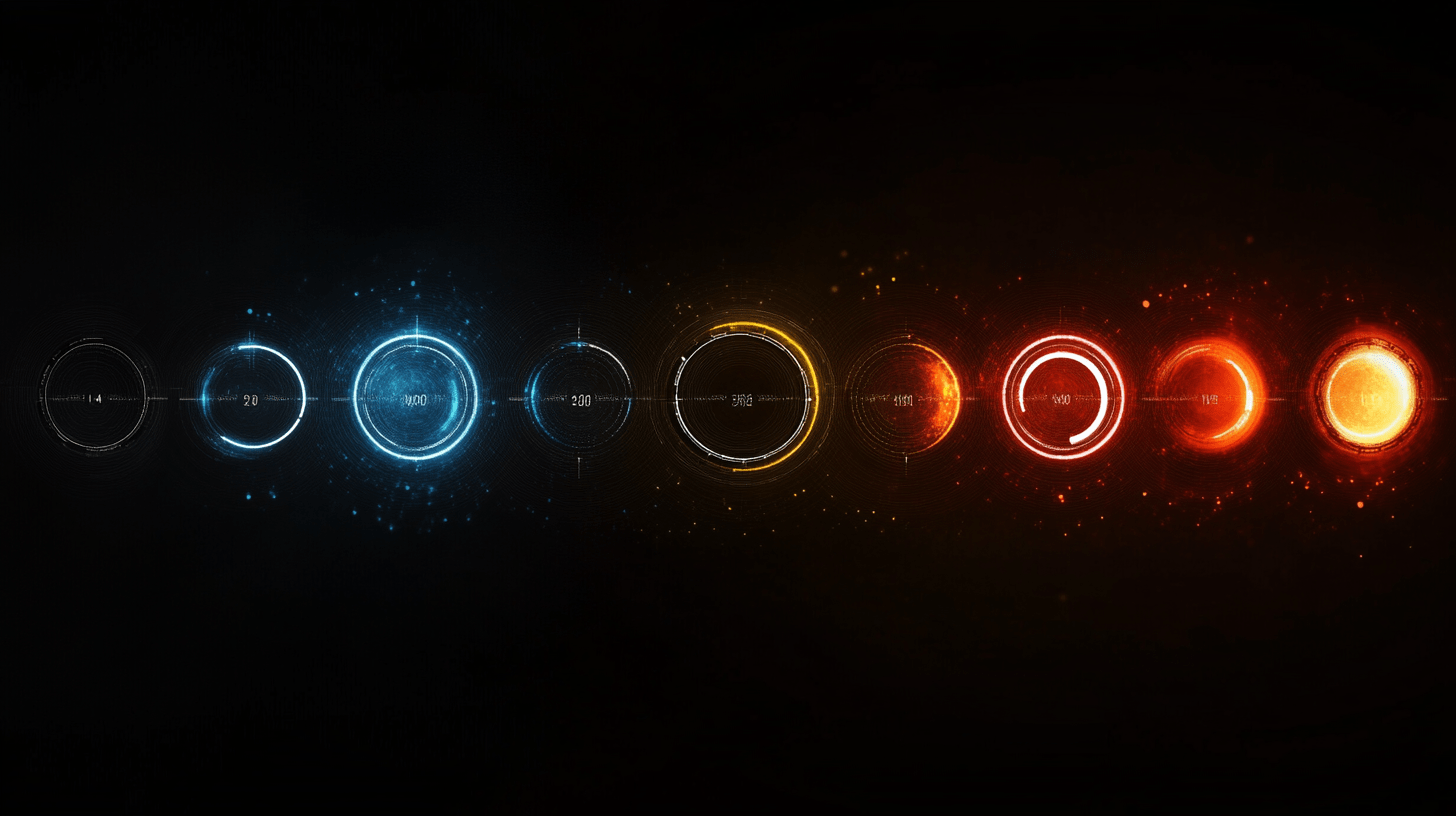

8 Key Stages of Supplier Lifecycle Management

Key Takeaways:

How important are your suppliers to your company’s success?

Without reliable suppliers, your business could face delays, inefficiencies, and other challenges.

That’s why managing your suppliers well—from the day you start working together to the day you stop—is so important.

This is supplier lifecycle management (SLM).

