Supplier Selection Scorecard: The Full Guide

Selecting suppliers that perfectly match the needs and broader goals of your organization is no easy feat.

One small lapse in judgment can trigger an avalanche of issues—from poor product quality and unnecessarily high procurement costs to potential damage to your organization’s reputation.

As a procurement professional, it is only natural that you’re always looking for tools and methodologies to help you make decisions about supplier partnerships confidently.

One of them is a supplier selection scorecard.

In this article, we’re diving into everything you need to know about this tool: from its purpose and what it should contain, to how it can benefit you and what best practices you should follow to create it.

Let’s get started!

A supplier scorecard, also known as a vendor scorecard, is an indispensable tool for evaluating and comparing the performance of your suppliers.

It enables you to objectively assess how well they’re fulfilling their contractual obligations and performance targets, driving data-based decisions about how to proceed with each partnership.

For instance, if the scorecard indicates that the supplier’s performance hasn’t been up to your usual standards, you can leverage this information to renegotiate contract terms or even terminate the partnership.

But scorecards go beyond just helping you keep track of performance and identify red flags in your existing suppliers.

They can be of great value when it comes to selecting new suppliers, too.

Source: Veridion

After all, why would you wait until after you’ve signed a binding contract to find out whether a supplier is truly the best fit for your needs?

When it comes to supplier selection, having a set of clear criteria for evaluating each prospective partner can save you a lot of trouble and ensure that you’re committing to the best in business.

With all that in mind, we could say that the purpose of supplier scorecards is to help you evaluate how beneficial working with each individual supplier is—or potentially could be—to your organization.

This brings us to the next question: what should you include in your supplier selection scorecard?

