Best Practices for Successful Global Procurement

Despite some setbacks caused by recent health and geopolitical crises, global procurement remains a strategic imperative for companies aiming to stay competitive and agile in the marketplace.

That’s because leveraging suppliers from around the globe offers a myriad of opportunities, from cost savings to access to specialized expertise.

However, managing the complexities that global procurement brings to the table requires a strategic approach and meticulous attention to detail.

In this article, we’ll explore five best practices that can help businesses successfully navigate the intricacies of global procurement to ensure cost-efficiency, supply chain resilience, and sustainable supplier partnerships.

Imagine you’re a company manufacturing products for which you source raw materials or components from local and regional suppliers.

One day, disaster strikes, and one of your key suppliers is suddenly put out of business.

Having to quickly pivot and find a new supplier, you decide to broaden your search to include suppliers from around the world.

In that case, what objectives would you set for your procurement team?

For instance, would lower costs offered by an overseas supplier take precedence over potential risks associated with compromising product quality standards?

Or perhaps, in light of your situation, would diversifying the supplier base to reduce dependency on a single supplier and mitigate future supply chain disruptions be a priority?

These considerations illustrate why procurement teams should clearly define what goals they’re trying to achieve, i.e., define objectives that align with their organization’s overall goals.

Naturally, generating cost savings usually tops this list, but there’s much more a company can aim to achieve through global procurement, as shown below.

Source: Veridion

As you can see, some of these objectives are straightforward, while others may not be so obvious.

For instance, it’s clear that companies can reduce costs and improve profitability by sourcing materials or services from countries with lower production costs.

In fact, achieving cost savings is one of the primary drivers for engaging in global procurement.

Similarly, companies can diversify their supplier base beyond their country or region, which fosters supply chain resilience and agility in the face of unforeseen challenges.

The example below illustrates this well:

Source: Vogue Business

Events such as those described above are also why risk mitigation is one of the critical objectives in global procurement.

Furthermore, companies often seek global suppliers to gain access to specialized materials, skills, or technologies that may not be readily available domestically.

This enables them to innovate and differentiate their products or services in the market or gain specific expertise at a lower cost.

Another potential objective of global procurement is market expansion.

In other words, procuring goods or services globally opens up new market opportunities for companies, enabling them to enter new territories and tap into diverse consumer bases.

Concurrently, by engaging with global suppliers, companies can leverage scalability, allowing them to ramp up production or expand their operations rapidly in response to changing market demands.

Likewise, they can leverage economies of scale to their (cost) advantage by procuring materials or components from foreign companies with larger markets and production capacities.

Ultimately, the overarching goal of global procurement is to gain a competitive edge in the marketplace.

Whether through cost leadership, product differentiation, or agility in responding to market dynamics, an effective global procurement strategy positions companies for sustained success.

Therefore, before engaging in global procurement, you should define clear objectives aligned with these key drivers, so your team can effectively steer their procurement efforts.

Once you defined your global sourcing objectives, it’s time to thoroughly research potential suppliers.

This best practice is not specific to global procurement but may include some specific considerations, tools, and methods.

In a nutshell, you want to evaluate potential suppliers from around the world based on factors such as their:

Considering that such suppliers are not local, finding and evaluating them can be challenging.

