Strategic Procurement Examples: 7 Companies That Nailed It

Instead of merely purchasing goods and services at the lowest possible price, strategic procurement takes a holistic approach and aims to deliver more value to your organization.

It drives innovation, sustainability, and better management of dynamic supply chains.

This enhances brand reputation, brings more value, and provides opportunities to improve your bottom line and lead in competitive markets.

Some companies have mastered this approach better than others.

Today, we will explore how seven renowned companies excel in strategic procurement, demonstrating their expertise through impressive results.

Let them inspire you to follow the path of strategic—and ultimately better—procurement.

If you take a quick look at BMW’s website, you’ll immediately see that innovation and sustainability are at the heart of this German car manufacturer.

Strategic procurement is the key to achieving these goals, making BMW Group a prime example of procurement excellence.

Another factor that significantly contributes to BMW’s name is resilience, which is especially crucial in today’s challenging climate.

As Oliver Zipse, Chairman of the Board of Management of BMW AG, states:

Illustration: Veridion / Quote: BMW Group

So, how does BMW achieve this resilience while also driving innovation and sustainability?

Responsible supplier sourcing, strong collaboration with suppliers, robust risk management, and transparent supply chains are all integral parts of their approach.

BMW enforces strict policies on the sustainable practices of their suppliers.

This includes social standards, ethical principles, and human rights.

Suppliers must meet these standards, and if BMW suspects non-compliance, they quickly implement preventive and corrective actions.

Risk analysis is another crucial component of BMW’s strategy.

They assess potential and active suppliers using various data sources, including country-specific risks and media analyses.

For direct suppliers, BMW uses a sustainability questionnaire and external audits. For indirect suppliers, they map the supply chain to identify risks.

Central to BMW’s strategy is transparency in supply chains, which also enables the sustainable extraction of raw materials and promotes a circular economy.

This reduces reliance on new raw materials and further supports environmental goals.

These comprehensive strategies ensure that BMW continues to manufacture highly customized cars and uphold its reputation.

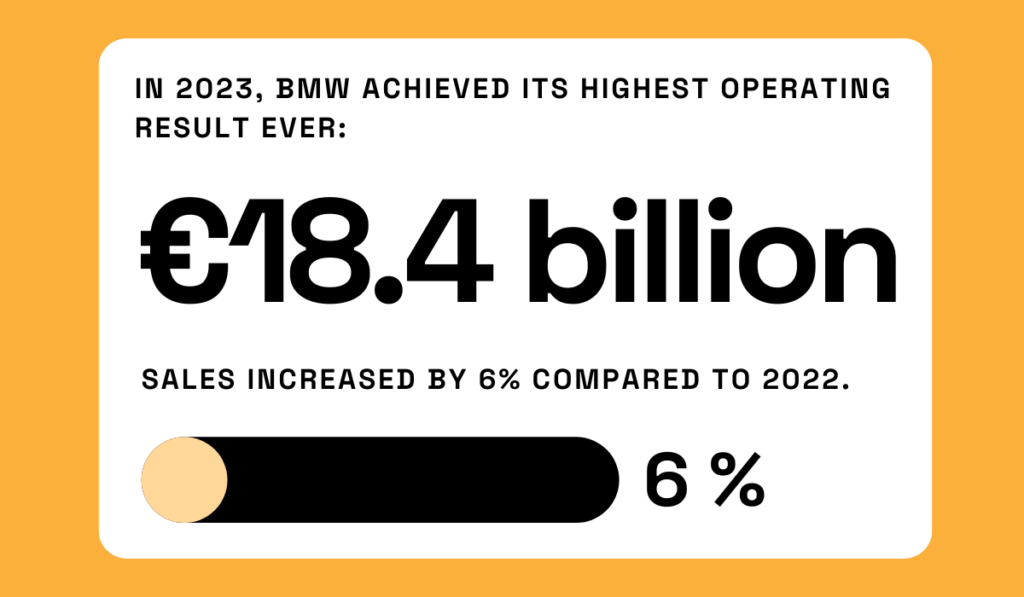

And the results speak for themselves: in 2023, BMW achieved its highest operating result in history, equal to 18.4 billion euros, with sales increasing by 6% compared to 2022.