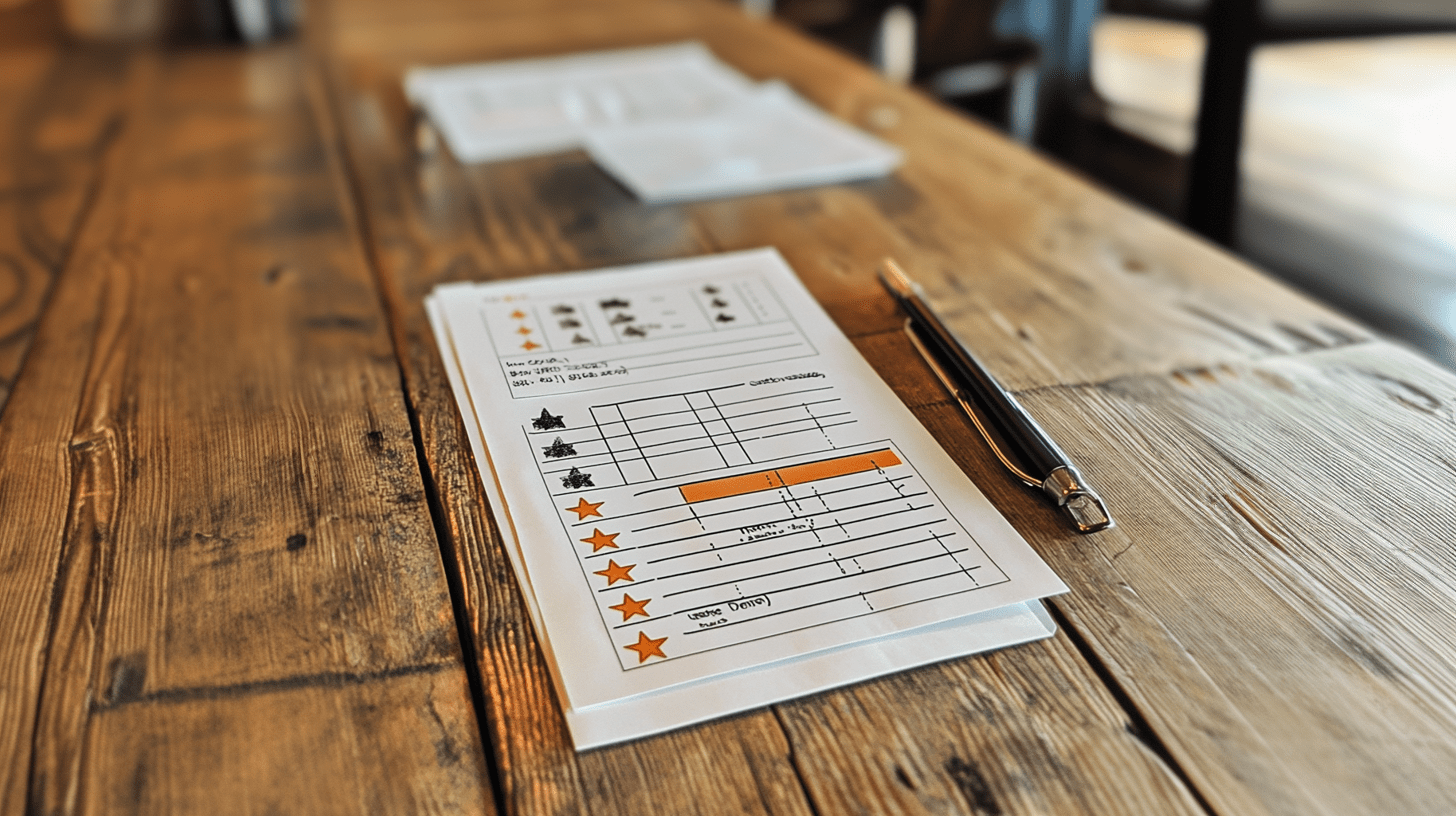

A good supplier scorecard is going to consist of basic supplier information and a set of KPIs that will help you assess different aspects of a supplier’s performance.

You’re going to start with elements like the supplier name, phone number, physical and email address, as well as the product or service category they fall into—that much is clear.

But deciding which performance metrics you should include is often easier said than done.

Yet, it is crucial to choose the right ones, as having relevant supplier data at your fingertips can bring your organization substantial benefits.

With a plethora of procurement KPIs to choose from, it’s easy to fall into the trap of “the more, the better” mindset.

However, evaluating potential suppliers against dozens of performance metrics—many of which might be irrelevant to you—can make the crucial information get buried.

So ask yourself, “Which KPIs are the most important and the most relevant to our organization?”

For instance, that could be:

In the end, you’ll end up with a scorecard that looks something like the example below.

Source: Tipalti

Focusing on fewer highly critical KPIs will help you detect the most important information about the performance of a prospective supplier, instead of getting lost in a sea of irrelevant data.

Naturally, with time and through some practice, you’ll be able to discern what works and what doesn’t and slowly add more relevant criteria.

Now that you have an idea of KPIs typically included in supplier scorecards, you might think that it’s enough to include the same ones in your version.

However, simply following these general guidelines won’t bring you the optimal results.

At the end of the day, every organization is different and has its own unique set of requirements.

So, you’ll have to tweak the criteria you measure prospective suppliers against.

That’s exactly why we want to share a couple of best practices that will help you create customized supplier selection scorecards that truly provide value.

Yes, supplier scorecards are primarily used by procurement teams, as they are the ones at the forefront of supplier selection and management.

But placing the burden of developing scorecards solely on them isn’t the best practice.

And when you think about it, it makes sense: without the input of stakeholders from other departments, the scorecard will be limited to the perspective of the procurement team alone.

So, if you want to create scorecards that will address the broader needs of your organization, consider involving other departments—like finance, operations, and quality assurance—in the scorecard development process.

Suman Sarkar, an expert in strategic sourcing and supplier management, agrees.

Illustration: Veridion / Quote: Smartsheet

An open conversation with stakeholders from different departments could uncover perspectives that the procurement team on its own perhaps wouldn’t have considered.