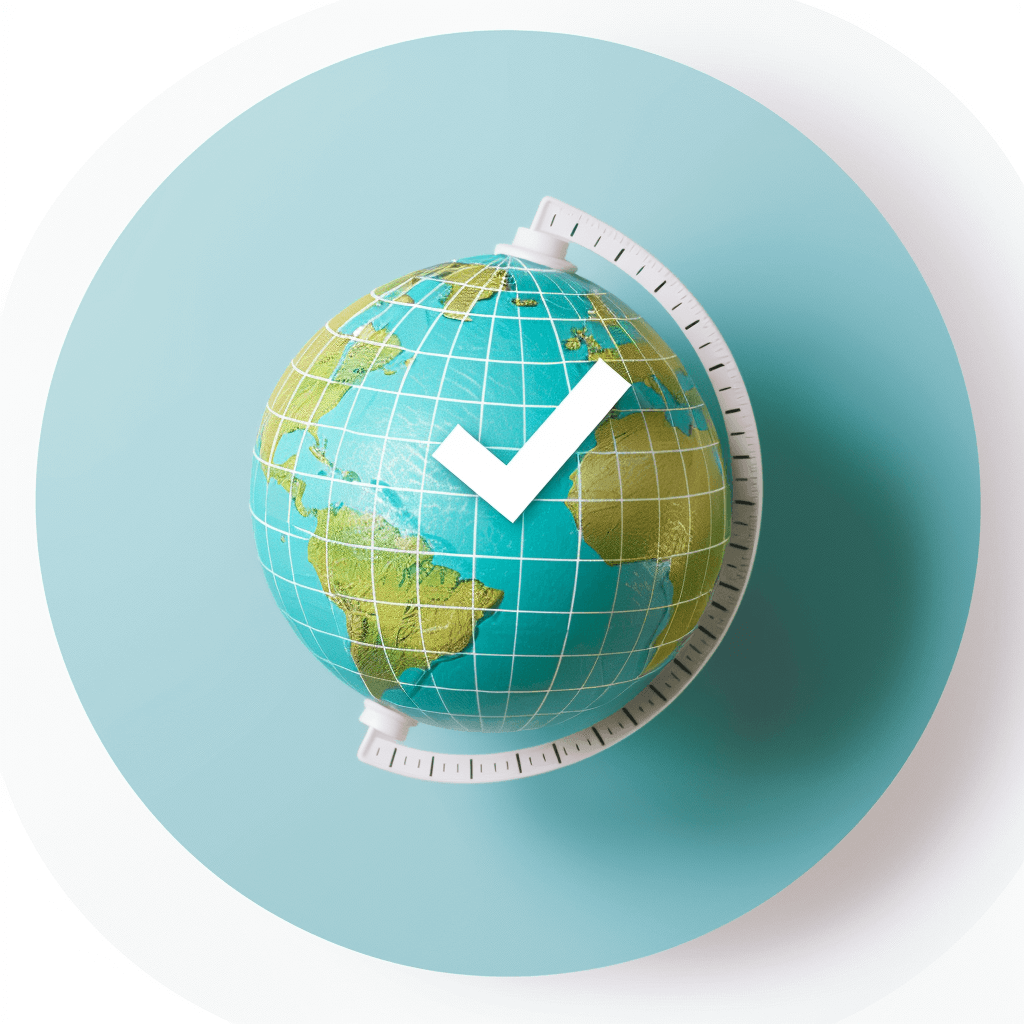

To counter this, you need to access extensive information about prospective suppliers, their prices, competitors, markets, and regulatory compliance, all of which are essential components of procurement market intelligence.

Source: Veridion

Naturally, to collect this extensive data, you first need to know which suppliers across the globe can provide specific materials, components, or services you’re looking for.

For most companies, discovering new suitable suppliers, particularly on a global scale, can be an extremely time-consuming and resource-intensive task.

According to McKinsey, one supplier search can take a single full-time procurement professional about three months, with them evaluating only a fraction of potential suppliers.

However, the same source also highlights that companies utilizing advanced supplier-sourcing tools can cut the time needed to find the right suppliers by 90% or more.

