8 Companies with Efficient Procurement Strategies

Procurement teams face many challenges these days. Not depending on a single supplier, ensuring sustainability, managing other risks, and reducing costs are just a few on the ever-growing list.

Sometimes, the best way to navigate these challenges is to learn from the best.

In the following sections, you’ll learn from eight companies, including some well-known giants, and see first-hand which procurement strategies they use to achieve efficiency and profitability.

If you’re a procurement professional aiming to optimize your internal processes or just curious about how top companies manage their procurement, keep reading—you may find valuable ideas to apply to your own operations.

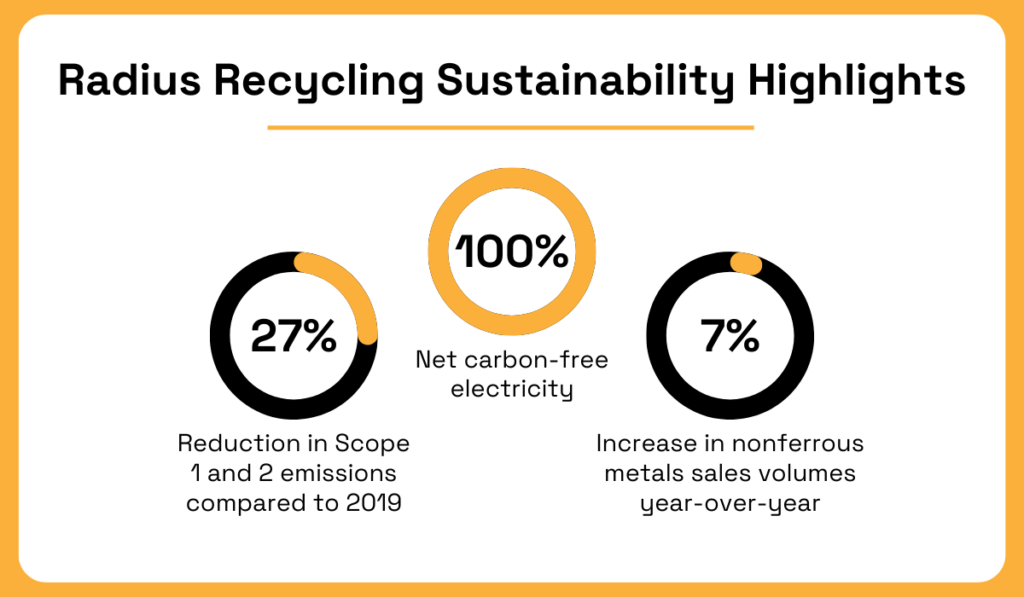

Radius Recycling, previously known as Schnitzer Steel, is a leading recycler of ferrous and nonferrous metals and a manufacturer of finished steel products.

Given that steel production significantly contributes to CO2 emissions, sustainability is a major concern for this company.

Radius Recycling was ranked #1 on Corporate Knights’ 2023 Global 100 most sustainable corporations in the world, outperforming over 6,720 organizations.

Tamara Lundgren, the company’s CEO, commented on the achievement with the following quote.