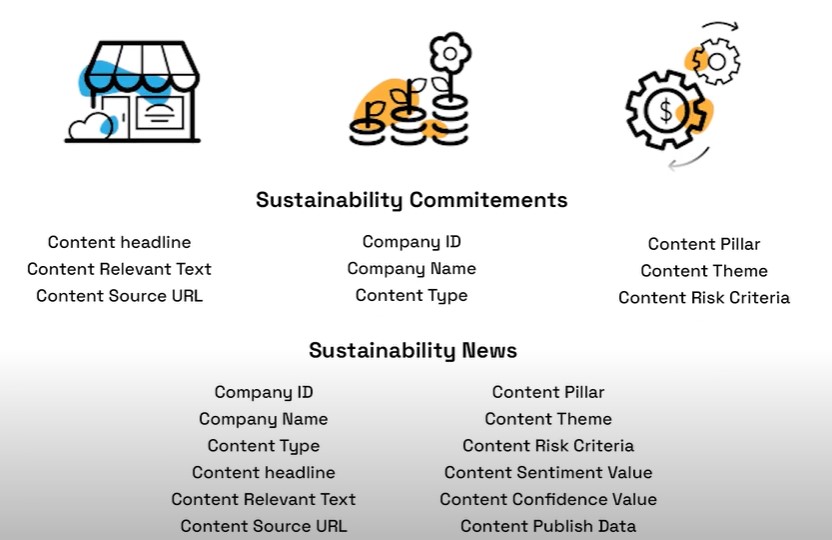

For instance, the corporate social responsibility (CSR) department might inform you that the company’s sustainability goals have changed.

Due to this, they need you to evaluate suppliers—current and potential—based on their sustainability practices, too.

This is a signal that adding a sustainability KPI to your scorecards is in order.

It is certainly an important supplier criterion for P&G, who are consistently working on reducing their carbon footprint and improving their responsible sourcing strategies.

Source: P&G

Rick Hughes, P&G’s global purchasing officer, stated:

“We worked closely with a global team of P&G personnel, suppliers and supply chain experts to determine the most effective way to measure the environmental performance of our diverse global supplier base. Our suppliers wanted a tool that was flexible yet grounded in existing measurement standards and, by working together, we developed a framework that will help drive real improvement across all industries.”

It’s reasonable to assume that such a strong focus on sustainability when evaluating suppliers is a result of cross-departmental collaboration.

Whether sustainability is a KPI you want to introduce into your scorecards, or something entirely different, the bottom line is:

Getting input from other departments is bound to result in a scorecard that perfectly matches the needs and goals of your organization as a whole.

High-quality supplier data is at the heart of any good scorecard.

After all, how can you confidently enter into a partnership with a new supplier if the data you have on them is outdated or downright false?

Well, you can’t—and you shouldn’t.

So, in order to create supplier scorecards that will help you identify the right suppliers, you have to make sure the data you’re working with is always fresh and accurate.

This is certainly a priority for Home Depot, a large home improvement retail corporation.

Their Director of Global Supplier Performance Management, Julia Saia, says:

Illustration: Veridion / Quote: SupplyChainBrain

To make sure that the data they’re basing their decisions on is accurate, they gather data from their own sources and compare it to that submitted by suppliers.

That way, they don’t have to worry about partnering with suppliers that used to meet their criteria, but no longer do.

