7 Global Procurement Mistakes to Avoid

Global procurement offers companies many benefits, starting with cost savings and access to specialized resources.

However, in the pursuit of these advantages, procurement teams must skillfully navigate specific challenges and risks to prevent falling into some common pitfalls associated with global sourcing.

In this article, we’ll explore seven such mistakes and provide practical tips on how to avoid them, helping you maximize the benefits of global procurement.

Today, the internet has seemingly opened doors wide for companies to easily find potential suppliers in any corner of the globe.

Although that’s partially true, relying on simple internet searches to discover and thoroughly evaluate suppliers is far from sufficient to make an informed procurement decision.

Aside from various types of scams, there’s the issue of incomplete information.

For instance, a supplier may present themselves favorably online, but leave out crucial details like their production capacity, quality control processes, or industry certifications, leaving you unsure about their ability to meet your requirements and standards.

And in some industries, this matters more than in others.

The procurement of surgical instruments requires a keen eye for quality and reliability. In one case, switching to a supplier known for its superior instruments reduced tissue damage during operations, subsequently improving patient recovery times. This experience underscored the importance of vetting suppliers rigorously and investing in high-quality products to enhance overall healthcare outcomes.

—Mike Breslin, CEO, ProMed DME

This means expanding your online search, which you have to do anyway to check some other critical elements, such as whether a supplier uses fair labor practices.

Needless to say, this mistake can cause significant reputational damage.

Source: LA Times

Furthermore, you’ll need to check whether a potential supplier is experiencing domestic tax or regulatory issues, as well as verify the political and economic stability of their home country, or the one where their factory is located.

So, it’s clear that your supplier evaluation needs to include comprehensive scrutiny beyond what can be gleaned from manual and time-consuming online searches.

To address these challenges and ensure thorough online supplier vetting, companies can leverage advanced technologies, such as AI-driven big data platforms that regularly update their vast databases of supplier data.

These tools use machine learning (ML) algorithms to scour billions of web pages, check all sources, and provide confidence scores regarding the accuracy and reliability of the data presented to you.

One such solution is our supplier sourcing and evaluation tool, Veridion.

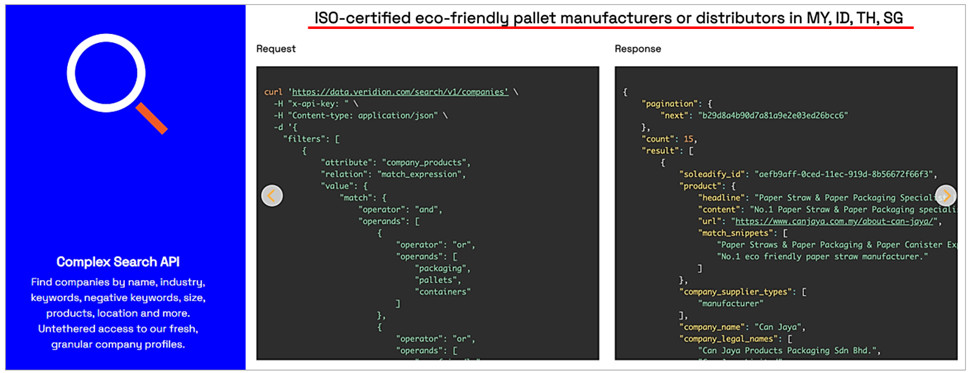

Source: Veridion

As one of the pioneers in using AI for large-scale data acquisition and analysis, Veridion leverages proprietary ML models to create and continuously update a highly accurate global supplier database.

Moreover, this database comes with powerful search APIs that allow you to set your search criteria in natural language.

Source: Veridion

Instead of spending weeks or months on discovering and evaluating potential suppliers through manual online searches, you can easily set very specific procurement criteria and find the candidates that meet them in a few minutes.

Equally, you can use Veridion’s database for market intelligence, i.e., checking parameters like the supplier’s financial stability, environmental compliance, and labor practices, or the political situation in their country and region.

So, to avoid inadequate supplier evaluation in global procurement, consider adopting advanced technologies and methods that enable your team to efficiently gather comprehensive supplier data and make informed decisions.

One of the primary reasons for global procurement is that companies can get goods or services your company needs at a lower price.

For this reason, many companies will focus solely on finding the cheapest supplier without considering quality, which can backfire in various ways.

First of all, there’s potential fraud.

For instance, fake suppliers may build entire dummy company websites, complete with pictures, client testimonials, and attractive low prices, all to get you to pay an advance fee for their “goods” and then disappear.

Source: Forbes

Therefore, if the listed price of materials or components you’re looking for seems too good to be true, the first thing to do is check whether that company actually exists.

To do this, you can use online resources, such as the global supplier database we mentioned, or search for your potential supplier’s name in different business registries, industry data repositories, or professional networks.

If the supplier does exist, it’s time to investigate why their offered price is significantly lower than other offers of similar or identical products.

For example, the supplier may be using lower-quality materials, exploiting workers, or cutting corners somewhere else.

Even if that’s not the case, there might be hidden costs that will only surface later, such as additional fees for shipping, taxes, or subpar customer service, which could ultimately outweigh the initial cost savings.