Illustration: Veridion / Data: Corporate Knights

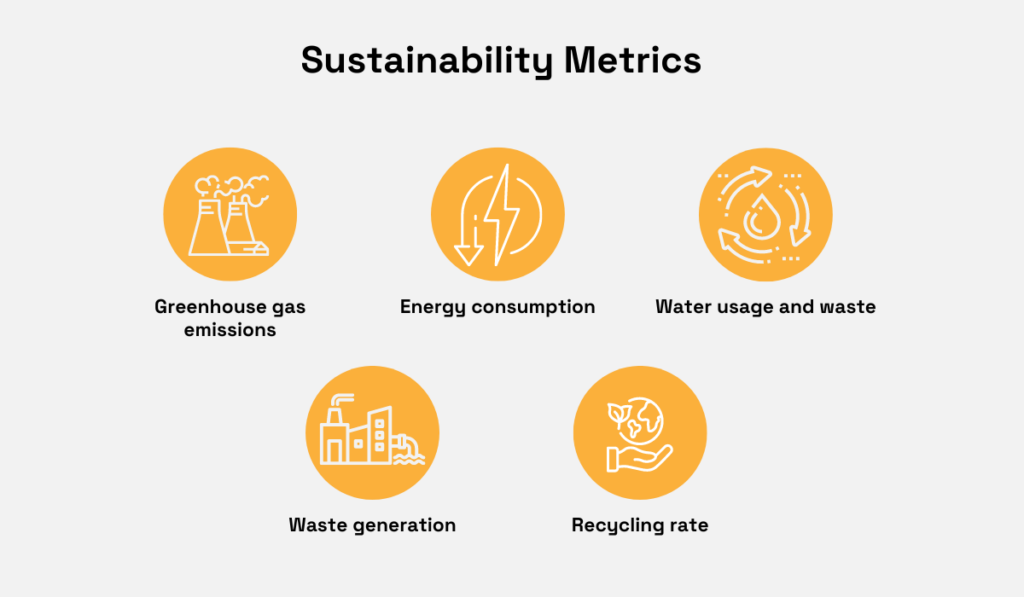

How did they become a leader in sustainability?

The answer lies in adopting sustainability metrics and goals, a practice they started back in 2019. They have since focused their operations on tracking and improving these metrics.

Their 2023 Sustainability Report offers a detailed look at their progress so far.

Illustration: Veridion / Data: Radius Recycling

Radius Recycling drastically cut emissions by using more recycled products and nonferrous metals, focusing on circularity. They did all this while operating on carbon-free electricity and producing overall less waste.

Source: Veridion

With increasing ESG regulations, consumers demanding eco-friendly practices, and the shift from cost-centric to more long-term goals from procurement professionals, sustainability is becoming more important.

Radius Recycling’s success proves that with the right strategy and careful monitoring, progress is possible even in carbon-intensive industries.

To help meet your own procurement sustainability goals, follow their example: define clear, measurable sustainability goals, and commit to them.

Apple’s products are among the highest-selling consumer electronics globally and they rely heavily on a complex network of suppliers to meet demand and maintain quality.

Here’s what they said themselves:

Apple requires each of its suppliers to meet the highest standards for all goods and services. Our requirements include a commitment to rigorous quality assurance.

This commitment to quality is assured with regular supplier assessments and engagement, with some of their practices illustrated below.

Source: Apple

Most of these practices are oriented toward evaluations and assessments. More specifically, they include the following:

They aim to achieve a big-picture view of their suppliers’ operations, performance, and adherence to Apple’s standards.

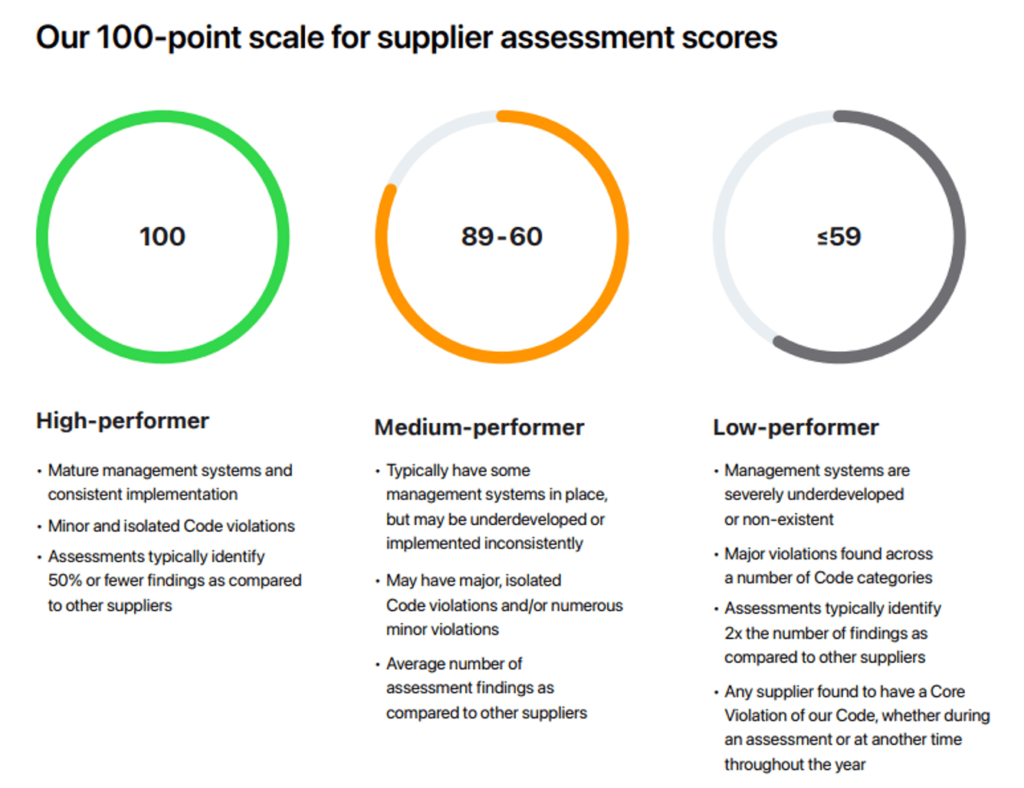

And, based on these assessments, suppliers are assigned scores from 0-100.