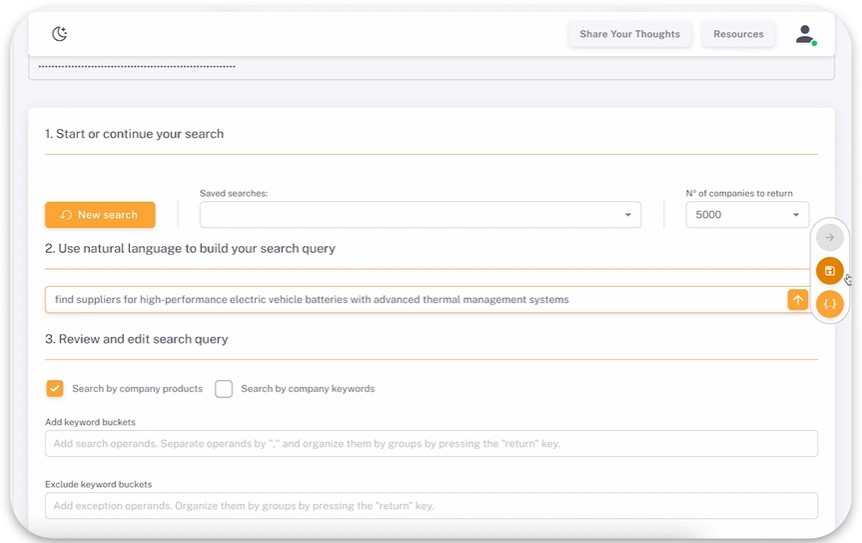

And if you’re wondering how you can make sure that you’re working with nothing but fresh supplier data, the answer is Veridion.

Source: Veridion on YouTube

Veridion is a supplier sourcing service committed to providing you with the latest information on millions of suppliers worldwide.

We consistently gather reliable business data by triangulating various sources, ensuring that each company profile we provide you with is 100% accurate.

All you have to do is tell us what you’re looking for using natural language, like in the example below.

Source: Veridion on YouTube

We won’t just provide you with a list of suppliers that match your criteria and call it a day.

We’ll also give you details like their locations, activities, revenue, and 60 other data points that will help you choose the right supplier(s) for your organization.

Source: Veridion on YouTube

You can then enter the data we provided into your scorecards and compare the performance of all the prospective suppliers in order to choose the best one.

Not only does Veridion make the whole process quick and effortless—it also allows you to make big decisions about strategic partnerships with confidence.

At this point, you understand how creating a supplier scorecard works and what strategies you should implement in order to avoid common pitfalls of the process.

But you also may be wondering, for instance, whether you could choose suppliers based on past industry reputation or referrals instead of developing a scorecard.

While simplifying the supplier selection process is probably much more appealing, the fact of the matter is, that putting effort into creating a scorecard is well worth it.

Let’s explore why.

One of the main benefits of using scorecards during the supplier selection process is the fact that they enable you to evaluate each supplier objectively.

Given that each supplier you choose to consider is going to be evaluated against the same set of predefined criteria, you can always be sure that the decisions you’re making are not biased.

Gary Gustafson, President of G-Force Consulting, highlights the importance of this.

Illustration: Veridion / Quote: Smartsheet

But most of all, this kind of data-driven supplier analysis helps you avoid making mistakes that can cause serious issues for your organization.

Let’s say you decided to ditch scorecards altogether and instead choose a supplier for one of your key products based on a recommendation from a trusted peer.

This supplier met all their requirements, and they have been in the industry for a long time.

Sounds good, right?

But what you don’t know is that the peer you’re taking the recommendation from worked with this supplier a while ago, and their product quality has deteriorated since then.

Aside from that, this supplier hasn’t been investing in innovation at all.

This means that you’ll likely fall behind competitors who are working with suppliers that can offer more added value.

And yet, thanks to biased methods of evaluating prospective suppliers, it’s all too easy to wind up in that exact position.

When you rely on supplier scorecards, though, you know you’re making decisions based on tangible KPIs and giving every potential supplier—well-established and emerging—a fair chance.

So far, we talked a lot about how using scorecards can help you scan the supplier landscape and identify the most suitable candidates.

That’s good. But what about the bad and the ugly?

Well, scorecards can help you with that too: they are a great tool for identifying risks associated with potential suppliers.

As it turns out, supplier risk management is important for the majority of business professionals.

Just take a look at the findings of the 2023 State of Risk & Compliance Report:

Illustration: Veridion / Data: Navex

So, it makes sense for businesses to leverage every available tool—including supplier scorecards—to effectively mitigate supplier-related risks.

This was the case for the users of Crossword Cybersecurity PLC, a company that provides cybersecurity solutions.

Laura Greenwood, the company’s Third-Party Assurance Consultant, explains that their users have been creating extensive supplier scorecards that assess suppliers’ financial, cyber, GDPR, slavery, and other risks, all in one place.