It’s a structured approach that helps you maximize supplier value, mitigate risks, and foster strong partnerships.

In this article, we’ll guide you through the eight key stages of supplier lifecycle management and share easy tips to help you succeed.

Every supplier’s lifecycle with your company begins with your procurement team identifying, evaluating, and selecting them.

Making the right choice at this stage is critical for many reasons, including:

That’s why a structured approach to supplier evaluation is essential—it provides a clear framework for assessing potential suppliers against key criteria and mitigating risks.

In short, this process ensures your team chooses the best possible supplier.

This stage lays the groundwork for successful relationships and the effectiveness of subsequent stages in supplier lifecycle management (SLM).

Source: Veridion

Of course, evaluation processes don’t stop after the initial supplier selection but continue throughout other SLM stages.

Key instances where evaluation remains critical include contract renewals, performance reviews, and ongoing risk monitoring.

Since these aspects will be addressed in later stages, here we’ll focus specifically on supplier evaluation for selection purposes.

This process involves everything from defining evaluation criteria and identifying potential suppliers to conducting detailed risk assessments and making the final decision.

Below, you can see the typical steps, activities involved, and tools and methods used to perform supplier evaluation.

| Step | Activities | Tools and Methods |

|---|---|---|

| Define evaluation criteria | Identify business needs, quality standards, delivery requirements, cost expectations, and compliance standards | Internal stakeholder input, spend and performance data, regulatory frameworks |

| Conduct marketresearch | Identify potential suppliers, gather initial information, and create a preliminary shortlist | Advanced sourcing tools, supplier directories, market reports, supplier profiling |

| Issue RFIs | Gather detailed information about supplier capabilities, capacity, and compatibility with business needs | RFI templates, sourcing platforms |

| Screen initial candidates | Review RFI responses, issue pre-qualification questionnaires (PQQs), review certifications, and filter candidates | PQQ templates, supplier certifications, compliance tools |

| Evaluate shortlisted suppliers | Issue RFPs, review responses, conduct initial risk assessments, verify references, and evaluate financial stability | RFP templates, supplier evaluation matrix, procurement software, financial reports |

| Perform final checks | Conduct site visits, audits, and detailed risk assessments for final candidates | Audit templates, risk management platforms |

| Select suppliers | Assess final scores, negotiate high-level contract terms, finalize selection, and prepare for onboarding | Supplier scorecards, decision matrices, executive reviews, contract management tools |

In practice, supplier evaluation processes are rarely linear.

Depending on procurement complexity, industry standards, supplier criticality, and resource availability, steps may overlap, some may be skipped, and others iterated.

Despite these variations, the tools and methods remain largely consistent, ranging from sourcing tools to supplier scorecards and risk management platforms.

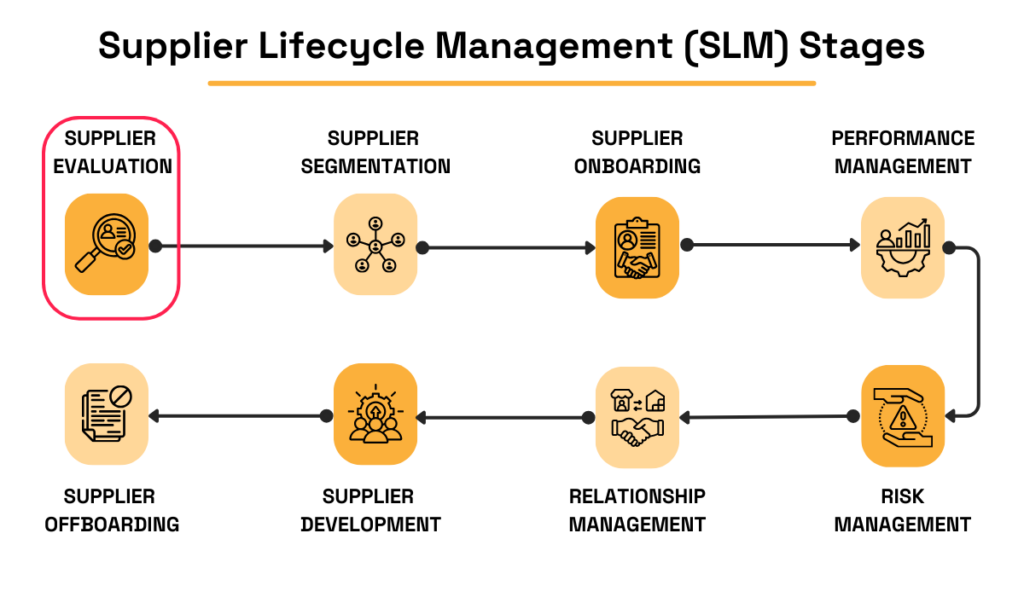

One of the crucial ingredients for effective evaluation is accurate and up-to-date supplier information.

