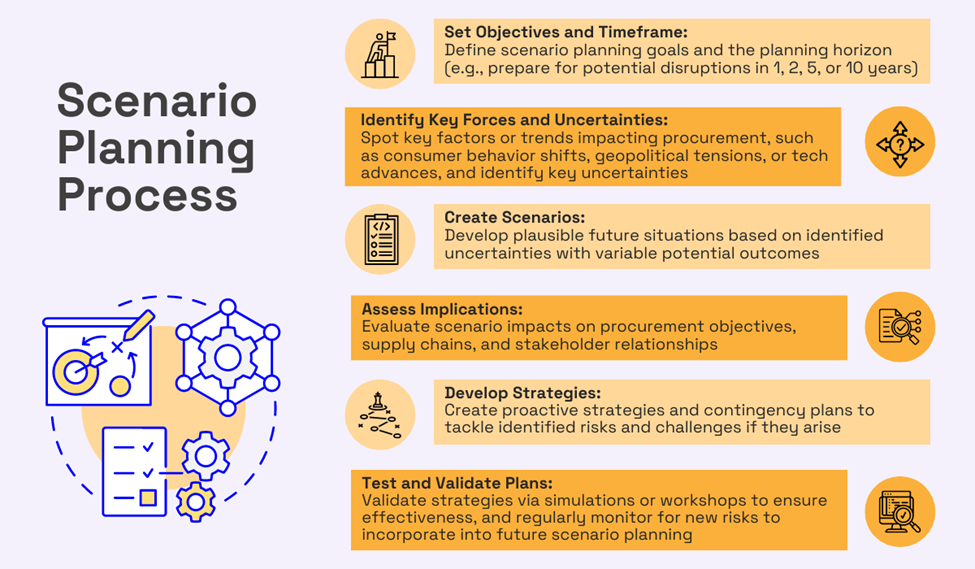

When it comes to mitigating procurement risks, the power of scenario planning arises from a well-executed comprehensive initial risk assessment and continuous risk monitoring.

While risk assessment focuses on identifying and prioritizing risks, scenario planning takes it a step further by creating and considering multiple plausible scenarios that could impact a company’s objectives or operations in the future.

As such, scenario planning typically looks beyond procurement risks, and includes positive scenarios that can reveal future opportunities.

Ultimately, these scenarios enable procurement teams to develop contingency plans and procurement strategies that are adaptable to a range of potential future conditions, thereby reducing vulnerability to unexpected events.

So, what’s the process for effective scenario planning in procurement?

You can see it outlined in the image below.

Source: Veridion

Despite possible variances in techniques and methodologies, these steps can guide procurement teams in anticipating and mitigating future risks effectively.

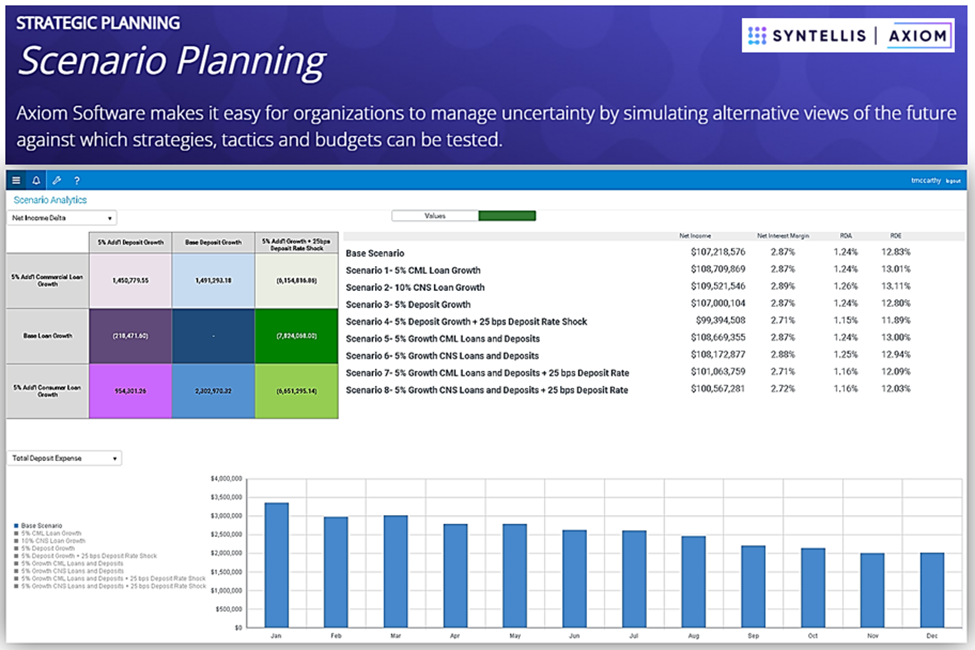

Now that we know what scenario planning entails, let’s see what tools are used to leverage its power.

Expectedly, the complexity of scenarios typically requires a combination of software tools and data analytics/forecasting techniques to analyze potential future situations and develop appropriate strategies.

Some commonly used tools include data analytics platforms, forecasting models, risk management and market intelligence solutions, strategic planning tools, and, naturally, scenario planning software.

Source: Axiom Software

In short, such software tools digitize, automate, and streamline the process of scenario planning.

This will allow you to run numerous scenarios with different assumptions, uncertainties, and potential outcomes.

For instance, scenarios could explore the impact of a global recession, trade wars, new ESG standards, commodity shortages, or natural disasters on your procurement operations.

To recap, scenario planning enables procurement teams to anticipate market fluctuations, identify new risks and opportunities, and prepare for potential disruptions, all of which contributes to successful risk mitigation.

In today’s complex procurement environment, effective risk mitigation is paramount for sustained success.

From accurate demand forecasting to scenario planning, each practice discussed offers a unique lens through which you can anticipate and navigate uncertainties.

By embracing a proactive mindset, harnessing innovative tools, and fostering collaboration, companies can not only weather disruptions but also seize opportunities, ensuring resilience and agility in an ever-changing environment.