“This creates a shared understanding of the totality of risk from each supplier and helps specialist teams, such as IT, and the supplier assurance team understand how their worlds fit together. This is what a truly strategic approach to supplier assurance looks like, and it creates direct benefits for the business and its wider supply chain partners.”

There is no doubt that supplier scorecards are key to spotting red flags in the way prospective suppliers operate before it’s too late.

So, don’t underestimate their power.

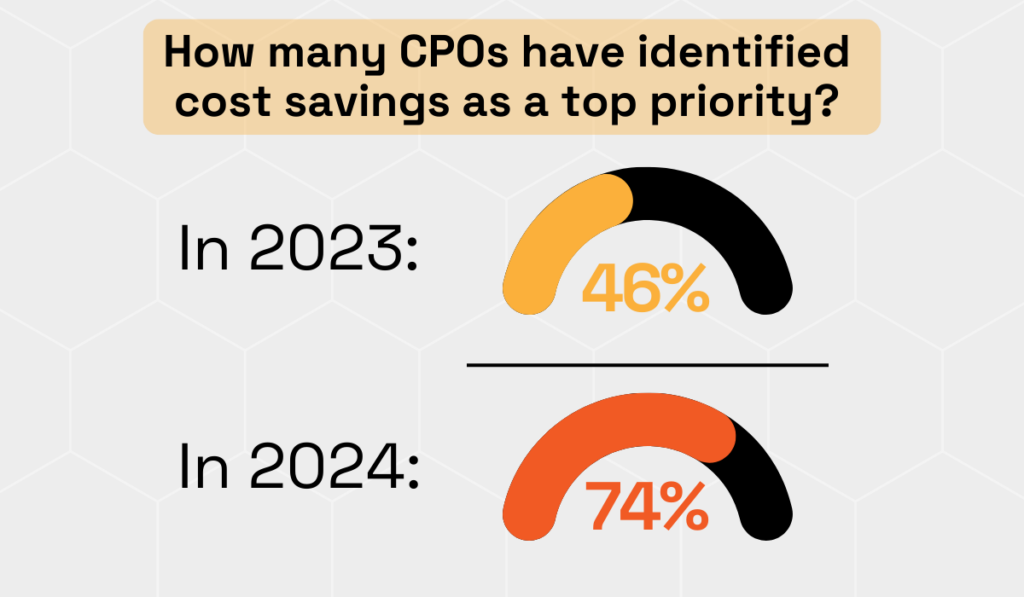

Finally, supplier scorecards can help you identify suppliers that can offer you the best value for money, ultimately reducing your overall procurement costs.

Yes, making sure that your suppliers check all the boxes in terms of product quality, reliability, and sustainability is important.

But so is making sure that the price is right.

This is supported by the fact that, for 74% of CPOs, cost savings are a top priority in 2024—a 61% increase compared to 2023.

Illustration: Veridion / Data: Ardent Partners

And that’s not all: the findings of Anvyl’s 2024 State of Supply Chain report point to the fact that companies recognize supplier selection as an area in which there is potential to reduce procurement costs.

In fact, 44.17% of them report that they’re planning to streamline the supplier selection and negotiation processes with the goal of reducing procurement costs.

So, how can supplier scorecards help with achieving this objective?

By paying attention to the pricing metric—alongside other key criteria—organizations can compare their top contenders and identify the one that provides the best value overall.

Yes, the process of developing, populating, and comparing scorecards will require time and effort from your procurement team.

But the long-term savings that your organization can realize thanks to having a standardized supplier evaluation process will far outweigh the initial investment.

We hope that this article has successfully proven how powerful supplier scorecards can be when it comes to the supplier selection process.

If there’s one thing that we want you to take away from this article, it’s this: take it slow.

If you haven’t used standardized ways to evaluate suppliers before, we know that starting with supplier scorecards might feel a bit intimidating.

But know that it’s okay to begin with just a few key metrics that matter most to you and build from there.

The most important thing is to take that first step.

Before you know it, you’ll be on the right path to selecting new suppliers more wisely and strategically.