Illustration: Veridion / Data: Agenzia Nova

Responsible supplier sourcing, robust risk management, and transparent supply chains are essential strategies for any procurement department.

In these areas, BMW indeed serves as a role model, demonstrating how strategic procurement can drive innovation, sustainability, and business success.

Walmart, the world leader in the retail industry, has a clear vision articulated by its founder, Sam Walton:

Illustration: Veridion / Quote: Walmart

Achieving this vision relies heavily on Walmart’s supply chain and procurement strategy, driven by the following factors:

Here’s how they do it.

Walmart uses advanced technology and data analytics to optimize its supply chain.

For example, they use data analytics to forecast demand by analyzing purchasing trends, seasonality, and various external factors.

This ensures Walmart knows exactly what it needs, when, and where, thereby maintaining efficiency and reducing excess inventory.

Walmart also works on the principle of a vendor-managed inventory system, which keeps shelves stocked while reducing costs.

This allows Walmart to lower prices for customers.

Since this inventory management system depends on reliable suppliers, Walmart is very cautious about suppliers they work with.

They look for suppliers that:

In addition to all of the above, Walmart is at the moment partnering with Bamboo Rose, a leading product development and supply chain platform, to develop a new enterprise sourcing platform (ESP) that will revolutionize its procurement process.

This platform will integrate various systems, improve efficiency, and enable better collaboration among sourcing associates, buyers, and suppliers.

Daniel Berg, Vice President of Product Global Sourcing at Walmart, points out:

Illustration: Veridion / Quote: Procurement Magazine

Walmart is indeed a company that can teach you many great things:

By adopting these strategies, you, too, can build a resilient and cost-effective procurement system that drives innovation, sustainability, and competitive advantage.

Unilever, a leading multinational fast-moving consumer goods company, is renowned for its focus on sustainability and innovation.

And it’s precisely their procurement strategy that helps them realize ambitious goals such as achieving net zero emissions across their value chain by 2039, ending plastic pollution, and more.

Source: Unilever

How?

Well, central to Unilever’s procurement approach is strong collaboration with suppliers who share the same values, as highlighted by Willem Uijen, Chief Procurement Officer:

“We encourage and support our suppliers on their own sustainability journeys and prioritize those who demonstrate shared values of respect and responsibility for people and planet by committing to our standards around responsible sourcing, sustainability and human rights. We believe that, by combining the expertise and integrity of our partners with our own, we can raise industry standards.”

So, instead of solely focusing on immediate cost gains, Unilever seeks to establish strong partnerships with the right suppliers.

Through initiatives like its Responsible Partner Policy, Unilever sets standards for its suppliers regarding sustainability, human rights, and ethical practices.

As they say, their approach moves away from traditional buyer-seller relationships towards more agile business practices and opportunities for innovation.

Illustration: Veridion / Quote: Unilever

And speaking of innovation, in 2023 alone, Unilever invested €949 million in research and development and protected over 20,000 patents.

On top of that, Unilever uses innovative technologies to improve visibility into its complex supply chains and make better, data-driven decisions.

If you want to learn more about how technology helps them do that, check out the video below.

Source: Unilever on YouTube

Overall, Unilever’s procurement strategy is largely focused on strong supplier partnerships and sustainability, which also leads to opportunities for innovation.

Coca-Cola is another shining example of a company with a strategic procurement approach that drives its success.

Their procurement strategy focuses on four key elements:

How do these elements keep Coca-Cola at the top?

