7 Overlooked Procurement KPIs Worth Tracking

You probably track your spending, savings, and the time it takes from purchase to delivery.

These are common key performance indicators, or KPIs, that procurement teams analyze.

But do you, for example, know precisely how much money you spend on diverse suppliers?

And what about your greenhouse gas emissions?

Unfortunately, procurement managers often overlook these KPIs.

Little do they know that having diverse data on various aspects of procurement—beyond just cost-savings—can improve procurement strategy and bring more value to organizations.

If this sparked your interest, read on as we explain which procurement KPIs you should pay more attention to.

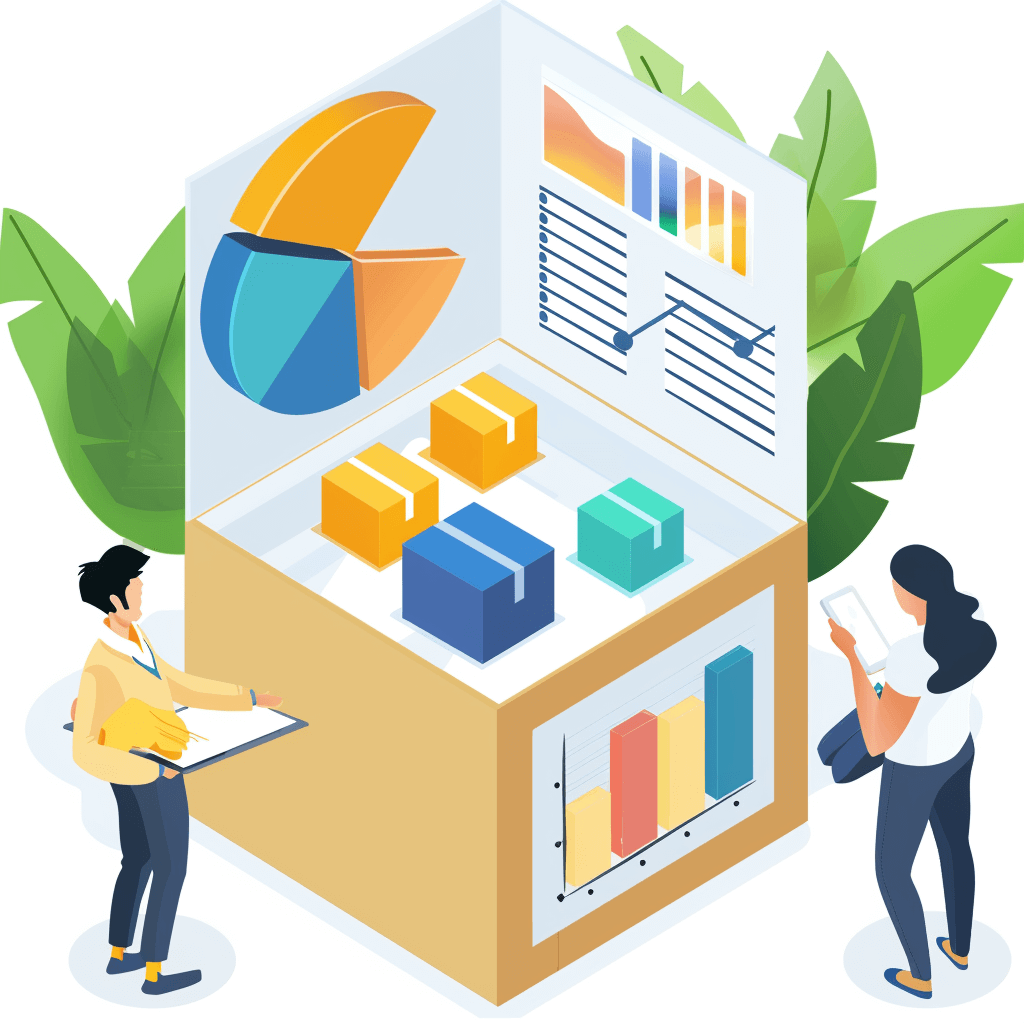

Invoicing is more than just paying your suppliers.

Invoice processing includes receiving the invoice, verifying its accuracy against purchase orders and delivery receipts, approving the invoice, issuing the payment to the supplier, and finally, archiving the invoice.

You can see the breakdown of this process illustrated below.