Without it, discovering and assessing suppliers can be limited in scope or overly time-consuming.

AI-powered supplier intelligence platforms like our Veridion address this challenge, enabling fast supplier discovery and streamlined evaluation through real-time data.

Source: Veridion

In short, Veridion enables your procurement team to:

As we’ll see, having access to accurate, weekly updated supplier data also plays a key role in subsequent SLM stages.

In addition to leveraging real-time supplier and market intelligence, establishing a structured evaluation process is equally critical.

Simply put, this ensures that all potential suppliers are assessed against the same criteria, resulting in a fair and unbiased selection.

As the list of potential suppliers narrows, conducting thorough background checks—including financial stability, ESG compliance, and references—is essential.

Performing quality audits, such as reviewing product samples, further validates a supplier’s suitability.

After suppliers have been selected, onboarding is the stage where a formal relationship with them is established.

The purpose is to ensure smooth future collaboration, making sure the supplier has everything they need to meet the previously agreed requirements.

Onboarding activities include:

To streamline this process, many organizations rely on supplier onboarding solutions that automate document verification, track compliance, and simplify system integration.

Source: HICX

As highlighted above, this solution offers a single portal for onboarding all suppliers.

It’s worth noting that if contract finalization fails for any reason and onboarding is aborted, the best alternative suppliers identified during the evaluation stage can be approached.

In summary, supplier onboarding ensures a smooth transition from selection to active collaboration, setting the foundation for efficient and compliant supplier relationships.

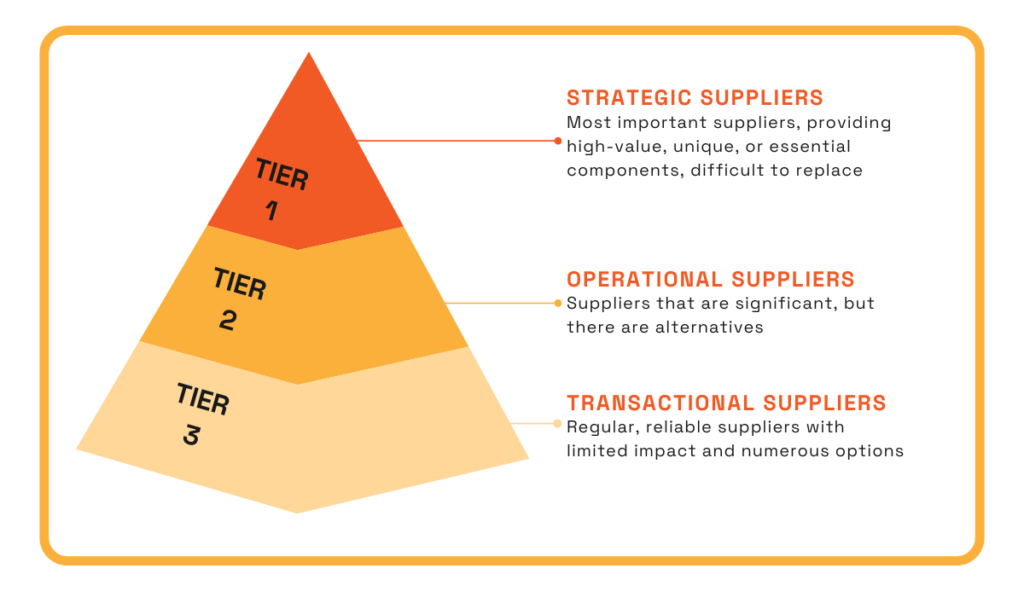

Your suppliers need to be categorized based on their strategic importance, risk level, and contribution to your organization.