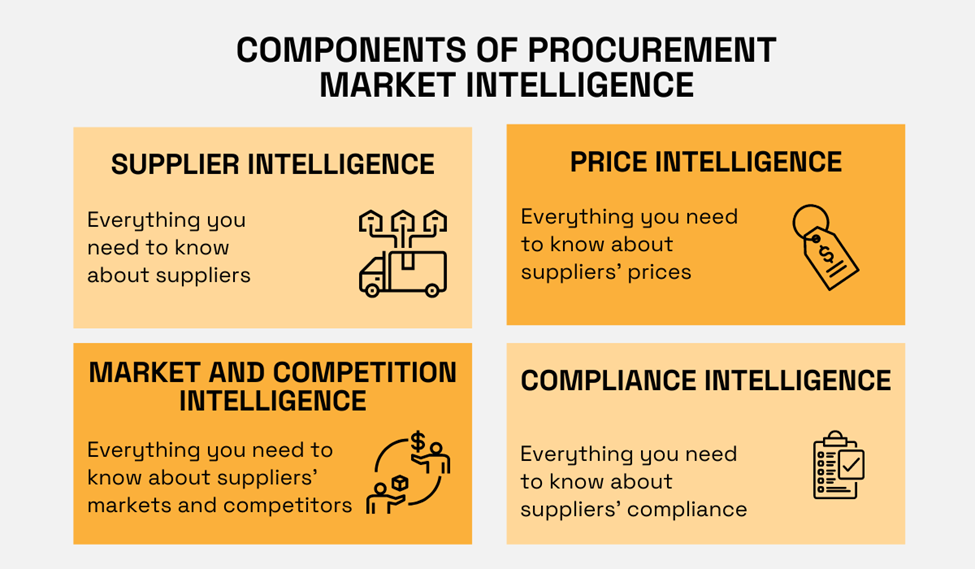

For example, our AI-powered supplier discovery tool, Veridion, gives you access to a global database of company data, which is updated on a weekly basis.

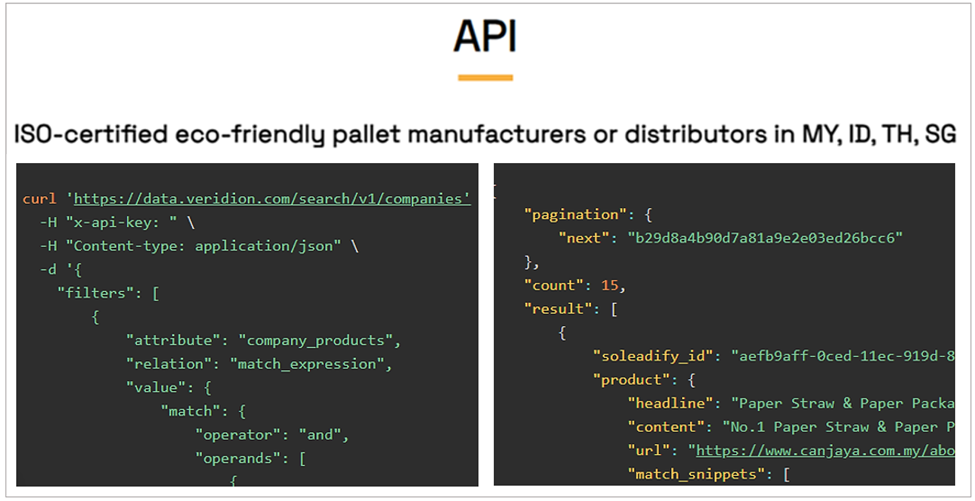

Source: Veridion

With Veridion’s advanced search APIs, you can use natural language input to set any specific supplier criteria and quickly find potential suppliers from anywhere in the world.

Here’s an example where a company seeking pallet suppliers has set several specific criteria, such as their product quality (ISO-certified), their commitment to sustainability (eco-friendly), and their geographic location.

Source: Veridion

With a list of prospective suppliers that fit these criteria, the company can confidently proceed with further evaluation, knowing that they align with its specific procurement needs and priorities.

Moreover, the same database and search functions can be used to verify other relevant supplier parameters, such as their financial stability, regulatory compliance, and reputation, or the political environment in their country.

So, it’s clear that procurement data collection and analysis tools can significantly streamline the supplier research process, saving time and resources while ensuring quick and easy access to global suppliers.

The bottom line is, extensive supplier research, supported by the right supplier-sourcing tools, is essential for successful global procurement.

Ensuring compliance with legal and ethical standards is crucial in all procurement endeavors, but it becomes even more imperative in the context of successful global procurement.

More precisely, procurement teams must navigate a complex landscape of laws, regulations, and cultural nuances to ensure seamless operations and mitigate risks.

Understanding local regulations is key to establishing trust with suppliers and safeguarding your company against potential legal and reputational issues.

First and foremost, procurement teams should familiarize themselves with the legal frameworks governing procurement activities in target countries.

This includes understanding local laws and regulations related to:

For example, when sourcing from certain countries, your team should ensure that potential suppliers comply with regulations governing intellectual property rights and labor practices to avoid legal disputes and reputational damage, like in this case.

Source: The Guardian

To ensure that suppliers adhere to regulations, your procurement team can:

Additionally, fostering open communication channels and building strong relationships with suppliers can facilitate ongoing compliance monitoring and address any potential issues promptly.

Another crucial aspect of successful global procurement are import and export requirements.

This involves procurement teams understanding customs regulations, tariffs, and trade agreements to ensure smooth transportation of goods across borders.