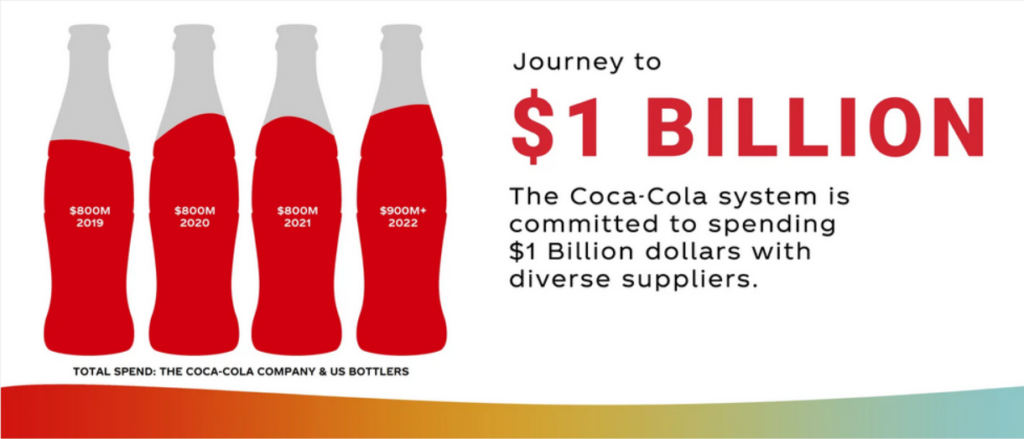

At the heart of Coca-Cola’s procurement strategy is a commitment to supplier diversity.

They aim to spend at least $1 billion annually with diverse suppliers, aspiring to join the Billion Dollar Roundtable, which sets the standard for supplier diversity.

This commitment fosters a more inclusive supply chain.

Source: The Coca-Cola Company

Moreover, Coca-Cola focuses on sourcing locally.

Over 95% of their procurement spending targets local suppliers, ensuring high-quality standards are met in an economically viable way.

By balancing these goals, Coca-Cola supports both diverse and local suppliers, maximizing the benefits for various communities and maintaining high standards.

Coca-Cola also excels in supplier performance management.

They annually screen the performance of all critical suppliers, covering over 90% of their total procurement spend and more than 95% of their Tier 1 suppliers.

Every supplier must adhere to Coca-Cola’s Supplier Guiding Principles, which include:

Continuous improvement is another cornerstone of their strategy.

Each year, Coca-Cola aims to have 50% of significant suppliers under corrective action support and capability-building programs.

But they exceed these numbers.

For example, in 2022, 67.8% of significant suppliers with substantial negative impacts received support for corrective action plans, and 53.7% participated in capability-building programs.

By working with specialist organizations, Coca-Cola helps suppliers enhance their environmental, social, and governance performance.

Coca-Cola’s procurement is further driven by innovation.

For instance, in 2023, Coca-Cola HBC Austria teamed up with Mondi and Krones to create “Hug-IT,” a high-strength paper sleeve that replaces plastic shrink wrap for bundling bottles.

Source: Packaging Strategies

This innovative and sustainable solution uses responsibly sourced fibers and demonstrates Coca-Cola’s commitment to reducing plastic waste.

And last but not least, quality assurance is vital to Coca-Cola’s strategy.

They maintain rigorous standards to ensure their products consistently meet customer expectations and uphold their reputation.

So, by focusing on supplier diversity, fostering innovation, managing supplier performance, and ensuring high quality, Coca-Cola truly shows how strategic procurement can drive sustainability and long-term success.

Have you ever wondered how Amazon became the epitome of procurement and supply chain excellence?

It’s a blend of cutting-edge technology, massive scale, and savvy data analytics that are all part of their procurement strategy.

At the core of Amazon’s strategy is its heavy reliance on advanced technologies like cloud computing, robotics, machine learning, and artificial intelligence.

These technologies automate procurement processes, enhance accuracy, and reduce costs.

For instance, robotics automate warehouse operations, while AI algorithms assist in supplier selection and risk assessment.

Amazon also capitalizes on its massive scale to drive down costs. By purchasing items in bulk, the company secures discounted prices from suppliers.

Additionally, it uses low-cost carriers and efficient transportation networks to further cut expenses.

This scale advantage allows Amazon to offer competitive prices to customers while maintaining profitability.

Big data is another cornerstone of Amazon’s procurement approach.

The company is an early adopter of these technologies, utilizing advanced analytics to predict future demand, track supplier inventory, and optimize product delivery to warehouses.

This predictive capability ensures that Amazon knows exactly what products are needed, when, and where, thus minimizing excess inventory and avoiding stockouts.

One of the most notable benefits of Amazon’s data-driven strategy is the optimization of supplier deliveries to warehouses.

By directing products to warehouses closest to customers, Amazon achieves significant cost savings.

According to Aranca, this optimization has led to a 30-40% reduction in shipping costs.

This not only enhances efficiency but also improves customer satisfaction with faster deliveries.

In essence, Amazon’s procurement is not merely about operations but also strategic decision-making.