To avoid making this costly mistake that can lead to compromised quality, legal issues, and reputational damage, it’s crucial to balance cost considerations with quality requirements.

So, beyond ensuring that potential lowest-price suppliers are real, all of them should be evaluated based not only on their price but also their track record and reputation for quality.

When engaging in global procurement, one of the more common mistakes is overlooking foreign regulations, which can have significant repercussions for companies.

Despite the allure of cost savings and access to a broader supplier base, neglecting to thoroughly understand and comply with foreign regulations can lead to legal, financial, and reputational risks.

For instance, failure to stay informed about trade restrictions, tariffs, and import/export regulations can result in delays, increased costs, or even seizure of goods at customs along with a fine.

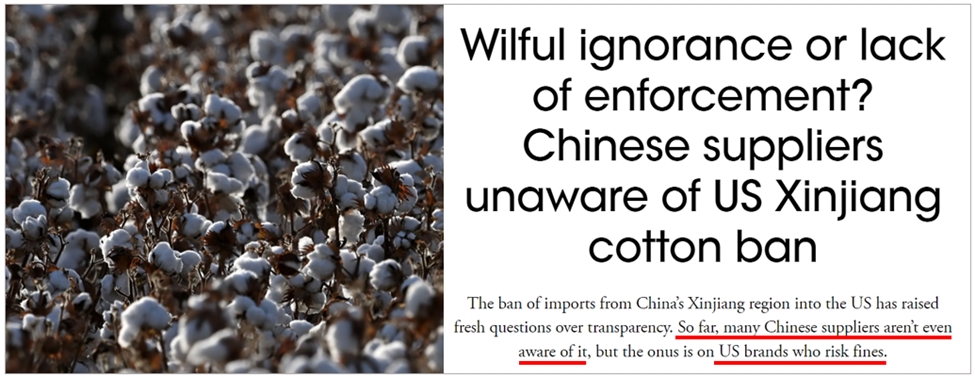

Source: Vogue Business

As the above article illustrates, in June 2022, the US banned imports from China’s Xinjiang region due to concerns over using forced labor in the cotton industry.

Since most Chinese suppliers were unaware of the ban when it was enforced, it’s easy to see how a US-based company, if it failed to double-check the sources of their cotton (or products made therefrom), could find itself facing customs seizure and fines.

Another issue with foreign regulations is environmental standards, which vary widely across countries and regions.

If your supplier does not comply with their national and local environmental regulations, they expose themselves to fines and legal action, and also directly expose your company to reputational risks.

Some countries, like Germany, have already enacted laws mandating large corporations to establish supply chain due diligence mechanisms to ensure that their suppliers are not committing offenses such as human trafficking, forced labor, and environmental harm.

Source: Fintech

Therefore, to mitigate the risks associated with neglecting foreign regulations, companies should prioritize due diligence and invest in resources to stay abreast of regulatory changes.

This may include conducting thorough supplier audits, establishing clear communication channels with suppliers, and leveraging technology to monitor environmental, social, and governance (ESG) compliance across the supply chain.

Source: Veridion

In addition to using automated risk monitoring solutions like Veridion to stay informed about local regulations and compliance requirements, it’s also recommended to work closely with legal experts or consultants familiar with specific foreign markets.

Overall, giving due diligence to foreign regulations allows companies to minimize legal and reputational risks while fostering ethical and sustainable procurement practices.

Of course, relying on a single supplier for critical components or services has its advantages, such as consistent product quality, less paperwork, and an enhanced long-term relationship.

However, if that supplier runs into problems of any kind—like their own sourcing issues, financial hardship, or political or health crises in their country—your company is left exposed, particularly if there’s no backup plan.

In addition to potential supply chain disruptions, over-reliance on one supplier also carries dependency risks and a lack of negotiation leverage.

To avoid this, you should diversify your company’s supplier base for critical items to include suppliers from several locations.

If you’re unsure which items provided by your suppliers are crucial, you can first rank them according to their impact on your profits and their supply risk level.

