6 Benefits of Measuring Your Procurement Performance

As the backbone of supply chain operations, procurement plays a critical role in ensuring that your company sources the right goods and services at the right time and cost.

However, achieving optimal procurement performance requires a comprehensive understanding of internal processes, supplier relationships, and market dynamics.

Among these elements, measuring procurement performance stands out as a practice that can generate the most advantages for growth-oriented businesses.

In this article, we’ll delve into six key benefits your organization can unlock by embracing performance measurement in its procurement processes.

For starters, measuring procurement performance allows companies to evaluate the efficiency of their procurement processes.

By analyzing metrics like cycle times, purchase order accuracy, and invoice processing speed, your procurement team can identify bottlenecks, streamline workflows, and improve overall efficiency.

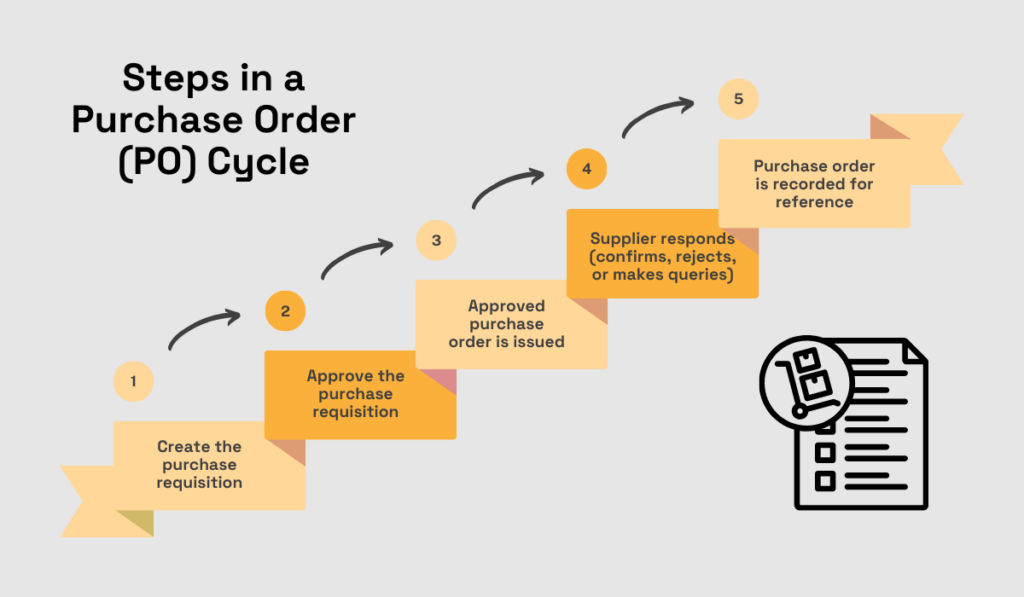

For instance, let’s consider the purchase order (PO) cycle time.

This metric refers to the duration it takes from the submission of a purchase requisition to the final approval and recording of the completed PO, which makes it one of the crucial elements for assessing procurement process efficiency.

Despite potential company-specific differences in this process, you can see the typical steps involved in the illustration below.

Illustration: Veridion / Data: Planergy

Delays may occur while completing any of these steps, thereby impacting overall PO cycle time.

For example, the process of approving purchase requisitions (PR), which often involves multiple stakeholders, is a typical bottleneck that affects the procurement performance of many companies.

Simply put, managers along the approval chain can prolong the PO cycle time by

Therefore, calculating the average PO cycle time and comparing it to cycle times across different departments can help you identify and address such issues.

In turn, this can significantly reduce delays in the procurement process.