The purpose of supplier segmentation is to prioritize resources and tailor management strategies for different supplier groups.

This involves analyzing spend and performance data, evaluating dependency, and classifying suppliers into categories such as strategic, operational, and transactional.

Source: Veridion

Of course, there are various ways to segment suppliers, so it’s crucial to choose an approach that best aligns with your company’s specific needs.

For instance, Volvo Cars manages around 8,300 suppliers—900 deliver production materials, while 7,400 provide indirect products and services.

According to Volvo Cars:

“Suppliers delivering critical components, high spending suppliers, non-substitutable and single-sourced suppliers are included in our definition of critical suppliers.”

This highlights how Volvo incorporates a broader range of operational factors into its definition of critical suppliers.

Overall, segmenting suppliers based on their potential impact on your operations is a vital step that shapes your future supplier management strategies.

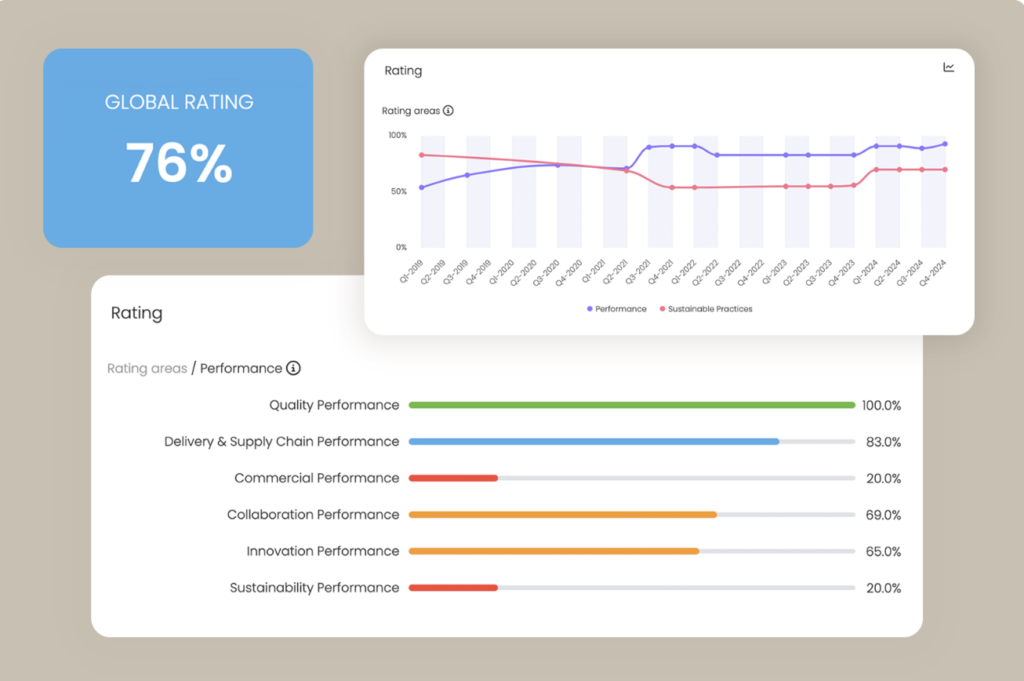

Performance management is a crucial stage in the supplier lifecycle, ensuring suppliers continuously deliver on agreed terms and meet your organization’s expectations.

It serves as an ongoing evaluation process, tracking suppliers’ compliance with quality, cost, and delivery standards, and identifying areas for improvement.

Key activities include:

KPIs for supplier performance management often focus on metrics such as defect rates, on-time delivery, and adherence to contractual terms.

Source: Veridion

Tracking these and other relevant metrics enables your company to foster continuous improvements and strengthen supplier relationships.

Advanced procurement tools offering supplier portals and performance dashboards can streamline monitoring efforts and provide real-time insights into supplier performance.

Example: performance dashboards from Kodiak Hub.

Source: Kodiak Hub

Of course, consistent communication with suppliers is crucial to ensure they understand expectations and have the support needed to meet them.

To recap, performance monitoring is implemented throughout the supplier lifecycle, serving as a way to ensure your suppliers comply with agreed-upon standards.

In addition to monitoring supplier performance, another crucial stage that spans the supplier lifecycle is risk management.