Source: Apple

And do they simply stop working with low-performing suppliers? Not necessarily.

Apple understands that creating a strong supplier relationship involves investment from the procurement organization.

They include remediation plans for larger violations involving human rights and worker conditions, as well as training and capability building for suppliers with underdeveloped management systems.

This example shows that supplier management is a two-way relationship. While you demand high performance from suppliers, you can also contribute to their growth and improvement.

Ultimately, this approach holds suppliers to higher quality and ethical standards and creates the possibility for long-term partnerships and mutual growth.

Next up, let’s look at people’s favorite jeans company Levi Strauss & Co.

One of Levi’s focus areas is supplier diversification. Their Sustainability Report states that the company sourced from more than 500 supplier facilities in 40 countries worldwide in 2021.

Former Levi’s president and CEO Chip Bergh comments on why they use this practice with the next quote.

Illustration: Veridion / Quote: Seeking Alpha

What Bergh is saying is that they use one of diversification’s primary benefits—risk mitigation—to ensure that they don’t rely too heavily on a few suppliers from a single country.

This proved especially helpful during China’s pandemic lockdowns as they’ve already reduced sourcing from China from 16% in 2017 to 1% in 2019.

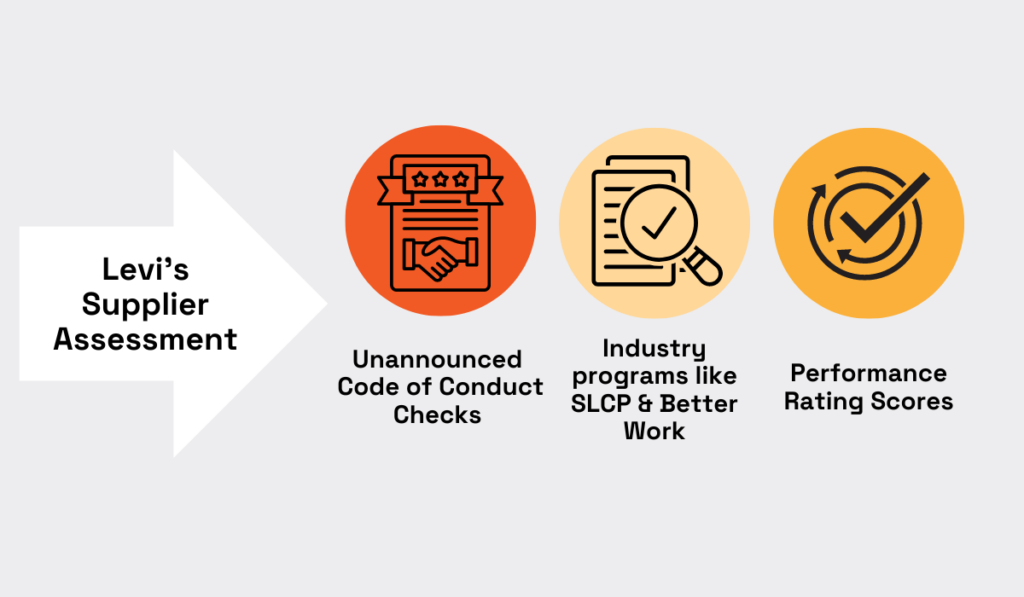

But even with a diversified supplier base, quality checks and evaluations are key. That’s why Levi’s has a Supplier Code of Conduct and Sustainability Guidebook and uses some of the following assessment practices.

Illustration: Veridion / Data: Levi Strauss

Through unannounced code of conduct checks, Levi’s sees the true day-to-day operations of their suppliers, without giving them time to hide any issues.

Levi’s also participates in programs like the Social Labor Convergence Project (SLCP) and Better Work, which aim to improve working conditions and labor rights in the apparel industry and help standardize supplier assessments.

Overall, this is a great example of how diversification and robust assessments result in more stable operations with better-quality suppliers.