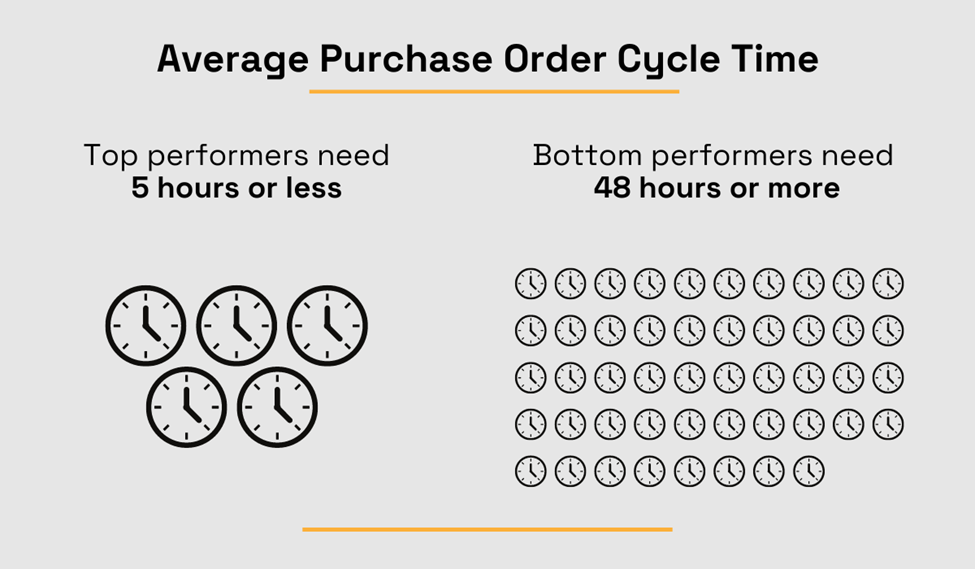

To illustrate what this means in practical terms, consider that the American Productivity and Quality Center (APQC) found that top-performing companies usually need about five hours to get a PO approved and submitted to the supplier.

Conversely, bottom-performing companies might need as much as two days.

Illustration: Veridion / Data: APQC

Other than considerable time-savings, shorter PO cycle times provide several benefits, such as:

Similar advantages can be obtained by measuring other procurement processes, such as how often a supplier fulfills their purchase order accurately and delivers it on time, or how long it takes for your accounting department to process incoming and outgoing invoices.

In any case, the values obtained for each metric should be benchmarked against your industry’s general or your company’s specific standards, allowing you to take appropriate actions to enhance the efficiency of your procurement processes.

Another benefit of measuring procurement performance is that teams can more easily identify areas where processes can be optimized, leading to increased efficiency or reduced costs, and often both.

For example, the data on your company’s direct and indirect spend can be regularly analyzed to uncover a range of improvement opportunities.

For both spend categories, such analyses involve:

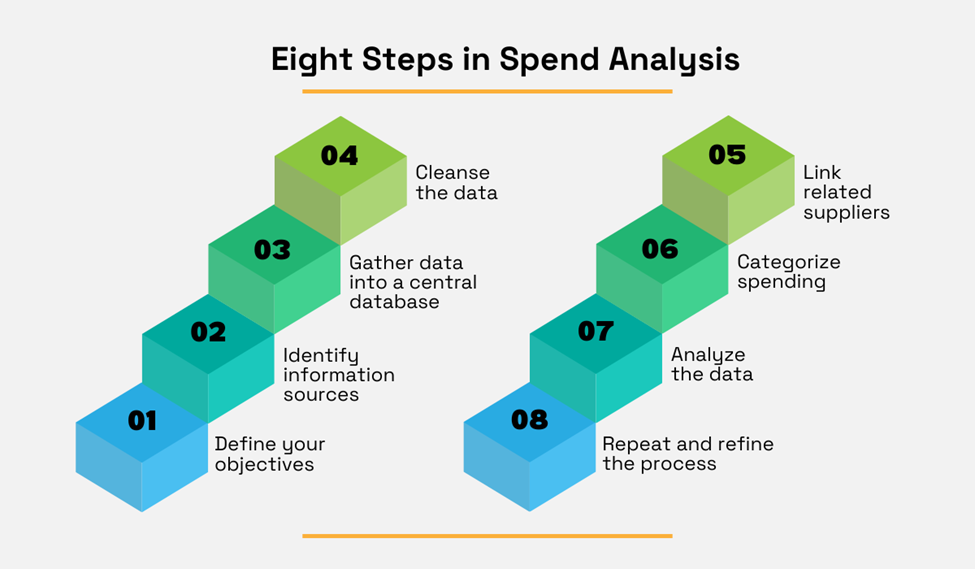

Of course, to perform a spend analysis, you’ll first need to prepare, i.e., establish procedures, and collect and organize your data, as these eight steps illustrate:

Illustration: Veridion / Data: NetSuite

Depending on whether the relevant data is readily available in one central location or needs to be gathered from various sources, the process of preparing for a spend analysis can be time-consuming.