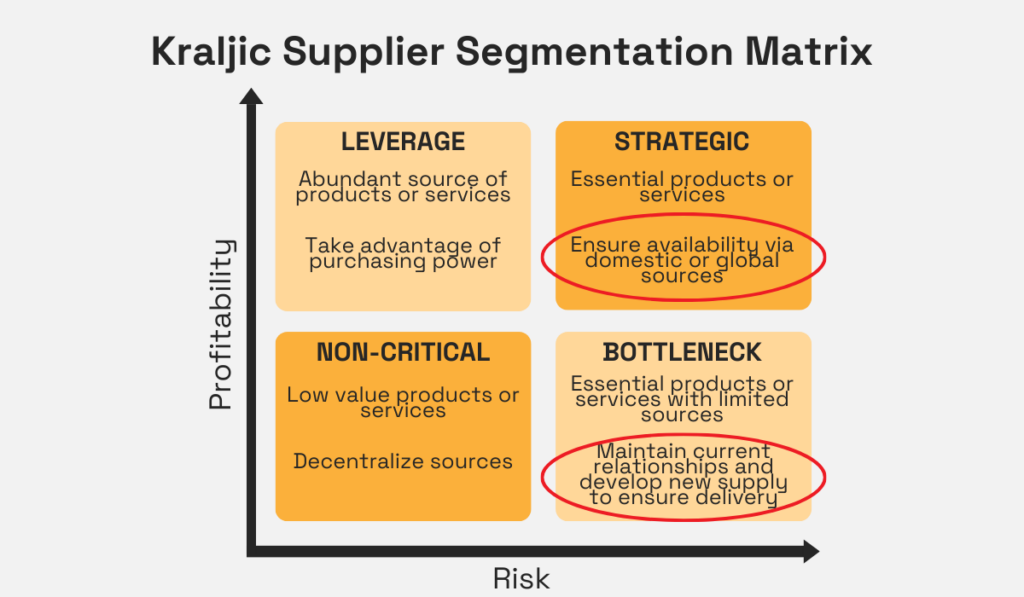

For example, using the Kraljic Supplier Segmentation Matrix, you can categorize your suppliers into four distinct groups.

The two groups with high risks and major impacts on your profitability, as highlighted below, represent those areas where supplier diversification is recommended.

Illustration: Veridion / Data: Smartsheet

The most critical group are your bottleneck suppliers, i.e., those that supply essential products or services but have limited capacities while their peers are hard to find on the market.

As suggested, finding new suppliers in this matrix category is extremely important to avoid over-reliance and associated risks.

The same applies to your strategic suppliers that provide materials or components essential for your company.

Although such suppliers are not as rare as those categorized as bottlenecks, any supply issues they experience could seriously jeopardize your operations, so finding backups from other countries is a necessary risk management measure.

Therefore, to avoid over-reliance on a single supplier, you should look to diversify your suppliers, particularly critical ones, as well as develop contingency plans and alternative sourcing strategies.

Imagine you shortlisted three prospective suppliers, each from a different country.

In such a case, visiting their production facilities could be an expensive endeavor, which is why many companies skip on-site visits and rely on virtual communications and product samples alone.

However, samples can be produced elsewhere or even bought at a store and sent to you masquerading as the supplier’s original products.

Likewise, neglecting to physically inspect supplier facilities can, for example, prevent you from learning that your potential supplier:

Therefore, despite potential traveling costs, it’s best to pack your suitcase and go visit them before finalizing any agreements.

Alternatively, you can hire third-party providers to audit potential suppliers on your behalf.

Source: Asiaction

If that supplier auditing company is reputable, this can provide an unbiased assessment of supplier facilities and operations.

Suppliers can be evaluated based on a list of criteria you provided, ensuring that they actually have one or more factories with good working conditions, are reliable, and can deliver high-quality products.

In summary, skipping on-site visits can have serious consequences for your company down the road, so it’s essential to visit them—in person or via a trusted third party—to verify critical supplier information and ensure their transparency.

Another common mistake in any procurement endeavor, let alone when sourcing globally, is failing to establish clear and comprehensive contracts with suppliers.

Unclear contracts can lead to misunderstandings, disputes, and potential legal issues down the line.

Therefore, when drafting contracts, it’s essential to clearly outline the terms and conditions of the agreement, including:

Failure to specify these details can result in ambiguity and disagreements between the parties involved.

For contract clarity, you should ensure that language barriers and cultural differences do not further complicate contract negotiations.

In other words, It’s crucial that contracts are written in a language that you and your supplier understand (with the help of certified translators, if necessary) and that any cultural nuances are considered to prevent misinterpretations.

Overall, to avoid the mistake of unclear contracts, companies should invest time and resources in drafting contracts that are clear, precise, and legally binding.

Consulting with legal experts familiar with international trade laws and practices can also help ensure that contracts meet all the requirements and protect your interests when dealing with global suppliers.

Last but not least, relying on verbal agreements when negotiating with potential suppliers or changing something in an already established supplier relationship can turn out to be a costly mistake.

For example, imagine you already found an overseas supplier and the first few deliveries went fine, but indicated a need to slightly change product specifications.

Therefore, you call your supplier and explain what modifications you need, and they agree and say it will be done.

However, when the next shipment comes, its inspection shows that no changes you requested were made.

Source: Safer Storage Systems

This can happen because they forgot (and had no written record to remind them) or because, in their culture, “Yes” doesn’t always mean “Yes”.

Rather, it may mean something along the lines of “Maybe we’ll do it if we can.”

To avoid such misunderstandings, always formalize any verbal agreements in writing, provide detailed specifications and expectations, and ensure clear channels of communication for addressing any changes or updates throughout the supplier relationship.

By avoiding the common mistakes outlined in this article, from inadequate supplier evaluation to verbal agreement considerations, your company can maximize the benefits of global procurement while minimizing risks.

Remember, effective global sourcing hinges on meticulous preparation, diligent supplier assessment, clear communication, and leveraging the right tools and methods.

Moreover, prioritizing transparency, accountability, and collaboration with suppliers is essential for achieving sustainable and successful procurement practices in a global marketplace.