Source: Veridion

When you think about it, all this takes time and requires labor.

The cost of processing invoices, then, includes all costs associated with these steps, from labor of your employees, paper, ink, and printing materials, all the way to hidden costs.

Yes, if you do it manually, there is always the risk of errors!

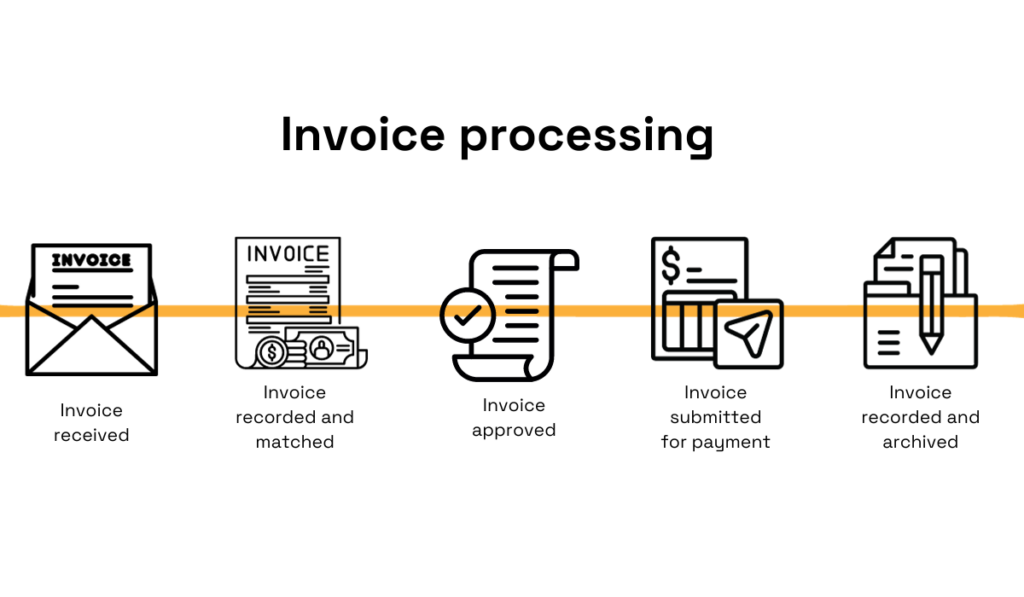

When you know the overall cost of processing invoices in a specific period, you divide it by the number of invoices in that period, and you will get your cost per invoice.

Source: Veridion

Why is it important to measure this KPI?

Because it can help you identify process inefficiencies, from too-common invoice disputes to manual workflows.

For example, if your costs are higher than industry benchmarks, and you still process your invoices manually, it may be time to consider automation.

A recent Billentis report found that electronic invoicing can cut costs by 60-80%, with a return on investment typically within 0.5 to 1.5 years.

As you can see, automating invoice processing can significantly reduce costs per invoice, so tracking this KPI is certainly worth the effort.