Additionally, your team will probably encounter some complexities, such as accurately categorizing expenditures and reconciling data discrepancies.

However, the insights gained from a well-executed spend analysis will likely far outweigh the efforts invested in its preparation, namely by allowing your team to identify cost categories and processes that can be optimized.

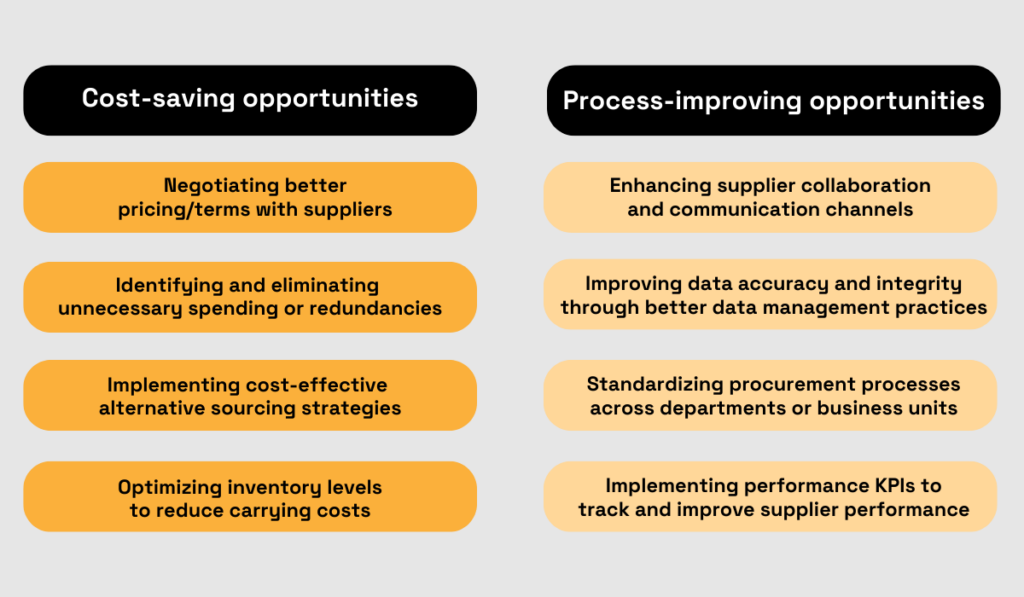

To illustrate, here are some cost-saving and process-improving opportunities that might arise from a spend analysis:

Source: Veridion

Let’s use a few examples to illustrate how comprehensive spend analysis can help reveal some of these opportunities.

For instance, spend analysis may uncover that various departments are purchasing the same or similar items from multiple suppliers at different prices.

By consolidating these purchases and negotiating with suppliers for volume discounts or better terms, you can achieve significant cost savings.

Similarly, analyzing procurement spend data, such as delivery dates and order quantities, enables you to identify patterns of late deliveries or order errors from specific suppliers.

These instances may indicate communication breakdowns or discrepancies between purchase orders and supplier contracts.

From there, you can gather feedback from internal stakeholders and from the identified suppliers and see what improvements should be made.

Other than spend analysis, improvement opportunities may come from monitoring a range of key performance indicators (KPIs), such as supplier lead times and defect rates.

Overall, regular spend analyses and KPIs tracking ensure a comprehensive assessment of procurement operations, enabling easier identification of improvement opportunities.

Another area where measuring procurement performance can be highly beneficial is risk mitigation.