Here’s what Hau Lee, Professor at the Stanford School of Business, says about that:

Illustration: Veridion / Data: Procurious

Of course, failure to comply with relevant import/export requirements can result in delays, fines, or even seizure of goods.

In addition to customs regulations, your team should also consider the target country’s cultural norms and business practices.

That’s because these norms and practices vary significantly across countries and can impact procurement negotiations and relationships.

For example, in Japan, building trust and maintaining harmonious relationships is highly valued in business dealings, so respecting these cultural norms can help you establish strong partnerships with Japanese suppliers.

To recap, understanding local laws, import/export regulations, and cultural norms in target countries enables procurement teams to mitigate risks and ensure compliance with regulatory, environmental, and ethical standards.

Moreover, this knowledge helps prevent legal, operational, and reputational damage for your company and lays the groundwork for building strong supplier relationships.

Another best practice essential for the success of any procurement initiatives, let alone global ones, is putting time and effort into building strong supplier relationships.

Beyond simply securing smooth supply operations, cultivating partnerships with suppliers fosters collaboration, trust, and mutual benefit.

These relationships go beyond the transactional nature of business and create long-term value and a multitude of benefits for your business.

Here are just some of them:

Illustration: Veridion / Data: LinkedIn

For example, a supplier that feels recognized and valued in their relationship with your company will be motivated to diligently perform their duties, resulting in improved on-time delivery.

Likewise, they’ll be driven to help you overcome potential supply chain disruptions caused by unforeseen challenges.

This increased responsiveness to crises enables your company to swiftly address unexpected problems, thereby minimizing operational disruptions and maintaining business continuity.

Furthermore, when suppliers are reliable and committed partners, there is less risk of logistical setbacks, missed deadlines, or quality issues tarnishing your company’s reputation, as the article below illustrates.

Source: WTW

In addition to fewer quality or reputation-related problems, another advantage of strong supplier relationships is access to innovation.

Specifically, suppliers who understand your company’s requirements and objectives are more likely to suggest or collaborate on innovative solutions involving new technologies or processes.

Moreover, if your supplier runs into their own sourcing issues limiting their production, a strong relationship with them will reduce the likelihood of your company experiencing supply scarcity.

Given all these advantages, it pays to invest time and effort in understanding your suppliers’ needs and processes while also accounting for any potential language barriers and differences in communication styles and cultural norms.

Building strong supplier relationships is not just beneficial, but crucial for successful global procurement.

These partnerships facilitate on-time delivery, crisis response, quality assurance, and innovation, ultimately increasing the resilience of your global supply chain.

While global procurement offers many cost-saving opportunities for companies, it also comes with a slew of potential risks.

That’s why having a robust risk management strategy is essential for safeguarding your procurement operations against disruptions and mitigating their impact on your business operations.

Again, collaboration with any supplier always carries certain risks, but global procurement initiatives bring some specific ones, such as:

Therefore, your procurement team should proactively assess and prioritize these risks to develop comprehensive mitigation plans.

An essential component of such plans is establishing a risk monitoring mechanism that will alert you if, for example, your supplier is experiencing financial troubles or the political situation in their country is becoming increasingly unstable.

To do so effectively, you can leverage the big data and analytics tools we mentioned earlier.

Source: Veridion

As illustrated, access to a global database of suppliers coupled with custom-made risk factors and real-time alerts allows your team to conduct thorough risk assessments when selecting new suppliers, as well as when managing ongoing supplier relationships.

In addition to establishing regular risk monitoring processes, you should develop contingency plans and crisis management protocols to provide clear guidance on how to respond effectively to unforeseen events.

By integrating risk management practices into procurement processes, your organization can enhance its ability to mitigate supply chain risks and adapt to changing market conditions.

This proactive approach can minimize the likelihood of disruptions and strengthen the overall resilience of your procurement operations in the face of unforeseen challenges.

Having covered these five best practices for successful global procurement, it’s evident that successful global procurement requires a strategic approach, meticulous attention to detail, and a robust risk management strategy.

By defining clear objectives, building strong supplier relationships, and implementing effective risk mitigation plans, your procurement team can navigate the complexities of global procurement with confidence.

Moreover, leveraging the right tools and methods can significantly enhance your procurement outcomes and drive your company’s long-term success.