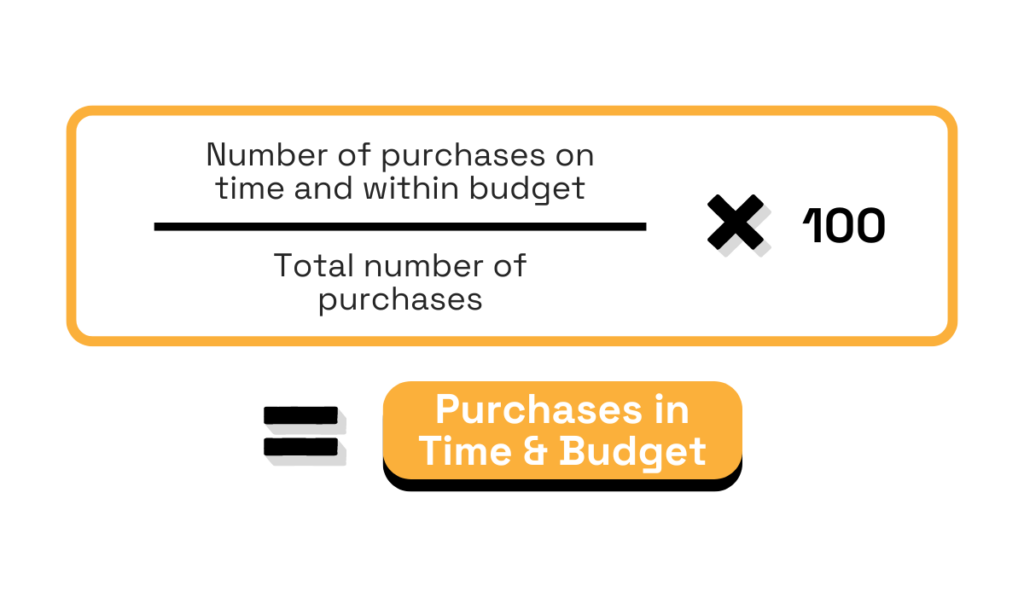

How well does your procurement team meet its delivery and budget targets?

You can find out by measuring the purchases in time and budget KPI.

This metric shows how effectively your team manages procurement tasks to meet deadlines and stay within budget.

For example, if your team planned to buy raw materials for $10,000 with a delivery time of two weeks, but they end up spending $12,000 and the materials arrive late because it took them too long to find suppliers, this KPI would highlight those issues.

To measure it, you can use the following simple formula:

Source: Veridion

Why is it important to measure this KPI?

Simply put, because it evaluates your team’s efficiency:

Tracking purchases in time and budget will help you address all these questions and give you insight into your procurement process and areas for improvement.

And if you do find inefficiencies—such as too much time being spent on specific steps of the procurement process—it might be time to consider automating those that prevent your teams from purchasing in time.

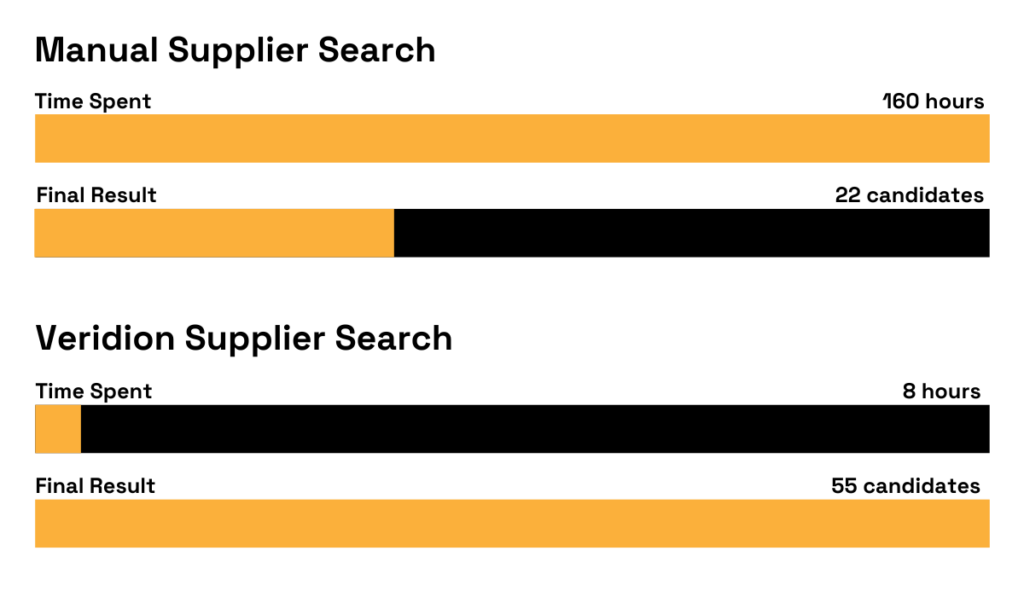

One such process is definitively the time-consuming and resource-intensive search for suppliers.

Our supplier sourcing tool, Veridion, can speed this up for you.

Using our always-fresh and updated information on millions of global suppliers, your team can quickly find and evaluate suppliers, ensuring you get the best value and meet your procurement timelines.

Take a look at how quicker Veridion-powered supplier search is as opposed to manual search:

Source: Veridion

Another important KPI to measure, for sure!

Are you getting the best deal for your purchases, or are you overpaying for goods and services?

Price competitiveness helps you find out by leveraging market intelligence and price data to benchmark costs against industry averages.

This KPI involves comparing the purchase price variance for similar products or services to identify cost-saving opportunities.

For example, let’s say you’re paying $110 per unit for a material, while the industry average is $100 per unit.