More specifically, this enables procurement teams to proactively identify and avoid or minimize risks by tracking supplier metrics such as order fulfillment reliability, delivery times, and product quality compliance.

Moreover, when changes in a supplier’s activities, such as pending bankruptcy or regulatory compliance issues, are continuously monitored, this can shield your organization from unexpected supply chain disruptions.

Generally, there are two instances where risk mitigation is crucial, namely during the supplier selection process and then for the remainder of your relationship.

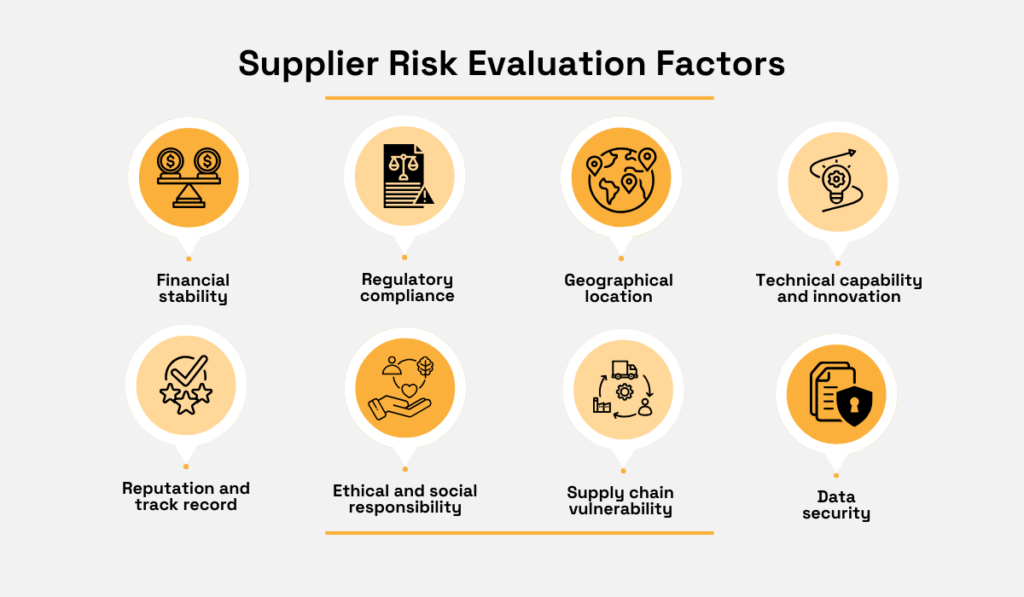

In both cases, there’s a range of risk evaluation factors to consider that go beyond the supplier’s price, quality, and delivery performance, such as:

Source: Veridion

For instance, assessing a supplier’s financial health and resilience to economic downturns or financial crises is crucial for avoiding disruptions and ensuring the continuity of your operations.

Likewise, a supplier’s location is highly relevant, as it impacts lead times, shipping costs, and logistics while allowing you to also assess potential geopolitical risks.

Typically, these parameters are tracked internally, and companies use supplier questionnaires, certificates, and other documentation to gather information about supplier performance and compliance.