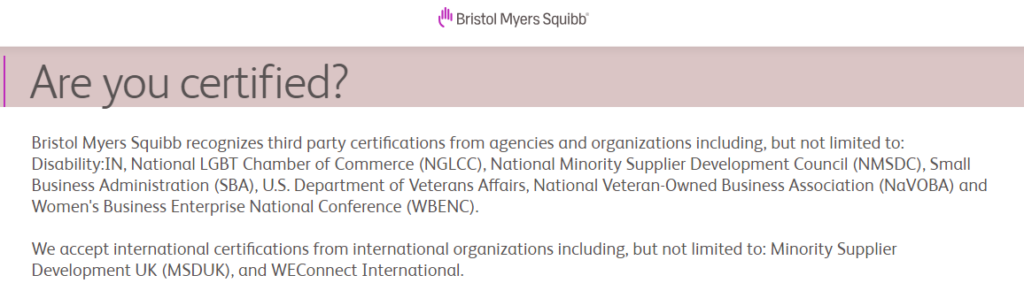

Bristol Myers Squibb (BMS), a global biopharmaceutical company, stands out for its commitment to supplier diversity.

Their diversity program, established 28 years ago, has evolved from a way to meet government regulations and requirements into a core business strategy that helped their business grow.

According to their website, BMS supports and sources from diverse businesses owned by:

They also extend their initiatives to include small and local businesses, a practice that is less common in diversity programs.

However, they do have third-party certification requirements from reputable US bodies and some international organizations.

Source: BMS

This ensures that their commitment to diversity doesn’t compromise the quality or reliability of their supply chain.

So what are the benefits of the diversity program in BMS’s own words?

Rondu Vincent, executive director of global supplier diversity & sustainability, says that their organization’s mission is to “transform patients’ lives through science.”

And he claims that diverse suppliers directly contribute to this aim.

Illustration: Veridion / Quote: CCC

Diverse suppliers also bring fresh perspectives, a critical asset for a pharmaceutical company dedicated to developing groundbreaking medicines.

By fostering a diverse supplier base, procurement organizations can economically empower various communities and enhance their own capacity for innovation.

In summary, BMS’s supplier diversity program demonstrates how inclusive procurement practices can align with the company’s core mission and support it.

Nike is deeply committed to social responsibility and responsible sourcing.

Here’s a snapshot of their achievements and future goals in this area.

Illustration: Veridion / Data: Nike

As you can see, Nike prioritizes diversity, worker engagement and well-being, and career development opportunities for their suppliers’ workers.

They are particularly focused on empowering women, who make up 70% of their supply chain workforce.

This strategic approach is crucial, given the troubling history of labor practices in the footwear and clothing industry, including forced labor and unsafe working conditions.

Source: Kharon

Ensuring suppliers adhere to legal and ethical practices and regulations is a responsibility all procurement organizations should share.

And, greater transparency is one way to hold companies accountable.

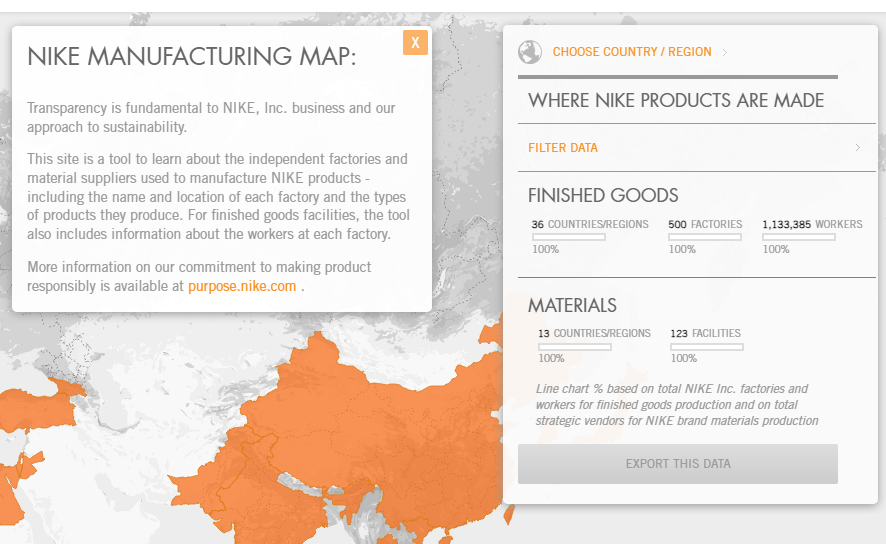

Nike takes a proactive approach to transparency with their Manufacturing Map, an interactive tool that displays all of their suppliers, the names and locations of factories, and, in some cases, even the information about the workers.