Based on this information, you can renegotiate your contracts with suppliers to bring your cost down to or below the industry average and generate savings.

But you can’t identify these opportunities if you don’t measure this KPI and compare your prices with those of the industry.

Where can you find this data to compare prices?

You can, for instance:

In a nutshell, tracking price competitiveness ensures you make more data-informed purchasing decisions and maintain cost efficiency.

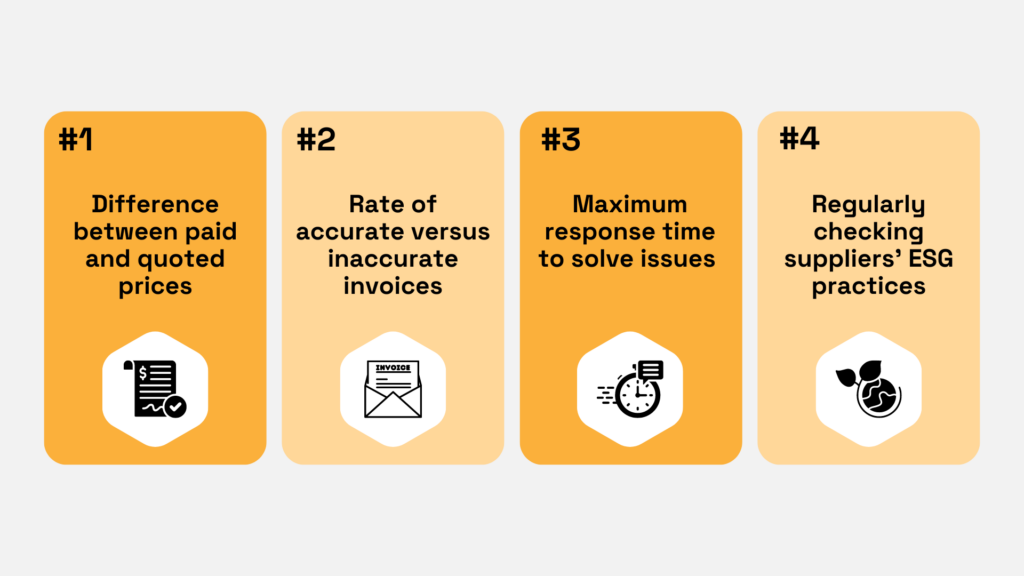

Don’t you want to know what percentage of your suppliers meet their contractual obligations?

While you likely measure KPIs like supplier delivery times, price, defect rates, and product quality, there’s more to contracts than these basics.

Are your suppliers adhering to maximum reaction times for delays, specified payment modes, invoice accuracy, and other service-level agreements?

Do they follow the ESG agreements you specified in the contract?

Contract compliance encompasses all these aspects, reflecting how well suppliers fulfill their contractual commitments.

That’s why this KPI can be measured in more ways than one, both quantitatively and qualitatively:

Source: Veridion

Why should you measure compliance rate?

It’s simple.

If you regularly monitor your suppliers’ contract compliance, you can quickly notice if a certain supplier is not performing according to the contract.

You can then communicate this to them or decide to end the contract before your quality and bottom line suffer.

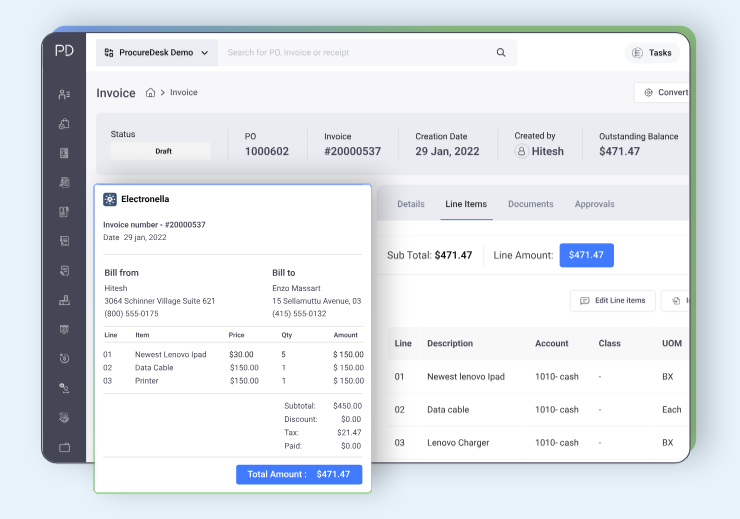

This KPI tracks two key factors: whether suppliers deliver what was ordered at the right time, and whether your purchase orders are error-free.