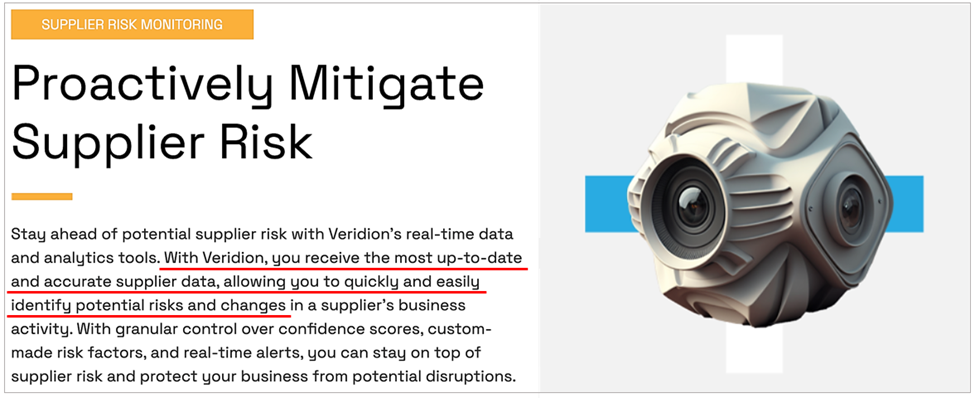

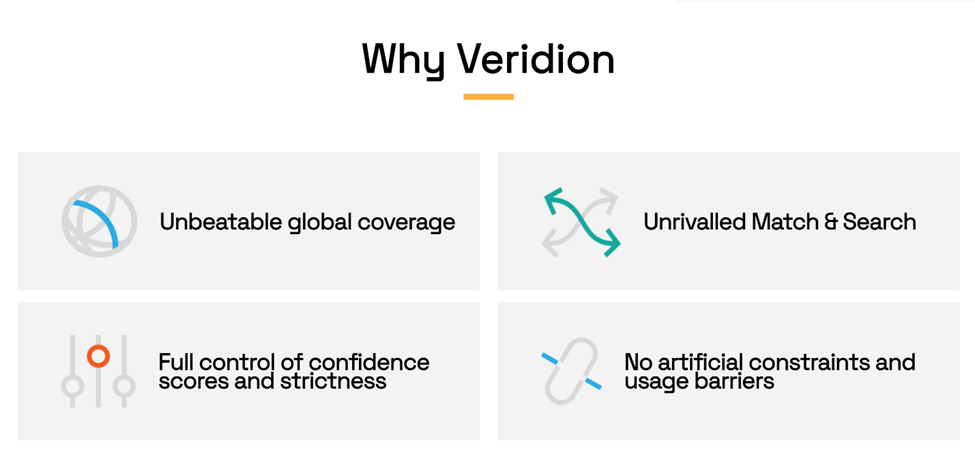

However, for some of these factors to be assessed, you need access to external big data platforms, such as our Veridion, that allow you to obtain comprehensive insights into supplier risks that might be harder to detect.

As highlighted below, Veridion uses proprietary AI-powered algorithms to maintain the most complete, weekly updated, supplier database.

Source: Veridion

By constantly searching the web, our algorithms track and keep you informed about all the major risk factors related to your potential and existing suppliers.

Additionally, you can receive real-time alerts if any of your current suppliers (or their wider environment) experience changes that could negatively affect your relationship.

Source: Veridion

In light of this, Veridion’s database and advanced search APIs (Complex Search and Match & Enrich) can be used to identify risks during supplier discovery and selection and monitor them as part of supplier relationship management.

In summary, proactively tracking supplier risks and measuring their performance can help you avoid or minimize disruptions in your supply chain, ensuring operational stability and resilience in the face of fast-evolving challenges.

By now, it’s clear that performance measurement ensures that procurement activities—both your company’s and your suppliers’—comply with internal policies and regulatory requirements.