Although a big chunk of supplier risks is assessed during the evaluation stage, it’s critical that risks are assessed during the supplier relationship as well.

Why?

Suppliers don’t operate in a vacuum, meaning they can be adversely affected by a range of risks, such as financial instability, own sourcing issues, geopolitical conflicts, and more.

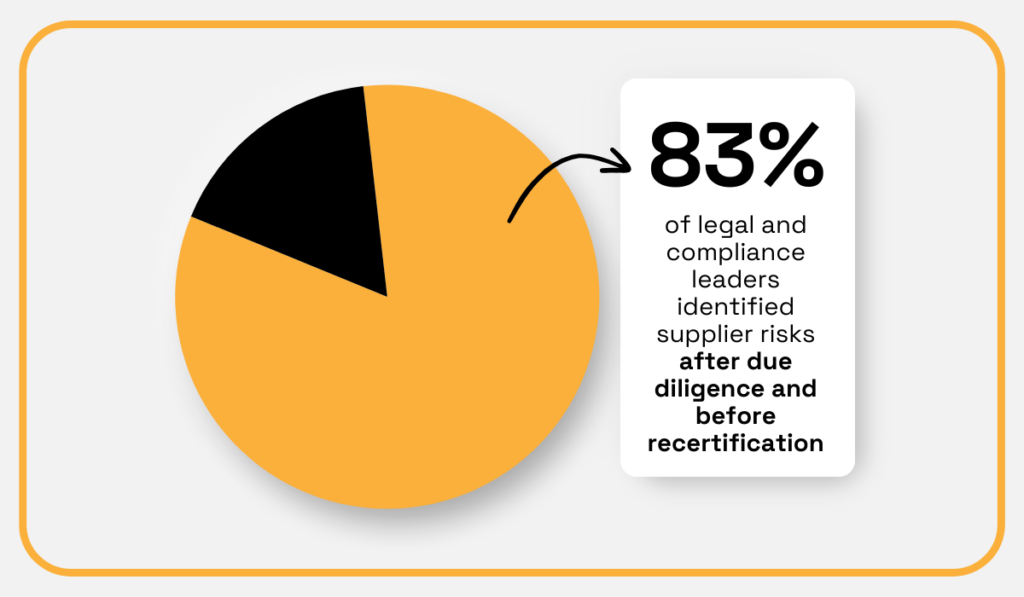

A Gartner survey revealed that over 80% of respondents identified supplier risks after the initial risk assessment (due diligence) and before contract renewal (recertification).

Illustration: Veridion / Data: Gartner

This finding underscores the critical importance of ongoing risk management throughout the supplier lifecycle.

Key activities include conducting regular risk assessments, monitoring supplier compliance, and creating contingency plans for critical suppliers.

The ultimate goal of risk monitoring is to minimize potential disruptions to your supply chain by proactively addressing vulnerabilities.

Given the complexity and variety of supplier risks, leveraging the right tools is essential to streamline the process.

These tools range from risk management software and contract management solutions to data intelligence platforms.

For example, Veridion enables you not only to vet potential suppliers during the initial evaluation stage but also to automate certain aspects of ongoing risk monitoring.

Source: Veridion

Our platform allows you to set specific risk factors and receive real-time alerts if those risks emerge.

This proactive approach ensures that your team can quickly respond to potential disruptions, safeguarding your supply chain.

Overall, managing risks throughout the supplier lifecycle requires an iterative, end-to-end approach to third-party risk management, supported by the right data and tools.

Supplier Relationship Management (SRM) is another comprehensive stage, so much so that some professionals equate it with the entire supplier lifecycle management process.

This perspective stems from the fact that SRM draws insights from the two prior stages—performance and risk management—and extends into the next, supplier development.

In essence, SRM focuses on building and maintaining collaborative partnerships with key suppliers to drive mutual growth.

Core SRM activities include regular communication, joint planning, and constructive resolution of disputes.

Transparency, clear expectations, and consistent communication are essential elements for nurturing strong supplier relationships.