As Alexandre Gagnon, Vice President of Amazon Business Worldwide, emphasizes, procurement plays a pivotal role in achieving key organizational goals:

Illustration: Veridion / Quote: CPO Strategy

Now, picture yourself applying Amazon’s strategies to your procurement process.

With the right tech, smart negotiations, and data-driven insights, you, too, can transform your supply chain into a well-oiled machine.

Johnson & Johnson, the world’s largest healthcare company, has undergone a remarkable transformation in its procurement strategy.

As their former Global Chief Procurement Officer, Len DeCandia, reflected for Procurement Magazine in 2022:

Illustration: Veridion / Quote: Procurement Magazine

How did they do it?

Firstly, they embraced digital transformation.

By leveraging advanced analytics and digital tools, they centralized procurement, strengthened supplier relationships, and streamlined operations.

This not only optimized efficiency by saving time in various processes but also made them more agile, especially during the challenges of the COVID-19 pandemic.

Secondly, they prioritized strategic sourcing.

This involves forming strong partnerships with suppliers who offer quality, innovation, and cost savings.

Innovation and sustainability are integral to their procurement approach.

By seeking out suppliers who offer innovative solutions and prioritize sustainability, they drive long-term value creation while minimizing environmental impact.

Additionally, Johnson & Johnson emphasizes diversity.

They actively seek out companies owned and operated by women, minorities, and veterans, supporting small and diverse businesses and ethical practices while ensuring that their suppliers uphold the same high standards.

Overall, Johnson & Johnson’s procurement strategy focuses on:

By aligning these elements with the company’s broader goals, they achieve strategic objectives and deliver value to stakeholders.

This comprehensive and forward-thinking approach is why Johnson & Johnson has been on Fortune’s World’s Most Admired Companies list for the 22nd year in a row.

Toyota’s procurement strategy, deeply rooted in its renowned Toyota Production System (TPS), offers invaluable insights for procurement professionals worldwide.

Central to their approach is the implementation of lean manufacturing and just-in-time (JIT) procurement methods, aiming to eliminate waste and maintain high efficiency.

This involves making products precisely when needed, minimizing overproduction and excess inventory.

Toyota also emphasizes the importance of nurturing diverse and resilient supplier relationships.

They prioritize building strong partnerships with suppliers and offering expertise and assistance when needed.

This collaborative effort ensures smooth operations and timely deliveries, essential for JIT inventory management.

Jamie Bonini, the president of the Toyota Production System Support Center, explains:

“If you are going to run a really tight just-in-time system, you have to have the expertise as well as the trusting relationship to go into a supplier and help out when there is a problem. If a supplier gets in real trouble, we’ve got people that can jump in, with the technical skills to really help solve the problem. We don’t walk in and call for an audit of their recovery plans; we roll up our sleeves and help problem-solve as part of a collaborative effort.”

Furthermore, Toyota’s shift towards risk management and supply security, rather than solely focusing on efficiency and cost reduction, sets a precedent for strategic procurement.

Prompted by events like the 2008 financial crisis and the 2011 Fukushima disaster, Toyota enhanced its supply chain resilience.

They developed a comprehensive supplier database and incentivized suppliers to stockpile parts, positioning themselves well during semiconductor shortages.

And in 2021, Toyota’s adept handling of semiconductor shortages propelled them to become America’s top-selling automaker for the first time in 90 years.

You can learn three key lessons from Toyota’s approach:

Source: Veridion

In essence, Toyota’s procurement strategy exemplifies the intersection of efficiency, resilience, and collaboration.

By adopting similar principles, procurement professionals across the globe can enhance their procurement strategies and navigate complex supply chains more effectively.

The companies on our list stand out as industry leaders due to their strategic approach to procurement and supplier sourcing.

Instead of simply buying from any supplier at the lowest price, they invest time and effort into crafting robust procurement strategies and establishing strong supplier partnerships aligned with their long-term organizational goals and values.

They achieve this by carefully analyzing markets, assessing suppliers and potential risks, leveraging new technologies, and utilizing data.

This procurement approach not only enhances their operations but also ensures they deliver exceptional products and services to customers and contribute to a more sustainable and environmentally conscious world.

Ultimately, their strategic procurement sets them apart and drives their success in the marketplace.

So, if you want to elevate your procurement practices, these seven companies are the role models to look up to.