Source: Nike

This level of transparency allows everyone to see who makes Nike’s products and where, fostering accountability and encouraging responsible practices throughout the supply chain.

Nike’s dedication to social responsibility and transparent sourcing practices sets a positive example for the industry and demonstrates that ethical considerations can and should go hand-in-hand with business growth.

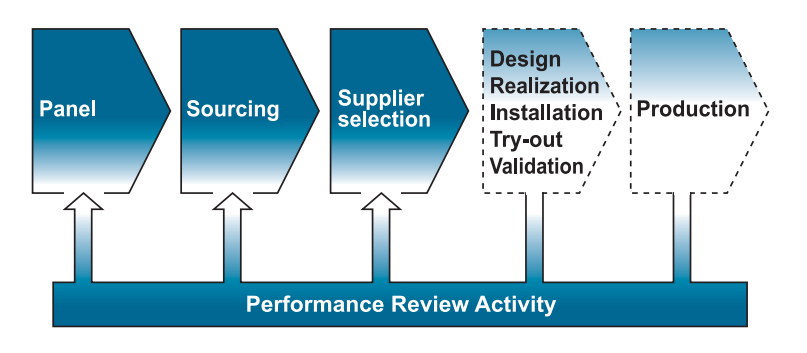

Renault Group, a major player in the automotive industry, emphasizes a thorough approach to supplier management, focusing on three pillars:

Before entering into a contract with suppliers, Renault evaluates them based on these three criteria.

Source: Renault

Their “Panel Committee” pre-selects candidates based on their performance in areas like quality, cost, delivery, development, and management.

The “Sourcing Committee” then makes the final selection for each project through a transparent bidding process.

Beyond performance and quality, over 80% of their purchase decisions involve a thorough assessment of suppliers’ social and environmental practices.

Their Corporate Social Responsibility Guidelines for Suppliers outline some of these specific requirements, which relate to safety, human rights, environmental policies, and transparency.

Source: Renault

Any non-compliance incidents are taken seriously, with suppliers expected to report them immediately. Renault conducts thorough investigations and may even halt RFQs during this process.

This meticulous approach helps Renault mitigate risks, maintain their brand reputation, and ensure consistent product quality. Their success is directly linked to the reliability and responsibility of their suppliers.

Two key areas where IKEA excels are global sourcing and automation.

| Practice | Description |

|---|---|

| Global Sourcing | IKEA sources goods from Europe, Asia, and the US, ensuring a large range of products at lower costs. |

| Automation of Processes | IKEA uses robots and automated systems to improve efficiency and reduce manual labor while maintaining consistent quality. |

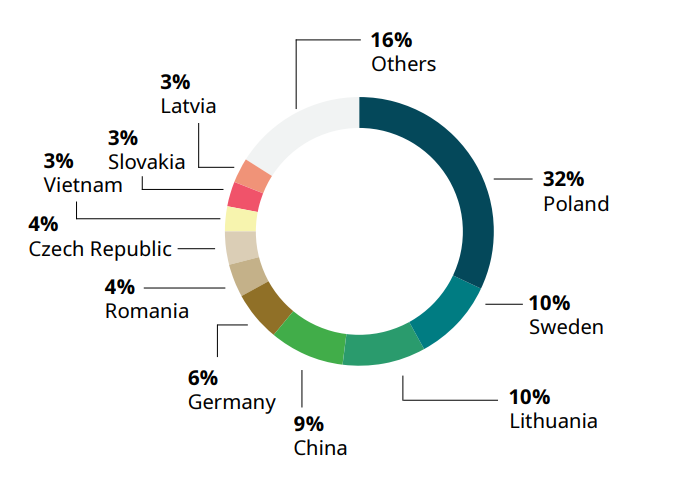

As a multinational corporation with a vast product range, global procurement ensures IKEA has access to all the materials it needs and keeps costs down by leveraging competitive pricing.

This strategy is also closely aligned with IKEA’s sustainability initiatives.

Consider the locations where IKEA sources virgin (unrecycled) wood.

Source: IKEA

By sourcing wood from multiple countries and suppliers, IKEA can select only the partners who adhere to responsible forest management practices while simultaneously reaping all other benefits of diversification.