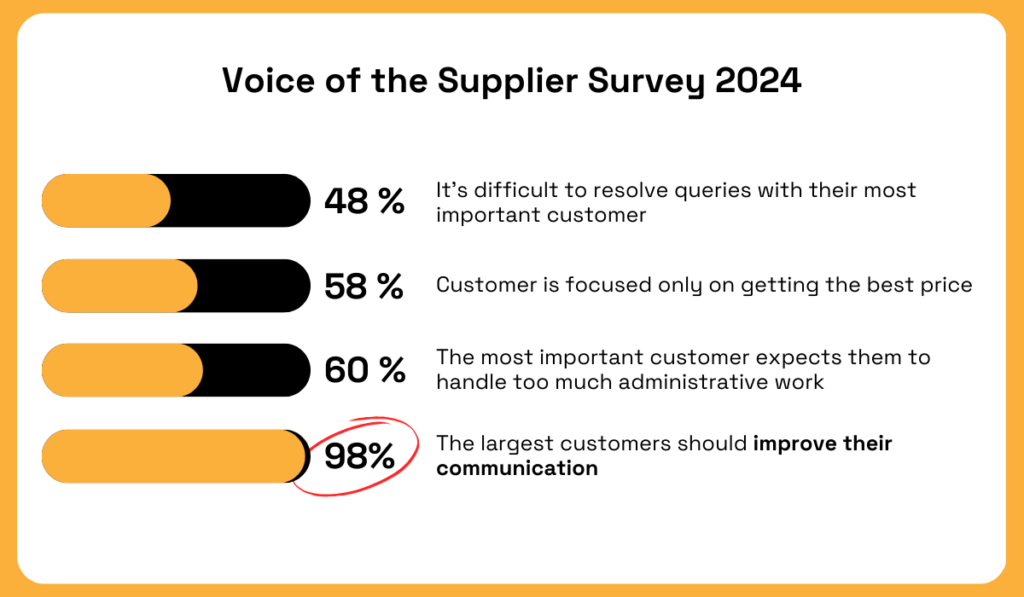

HICX’s 2024 Voice of the Supplier Survey underscores this point, revealing that nearly all suppliers desire better communication from their clients.

Below, you’ll find this insight along with other notable findings:

Illustration. Veridion / Data: HICX

The above findings show that buyers still have a lot of work to do to transition from a transactional mindset to a collaborative one.

The rewards of doing so can be immense, especially when disruptions arise.

As Daniel Chua, Procurement Director at HARMAN International, explains:

“If you have a good relationship with suppliers, they actually allocate more resources to support you. Procurement is all about relationship management that you build for a long time.”

Therefore, building strong, collaborative relationships with suppliers not only enhances your day-to-day operations but also ensures greater resilience and support during times of disruption.

Supplier development is an SRM component that runs in parallel with most other lifecycle stages.

As the Chartered Institute of Procurement and Supply (CIPS) defines it, supplier development is:

“…the process of working with certain suppliers on a one-to-one basis to improve their performance for the benefit of the buying organization.”

So, the goal of this stage is to ensure suppliers can meet evolving business needs and deliver higher value over time.

Fostering supplier development includes providing training, sharing best practices, and collaborating on innovation and efficiency improvements.

As Marco Garzon Huante, supplier performance manager at Amazon, highlights:

Illustration: Veridion / Quote: LinkedIn

He also notes that the main challenge lies in aligning supplier interests with your company’s goals and providing the right incentives to foster collaboration.

This can be achieved by establishing a joint business plan, running a supplier development program, or launching co-innovation projects to address shared challenges and opportunities.

Ultimately, investing in supplier development strengthens partnerships, drives long-term value, and ensures that suppliers remain aligned with your evolving business goals.

While some supplier relationships can last for decades, it’s only natural that most come to a close at some point.

Enter the final lifecycle stage—supplier offboarding.

This step manages the orderly termination of a supplier relationship when it is no longer beneficial or necessary.

The purpose is to ensure a smooth transition while addressing outstanding issues such as payments and the return of assets.

Offboarding activities include:

Having a standardized offboarding procedure and checklist is considered best practice.

This ensures your company is protected from potential cybersecurity risks and post-offboarding disputes.

Having explored all the stages, it’s clear that effective management is essential for building strong, resilient supply chains that deliver value.

By addressing each supplier lifecycle stage carefully, you can foster collaboration, minimize risks, and strengthen relationships.

With the right strategies, tools, and a focus on continuous improvement, your company can unlock the full potential of supplier partnerships.