Imagine you order office supplies for your company.

If a supplier delivers 50 chairs instead of the 100 desks you ordered, or they deliver them a week late, it affects your ability to work and costs you time and money to correct.

But the question is:

Did the supplier make a mistake, or was there an error in the purchase order in the first place?

Measuring this KPI helps you pinpoint the root cause of discrepancies and identifies areas for improving purchase order accuracy.

One highly effective method to improve purchase order accuracy is using procurement software that, when approved, automatically converts purchase requisitions into purchase orders and minimizes human error.

ProcureDesk is one such solution:

Source: ProcureDesk

This automation leaves no room for mistakes and ensures that orders are precise and consistent.

All in all, improving purchase order accuracy will bring you two significant benefits: it will ensure smooth operations and enhance supplier relationships.

But that’s impossible without tracking and measuring purchase order accuracy in the first place.

Today, procurement has a unique chance to promote social and economic justice like never before.

One effective way to do this is by engaging with diverse suppliers, which includes businesses owned by women, minorities, the Black community, LGBTQIA+ individuals, people with disabilities, and other traditionally underrepresented groups.

According to Supplier.io’s 2023 Supplier Diversity Benchmarking report, companies on average spend about 3.6% of their budgets with diverse suppliers.

However, this number varies widely across different industries.

For instance, energy companies spend around 9%, while tech companies are close behind at 8%.

In contrast, the food and beverage sector spends about 1.6%, and retail spends about 2.1%.

Illustration: Veridion / Data: Supplier.io

Monitoring this KPI helps you understand how well you’re doing compared to others in your industry and encourages continuous improvement.

To measure your spending with diverse suppliers:

Why is this KPI important?

Tracking spending with diverse suppliers allows companies to publicly share their progress in supporting diversity and sustainability, which is required for some government contracts and public tenders.

It also boosts your brand’s reputation across the value chain, leading to greater customer loyalty, increased revenues, and higher profits.

For example, at Bristol Myers Squibb, a pharmaceutical company, working with diverse suppliers leads to more innovation and agility.

Rondu Vincent, Executive Director of Global Supplier Diversity & Sustainability, explains:

Illustration: Veridion / Quote: BC CCC

In summary, spend with diverse suppliers is an essential KPI that helps you assess your commitment to diversity and inclusion.

It motivates you to increase spending with diverse suppliers and strengthen your overall dedication to these important values.

Besides promoting social and economic justice, procurement can also significantly influence a company’s environmental impact.

One key performance indicator (KPI) that helps track, measure, and analyze this impact is total greenhouse gas emissions.

This KPI measures the amount of gases your company releases that contribute to climate change.

These include emissions from your own operations and those from your suppliers and product use.

Greenhouse Gas Protocol categorizes greenhouse emissions into three scopes:

| Scope 1 | Direct emissions from company-owned sources (e.g., vehicles, machinery). |

| Scope 2 | Indirect emissions from the energy the company purchases (e.g., electricity, heating). |

| Scope 3 | Indirect emissions from the entire value chain, including suppliers, logistics, and customer product use. |

Scope 1 emissions are measured by tracking fuel consumption and applying standard emission factors.

Scope 2 emissions are measured using utility bills to determine energy usage and converting this to emissions.

Finally, scope 3 emissions—often the largest portion—are where the procurement team helps the most by collecting data on emissions from suppliers and logistic providers.

When data on all three scopes is collected, you can have a clear picture of your total greenhouse gas emissions.

This data is important for several reasons, as it:

At the end of the day, tracking total greenhouse gas emissions should be a vital KPI for procurement managers.

It helps ensure regulatory compliance, achieve sustainability goals, reduce costs, and enhance your company’s reputation, all while contributing to combat climate change.

So, don’t overlook it anymore.

Tracking these eight often overlooked procurement metrics alongside your essential KPIs will give you a clearer picture of how well your procurement is performing.

You will see more details and nuances that can make a big difference.

The data you gather along the way will help you boost efficiency across different aspects of procurement and align your procurement practices with broader business and societal goals.

So, give these KPIs the attention they deserve.

It will soon pay off!