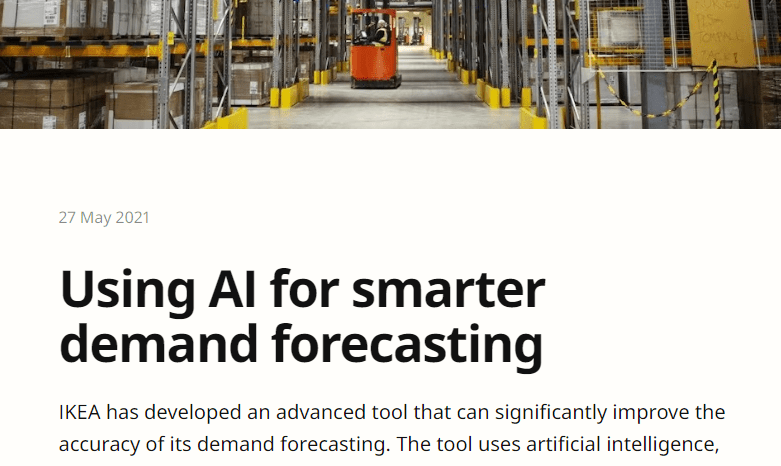

In addition to global sourcing, IKEA has embraced automation, including robots in their warehouse operations, along with automated systems to replace manual work.

Staying at the forefront of innovation, they even developed their own AI-powered demand forecasting system.

Source: IKEA

IKEA is a very complex operation. According to Peter Grimvall, former head of supply chain design, they handle a couple of billion products. It’s understandable that automation shines at tackling these complexities and optimizing the entire process.

The takeaway here is that by carefully selecting suppliers and embracing innovative technologies, companies can build a resilient and efficient supply chain that delivers great products to consumers.

Finally, let’s examine Samsung’s approach to risk management in their supply chain.

Samsung focuses on a variety of supplier risks, including environmental, health, and safety (EHS) concerns, and human rights issues.

Source: Samsung

One of their key risk management strategies is conducting on-site audits based on the Responsible Business Alliance (RBA) Code of Conduct.

In 2022, Samsung audited 329 of their high-risk suppliers using RBA criteria and implemented corrective actions where needed. This resulted in an average on-site audit compliance rate of 95%, meaning that most suppliers met the high standards.

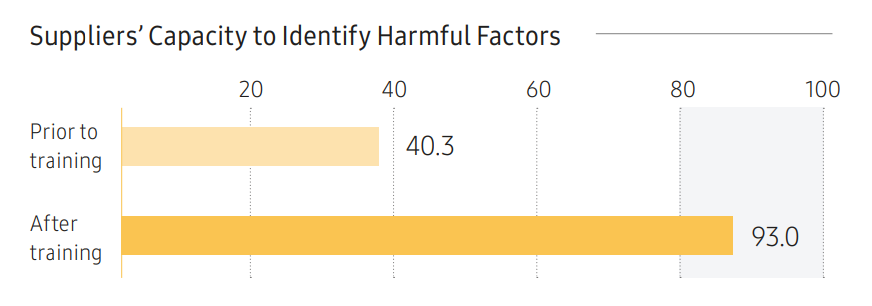

But assessments are only part of the equation. Samsung goes further by investing in training for both their own employees and their suppliers’ employees.

Their Device Solutions division runs a risk assessment expert program to strengthen risk assessment capabilities. By the end of 2022, 3,494 experts, including 1,294 from supplier companies, had completed the program.

Through specialized training courses, participants learn how to identify and address potential risks in the workplace.

Before the training, only 40% of suppliers could identify harmful factors in their workplaces. After the training, this number jumped to 93%.

Source: Samsung

This improvement shows the positive impact of Samsung’s investment in risk management education on top of thorough audits.

It’s a proactive approach that addresses risks at their source, creating long-term benefits for both Samsung and its suppliers.

In this article, we explored some efficient procurement strategies from eight successful organizations.

We looked at different aspects, from tracking supplier performance to sourcing from minorities and having educational programs for risk management.

But what we’ve covered here is just a starting point.

We encourage you to explore the resources linked throughout the article to gain a more complete understanding of how these companies operate.

Every organization is different, and what works for one might not work for another. But, we hope these examples have some useful takeaways that you can use and adapt to your specific needs.

To mitigate risk and improve the efficiency of your own procurement, try Veridion next time you’re looking for new suppliers. We have unparalleled data that is always fresh.