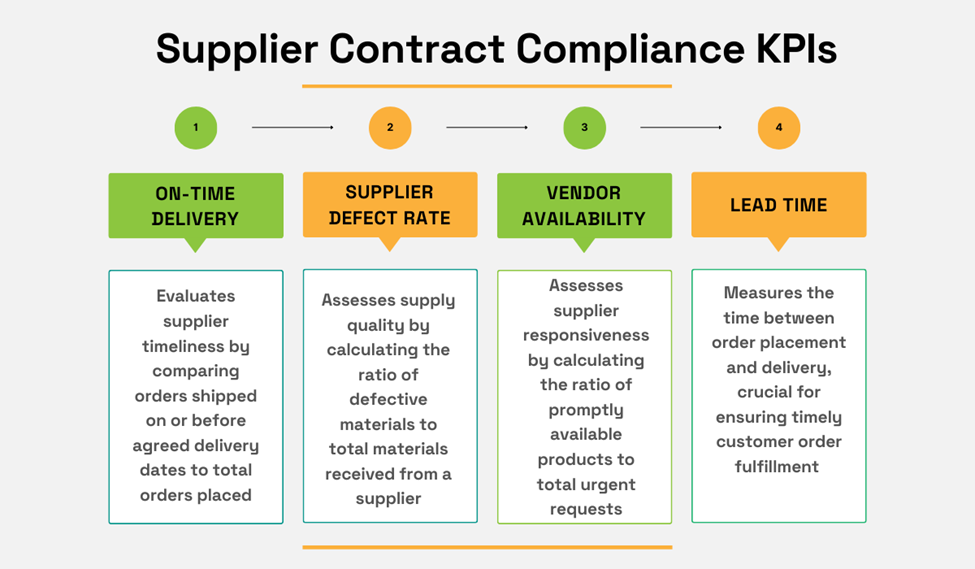

For example, consider a scenario where a company wants to measure the suppliers’ rate of contract compliance.

To do this, the company’s procurement team first needs to decide what KPIs will enable this metric to be measured.

Here are just some KPIs that can be used for this purpose:

Source: Veridion

Of course, a range of other KPIs may be defined and monitored to get an even more accurate rate of contract compliance, such as the supplier’s invoice accuracy and dispute resolution time.

By establishing and tracking these indicators, your procurement team can identify instances where suppliers fail to adhere to contractual terms and can take corrective actions.

The approach illustrated in this example can be extrapolated to other areas where supplier compliance is crucial, such as:

To recap, by measuring supplier performance across these areas, your procurement team can detect compliance issues before they escalate, thus avoiding potential penalties or legal issues, and building your company’s reputation as a responsible and trustworthy organization.

Measuring your procurement team’s performance is just as important as monitoring your suppliers.

By providing clear performance metrics for your team, you’re fostering accountability and facilitating targeted training and improvement initiatives.

Moreover, any measures you decide to take are usually much easier to implement internally, within your organization, than externally with your suppliers.

There are many possible KPIs that can reveal where your procurement team’s internal processes can be improved.

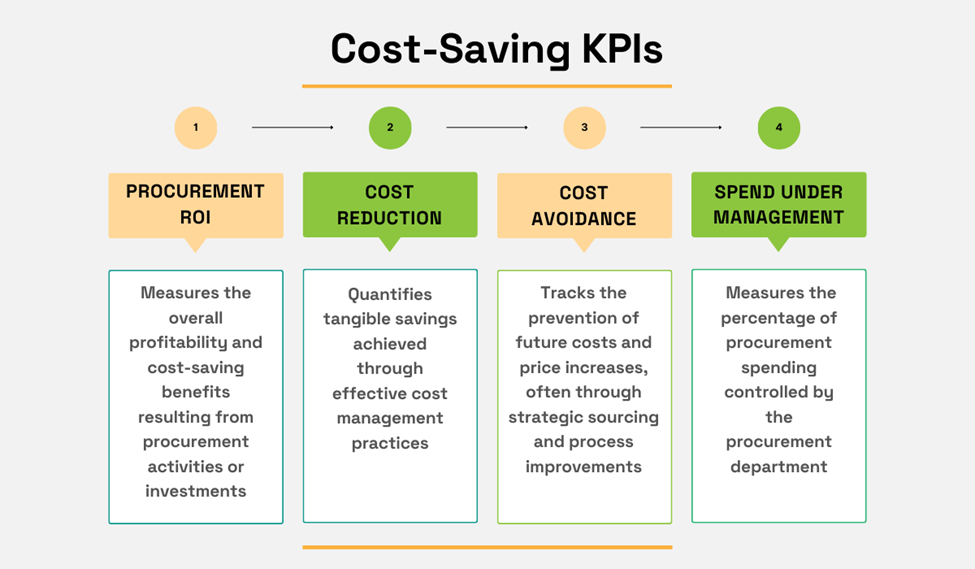

Among them, let’s consider so-called cost-saving KPIs, which are illustrated below:

Illustration: Veridion / Data: Precoro

Establishing and measuring these cost-saving KPIs involves gathering relevant historical data from procurement activities, financial records, and supplier interactions.

This data is used to establish benchmarks against which your procurement team’s performance will be measured.

For example, a company might set a target (e.g., 5%) for annual cost reductions in procurement activities.

By comparing the actual cost savings achieved by the procurement team against this target, the company can assess the team’s performance in delivering cost savings.

If the savings fall short of the target, this may indicate inefficiencies in the procurement process, missed negotiation opportunities, or failure to leverage economies of scale.

The same principle can be applied to other KPIs you want to track, allowing you to detect deviations from targets and take measures to address them, thereby improving your procurement team’s performance.

Last but not least, tracking various aspects of your procurement performance enables you to assess the effectiveness of your supplier relationships.

By monitoring the metrics we already mentioned, such as on-time delivery, quality of goods or services, and lead time, you can identify areas where relationships with suppliers can be improved.

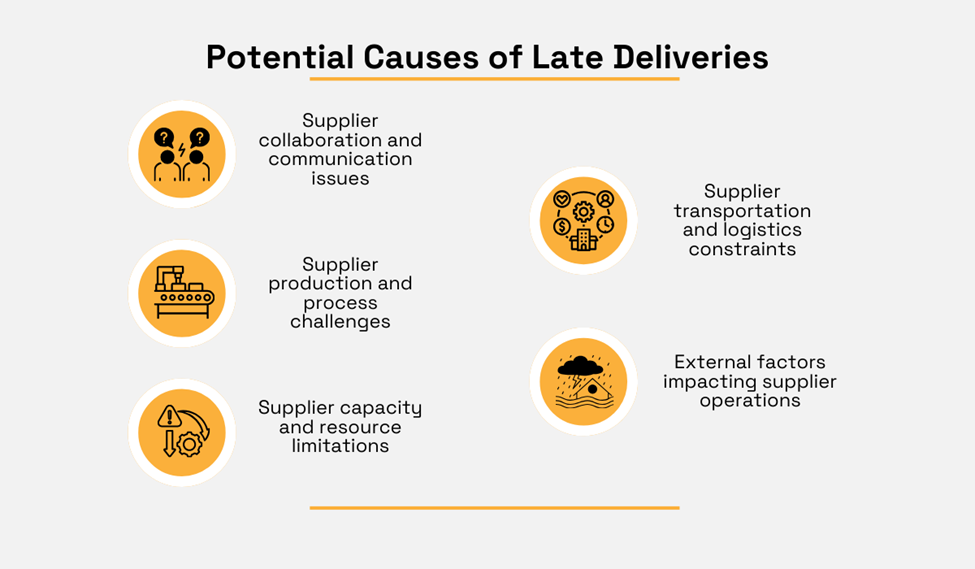

For example, if a certain percentage of a supplier’s deliveries are late, this may be caused by a number of factors, some of which are illustrated below:

Source: Veridion

Identifying one or more root causes behind late deliveries can help you implement targeted improvements in your supplier relationships.

Some issues might be simple to address, such as moving your purchase order a few days earlier to allow the supplier enough time to adjust production schedules.

Others, such as communication breakdowns or capacity limitations, may require more proactive measures like enhancing communication channels or diversifying your supplier base.

While most of the root causes behind late deliveries (and other supplier performance issues) are external, it’s important to recognize that your company’s internal inefficiencies can also be a factor.

For instance, constant delays in paying a supplier can strain the relationship, causing them to give less importance to meeting their contractual obligations.

In summary, by measuring the procurement performance of your suppliers and your organization, you can identify areas for improvement and take relevant actions to foster stronger, more collaborative partnerships with key suppliers.

The six benefits we covered show what implementing performance measurement in procurement processes can do for your company.

It’s clear that effective procurement management hinges on the strategic measurement of both internal processes and supplier performance.

By leveraging key performance indicators (KPIs), continuous monitoring, and thorough analyses, your procurement team can identify areas for improvement, optimize cost-saving opportunities, mitigate risks, and build stronger supplier relationships.

Moreover, through data-driven insights and targeted actions, you can drive efficiency, improve compliance, and ultimately achieve enhanced procurement performance.